ABSTRACT

The problem of uneven ventilation in pig houses must be solved to effectively improve the winter environmental quality of pig nurseries in cold regions. In this study, the airflow field and airflow uneven coefficients of pig nurseries with duct ventilation were simulatedand calculated using computational fluid dynamics, and compared with pig nurseries with different duct diameters, inlet and outlet air velocities and air supply angles. The average relative error between the simulated and measured values was 12%. Comparison of simulation results and airflow uneven coefficients showed that the airflow uneven coefficients of the fences were reduced, and the airflow field was uniformly distributed with a duct diameter of 0.3 m, inlet and outlet air velocities of 1.5 and 2.0 m/s, respectively, and an air supply angle of 45°. These improvements resulted in a more homogeneous ventilation, which led to more uniform ventilation and contributed to discharging dirty air outdoors. Then the test pig nursery was modified based on the simulation and analysis results. Difference analyses were carried out between the control and the test pig nurseries. Comparative analyses showed the differences between the test data and the monitoring data were smaller, and the duct ventilation was more uniform, which was suitable for the healthy growth of piglets.

Keywords: Pig nursery; Airflow field; Numerical simulation; Duct Ventilation

1. Introduction

Northeastern China is distinguished by its extensive land resource base and ample provision of feed resources, which are conducive to the flourishing growth of the swine farming sector [1]. However, because of the cold and long winter in this region, most pig nurseries have little or no ventilation in winter to avoid cold stress on pigs and reduce energy consumption [2-4]. If only thermal insulation and reduced ventilation are considered, harmful indoor gases (e.g., ammonia, hydrogen sulfide, and carbon dioxide) and excessive moisture and dust interfere with the healthy growth of pigs and largely harm the health of breeders [5-6]. Therefore, innovative design of ventilation systems to guarantee the environmental quality of pig nurseries in cold regions is crucial for healthy breeding of pigs.

The engineering equipment and technology used in pig-raising facilities are always improving with the increasing demands from the global pig-raising industry. A single ventilation mode (e.g., longitudinal, horizontal, or vertical mode) can no longer meet the needs of healthy pig production. Hence, the basic theory of ventilation and the innovation of ventilation modes need to be studied further [7]. Li et al. analytically tested the effects of two ventilation modes on the indoor environment of a large pig nursery house in Guangxi in winter [8]. The environmental quality of the nursery house with the underground duct air intake mode was better compared with the ceiling air intake mode [8]. In southern China, the cold air temperature in winter is generally not lower than 0 ℃, so the two modes are more suitable for farm buildings, and the outside fresh air can directly enter the buildings. However, in Northeast China, due to the low winter temperature, tunnel ventilation will bring in abundant cold air and rapidly decrease the temperature inside the barn, which will induce cold stress on piglets and may cause ice formation in the faecal tract, so that faeces cannot be discharged normally. Kwon et al. simulated and studied the ducted exhaust system of a nursery pig house based on the computational fluid dynamics (CFD) theory, and found this system effectively improved the environmental quality of the pig house [9]. Compared with the above ventilation modes, evenly-arranged air vents are more suitable for both cold and hot areas [10]. At the same time, the ducted ventilation model introducing fresh air into a sealed space in the form of supply air facilitates air heating, filtering, cooling, and other treatments. Additional ducts can be installed and ventilation openings be evenly distributed along the duct walls to ensure an even distribution of airflow within the space [11]. Moreover, exhaust air ventilation removes polluted air from the enclosed environment quickly and expels it outdoors. However, areas with poor airflow circulation or variations in airflow velocity are prone to dead zones or cross drafts [12]. The combined supply and exhaust air system can effectively integrate the advantages of both supply air and exhaust air ventilation, and thus improves ventilation efficiency and facilitates precise environment control in weaned pig nurseries [13]. This system combines the benefits of both supply air and exhaust air, allows for efficient air exchange and meets the specific requirements for maintaining the optimal environment for pigs. The duct ventilating mode better ensures consistent ventilation in a pig nursery and helps accurately control ventilation [14-15].

The design of ventilation structures requires much field test data, but the pig nursery is restricted by a complicated environment and only a few monitoring points. At the same time, the environmental conditions cannot be stable and controllable for long periods, which leads to large margins of errors. Application and research with the CFD technology can accurately simulate the distribution laws of temperature and airflow fields in livestock and poultry houses, and theoretically underlie the optimization of ventilation structures [16-18]. Five two-way turbulence models were utilized to model a mechanically ventilated pig nursery and predict the airflow distribution in the pigsty. The choice of the turbulence model depended on the specific situation [19]. CFD-based simulation of airflow in pregnant sow barns under centralized ventilation revealed that the temperature field uniformity increased when the air outlet was located in the middle of the enclosure and that changes in the ventilation structure caused changes in the airflow field distribution in the pig nursery [20]. The effects of air inlet on airflow and temperature in a summer laying hen house were investigated using CFD, and the uniformity of airflow and temperature distributions increased with the location of air inlet and the distance from the hen house [21]. After the conditions of air inlet and outlet were optimized through CFD simulation, the environmental quality of the house was improved and the cold stress of pigs in winter was effectively alleviated [22]. CFD was used to study the influence of wind speed on temperature fields in pigsties and the influence of pigsty structural changes on airflow fields, and the results theoretically underlay the optimization of an environmental control scheme [23]. Based on the above research methods, CFD was used to simulate the airflow field in a pig nursery under duct ventilation, and the simulation results were analyzed, which provide a reference basis for optimal ventilation system design and on-site renovation.

In this study, the theory of duct uniform ventilation and the factors affecting uniform air supply were analyzed, and a CFD model of a pig nursery under the duct ventilation mode was built on basis of field measurement data. The model was used to simulate the airflow field under different duct diameters, inlet and outlet air velocities, and air inlet angles, and analyze the influence of the ventilation structure on the airflow field. Then the main parameters of the ventilation structure were selected, and reference data were provided for ventilation structure optimization and on-site renovation. This study has a certain reference value for the construction of large-scale pig nurseries in cold areas to improve the pig nursery rearing environment and pig breeding quality.

2. MATERIALS AND METHODS

2.1 Test pig nursery

The test-simulated pig nursery was located in Qiqihar, Heilongjiang Province, China (47°44’ N,124°04’ E). In this region, the average maximum and minimum temperatures are 27.3 and 18 ℃ respectively in summer, and -10.7 and -21.7 ℃ respectively in winter. Figure 1a shows the status of the pig nursery. The pig nursery was 17 m long, 10 m wide, and 3 m from the roof to the shed. There were 12 fences in two columns. Each fence was 3.5 m long and 2.5 m wide and housed 10 to 12 piglets. The fence floor was 0.5 m away from the cement floor of the pig nursery and was composed of the slatted floor and the heated cement floor. The gap width of the floor for the slatted floor was 15 mm. Figure 1b shows the three-dimensional effect diagram of the renovated pig nursery.

Figure 1. The pig nursery in the field experiment; (a) floor plan; (b) three-dimensional effect diagram of the renovated pig nursery (two lines of ducts for both air inlet and air outlet; six air inlets or outlets in each row)

2.2 Model parameter measurement

The neighboring pig nursery was selected as the control, which had the same structure and layout as the test pig nursery before the renovation. On-site measurements were conducted from December 2019 to January 2020. Sensor monitoring nodes were arranged in the same way as shown in Figure 1. The monitoring data were extracted from the test and control pig nurseries at a 15-minute interval. Then groups of data were sampled continuously for a single monitoring data, and then the average value was recorded. To ensure the validity of data comparison and analysis results, the processes of heating, feeding, and manure cleaning during the monitoring period were kept the same in the two nurseries. The ventilation time of the two nurseries for duct ventilation and ventilation opening of the door and window on one side of the corridor is shown in Table 1. Real-time temperature, humidity, CO2, and NH3 in the existing ventilation mode of the pig nursery were monitored. The monitoring equipment used at the site is listed in Table 2.

| Ventilation method and

duration |

Duration of door

opening in two nurseries /(min) |

Duration of window

opening in two nurseries /(min) |

Duration of ducted air

exchange in the test pig nursery /(min) |

| 07:35 | 1 | 5 | — |

| 10:00 | 10 | 20 | — |

| 12:00 | 10 | 120 | — |

| 12:35 | — | — | 4 |

| 16:00 | 5 | 30 | — |

| 17:54 | — | — | 6 |

| 22:40 | 5 | 20 | — |

| Name | Type | Company | Range | Precision |

| Humidity and temperature measuring instrument | Testo 625 | Testo Group, Black

Forest, Germany |

Temperature: -10 - 60 ℃ | ± 0.5 °C |

| Humidity:0~100% | ±2.5 % | |||

| Pump gas detector | HYE 2000 | Taizhou HanYao Electronic Technology Co., Taizhou, China | CO2: 0 - 5398 mg/m3 | ±1 mg/m³ |

| NH3: 0 - 69 mg/m3 | ±0.1 mg/m3 | |||

| Thermal anemometer | Testo 425 | Testo Group, Germany | 0.01 - 30 m/s | ±(0.03 m/s +4.0 %) |

A total of sensor nodes were placed inside the pig nurseries at a height corresponding to the breathing level of the weaned pigs (0.2 m above the slatted floor). The environmental data obtained at this height can represent the quality of exhaled air by weaned pigs.

2.3 Governing equations

Fluid flow in nursery in the pig nursery obeys the laws of conservation of mass, momentum and energy and the law of composition. The governing equations are as follows [24]:

Mass conservation:

|

|

|

(1) |

Energy conservation:

|

|

|

(2) |

Momentum conservation:

|

|

|

(3) |

Conservation of composition:

|

|

|

(4) |

where ρ is the fluid density, kg/m3; u, v, and w are the velocity vectors in the direction of x, y, and z, respectively, m/s; k is the heat transfer coefficient, , T is the thermodynamic temperature, K; CP is the specific heat capacity, , is the internal heat source, W; P is the pressure fluid microelement, Pa; Cs is the volume concentration of component s, kg/kg; Ds is the diffusion coefficient of component s, m2/s.

2.4 Pig nursery model

The pig nursery has a symmetrical structure. To improve computational efficiency and save computer simulation time, a half-scale physical model of the nursery house was created and the rest of the house was symmetrical. For simplification of modeling, the effects of fences, slatted floor and piglets on the airflow in the house were ignored (Figure 2). The air inlet was 0.9 m above the concrete floor, and the middle aisle was the air outlet and was 0.4 m from the ground.

2.5 Boundary conditions and numerical calculation

The air in the pig nursery was an incompressible ideal gas, and the fences, ducts, and walls were all non-slip wall boundaries. The walls on both sides were set as symmetric boundary conditions without friction or energy flow. The outlet and inlet of the air duct were arranged as the velocity inlet and outlet respectively. The simulation was conducted under a steady-state. Bjerg et al. showed that CFD simulations of livestock buildings using a standard k-ε turbulence model resulted in the smallest absolute and relative errors between simulation and monitoring results [25]. The standard k- ε turbulence model was selected. Standard wall functions were used for simulations near the wall. The control equation was discretized using the finite volume method. The SIMPLEC algorithm with good convergence was used to solve the pressure velocity coupling equation [26]. The initial boundary conditions were listed in Table 3 [27]. The solution was assumed to converge when the sum of residuals for all cells in the computational domain was less than 1×10-6 for continuity and energy, and 1×10-3 for other variables such as X-, Y-, Z-velocity, k, and ε.

| Items | Boundary conditions |

| Inlet | Velocity inlet (0.5 m/s, 20 ℃) |

| Outlet | Velocity outlet (1 m/s) |

| Floor | Non-slip wall, 12 ℃ |

| North wall | Non-slip wall, 18 ℃ |

| South wall | Non-slip wall, 15 ℃ |

| Roof | Non-slip wall, 16 ℃ |

2.6 Evaluation Indicators

The main factors affecting the ventilation are duct diameter (D), air inlet angle (A), air inlet velocity (vin), and air inlet velocity (vout) [28-29]. The values of D, A, and v were changed to simulate the airflow field in the pig nursery while boundary conditions, initial conditions, and other relevant parameters were the same.

In general, the piglets were 0.4 m high, so the cross-section of the airflow field was selected as the backplane of the piglets. The suitable air velocity for a pig nursery is 0.2 - 0.3 m/s, and uniform ventilation must be ensured. Airflow uniformity in pig nurseries was assessed using the airflow uneven coefficient [30]. With the fence as the unit, 10 points from each unit of F1 - F6 were taken to read the air velocity evenly as the air dispersed, and the Jh of each case was calculated. Smaller Jhimplies the ventilation in the pig nursery is more uniform. The airflow uneven coefficient of the cross-section at height h in the pig nursery (Jh), and the average air velocity of the cross-section at height h (vh, m/s) are calculated as follows:

|

|

|

(5) |

|

|

|

(6) |

where vi is the air velocity of monitoring point i, m/s; n is the number of monitoring points.

3. RESULTS AND DISCUSSION

3.1 Model validation

3.1.1 Grid independence validation

The efficiency of calculations is affected by the number of grids and can be improved by choosing the appropriate grid number. The results for certain characteristic physical quantities obtained with a particular grid size stabilize when the variability of the results due to an increase in grid number is acceptable. Unstructured grids with high flexibility are often used to simulate airflow [31].

Three different grids were used for independence tests, and the changing trends of wind speed were similar among the different grids, except that the wind speeds were different. The average wind speed of monitoring points 1-4 in F1 was taken as the reference. The maximum relative errors of coarse, normal and fine grids from the simulation results were 10.4%, 4.25% and 3.96%, respectively (Table 4). The wind speed fluctuation amplitude of a normal grid or a fine grid was very small, and did not largely impact the results. At the same time, computer performance and time cost were comprehensively considered during simulation and analysis with normal grid number.

| Number of grids | Average wind speed (m·s-1) | Relative error (%) | |

| Grid 1 (Coarse) | 538,527 | 0.1053 | 10.4 |

| Grid 2 (Normal) | 1,463,425 | 0.1125 | 4.25 |

| Grid 3 (Fine) | 2,325,956 | 0.1128 | 3.96 |

3.1.2 CFD model validation

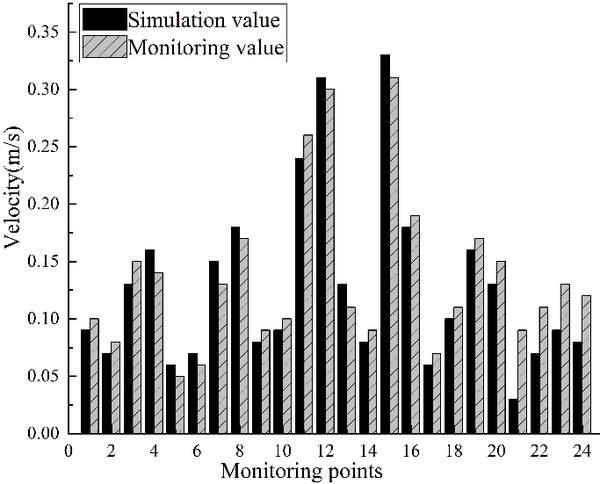

Based on the simulation of airflow field, the 0.4 m high section in the living area of piglets was chosen. Four test points were selected for each fence to monitor air velocity, which was compared to the simulation data at the same location. The data curves are shown in Figure 3. As the south fence was close to the window, external air entered the pig nursery through the gaps in the windows. As a result, the monitored air velocity and the simulated air velocity from monitoring points 21 to 24 were largely different. For the other 20 monitoring points, the relative errors calculated using the relative error formula were between 0 and 0.2, and the average error was 11.79%. These results indicate the simulation results agree well with the monitoring data, and the simulations are effective.

3.2 Influence of duct diameter on simulation results

When the air velocity was constant, the cross-sectional area of the duct was the main factor affecting the ventilation rate in unit time. At the same time, the duct diameter directly affected both the area and construction cost of the pig nursery. After comprehensive consideration, the ducts with diameters D1 = 0.2 m, D2 = 0.3 m and D3 = 0.4 m were selected for simulation. The ducts were perpendicular to the horizontal plane, and the inlet and outlet air velocities were set as vin = 1.0 m/s and vout= -1.5 m/s, respectively.

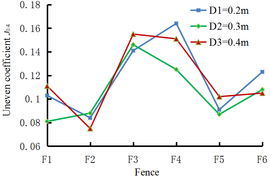

Figure 4 reveals the changing rules of airflow field corresponding to different duct diameters. The air velocities of middle fences F3 and F4 were higher than those of other fences. The reason for this phenomenon is that the static pressure of the fluid inside the ventilation duct gradually increases along the flow direction. In contrast, the dynamic pressure decreases near the fence, resulting in higher outlet speeds at the rear end compared to the front end[32-33]. When the duct diameter increased from 0.2 to 0.4 m, the airflow field distribution was more uniform, but the maximum local air velocity reached 0.39 m/s, which exceeded the ventilation requirement for piglets. At the same time, many weak ventilation areas existed in the pig nursery, and the air velocity on the side of slatted floor was generally low.

The variation curves of airflow uneven coefficient J0.4 for each fence calculated from Eqs. (5) and (6) are shown in Figure 5.

The uneven coefficient J0.4 of fences F3 and F4 was higher (Figure 5) owing to the higher local air velocities of fences F3 and F4. As the duct diameter rose from 0.2 to 0.4 m, the difference in air velocity for each fence increased, resulting in an increment in J0.4. When the duct diameter was 0.3 m, J0.4was generally smaller. Given the airflow field distribution, airflow uniformity, the space occupied by the duct, and the initial cost, we selected the 0.3 m duct as the inlet and outlet ventilation duct.

3.3 Influence of wind velocity on simulation results

Negative pressure ventilation was adopted in the pig nursery, and the duct diameter was set at 0.3 m. The situations V1, V2, and V3 were simulated, and the air inlet and outlet velocities (vin,vout) were set as 0.5 and -1.0 m/s; 1.0 and -1.5 m/s; 1.5 and -2.0 m/s, respectively. The simulation results at vin = 1.0 m/s and vout= -1.5 m/s are shown in Figure 4b. Other simulation results are shown in Figure 6.

At vin = 0.5 m/s and vout = -1.0 m/s, many windless areas appeared, and the air velocity on the side of the slatted floor was too low (Figure 6a). The air inlet and outlet velocities as well as the local air velocities on the concrete floor increased. At vin = 1.5 m/s and vout = -2.0 m/s, the local air velocity maximized to 0.4 m/s and the air velocity on the side of the slatted floor also increased (Figure 6b), but the weak ventilation on the side of the slatted floor was not fixed.

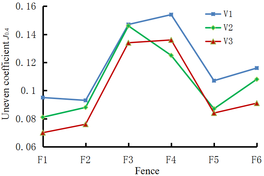

The variation curves of airflow uneven coefficient J0.4 for each fence calculated from Eqs. (5) and (6) are shown in Figure 7.

When the air velocity increased, the airflow uneven coefficient J0.4 decreased. However, at vin = 1.5 m/s and vout= -2.0 m/s, the local air velocity difference for fence F4 was large, resulting in an increase of J0.4 in this area. Given the airflow field distribution and airflow uniformity analysis results, the ventilation requirements of piglets were better met at vin = 1.5 m/s and vout= -2.0 m/s.

3.4 Influence of ventilation inlet angle on simulation results

According to the analysis results in sections 3.1 and 3.2, there were problems of excessive local air velocity in fences F3 and F4 and weak ventilation on the side of the slatted floor, regardless of the changes to duct diameter and air inlet and outlet velocities. The air inlet angle also changed the airflow field distribution. To improve this problem, the air inlet angle was changed. The air inlet angles at 60°, 45° and 30° were simulated when the duct diameter was 0.3 m, the air inlet and outlet velocities were vin = 1.5 m/s and vout= -2.0 m/s, the vertical ground angle was 90 °, and the inlet of the duct was inclined to the side of the slatted floor. The simulation results are shown in Figure 8.

Comparison of the left side of the colorimetric map showed as the ventilation angle decreased, the area of maximum air velocity in the airflow field moved from the cement floor to the slatted floor, and the maximum air velocity for local ventilation decreased from 0.42 to 0.21 m/s. When the ventilation angle was 30°, many weakly ventilated areas appeared. At a ventilation angle of 45°,the ventilation was more uniform, and a few areas with weak ventilation were formed.

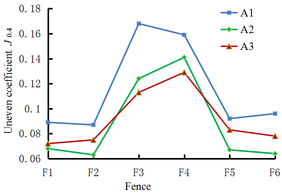

The variation curves of airflow uneven coefficient J0.4 for each fence calculated as per Eqs. (5) and (6) are shown in Figure 9.

When the air inlet angle was 45°, the J0.4 of the other fences was smaller, except for F3 and F4 in which J0.4was large because of the large local air velocity difference of the slatted floor. Nevertheless, the overall air velocity met the requirements of the piglets, and the air velocity on the side of the slatted floor increased, which was more conducive to the discharge of dirty gas. Given the reduction of the weak ventilation areas, an air inlet angle of 45° is more suitable for raising piglets.

3.5 Structural Optimization and Testing

Based on the numerical simulation results from the airflow field of the pig nursery under various conditions, the experimental pig nursery was redesigned by considering the variation in airflow uneven coefficient curves. The redesigned pig nursery is shown in Figure 10. Each fence was provided with an air inlet right above the concrete floor, and an air outlet in the middle aisle.

The main parameters are as follows: the diameters of both the inlet and outlet ducts were 0.3 m; the air velocities of the fans in the inlet and outlet ducts were 1.5 and 2.0 m/s, respectively; the air inlet was equipped with a hood to adjust the ventilation angle to 45 °.

The environmental conditions in the pig nursery from 6:00 on 19 January, 2020 to 6:00 the next day were monitored. The outdoor temperature maximized to -15 °C during the day, and minimized to -28 °C at night. The monitored parameters included temperature, relative humidity, and CO2 and NH3 concentrations. Data were sampled every 15 minutes, and 10 sets of data for each monitoring session were continuously sampled. The average values were then recorded. Some of the data are shown in Table 2.

The significance of differences between the monitoring data at each node was calculated to further analyze whether the airflow in the pig nursery was uniform under the duct ventilation mode. The variability of temperature, humidity, and CO2 and NH3 concentrations among the nodes was tested on SPSS. The results are shown in Table 5.

| A | B | C | D | E | F | ||

| Control pig nursery | Temperature (℃) | 24.00±

0.66c |

24.91±

0.48ac |

24.96±

0.51a |

24.91±

0.46ac |

24.60±

0.48b |

23.68±

0.53d |

| Humidity (%) | 78.19±

2.47c |

88.46±

0.85b |

85.53±

1.36b |

90.24±

0.80a |

90.35±

0.66a |

88.32±

0.88b | |

| CO2(mg/m3) | 1660.04±

124.82d |

1746.71

111.27c |

1784.72

128.58b |

1817.06

134.12ab |

1834.63

139.06a |

1754.94

119.27b | |

| NH3(mg/m3) | 2.42±

0.51c |

2.59±

0.48b |

2.75±

0.44a |

2.74±

0.49a |

2.79±

0.42a |

2.72±

0.50ab | |

| Test pig nursery | Temperature (℃) | 22.91±

0.80c |

23.47±

0.48b |

23.51±

0.51b |

23.75±

0.45a |

23.91±

0.51a |

23.41±

0.51b |

| Humidity (%) | 53.21±

3.05b |

64.56±

2.21a |

64.62±

2.45a |

64.74±

2.41a |

64.87±

2.45a |

64.56±

2.42a | |

| CO2(mg/m3) | 941.93±

36.31b |

1018.34±

41.11a |

1024.73±

41.08a |

1023.08±

39.05a |

1023.53±

40.24a |

1019.15±

40.21a | |

| NH3(mg/m3) | 1.10±

0.28c |

2.10±

0.46b |

2.22±

0.45a |

2.21±

0.41a |

2.27±

0.39a |

2.16±

0.40ab |

Note: Differences between different letters in the same row are significant (p<0.05) and differences between the same mothers are not significant (p>0.05).

Because node A was closer to the door and window and was more affected by the outdoor air, the data at node A were significantly different from the data at other nodes in both the control and test pig nurseries. The main reason for the consistency in the difference of NH3 concentrations at different nodes in the two nurseries was that the amount and moment of fecal discharge were more random, resulting in large changes in NH3 concentrations at a certain time point.

In the control pig nursery, the data of neighboring nodes were more significantly different. For instance, the differences in temperature and humidity between nodes B and C were not significant (p >0.05), but the differences in CO2 and NH3concentrations were significant (p <0.05). In contrast, the data of neighboring nodes in the test pig nursery were less significantly different, such as the insignificant differences in temperature, humidity, and CO2 concentration between nodes B and C (p >0.05). This result indicates the test barn has better ventilation uniformity and is more suitable for piglet growth.

4. Conclusions

The duct-ventilated system of a pig nursery in a cold region was studied. CFD was used to simulate the airflow field of the pig nursery with different duct diameters, air velocities, and air inlet angles. The ventilation state in each case was evaluated and analyzed using the uneven coefficient of airflow field. The accuracy of the simulation results was verified through field measurement.

(1) The maximum relative error between the simulated and measured data is 20%, and the average relative error is 11.79%. The simulation results well agree with the actual environment, and thus can be used as a basis for optimizing the ventilation system design. Based on the CFD simulation and data analysis, the duct diameter was determined to be 0.3 m, the air inlet and outlet velocities were 1.5 and 2.0 m/s, respectively, and the ventilation angle was 45°.

(3) The ventilation system in the test pig nursery was modified, and the monitoring data in the control and test nurseries were compared. The data at neighboring nodes of the control pig nursery were significantly more different. The test pig nursery had significantly less difference in the data of neighboring nodes. Hence, the modified test pig nursery had better ventilation uniformity and was more suitable for the healthy growth of piglets.

The pig nursery ventilation system was optimally designed, but the control strategy still needs to be improved. To better control the pig nursery environment in the future, the coupling mechanism of the environment inside the pig house can be investigated, and the environmental control strategy related to the environment outside the pig nursery can be established. The seasonality of the pig nursery environment can also be analyzed to achieve autonomous and precise control of the pig house environment in different seasons.

Acknowledgement:

The author would like to thank the anonymous reviewers for their constructive comments, which helped improve the quality of this paper.

Funding Statement:

This work was supported by Collaborative Innovation Achievement Project of “Double First-Class” Disciplines in Heilongjiang Province, grant number LJGXCG2024-P25, Key Projects of Qiqihar City Scientific and Technological Plan, grant number ZDGG-202202, the Basic Research Fund for State-owned Universities in Heilongjiang Province, grant number 145309319, General Research Project on Higher Education Teaching Reform in Heilongjiang Province, grant number SJGY20220410, and Educational Science Research Project of Qiqihar University, grant number GJQTYB202212.

Author Contributions:

Zhidong Wu: Writing review, project administration; Kaixiang Xu: writing original draft; Yanwei Chen: Formal analysis; Yonglan Liu: Validation; Meiqi Liu: Conceptualization. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials:

The experimental data are original and not convenient for public disclosure. If there is a reasonable request, please contact the authors.

Conflicts of Interest:

The authors declare no conflicts of interest to report regarding the present study.

Ethics Approval:

Not applicable.

References

1. Wang B, Xiao H. Regional analysis on structure and competitiveness of China’s animal husbandry—Based on shift-share analysis space model. Chin J Agric Resour Reg Plan. 2021;42(5):142–8 (In Chinese).

2. Lesser T, Braun C, Wolfram F, Gottschall R. A special double lumen tube for use in pigs is suitable for different lung ventilation conditions. Res Vet Sci. 2020;133:111–6. doi:10.1016/j.rvsc.2020.09.007.

3. Costa A, Borgonovo F, Leroy T, Berckmans D, Guarino M. Dust concentration variation in relation to animal activity in a pig barn. Biosyst Eng. 2009;104(1):118–24.

4. Zong C, Li H, Zhang G. Ammonia and greenhouse gas emissions from fattening pig house with two types of partial pit ventilation systems. Agri Ecosyst Environ. 2015;208:94–105. doi:10.1016/j.agee.2015.04.031.

5. Ma H, Xie Y, Li A, Zhang T, Liu Y, Luo X. A review on the effect of light-thermal–humidity environment in sow houses on sow reproduction and welfare. Reprod Domest Anim. 2023;8(8):1023–45. doi:10.1111/rda.14400.

6. Dai X, Ni JQ, Pan Q, Wang K, Heber AJ. Monitoring of temperature, humidity and air quality inside pig weaner house in Eastern China. Trans Chin Soc Agric Eng. 2016;47(7):315–22.

7. Wang D, Huang H, Zhang H, Liu J, Dong X. Analysis of research status and development on engineering technology of swine farming facilities. Trans Chin Soc Agric. 2018;49(11):1–14 (In Chinese). doi:10.6041/j.issn.1000-1298.2018.11.001.

8. Mostafa E, Hoelscher R, Diekmann B, Ghaly AE, Buescher W. Evaluation of two indoor air pollution abatement techniques in forced-ventilation fattening pig barns. Atmos Pollut Res. 2017;8(3):428–38. doi:10.1016/j.apr.2016.11.003.

9. Thalfeldt M, Kurnitski J, Latõˇ sov E. Exhaust air heat pump connection schemes and balanced heat recovery ventilation effect on district heat energy use and return temperature. Appl Ther Eng. 2018;128:402–14. doi:10.1016/j.applthermaleng.2017.09.033

10. Li X, Ye Z, Li B, Feng X, Zhu S, Shen P. Influence of different ventilation system on environment of nursery piggery in winter. Trans Chin Soc Agricult Mach. 2020;51:317–25 (In Chinese). doi:10.6041/j.issn.1000-1298.2020.03.036.

11. Kwon KS, Lee IB, Ha T. Identification of key factors for dust generation in a nursery pig house and evaluation of dust repipeion efficiency using a CFD technique. Biosyst Eng. 2016;151(3):28–52. doi:10.1016/j.biosystemseng.2016.08.020.

12. Xu X, Ge B, Tao D, Han J, Wang L. 3Dtemperaturefield of high-temperature gas cooling reactor cooling medium drive motor and ventilation structure improvement. IET Electr Pow Appl. 2018;12(7):1020–6. doi:10.1049/iet-epa.2017.0661.

13. Shi L, et al. Experimental study ontheapplication effect of targeted ventilation inmulti-floor farrowing sow house. J China Agricult Univ. 2023;28(2):217–26 (In Chinese). doi:10.11841/j.issn.1007-4333.2023.02.19.

14. Zong C, Feng Y, Zhang G, Hansen MJ. Effects of different air inlets on indoor air quality and ammonia emission from two experimental fattening pig rooms with partial pit ventilation system–Summer condition. Biosyst Eng. 2014;122:163–73.

15. Hu Z, Yang Q, Tao Y, Shi L, TuJ, WangY. Areview of ventilation and cooling systems for large-scale pig farms. Sustain Cities Soc. 2023;89:104372. doi:10.1016/j.scs.2022.104372.

16. Kim RW, Kim JG, Lee IB, Yeo UH, Lee SY. Development of a VR simulator for educating CFD-computed internal environment of piglet house. Biosyst Eng. 2019;188(1):243–64. doi:10.1016/j.biosystemseng.2019.10.024.

17. Wang K, Pan Q, Li K. Computational fluid dynamics simulation of the hygrothermal conditions in a weaner house in Eastern China. Trans ASABE. 2017;60(1):195–205. doi:10.13031/trans.11655.

18. Qi F, Zhao X, Shi Z, Rong L, Zhang G, Li H. Applicability evaluation of innovative simplified methods of slatted floor in pig houses-A CFD study. Comput Electron Agric. 2024;216(4):108532. doi:10.1016/j.compag.2023.108532.

19. Li H, Rong L, Zhang G. “Reliability of turbulence models and mesh types for CFD simulations of a mechanically ventilated pig house containing animals. Biosyst Eng. 2017;161:37–52. doi:10.1016/j.biosystemseng.2017.06.012.

20. Wei X, Li B, Lu H, Lü E, Guo J, Jiang Y, et al. Numerical simulation of airflow distribution in a pregnant sow piggery with centralized ventilation. Appl Sci. 2022;12(22):11556.

21. Cheng Q, Wu W, Li H, Zhang G, Li B. CFD study of the influence of laying hen geometry, distribution and weight on airflow resistance. Comput Electron Agric. 2018;144:181–9.

22. Yeo UH, Lee IB, Kim RW, Lee SY, Kim JG. Computational fluid dynamics evaluation of pig house ventilation systems for improving the internal rearing environment. Biosyst Eng. 2019;186:259–78.

23. Mossad RR. Numerical predictions of air temperature and velocity distribution to assist in the design of natural ventilation piggery buildings. Aust J Multi-Discip Eng. 2011;8(2):181–7. doi:10.1080/14488388.2011.11464837.

24. Guo J, Wei X, Du X, Ren J, Lü E. Numerical simulation of liquid nitrogen injection in a container with controlled atmosphere. Biosyst Eng. 2019;187(1):53–68. doi:10.1016/j.biosystemseng.2019.08.015.

25. Bjerg B, Cascone G, Lee IB, Bartzanas T, Norton T, Hong SW, et al. Modelling of ammonia emissions from naturally ventilated livestock buildings. Part 3: CFD modelling. Biosyst Eng. 2013;116(3):259–75. doi:10.1016/j.biosystemseng.2013.06.012.

26. Qin J, Pan H, Rahman MM, Tian X, Zhu Z. Introducing compressibility with SIMPLE algorithm. Math Comput Simulat. 2021;180(1):328–53. doi:10.1016/j.matcom.2020.09.010.

27. Wu Z, Fang J, Ba W, Wu S, Li H, Cai Y, et al. Design and evaluation of combined ventilation system with air supply and exhaust ducts for a pig nursery heating piggery in winter. Trans Chin Soc Agric Eng. 2021;37(10):152–8 (In Chinese)

28. Liu H, Fang H, Cheng R, Yang Q. Simulation and optimization of the air flow and temperature in plant factory with artificial light based on CFD. J China Agric Univ. 2018;23(5):108–16 (In Chinese).

29. Wang X, Chen Z, Wang M, Liu J. Numerical simulation of heat supply for heat recovery ventilation system of piggery in winter. Trans Chin Soc Agric Eng. 2011;27(12):227–33+438 (In Chinese).

30. Deng S, Shi Z, Li B, Zhao S, Ding T, Zheng W. CFDsimulation of airflow distribution in low profile cross ventilated dairy cattle barn. Trans Chin Soc Agric Eng. 2014;30(6):139–46 (In Chinese).

31. Wang H, Liu J, Wu Z, Feng G, Shen Z, Wang M. Airflow characteristics of attachment ventilation in a nursery pig house under heating mode. Biosyst Eng. 2022;224(9):346–60. doi:10.1016/j.biosystemseng.2022.10.018.

32. Gu Y, Mu J, Zheng S, Gang Z, Jing R, Wang C. Effect of jet hole arrangement on drag reduction

characteristics of jet surface. Trans Chin Soc Agric. 2014;45(10):340–6 (In Chinese).

33. Xing D, Yan C, Wang C, Sun L. Effects of aspect ratio of rectangular channel on characteristics of single phase laminar flow. Chin J Theoretical Appl Mech. 2013;45(3):331–6 (In Chinese).

Document information

Published on 28/11/24

Accepted on 09/10/24

Submitted on 18/07/24

Volume 40, Issue 3, 2024

DOI: 10.23967/j.rimni.2024.10.056321

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?