Abstract

In the production environment, there are many disruptions, such as machine breakdown, rush orders, and so on. Under these circumstances, the shipyards have to meet customer demand. If this is not done, the shipyard may face customer loss, since they cannot meet the deadline. So, it is very important to understand the effects of machine breakdown on system throughput. In this study, the hull production system of a shipyard situated in Turkey has been considered. In the first step of the study, the structure of the double bottom block, which is produced in the shipyard production system, and the workstations, which constitute the production system, were identified. Secondly, the simulation model of the production system was created using simulation software. By creating some machine breakdowns for various work stations in the production system, the effects of breakdown on system throughput have been investigated. As a result of the study, the critical rates of machine breakdown, which have affected system throughput, have been determined. The main contribution of the study is to allow production engineers to take measures against machine breakdowns in advance, so that target throughput can be reached.

Keywords

Shipyard ; Ship production ; Simulation ; Machine breakdown ; Critical breakdown rate

1. Introduction

Manufacturing environments are dynamic in nature and are subject to various disruptions, refered to as real-time events, which can change system status and affect its performance [1] . These disruptions are machine breakdown, rush orders, and order cancellations etc. Machine breakdown is often an important factor in the throughput of manufacturing systems [2] . If a machine breakdown occurs in a production system, throughput, which is one of the performance measures, might change, therefore, production planners must take precautions against this happening.

Throughput is one of the most significant performance measures in a production system. Companies need to reach the target throughput which was planned before. While system throughput is decreasing, customer needs cannot be met and deadlines have to be revised by the production planners. This situation causes companies to lose their customers, which also means money loss. Therefore, a production system has to meet deadlines using available resources, despite a disturbed environment [3] .

Machines are key elements in manufacturing systems and their breakdown can dramatically affect system performance measures [4] . So, it is a big problem for the production planners if the breakdowns are unplanned. In the production process, it is very difficult to estimate where and when a machine breakdown occurs. But, as critical workstations, in terms of machine breakdown, are determined, production planners can take precautions regarding these critical workstations, which will allow the production process to continue without stopping.

Machine breakdown can cause delays in the production system. Due to these delays, work activities are completed later than the time planned. The delays in workstations affect the whole production system and lead to deviations from target throughput. In order to prevent dramatic deviations in the production process, the effects of machine breakdown on system throughput should be determined. So, as critical workstations, in terms of machine breakdown, are determined, it is possible to take precautions against the effects of time delays. When a machine breakdown changes the system throughput, the station, where the machine breakdown has taken place, is regarded as a critical station for the breakdown. By considering the critical workstations, it is possible to take some precautions, such as creating an extra buffer area in front of the critical station. The parts manufactured in critical workstations can be reserved on this additional buffer area. In cases of machine breakdown that takes place in critical stations, the parts reserved in the buffer area can be used so that the production can carry on without stopping. As this is done, target throughput becomes reachable.

There are many papers in literature with respect to machine breakdown. In Gupta’s study [5] , he considered a production line consisting of 7 workstations. When a machine breakdown occured in station 3, the performances of TKS (Traditional Kanban System) and FKS (Flexible Kanban System) were compared in terms of order completion time and product quantity. Shin [6] simulated a production line, and when a machine breakdown occured in the production line, the effect of the breakdown on system throughput was determined. Wazed analysed the effects of common processes and batch size on production quantity and cycle time [7] . Elleuch modelled two distinct production cells with ARENA software, and investigated the effects of machine breakdown on the productivity of production cells [8] . Considering a production line, Ilar investigated the effects on productivity of machine replacement and the exchange of new machines with old [9] .

In this study, machine breakdowns, which may occur in a shipyard production system, and their effects, have been investigated, and the critical workstations in cases of machine breakdown have been determined. For doing this, some machine breakdown scenarios have been created and applied to the shipyard production system using simulation software. In each machine breakdown scenario, the operation times of machines located in the workstations have been increased regularly, and the critical rates of machine breakdown, which affect system throughput, have been determined. Firstly, the structure of a double bottom block, which was considered a product in this study, was identified. Secondly, the workstations that are involved in ship production have been investigated. Then, the whole operation process has been analysed using ARENA simulation software. This is because the ARENA model provides the platform where virtual experiments are conducted to study different solutions and find the best one [10] . Then, the data achieved from the process analysis have been transmitted to the ARENA software [11] and the simulation model of the production system (Figure 1 ) was run for 720 h (90 days) without any breakdown. As a result of running the simulation, the production quantity of the system for this time period (720 h) has been obtained. Then, some breakdown scenarios have been applied to the simulation model. The breakdown scenarios are based on “what if” situations using simulation [12] . In this way, the effects of machine breakdown on system throughput have been investigated. By doing this, the aim is towards determination of critical workstations, in terms of machine breakdown, so that production planners can take precautions, and target throughput can be achieved. Therefore, during the production process, the planners have to be ready for time delays which are resulted from machine breakdown.

|

|

|

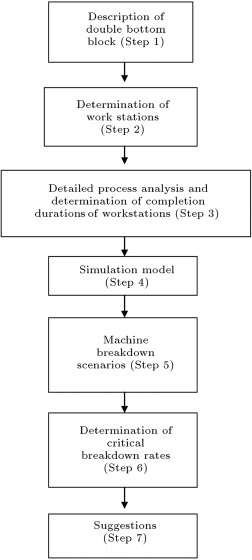

Figure 1. The phases of the study.

|

2. The phases of the study

The phases of the study contain seven steps, as can be seen from Figure 1 . Implementing the steps one by one, it is aimed to determine the effects of machine breakdown on a shipyard production system and, finally, to make some suggestions. Here, a double bottom block of a containership was considered, since it includes all workstations that are involved in hull production. The phases of the model were implemented for the production system of the shipyard, which is located in Turkey. The phases of the model are given in Figure 1 .

In the first phase of the study, the structure of the double bottom block is identified (Step 1). In this phase, the structure of the double bottom block and its production stages are presented. In the second phase (Step 2), called the determination of workstations, the workstations which are involved in hull block production are determined and defined. In the third phase (Step 3), a detailed process analysis of the workstations is performed and the completion durations are calculated. Then, the simulation model of the production system is created (Step 4). After the simulation model is created, some machine breakdown scenarios are implemented on the shipyard production system using the simulation model (Step 5). In (Step 6), the effect of machine breakdown on the production system is determined. In the last step (Step 7), some suggestions on how to deal with the effects of machine breakdown on the production system are made.

3. Case study

3.1. Description of double bottom block (Step 1)

A double bottom block is manufactured by bringing together the production stages mentioned above. In the first phase of the double bottom production, single section parts (A) and single plate parts (B) are fabricated. These parts are cut from the plates and profiles in the shipyard and have specific dimensions after the cutting process. Then, they are fitted and minor assembly is undertaken (C). Two or more minor assemblies constitute sub assembly (D). Flat plates are welded using the SAW (Submerged Arc Welding) method, and flat plate assembly (E) is undertaken. When the profiles are welded on top of the flat plate assembly, the flat plane assembly (F) is fabricated. Minor and sub assemblies are welded onto the flat plane assembly (F) and major sub assembly (G) is manufactured. Curved panel assembly (H) is manufactured on pin jigs. In the block assembly area, sub unit assembly (J) and curved panel assembly are mounted and welded. Finally, a double bottom block (K) is produced. Table 1 shows the production stages and their definitions.

| Production stage | Definitions of production stages | Structures representing production stage |

|---|---|---|

| A | Single section part | |

| B | Single plate part | |

| C | Minor assembly | |

| D | Sub assembly | |

| E | Flat plate assembly | |

| F | Flat panel assembly | |

| G | Major sub assembly | |

| H | Curved panel assembly | |

| J | Sub unit assembly | |

| K | Unit assembly |

3.2. Determination of work stations (Step 2)

Ship production is a hard task, since it involves thousands of work activities. These work activities are carried out in the workstations which have different functions. Table 2 shows the workstations and work activities related to double bottom block production.

| Station no | Station name | Activity |

|---|---|---|

| I1 | Edge cutting | Edge cutting operation of ship hull plates |

| I2 | Edge cleaning and sequencing | Edge cleaning operation of the ship hull plates |

| I3 | Panel production | The hull plates are welded and the panel structure is produced |

| I4 | Panel cutting | Counter cutting of the plates |

| I5 | Profile spot welding | Profiles are assembled on the panel by spot welding |

| I6 | Profile tig welding | Profiles are welded on the panel by tig welding |

| I7 | Section spot welding | Minor and sub assemblies are joined on the flat panel assembly by spot welding |

| I8 | Section tig welding | Minor and sub assemblies are welded on the flat panel assembly by tig welding |

| I9 | Grinding | Grinding operations of the flat panel and major sub assemblies |

| I10 | Profile cutting | Standart-dimensioned profiles are cut and specific dimensioned profiles are fabricated |

| I11 | Profile bending | Bending operations of the profiles |

| I12 | Nest cutting | Single plate assemblies are manufactured |

| I13 | Pre-fabrication | Minor and sub assemblies are produced |

| I14 | Jig | Curved panel assemblies are produced |

| I15 | Plate bending (press) | Bending operations of the plates |

| I16 | Block assembly | Block structure is formed by assembling the related parts. |

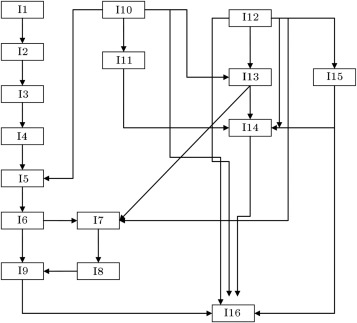

There are 16 workstations in the production process of the double bottom block, as can be seen from Table 2 , which are located in the shipyard production system. Every workstation has a defined task. For instance, in the panel production station (I3), the hull plates are welded and the panel structure is produced. On the other hand, in a panel cutting station (I4), the panel, which is manufactured in the panel production station (I3), is subject to counter cutting, in accordance with its dimensions. Therefore, various types of workstation come together in order to manufacture the double bottom block of a containership. Each workstation has a relation with the other(s). Figure 2 shows the material relationships between the workstations.

|

|

|

Figure 2. Work flow in the shipyard production system.

|

3.3. Detailed process analysis and determination of completion durations of workstations (Step 3)

A detailed process analysis is needed in order to model the production system by simulation. In this section, the workstations given in Table 2 will be investigated, as detailed, and the operation activities and durations of each workstation will be determined. Then, by using the operation times of the activities, the operation completion durations of thework stations is determined. While calculating the workstation completion duration, parallel and serial work activities are considered. Table 3 and Table 4 show the process analysis of profile spot welding (I5) and profile tig welding stations (I6), respectively. As a result of the process analysis of a profile spot welding station (I5), the work station total activity duration is found to be 380 min. But, the completion duration is 372 min, as can be seen from Table 4 . This is because there are parallel work activities in the profile spot welding station (I5), and why total activity and the completion duration of each station are different. The total activity duration and completion duration of the profile tig welding station are the same, since no parallel activity is available in the station. As all work activities are serial, the completion duration is the same as activity time.

| Activity no | Activity description | Repetition number of activity | Activity duration (min) |

|---|---|---|---|

| 1 | The operator walks to the crane | 2 | 0.146 |

| 2 | The operator runs the crane | 2 | 0.166 |

| 3 | The crane goes to profile stock area | 36 | 8.178 |

| 4 | The operator assistants go to profile stock area | 36 | 3.493 |

| 5 | The crane comes down the profile | 38 | 18.051 |

| 6 | The crane holds the profile | 38 | 15.2 |

| 7 | The crane lifts the profile | 38 | 18.037 |

| 8 | The crane transports the profile from the profile stock area to the porter system | 38 | 8.473 |

| 9 | The workers walk to the porter system | 38 | 3.609 |

| 10 | The crane takes down the profile on the porter system | 38 | 12.274 |

| 11 | The crane leaves the profile surface | 38 | 4.428 |

| 12 | The workers settle the profile on the porter system | 38 | 3.8 |

| 13 | The operator walks to the porter system | 2 | 0.118 |

| 14 | The workers walks to the profile welding area | 2 | 0.404 |

| 15 | The operator runs the porter system | 2 | 0.166 |

| 16 | The operator drives the porter system to the welding area | 2 | 2.926 |

| 17 | The operator walks to the profile spot welding machine | 2 | 0.042 |

| 18 | The operator cleans the welding torch | 2 | 1.5 |

| 19 | The operator runs the profile spot welding machine | 2 | 0.5 |

| 20 | The profile spot welding machine goes to the porter system | 37 | 44.755 |

| 21 | The profile spot welding machine comes down the profiles | 38 | 3.8 |

| 22 | The profile spot welding machine transports the profile from the porter system to the flat plate assembly | 38 | 46.486 |

| 23 | The profile spot welding machine takes down the profile on the flat plate assembly and alignment | 38 | 111.394 |

| 24 | The profile spot welding is prepared for welding operation. | 38 | 6.328 |

| 25 | The process of spot welding | 38 | 63.82 |

| 26 | The conveyor system transports the flat plane assembly | 2 | 1.9 |

| Total | 380 | ||

| Activity no | Activity description | Repetition number of activity | Activity duration (min) |

|---|---|---|---|

| 1 | The conveyor transports the flat panel assembly to the tig welding station | 2 | 0.574 |

| 2 | The operator removes the slags from the welding torch | 38 | 38 |

| 3 | The operator checks the welding system and its connections | 38 | 38 |

| 4 | The operator drives the tig welding machine to the starting point of welding | 36 | 11.577 |

| 5 | The operator takes down the welding torches on the welding area | 38 | 17.1 |

| 6 | The process of tig welding | 38 | 301.071 |

| 7 | The operator takes up the welding torches | 38 | 3.154 |

| 8 | The conveyor transports the flat panel assembly to the buffer area | 2 | 4.134 |

| Total | 413.61 | ||

In the same way, a detailed process analysis of other workstations, given in Table 2 , is performed, and all the completion times of the workstations are achieved. Table 5 shows the completion durations of the workstations which are involved in double bottom hull production. These durations are used in the simulation analysis of the target shipyard production system.

| Station no. | Station name | Completion time (min) |

|---|---|---|

| I1 | Edge cutting | 190 |

| I2 | Edge cleaning and sequencing | 203 |

| I3 | Panel production | 622 |

| I4 | Panel cutting | 356 |

| I5 | Profile spot welding | 372 |

| I6 | Profile tig welding | 414 |

| I7 | Section spot welding | 501 |

| I8 | Section tig welding | 660 |

| I9 | Grinding | 99 |

| I10 | Profile cutting | 410 |

| I11 | Profile bending | 350 |

| I12 | Nest cutting | 653 |

| I13 | Pre-fabrication | 1080 |

| I14 | Jig | 1522 |

| I15 | Plate bending (press) | 1317 |

| I16 | Block assembly | 2196 |

3.4. Simulation model (Step 4)

Simulation has a great importance for production companies. In a competitive environment, the changes of the production system and the effects of these changes have a significant meaning from the point of view of company competitiveness.

After creating a simulation model, a considerable number of changes on the simulation model can be performed in order to understand the effects of the changes. In real production systems, making changes to the system is very expensive, and that is why it is mostly impossible to see the effects of changes, such as manpower, and equipment, etc. Under these circumstances, simulation is a very useful tool in terms of determining the effects of changes on the production system.

Simulation has been used in many industries, as it provides a great advantage for the planner. In the shipbuilding industry, it has a great deal of application areas, such as layout, production processes and so on.

In this study, arena simulation was used for the modeling of work flow between stations, because the functions of Arena are very suitable for modeling shipbuilding activities.

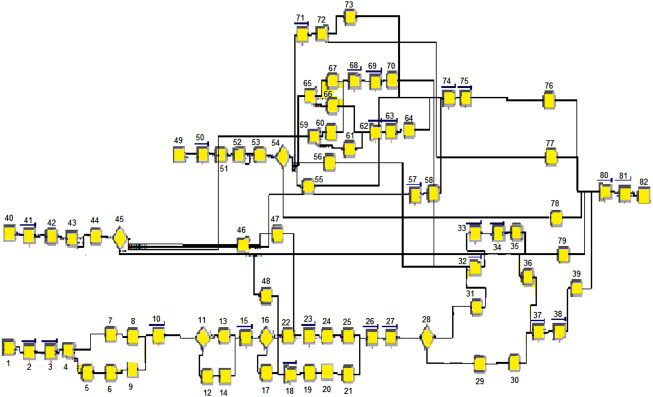

The activities can also be modeled easily using the modules of simulation. Figure 3 shows the simulation model of the shipyard production system.

|

|

|

Figure 3. Simulation model of the shipyard production system.

|

As can be seen from Figure 3 , a large number of modules are used. Table 6 shows the definitions of the modules in Figure 3 .

| Module no | Module name | Module no | Module name | Module no | Module name |

|---|---|---|---|---|---|

| 1 | Create 1 | 29 | Assign 13 | 57 | Process of profile bending (I11 station) |

| 2 | Process of plate edge cutting (I1 station) | 30 | Assign 14 | 58 | Assign 27 |

| 3 | Process of plate edge cleaning | 31 | Assign 15 | 59 | Seperate 5 |

| 4 | Separate 1 | 32 | Batch 3 | 60 | Assign 28 |

| 5 | Assign 1 | 33 | Process of section spot welding (I7 station) | 61 | Assign 29 |

| 6 | Assign 2 | 34 | Process of section tig welding (I8 station) | 62 | Batch 5 |

| 7 | Assign 3 | 35 | Assign 16 | 63 | Process of pre-fabrication 1 |

| 8 | Assign 4 | 36 | Assign 17 | 64 | Assign 30 |

| 9 | Delay 1 | 37 | Process of grinding (I9 station) | 65 | Seperate 6 |

| 10 | Process of panel production (I3 station) | 38 | Batch 4 | 66 | Assign 31 |

| 11 | Decide 1 | 39 | Assign 18 | 67 | Assign 32 |

| 12 | Assign 5 | 40 | Create 2 | 68 | Batch 6 |

| 13 | Assign 6 | 41 | Process of profile cutting (I10 station) | 69 | Process of pre-fabrication 2 |

| 14 | Delay 2 | 42 | Assign 19 | 70 | Assign 33 |

| 15 | Process of panel cutting (I4 station) | 43 | Separate 2 | 71 | Process of plate bending (I15 station) |

| 16 | Decide 2 | 44 | Assign 20 | 72 | Seperate 7 |

| 17 | Assign 7 | 45 | Decide 4 | 73 | Assign 34 |

| 18 | Batch 1 | 46 | Separate 3 | 74 | Batch 7 |

| 19 | Assign 8 | 47 | Assign 21 | 75 | Process of jig (I14 station) |

| 20 | Delay 3 | 48 | Assign 22 | 76 | Assign 35 |

| 21 | Assign 9 | 49 | Create 3 | 77 | Assign 36 |

| 22 | Assign 10 | 50 | Process of nest cutting (I12 station) | 78 | Assign 37 |

| 23 | Batch 2 | 51 | Assign 23 | 79 | Assign 38 |

| 24 | Assign 11 | 52 | Separate 4 | 80 | Batch 8 |

| 25 | Assign 12 | 53 | Assign 24 | 81 | Process of block assembling (I16 station) |

| 26 | Process of profile spot welding (I5 station) | 54 | Decide 5 | 82 | Dispose |

| 27 | Process of profile tig welding (I6 station) | 55 | Assign 25 | ||

| 28 | Decide 3 | 56 | Assign 26 |

A description of the modules in the ARENA simulation model are presented in Table 7 .

| Module name | Description | Symbol |

|---|---|---|

| Create | Describes the arrival time and quantity of the materials entering into the production system. | |

| Process | Describes the work stations in the production system | |

| Assign | Makes assignments the products leaving any work station and it is also used in assembly operations. | |

| Decide | This module orients the products to the work stations where they will go to. | |

| Batch | Used in assembly operations. It combines the products for assembly operation. | |

| Seperate | Divides the main product into sub products. It is usually used for cutting operations. | |

| Dispose | Shows the exit of the production system. |

In the simulation process, the modules are created as shown in Figure 3 . For instance, module nos. 2 and 50, which are seen in Figure 3 and Table 6 , are process modules, and represent the process of plate edge cutting (I1) and nest cutting stations, respectively. Furthermore, while module no. 18 is showing a batch module, module no. 43 is depicting a separate module. Table 8 shows the contents of the process module used in this study. While the first column is representing the module numbers in Figure 3 , the second one is showing the module name, and the third column demonstrates model type. In this simulation software, there are two model types; submodel and standard. Here, the model is the standard model. The fourth column represents the logic of the action. In this study, the logic action was deemed to be seize-delay-release. This means that the resource seizes the part and then fabricates. Finally, the resource releases the part so that it can be transferred to other workstations. In the fifth column, the resource name, which is employed in the work station, is indicated. The sixth column shows the number of resources used in the corresponding station. In the seventh column, the type of delay time is presented, which means distributions of workstation completion durations. In this study, the station completion durations were considered constant. In the eighth and ninth columns, the units of station completion durations and values are shown, respectively.

| Module no | Name | Type | Logic action | Resource name | Quantity | Delay type | Units | Value |

|---|---|---|---|---|---|---|---|---|

| 2 | Process of plate edge cutting | Standart | Seize-delay-release | Plasma cutting machine | 1 | Const. | min | 190 |

| 3 | Process of plate edge cleaning | Standart | Seize-delay-release | Grinding machine | 2 | Const. | min | 203 |

| 10 | Process of panel production | Standart | Seize-delay-release | Submerged arc welding machine | 1 | Const. | min | 622 |

| 15 | Process of panel cutting | Standart | Seize-delay-release | Panel cutting machine | 1 | Const. | min | 356 |

| 26 | Process of profile spot welding | Standart | Seize-delay-release | Profile spot welding machine | 1 | Const. | min | 372 |

| 27 | Process of profile tig welding | Standart | Seize-delay-release | Automated profile tig welding machine | 1 | Const. | min | 414 |

| 33 | Process of section spot welding | Standart | Seize-delay-release | Spot welding torches | 6 | Const. | min | 501 |

| 34 | Process of section tig welding | Standart | Seize-delay-release | Tig welding torches | 15 | Const. | min | 660 |

| 37 | Process of grinding | Standart | Seize-delay-release | Grinding machines | 7 | Const. | min | 99 |

| 41 | Process of profile cutting | Standart | Seize-delay-release | Automated profile cutting machine | 1 | Const. | min | 410 |

| 50 | Process of nest cutting | Standart | Seize-delay-release | Plasma cutting machine | 2 | Const. | min | 350 |

| 57 | Process of profile bending | Standart | Seize-delay-release | Frame bender machine | 1 | Const. | min | 653 |

| 63–69 | Process of pre-fabrication 1 and 2. | Standart | Seize-delay-release | Grinding machine, spot and tig welding torches | 16, 16, 16 | Const. | min | 1080 |

| 71 | Process of plate bending | Standart | Seize-delay-release | Plate bending machine | 1 | Const. | min | 1522 |

| 81 | Process of block assembling | Standart | Seize-delay-release | Grinding machine, spot and tig welding torches | 8, 4, 4 | Const. | min | 1317 |

3.5. Machine breakdown scenario (Step 5)

In this section, machine breakdown scenarios have been applied to machines located in some workstations. The machines are described in Table 9 .

| Station | Types of machine |

|---|---|

| Edge cutting (I1) | CNC controlled plasma cutting machine |

| Panel production (I3) | CNC controlled submerged welding machine |

| Panel cutting (I4) | CNC controlled panel cutting machine |

| Profile spot welding (I5) | CNC controlled profile spot welding machine |

| Profile tig welding (I6) | CNC contolled tandem profile tig welding machine |

| Profile cutting (I10) | CNC contolled profile cutting machine |

| Profile bending (I11) | Profile bending machine (frame bender machine) |

| Nest cutting (I12) | CNC contolled nest cutting machine |

| Plate bending (I15) | Plate bending machine |

Table 9 shows machines to which breakdown scenarios will be applied. Most machines are CNC controlled, except profile bending and plate bending machines. If one pays attention, it can be seen that no breakdown scenarios were applied to some stations. In this study, the breakdowns of the grinding, tack welding and tig welding tools are not considered because there are auxiliaries of these tools in the shipyard, adn, therefore, they are not critical. Here, the main machines were considered. This is why breakdown scenarios were not applied to some workstations.

In each machine breakdown application, the operation times of the machines have been increased regularly and the critical rates of breakdown, which are defined as the percentage rates which change throughput, have been determined. The operation durations were increased regularly in minutes. For instance, the operation time of the edge cutting station (I1) is 190 min. At first, for example, this operation time is increased to 200 min, and the effect of this enhancement on throughput was determined. If system throughput does not change, the operation time’s enhancement is continued until the system throughput alters. The machine breakdown scenarios applied in this study are shown in Table 10 .

| Scenario number | Scenario name | Station |

|---|---|---|

| 1 | Machine breakdown | Edge cutting (I1) |

| 2 | Machine breakdown | Panel production (I3) |

| 3 | Machine breakdown | Panel cutting (I4) |

| 4 | Machine breakdown | Profile spot welding (I5) |

| 5 | Machine breakdown | Profile tig welding (I6) |

| 6 | Machine breakdown | Profile cutting (I10) |

| 7 | Machine breakdown | Profile bending (I11) |

| 8 | Machine breakdown | Nest cutting (I12) |

| 9 | Machine breakdown | Plate bending (I15) |

When a machine breakdown occurs in a workstation, the completion time increases naturally. For instance, if a machine breakdown occurs in the nest cutting station, the operation time of the nest cutting machine increases, due to time delay. Therefore, the breakdowns directly affect the operation times of the machines of the workstations.

Here, using simulation, for each work station, time delays that are resulted from machine breakdowns have been added to machine operation time, and the rates of breakdowns which affect system throughput have been determined. It should be reminded that the time delay of each work station will be applied discretely to the production system.

3.6. Determination of critical breakdown rates (Step 6)

The edge cutting station (I1) has a completion time of 190 min without any breakdown. If the rate of 930% time delay occurs in the operational time of the I1 station machine, the system throughput changes. Therefore, the rate of 930% breakdown is regarded as a critical rate. Until this breakdown rate reaches 930%, system throughput does not change. But, if the breakdown rate of 930% is exceeded and completion time of the plate edge cutting station is 760 min, then system throughput changes. Similarly, the same can be discussed for other stations.

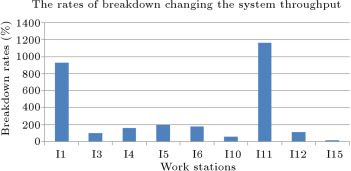

As can be seen from Table 11 and Figure 4 , the most critical workstations in terms of breakdown are press bending (I15) and profile cutting (I10) stations. Even in a small time delay that is resulted from machine breakdown, system throughput alters. If the rate of 15% time delay occurs in the operational time of the press bending (I15) station machine, system throughput changes. In the same way, if the rate of 57% time delay occurs in the operational time of the I10 station machine, system throughput changes. So, these two stations are critical and the production planners, firstly, have to consider press bending and profile cutting stations while planning the production process.

| Breakdown station | Station completion time without breakdown (min) | Rate of time delay (%) | Station completion time (min) (including breakdown) | Throughput (double bottom) (without breakdown) | Throughput (double bottom) (including breakdown) |

|---|---|---|---|---|---|

| I1 | 190 | 930 | 760 | 18 | 17 |

| I3 | 622 | 100 | 894 | 18 | 17 |

| I4 | 356 | 160 | 860 | 18 | 17 |

| I5 | 372 | 200 | 929 | 18 | 17 |

| I6 | 414 | 180 | 955 | 18 | 17 |

| I10 | 410 | 57 | 643 | 18 | 17 |

| I11 | 350 | 1160 | 1740 | 18 | 17 |

| I12 | 653 | 116 | 840 | 18 | 17 |

| I15 | 1317 | 15 | 1500 | 18 | 17 |

|

|

|

Figure 4. The critical rates of machine breakdowns changing the system throughput.

|

3.7. Suggestions (Step 7)

In this study, the production process of a shipyard was taken and modeled by simulation software. Using the simulation model, some breakdown scenarios were applied and various results were achieved. As a result of this study, the most critical workstations were found to be plate bending (15) and profile cutting (I10) stations, since the rates of critical machine breakdown were lower than the other workstations in the production system.

While the production planners are making schedules, they have to take measures for plate bending (I15) and profile cutting (I10) stations. Maintainance of the plate bending and profile cutting machines must be performed regularly. And also, necessary equipment and spare machine parts have to be available near to the machines.

Apart from the measure mentioned above, additional buffer areas can be separated in front of plate bending (I15) and profile cutting (I10) stations. The products or items of the two critical workstations should be reserved on these additional buffer areas. This is because, if a breakdown occurs in these stations, the products which are reserved in these additional buffer areas can be used. In this way, the target throughput level is achieved.

4. Conclusions

Machine breakdown often takes place in shipyard production systems and cause delays, loss of motivation, money loss and so on. Therefore, the shipyard has to consider machine breakdowns and follow those that are critical for system throughput. In this study, the machines in press and profile stations are found to be critical in terms of breakdown. In other words, if a small delay happens in the machine operation times of press and profile cutting machines, system throughput changes. Therefore, the shipyard production planners must closely check those machines located in press and profile workstations.

References

- [1] M. Gholami; Scheduling hybrid flow shop with sequence-dependent setup times and machines with random breakdowns; Int. J. Adv. Manuf. Technol., 42 (2009), pp. 189–201

- [2] Lu, L. “Classification analysis for simulation of machine breakdowns”, Proceedings of the 2007 Winter Simulation Conference , pp. 480–487 (2007).

- [3] F. Ounnar, P. Ladet; Consideration of machine breakdown in the control of flexible production systems; Int. J. Comput. Integr. Manuf., 17 (1) (2004), pp. 69–82

- [4] M.S.J. Ameli; Modeling the effects of machine breakdowns in the generalized cell formation problem; Int. J. Adv. Manuf. Technol., 39 (2008), pp. 838–850

- [5] Gupta, S.M. “The effects of machine breakdown on the performance of a JIT system”, Proceedings of the 26th Annual Meeting of Decision Sciences Institute , pp. 1135–1137 (1995).

- [6] Shin, F. “A decision tool for assembly line breakdown action”, Proceedings of the 2004 Winter Simulation Conference , pp. 1122–1127 (2004).

- [7] M.A. Wazed; Impacts of common processes in multistage production system under machine breakdown and quality uncertainties; Afr. J. Bus. Manag., 4 (6) (2010), pp. 979–986

- [8] M. Elleuch; Simulation of manufacturing cells with unreliable machines; Int. J. Simul. Model, 1 (2007), pp. 5–12

- [9] T. Ilar; Simulation of production lines—the importance of breakdown statistics and the effect of machine position; Int. J. Simul. Model, 4 (2008), pp. 176–185

- [10] S.Y. Abed; A simulation study to increase the capacity of a rusk production line; Math. Comput. Simul., 2 (3) (2008), pp. 228–237

- [11] W.D. Kelton, R.P. Sadowski, D.T. Sturrock; Simulation with Arena; (3rd edn.)McGraw-Hill (1998)

- [12] Mohamad, F. “Evaluating capacity of palm oil mill using simulation towards effective supply chain—a case study”, International Conference on Management, ICM 2011 Proceeding , pp. 353–362 (2011).

Document information

Published on 06/10/16

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?