ABSTRACT: The construction industry uses a complex combination of materials associated with a high carbon dioxide footprint. Therefore, several new building systems and solutions have emerged with higher sustainability and improved energy efficiency over their service lives, with the development of customizable lightweight sandwich structures, being one of the most promising strategies. The common processes for manufacturing fibre-reinforced polymer (FRP) composites, with large dimensions, are both hand layup-assisted vacuum bagging and vacuum bagging infusion. Besides, composite sandwich panels are traditionally composed by glass fibres and thermoset resins. However, basalt fibres can be an interesting substitute, since they are more sustainable, and have a higher performance. Despite the large amount of research work carried out on advanced composite sandwich panels, only a few studies were focused on the manufacturing of these structures based on basalt fibres assisted by vacuum infusion. Therefore, this work aims to design, manufacture and compare the mechanical, physical, thermal and environmental performance of these composite sandwich panels, comprising either glass or basalt fibres, which will be further applied in modular construction. The results revealed that it is feasible to produce composite sandwich panels through this method, and the most promising solution attained through this study is based on basalt fibres.

Keywords: eco-composites, modular construction, multifunctionality, prefabrication, sustainability.

1. Introduction

Ongoing climate changes and ecological degradation are challenging for the whole world, especially considering that global primary materials extraction and their use in the construction sector are projected to double in the coming decades [1-3]. This sector is also the one with higher environmental impact, since it is responsible for the consumption of approximately 60 % of the entire volume of natural and critical resources at the global scale [1-3], for high energy consumption, greenhouse gas emissions, solid waste generation, and pollution [4, 5]. In the several phases of the building’s life cycle, a large amount of carbon dioxide (CO2) is emitted into the atmosphere. In fact, this sector is responsible for 37 % of global CO2 emissions and 34 % of energy consumption [6]. The growing concerns with environmental impact and the awareness to save materials, and energy resources have raised the need to develop more sustainable solutions. These include both reducing the amount of resources and using more environmentally friendly materials in construction technologies. The use of advanced composite materials is one of the most promising strategies for the construction of new structures, rehabilitation or expansion of existing ones. Although they present significant advantages, the limited knowledge, and the lack of standards for the application of composite structures in the construction industry are delaying their widespread industrialization [7, 8].

Composite sandwich panels are an example of advanced composite structures, which consist of two thin and rigid laminates separated by a lightweight core [9]. These structures exhibit several advantages, such as high strength-to-weight ratio, thermal and acoustic insulation, vibration absorption, impact resistance and versatility, allowing prefabrication and modularity [9, 10]. The production method and materials selection for the design and development of these panels are crucial, as it determines their overall final properties and sustainability [11]. The most common process for manufacturing fibre-reinforced polymer (FRP) composites, with considerable dimensions and good quality, are liquid moulding techniques, including hand layup-assisted vacuum bagging and vacuum bagging infusion [12-15]. Due to its reliance on manual procedures, the hand layup process is highly labour-intensive and time-consuming. Additionally, the final properties of the structure may be highly affected by the manual procedure, because it is heavily dependent on the skill and experience of the operator [16]. The application of vacuum pressure in this process can improve the composite properties, since it compacts the laminate layers, reducing the number of voids and removing excessive resin [16, 17]. One of the main advantages of this technique is that it can be used for the maintenance and repair of damaged structures [16]. On the other hand, the vacuum infusion process is a more versatile, accurate, and well-established methodology that uses vacuum pressure to drive resin into the composite laminate [11, 18]. The manufactured composite materials by this process exhibit a good fibre-to-resin ratio, and an overall high mechanical performance [19].

Although glass fibres are usually applied on composite sandwich panels, basalt is a promising material for a more sustainable development of these structures, considering that it is an environmentally safe and inert material with no reaction with air and water [20, 21]. These fibres have better properties than glass counterparts, such as higher temperature stability and resistance against corrosion, superior strength, and chemical resistance [21, 22].

Table 1 presents a comparison of the main properties of both fibres.

| Fibre | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Thermal Conductivity (W/m·°C) | Sound Absorption Coefficient |

| Glass | 2.55 | 1 930 – 2 050 | 72 – 85 | 1.2 – 1.35 | 0.8 – 0.93 |

| Basalt | 2.67 | 1 430 – 4 900 | 71 -110 | 0.03 – 0.038 | 0.95 – 0.99 |

Even though extensive research work has been carried out on advanced composite sandwich panels, only a limited number of studies have been published involving the vacuum infusion method and basalt fibres [21, 24-26]. Therefore, this work aims to design, manufacture and compare the mechanical, physical, thermal, and environmental properties as well as evaluate the performance of two different composite sandwich panels with an extruded polystyrene (XPS) foam core, one with glass fibres and the other with basalt fibres.

2. Materials and methods

2.1. Materials

XPS foam core (ifoam®, IMPERALUM, Portugal) was directly bonded to a composite laminate that comprises an epoxy resin (Biresin® CR83/CH 83-6, SIKA Portugal, Portugal) and fibres. Thus, two panels with different laminates were compared, one with glass fibres (450 g/m2, Castro Composites, Spain) and other with basalt fibres (450 g/m2, Castro Composites, Spain).

2.2. Experimental Procedure

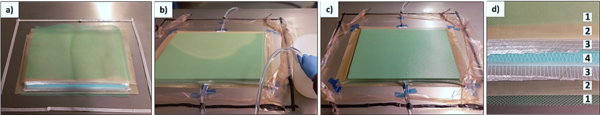

The composite sandwich panels were produced by vacuum infusion, as it can be seen in Figure 1, with two layers of fibres on both sides of the core material. The fibre fabrics with 40 cm × 60 cm were laid up with ± 45° orientation. The epoxy resin (A) was mixed with the hardener (B), at room temperature, in a proportion of 100A:30B, and then, degassed (for approximately 10 minutes) to minimize the presence of air bubbles and, therefore, potential defects. After the application of the release agent, positioning of the peel ply, infusion mesh, spiral, tube, vacuum bag and sealant tape, a vacuum pressure of 500 mbar was set, and a leak test was performed. Afterwards, the inlet valve was opened and the resin starts to flow through the layers of fibre. The panels were cured for 10 h at 60 °C, keeping the vacuum pressure till the end of the procedure. After the removal of all the consolidation materials, the produced composite sandwich panels were machined into different specimens for further characterization.

2.3. Test procedures

The composite sandwich panels and the laminates were characterized to evaluate physical, thermal, and mechanical properties using several techniques.

2.3.1 Laminates

The density and the fibre volume fraction were determined to evaluate the physical properties of both laminates and analyse the influence of the core in the infusion of the top laminate. The density of the laminates was calculated using Method A of ASTM D 792, and the fibre volume fraction and void content were determined, following ASTM D 3171 – G.

Differential scanning calorimetry (DSC) experiments were performed using a Q20 model calorimeter (TA Instruments), to determine if the curing reactions were complete, and evaluate the thermal transitions of the laminates. The experiments were carried out according to ISO 11357. The samples were heated from 30 °C to 110 °C, at a constant rate of 20 °C/min, under a nitrogen flow rate of 50 mL/min.

2.3.2 Sandwich panels

The mechanical properties of the sandwich panels were determined by i) three-point flexural, and ii) edgewise compression tests performed using an Instron 5900R Universal Testing Machine, following ASTM C 393/ C3939 M and ASTM C364/ 364 M, respectively.

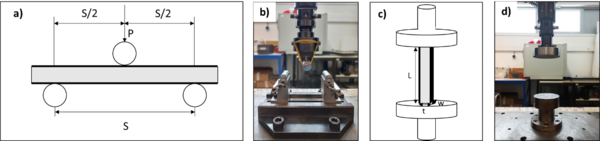

The dimensions of the specimens for the three-point flexural test were 200 mm × 75 mm. The test was carried out with a 100 kN load cell and at a constant loading rate of 6 mm/min. Aiming at avoiding early failure, the loading bar and support bars had a 25 mm diameter. Edgewise compression tests were conducted with the same load cell and at a speed of 0.5 mm/min. The specimens with 160 mm × 40 mm were subjected to a compression force parallel to the plane of the laminates. Figure 2 a) and b) describe the set-up for the flexural tests, where S is the support span with 150 mm, and P is the load, and Figure 2 c) and d) the set-up for the compression tests.

The composite sandwich panels’ density was calculated based on the ASTM C271, by using a digital calliper (150 mm ProK) and a Radwag Scale AS 220.R2.

To analyse the environmental impact of the two sandwich panels, it was used the GRANTA EduPack eco audit tool (only at material level). With this software, it is possible to analyse the energy consumption and carbon footprint for the whole life cycle, without exploring every parameter of the developed solutions [27].

3. Results and Discussion

3.1. Laminates

The physical and thermal properties of the produced laminates were determined, and the average results for three samples with the respective standard deviations are summarized in Table 2.

| Test | Property | Glass Laminate | Basalt Laminate | ||

| Top | Bottom | Top | Bottom | ||

| Density | Epoxy resin density (g/cm3) (according to datasheet) | 1.15 | 1.15 | ||

| Composite density (g/cm3) | 1.74 ± 0.04 | 1.73 ± 0.02 | 1.84 ± 0.04 | 1.87 ± 0.02 | |

| Constituent content | Fibre volume fraction (%) | 47.7 ± 1.0 | 47.5 ± 0.9 | 54.1 ± 0.8 | 54.4 ± 0.3 |

| Void content (%) | 7.2 ± 2.3 | 7.0 ± 1.0 | 5.4 ± 2.6 | 3.5 ± 1.4 | |

| DSC | Glass transition temperature (°C) of the 1st heating ramp | 76.9 ± 0.1 | 82.6 ± 0.4 | ||

The density of the basalt laminate is slightly higher than the counterparts containing glass fibres (+5.7 % for the top laminate and +8.1 % for the bottom laminate) as expected, considering that the basalt fibres are denser, and the fibre volume fraction of the produced basalt composites is higher (+6.4 % and +6.9 %, for the top and bottom laminate, respectively). The evaluation of void content showed that the glass laminate presented a superior value (+1.8 % for the top laminate and +3.5 % for the bottom laminate). Furthermore, by making the panel in a single step, the impact of a core on the properties of the top laminate was reduced, although in the basalt panel there was a slight increase in the void content (+1.9 %). Moreover, the DSC experiments revealed that the basalt laminate, contrary to the glass counterparts, achieve higher glass transition temperature than the one presented in the resin datasheet (80 °C), what can lead to better properties. The presented results showed that is relevant to control the design and the process parameters, since the performance of the developed composites can be further improved, essentially by reducing the void content.

3.2. Composite Sandwich Panels

The mechanical properties and the sustainability of both sandwich panels were evaluated and are summarized in Table 3. The average and standard deviations for five valid results are reported.

| Test | Property | Glass | Basalt |

| Flexural Test | Maximum load (N) | 499.5 ± 30.8 | 488.9 ± 22.0 |

| Core shear ultimate strength (MPa) | 0.18 ± 0.01 | 0.17 ± 0.00 | |

| Facing stress (MPa) | 15.7 ± 0.7 | 16.2 ± 0.7 | |

| Modulus of elasticity in bending (MPa) | 350.2 ± 11.0 | 243.1 ± 14.8 | |

| Compression Test | Maximum load (kN) | 3.05 ± 0.14 | 3.36 ± 0.29 |

| Ultimate edgewise compressive strength (MPa) | 47.7 ± 3.6 | 59.8 ± 5.6 | |

| Density | Composite sandwich panel density (g/cm3) | 0.16 ± 0.00 | 0.15 ± 0.00 |

| Sustainability

(material) |

Energy (MJ) | 65.2 | 38.3 |

| CO2 Footprint (kg) | 3.4 | 1.8 | |

| Cost of the fibres (€/m2) | 6.45 | 12.99 |

An overall positive trend was observed for specimens with basalt fibres, where a more pronounced improvement was attained for the ultimate edgewise compression strength (+25 %). However, lower values of core shear ultimate strength (-6 %), and modulus of elasticity in bending (-31 %) were found on the flexural tests performed, in comparison with specimens containing glass fibres. This limitation can be associated to the smaller thickness of the basalt laminate (0.85 ± 0.06 mm and 0.75 ± 0.04 mm for the glass and basalt laminates, respectively) obtained at the end of the vacuum infusion process promoted by the higher fibre volume fraction.

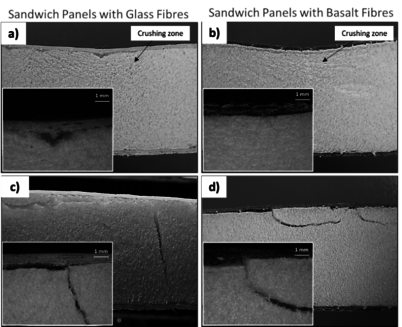

Figure 3 shows the failure mode of the composite sandwich panels in study.

The failure mode in both sandwich panels was similar, mainly promoted by core crushing in the flexural test, and in the compression experiments, the mechanical failure was due to partial debonding combined with core shear failure [28]. These results indicate that a good adhesion was established between the laminates and the core.

Regarding the sustainability study, since GRANTA Edupack 2021 software does not consider XPS, a similar material, expanded polystyrene (EPS) was used. According to Table 3, it is possible to observe that the highest impacts were found for the glass fibre sandwich panel because of its high-energy consumption and CO2 footprint (+70 % and +86 %, respectively). Although the basalt fibres have a lower environmental impact, it leads to a higher cost in relation to the glass fibres (+101 %).

4. Conclusions

With the goal of finding a sustainable product for the construction sector, it was proposed the use of composite sandwich panels. In this research, the physical and mechanical behaviour of the developed solutions, by vacuum infusion, was evaluated as well as their sustainability. In summary, the concluding remarks can be stated as:

- The laminates of the sandwich panels presented a fibre volume fraction of 48 % and 54 %, and a void content of up to 5.4 % and 7.2 %, for those containing glass and basalt fibres, respectively. The impact of the core on the properties of the top laminate was relatively low. The performed thermal tests revealed that the combination of basalt fibres and resin resulted in a higher glass transition temperature than the one found on the resin datasheet.

- In general, the basalt composite sandwich panel presented better mechanical performance, however, the flexural properties were slightly lower due to the thinner composite laminate. The compression tests showed a good adhesion between the core and the laminate, since occurred rupture of the core combined with a slight delamination of the composite laminate.

- Regarding the sustainability of the developed composite sandwich panels, the one with basalt fibres presented lower energy consumption and CO2 footprint, yet the cost is relatively higher than the one with glass fibres. This can difficult the utilization and spread of these materials in the construction sector.

The results revealed that it is feasible to produce composite sandwich panels through the vacuum infusion method and the most promising solution is the one with basalt fibres. However, additional studies are anticipated, to optimize the vacuum infusion procedure, and to further decrease the void content. This could enhance even more its global performance and allow the full exploitation of the promising properties of the basalt laminates and composite sandwich panels. In complement, future work can be carried out with more sustainable core materials to find a more ecological and promising structure.

5. Acknowledgements

This work was developed in the scope of “iclimabuilt” project, supported by the European Union under the HORIZON2020 Framework Programme for Research and Innovation under grant agreement no 952886.

6. References

[1] Baabou, W., A. Bjorn, and C. Bulle, «Absolute Environmental Sustainability of Materials Dissipation: Application for Construction Sector». Resources-Basel. 11(8), 2022. DOI: 10.3390/resources11080076

[2] Maxineasa, S.G., et al., «Environmental Performances of a Cubic Modular Steel Structure: A Solution for a Sustainable Development in the Construction Sector». Sustainability. 13(21), 2021. DOI: 10.3390/su132112062

[3] Luca, A., et al., «Life cycle assessment of a new industrial process for sustainable construction materials». Ecological Indicators. 148, 2023. DOI: 10.1016/j.ecolind.2023.110042

[4] Mateus, R., et al., «Sustainability assessment of an innovative lightweight building technology for partition walls – Comparison with conventional technologies». Building and Environment. 67, 2013. DOI: 10.1016/j.buildenv.2013.05.012

[5] Loizou, L., et al. «Quantifying Advantages of Modular Construction: Waste Generation». Buildings, 11, 2021. DOI: 10.3390/buildings11120622.

[6] United Nations Environment Programme, «2022 Global Status Report For Buildings and Construction: Towards a Zero‑emission, Efficient and Resilient Buildings and Construction Sector», 2022. p. 101.

[7] Manalo, A., «Structural behaviour of a prefabricated composite wall system made from rigid polyurethane foam and Magnesium Oxide board». Construction and Building Materials. 41, 2013. DOI: 10.1016/j.conbuildmat.2012.12.058

[8] Lacey, A.W., et al., «Structural response of modular buildings – An overview». Journal of Building Engineering. 16, 2018. DOI: 10.1016/j.jobe.2017.12.008

[9] Al-Khazraji, M.S., S.H. Bakhy, and M.J. Jweeg, «Composite sandwich structures: review of manufacturing techniques». Journal of Engineering, Design and Technology. ahead-of-print(ahead-of-print), 2023. DOI: 10.1108/JEDT-03-2022-0141

[10] Jackson, K.P., J.M. Allwood, and M. Landert, «Incremental forming of sandwich panels». Journal of Materials Processing Technology. 204(1), 2008. DOI: 10.1016/j.jmatprotec.2007.11.117

[11] Kim, S.-Y., et al., «Mechanical properties and production quality of hand-layup and vacuum infusion processed hybrid composite materials for GFRP marine structures». International Journal of Naval Architecture and Ocean Engineering. 6(3), 2014. DOI: 10.2478/IJNAOE-2013-0208

[12] Gaiotti, M. and C.M. Rizzo. «Buckling behavior of FRP sandwich panels made by hand layup and vacuum bag infusion procedure». in 14th International Congress of the International-Maritime-Association-of-the-Mediterranean (IMAM). 2011. Genova, ITALY.

[13] Sousa, S.P.B., et al. «Compósitos Avançados Aplicados no Setor da Construção». in Construção 2018. 2011. Porto, Portugal.

[14] Hindersmann, A., «Confusion about infusion: An overview of infusion processes». Composites Part a-Applied Science and Manufacturing. 126, 2019. DOI: 10.1016/j.compositesa.2019.105583

[15] Abdurohman, K., T. Satrio, and N. Muzayadah. «A comparison process between hand lay-up, vacuum infusion and vacuum bagging method toward e-glass EW 185/lycal composites». in Journal of Physics: Conference Series. 2018. IOP Publishing.

[16] John, M., «Design and Manufacturing of Bio‐Based Sandwich Structures», 2017. p. 93-110.

[17] Kausar, A., et al. «State-Of-The-Art of Sandwich Composite Structures: Manufacturing—to—High Performance Applications». Journal of Composites Science, 7, 2023. DOI: 10.3390/jcs7030102.

[18] Gajjar, T., et al., «Analysis of Process Parameters for Composites Manufacturing using Vacuum Infusion Process». Materials Today: Proceedings. 21, 2020. DOI: 10.1016/j.matpr.2020.01.112

[19] Rahman, M., A.A. Jasani, and M.A. Ibrahim, «Flexural Strength of Banana Fibre Reinforced Epoxy Composites Produced through Vacuum Infusion and Hand Lay-Up Techniques - A Comparative Study». International Journal of Engineering Materials and Manufacture. 2(2), 2017. DOI: 10.26776/ijemm.02.02.2017.02

[20] Jamshaid, H. and R. Mishra, «A green material from rock: basalt fiber – a review». The Journal of The Textile Institute. 107(7), 2016. DOI: 10.1080/00405000.2015.1071940

[21] Oliveira, P.R., et al., «Bio-based/green sandwich structures: A review». Thin-Walled Structures. 177, 2022. DOI: 10.1016/j.tws.2022.109426

[22] Liu, J., et al., «Study on Mechanical Properties of Basalt Fibers Superior to E-glass Fibers». Journal of Natural Fibers. 19, 2020. DOI: 10.1080/15440478.2020.1764438

[23] Ansys GRANTA EduPack software, «Fibers and particulates», 2021.

[24] Torres, J.P., et al., «Manufacture of Green-Composite Sandwich Structures with Basalt Fiber and Bioepoxy Resin». Advances in Materials Science and Engineering. 2013, 2013. DOI: 10.1155/2013/214506

[25] Subramaniam, S., et al., «Enhancement of mechanical properties of sandwich composites». Materials Today: Proceedings. 68, 2022.

[26] Scalici, T., V. Fiore, and A. Valenza, «Experimental assessment of the shield-to-salt-fog properties of basalt and glass fiber reinforced composites in cork core sandwich panels applications». Composites Part B: Engineering. 144, 2018. DOI: 10.1016/j.compositesb.2018.02.021

[27] Ansys GRANTA EduPack software, «GRANTA EduPack eco audit tool », 2021, Granta Design Limited.

[28] Eyvazian, A., et al., «Buckling and crushing behavior of foam-core hybrid composite sandwich columns under quasi-static edgewise compression». Journal of Sandwich Structures & Materials. 23(7), 2019. DOI: 10.1177/1099636219894665

Document information

Published on 19/06/24

Accepted on 31/03/24

Submitted on 18/05/23

Volume 08 - COMUNICACIONES MATCOMP21 (2022) Y MATCOMP23 (2023), Issue Núm. 5 - Materiales y Estructuras, 2024

DOI: 10.23967/r.matcomp.2024.05.09

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?