1 Introduction

European railway industries require a step change in terms of technologies and design for the next generation of rail vehicles in order to remain competitive globally. Innovative materials and modular design for rolling stock are considered to become key to success.

Composite materials, with unique properties (lightness, repairability, corrosion resistance…), have demonstrated high potential for lighter, more energy- and cost-efficient structural components in relevant sectors such as aeronautics and the automotive industry.

However, currently available structural composites do not meet fire, smoke and toxicity requirements of the railway sector, and thus cannot be used for the manufacturing of car bodyshell parts.

That is why research has been done on a wide variety of phosphorus-based flame retardants, for their flammability and their mechanical and rheological properties. However, there are little studies on epoxy resins with non-halogenated flame retardants and on their mechanical properties. For this reason, it is of great interest to study their mechanical behaviour in conjunction with their fireproof characteristics in order to acquire a global vision of the compound.

In the present work, research has been done on the existing correlation between the addition of non-halogenated flame retardants and the mechanical properties of composite materials.

These results are included in the results of the MAT4RAIL project (www.mat4rail.eu) in which AIMPLAS collaborates.

2 Experimental study

A series of composite materials have been prepared using one epoxy resin, two fiber types (glass and basalt) and three different flame retardants.

The composite materials obtained have been processed by infusion. Three of the most important mechanical properties have been evaluated when studying the behaviour of these materials. Tensile, flexural and apparent interlaminar shear properties have been determined, which allowed establishing the correlation between the mechanical behaviour of the manufactured composite materials and the different types of flame-retardant additives.

The percentages of flame retardants of the different composites object of this experimental study have been established taking into account the manufacturer’s recommendations and the viscosity values necessary for an infusion process, thus obtaining a good dispersion in the matrix.

2.1 Raw materials

The composites were made of Araldite MT 40050 epoxy resin with three types of non-halogenated flame retardants (AP462, FOS35 and Fyrolflex) and two types of reinforcing fibres (glass and basalt).

Therefore, the following composite laminates are generated according to the combination of the described raw materials (Table 1).

| Sample | System resin + Flame retardant | Fibre type |

| 1 | Epoxy | Glass |

| 2 | Basalt | |

| 3 | Epoxy +

AP462/FOS35 |

Glass |

| 4 | Basalt | |

| 5 | Epoxy +

Fyrolflex |

Glass |

| 6 | Basalt |

2.2 Manufacturing of laminates

The infusion process is a cost-effective process for making composite parts with high quality, good consistency, high reinforcement/matrix rate (up to 60 % fibres by weight) and good interior finish. That process is widely used in the production of large composite parts.

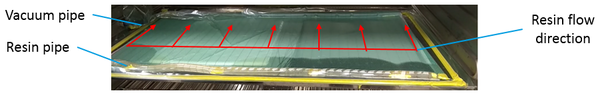

The infusion process consists of infusing resin into a reinforcement placed in a mould using only vacuum pressure (Figure 1).

The first step is to load the reinforcement into the mould and cover the reinforcement with a peel ply and a distribution mess.

Then, the dry material is seal closed using a vacuum bag and tacky tape.

Afterwards, under vacuum, the resin is infused into the mould cavity to wet the fibres.

Finally, the part is cured at the appropriate temperature and it is extracted from its mould.

The infusion rate depends on the resin viscosity, the geometry of the part, the permeability of the mixture and the vacuum pressure. Therefore, the choice of materials, flow phase, resin flow layout and location of the vacuum are critical to obtaining good parts.

In this regard, the resin formulations selected and their processing temperatures are shown in Table 2.

| Resin | Hardener | Flame retardant | Processing T (ºC) |

| MT 40050 | 3473 | - | 80 |

| AP462/FOS35 | 65 | ||

| Fyrolflex | 75 |

Regarding the use of glass and basalt fibres, their main advantage is the good flame retardant properties. The specifications of the selected fibres are shown in Table 3.

| Material | E-glass | Basalt |

| Type | Twill fabric | Twill fabric |

| Weight (g/m2) | 390 | 350 |

| Density (kg/dm3) | 2,59-2,62 | 2,67 |

| Tensile strength (MPa) | 2600 | 3000 |

| Elasticity Modulus (GPa) | 73 | 87 |

| Elongation at break (%) | 3,5-4 | 3,15 |

Considering the weight and the density of each fibre fabric, the objective fibre ratio and the objective laminate thickness, the number of required fabric layers have been calculated. Different layers are required to obtain a 4 mm composite laminate depending on the type of fibre and surface area :

- 14 layers of glass fibre fabric

- 15 layers of basalt fibre fabric

The next step was the manufacturing of composite laminates for basic and mechanical characterisation. Moreover, reference composite samples were manufactured. The specifications and the manufacturing conditions of this laminates are shown in Table 4.

| Reference | 1 | 2 | 3 | 4 | 5 | 6 |

| Resin | MT 40050 | |||||

| Hardener | 3473 | |||||

| Flame retardant | - | AP462/FOS35 | Fyrolflex | |||

| Fibre | Glass | Basalt | Glass | Basalt | Glass | Basalt |

| Layers | 14 | 15 | 14 | 15 | 14 | 15 |

| Processing T (ºC) | 80 | 80 | 65 | 65 | 75 | 75 |

| Curing cycle | 2h120ºC+ 2h140ºC | |||||

2.3 Mechanical characterisation

To characterise the mechanical behaviour of the composites obtained, the tensile properties (strength, Young's modulus and elongation), the flexural properties (strength) and the interlaminar shear strength have been determined.

The tests were carried out according to UNE-EN ISO 527-4, UNE-EN ISO 14125 and UNE-EN ISO 14130 standards respectively and under the same conditions in order to obtain comparative results.

The equipment used to carry out the tests is a Universal Test Machine with a load cell, of 250 kN in the case of tensile properties and 10 kN in the case of flexural and interlaminar shear resistance properties, as an indicator of force. Clamp extensometers have also been used as strain gauges for tensile tests and an arm-type extensometer for flexural tests. The specimens used, rectangular in all cases, have been prepared by machining on a CNC machine. The test speeds, as well as the distances between marks and supports, have been indicated by the aforementioned corresponding standards and the preconditioning of the specimens has been 88 hours at (23 ± 2) ° C and (50 ± 10)% RH.

3 Results

The results corresponding to the characterisation of the different laminates are shown in the figures below.

4 Conclusions

In view of the results obtained, it can be concluded that there are no significant differences between the reference samples and those that incorporate the flame retardant.

In some cases, the mechanical properties improve with the retardants and in others, they suffer a small shrinkage but in a random way in both the glass and the basalt fibres and independently of the flame retardant used. In addition, it is important to note that, taking into account the standard deviations obtained, these variations are considered negligible in most cases.

Therefore, with the present study, it has been shown that the incorporation of non-halogenated flame retardants in an epoxy resin composite reinforced with glass or basalt fibres does not negatively alter the mechanical properties, even in some cases they are slightly improved.

Acknowledgment

These results are included in the results of the MAT4RAIL project in which AIMPLAS collaborates. MAT4RAIL [3] project has received funding from Shift2Rail consortium within the framework of the research and innovation program Horizon 2020 of the European Union under grant agreement no. 777595.

The sixteen partners that form the Mat4Rail consortium bring extensive expertise in engineering and materials research covering resin development and composite manufacturing and joining technologies, testing and characterisation of materials regarding fire, smoke and toxicity (FST) as well as mechanical properties. In addition, the consortium assembles experts in industrial and product design with a wide experience in the rail as well as automotive, aeronautic and other industry sectors.

References

[1] Jain, P., Choudhary, V., Varma, I.K. Flame retarding epoxies with phosphorus. 2002.

[2] Levchik, S.V., Weil, E. Thermal decomposition, combustion and flame-retardancy of epoxy. 2004.

[3] www.mat4rail.eu.

Document information

Published on 24/01/23

Accepted on 27/12/22

Submitted on 27/12/22

Volume 03 - Comunicaciones Matcomp17 (2019), Issue Núm. 3 - Procesos de Fabricación II y Materiales Avanzados, 2023

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?