1 Background

Additive manufacturing (AM) is one of the most promising areas in the manufacturing of components [1-6]. AM has moved beyond its initial role as prototyping technology to a process that can build finished parts. These technologies are able to accurately form complex 3D parts directly. Furthermore, they enable the manufacture of a large range of prototypes or functional components with complex geometries, which are difficult, if not impossible, to manufacture using conventional methods [7] without tooling or touch labour [8-10]. Compared to conventional methods, AM technologies can shorten the design-manufacturing cycle, reduce production costs, and increase competitiveness [9,11,12]. AM technologies cover a broad spectrum of application such as the aerospace and automotive industry, medicine, architecture, education, and fashion [13-19].

The term 3D printing is often used as synonymous to AM technologies, but it is more commonly associated with low cost desktop 3D printers of polymers and non-metal materials. 3D printing or Rapid Prototyping is a manufacturing process that can reproduce complex geometries, such as those obtained from a topology optimization process [20-21], or generated from a fitting process in Computer-Aided Design [22]. 3D printing is not an entirely new technology, but with the advent of open source, low cost 3D printers has become a widespread manufacturing process. The popularity of 3D printing among researchers and hobbyists for the design and manufacture of complex components has led to the rapid growth of this technology worldwide [23-25].

AM technology is a very broad term encompassing numerous methods such as Stereolithography (STL) of a photopolymer liquid, Fused Deposition Modeling (FDM) from plastic filaments, Laminated Object Manufacturing (LOM) from plastic laminations, and Selective Laser Sintering (SLS) from plastic or metal powders [3,26]. However, the FDM technique is of particular interest due to its association to desktop 3D printers, and it is the most widely used method among all the AM techniques for fabricating pure plastic parts with low cost, minimal wastage and ease of material change [19,27].

FDM, developed by Stratasys in 1988 [10], forms a 3D geometry by assembling individual layers of extruded thermoplastic filament, such as acrylonitrile butadiene styrene (ABS) or polylactic acid (PLA), which have melting temperatures low enough for use in melt extrusion in outdoor non-dedicated facilities [1]. PLA materials offer better thermomechanical characteristics than ABS, have higher mechanical performance, and a lower thermal expansion coefficient. FDM is a complex process with a larger number of parameters that influence product quality and material properties, and the combination of these parameters is often difficult to understand [5,28]. Printing parameters such as build orientation, layer thickness, raster angle, raster width, air gap, infill density and pattern, and feed rate, among others, have a substantial effect on quality and performance of FDM printed parts [1,4,5,7,8,9,12,23,29,30]. Since mechanical properties are crucial for functional parts, it is absolutely essential to examine the influence of process parameters on mechanical performance, so that improvements can be made in selecting the best FDM process parameters settings [11,12,31,32,33]. Moreover, the layered nature of FDM processes has considerable implications on the resulting parts.

Thus, further research is required to determine printer parameters such as build orientation, layer thickness and feed rate, particularly since the literature on the mechanical properties of parts processed by low cost 3D printers is somewhat scarce. This applies to the PLA material used in this study that, unlike ABS material, has not been extensively analysed [1,8,34]. Certain studies have specifically focussed on the optimization of FDM process parameters in order to improve ABS thermoplastic performance [28].

To date, anumber of studies have highlighted the impact of build orientation on aspects such as surface quality, geometric accuracy, build time and overall manufacturing cost [30]. However, build orientation has a significant impact on the structural properties of additively manufactured parts. This is often observed in the form of anisotropically printed objects, making structural performance highly dependent on build orientation, in a similar way to composites laminates [35-37]. This effect has been observed and experimentally demonstrated thorough tensile, flexural, impact or compression testing in a limited number of studies [1,4,5,9,10,33,38,39]. These authors agree that the strongest printing orientation is always along the pull direction [6]. A more controversial parameter is layer thickness [1,9,11,32,38]. Several studies have concluded that the optimum selection of parameters for the best mechanical performance includes the minimum layer thickness [6,32]. In contrast, tensile strength and stiffness was found to increase as layer thickness increased [1,9] . Though the effect of feed rate on the mechanical properties of PLA samples is a crucial parameter directly related to manufacturing cost [28], it has not been extensively studied. The inconsistency in the results of mechanical performance is a further indicator of the effects of printing parameters on the mechanical properties of parts, particularly in regard to build orientation, layer thickness or feed rate of PLA samples fabricated by FDM.

In this study, the characterization and assessment of the effect of different process parameters on the mechanical properties of PLA samples fabricated with a low cost desktop 3D printer using FDM technique were examined. Three main process parameters were analysed: build orientation (Flat, On-edge and Upright), layer thickness and feed rate, respectively. These process parameters were selected in order to assess the mechanical response of the printed samples under tensile and flexural loading. The aim was to determine the optimum settings in order to assist users in the correct selection of process parameters. Special attention was paid to the anisotropic response (strength and stiffness) of the printed samples under tensile and flexural loading. Moreover, ABS specimens fabricated by a commercial 3D printer were used for comparative purposes. The results of this study will be useful for defining the best selection of process parameters for optimum mechanical performance and to minimize manufacturing costs. Furthermore, the analysis of the effects of fused deposition modelling process parameters on the mechanical performance of FDM parts are of special interest for the fabrication of continuous reinforced fibre 3D printed structures using the FDM technology [2,3,7,19,40,41]. Finally, the practicality of the previous results was assessed further by testing an functionally static load-bearing assembly as a case example.

2 Experimental methodology

2.1 Materials, 3D printers and specimen preparation

The goal of this study was to analise the mechanical performance of PLA samples using different process parameters. Furthermore, ABS plusTM-P430 samples were used for comparative purposes. Typical values of the main mechanical properties of PLA and ABS materials fabricated by FDM technology [8,26] are presented in Table [1]

| Table 1. Typical range of mechanical properties for PLA and ABS materials fabricated with FDM technology | ||

| Properties | PLA | ABS |

| Tensile Strength | 15.5-72.2 MPa | 36-71.6 MPa |

| Tensile Modulus | 2020-3550 MPa | 99.8-2413 MPa |

| Elongation at Break | 0.5-9.2% | 3-20% |

| Flexural Strength | 52-115.1 MPa | 48-110 MPa |

| Flexural Modulus | 2392-4930 MPa | 1917-2507 MPa |

PLA samples were fabricated using a WitBox desktop 3D printer, manufactured by BQ [42]. WitBox is a low cost desktop printer that uses PLA material with a 0.4 mm nozzle size. WitBox can be controlled with any open source software. In this study, Cura software [43] was used to generate G-code files and to command and control all the process parameters. Furthermore, ABS samples were fabricated using the industrial 3D printer Dimension Elite, developed by Stratasys. The Dimension Elite is a high performance industrial printer that uses ABS material, and is controlled by CatalystEX Software [44], a specific software that can modify only a limited number of process parameters.

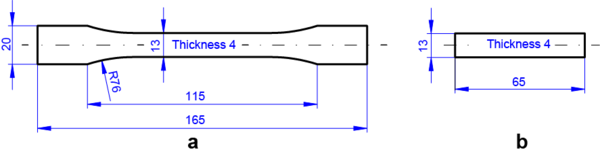

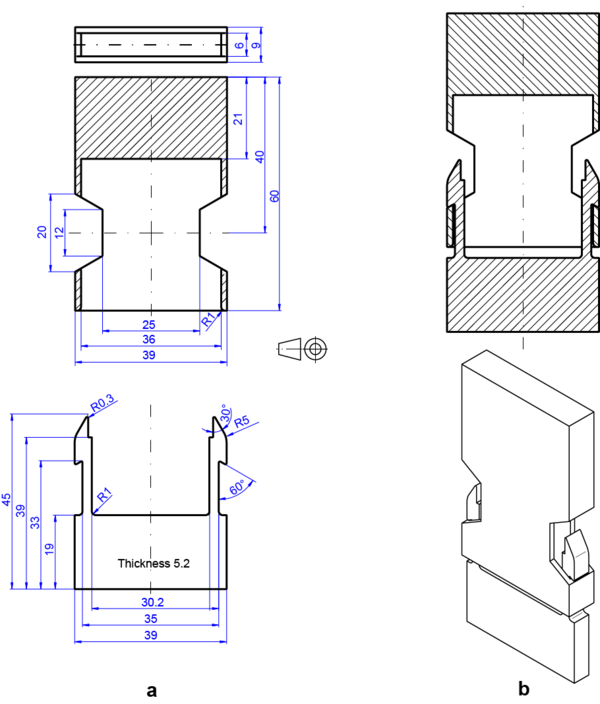

There are no standard test methods for tensile and flexural properties of parts fabricated using FDM. In this work, the ASTM D638 [45] and D790 [46] methods were applied for testing tensile and flexural specimens, respectively. The geometry of the 3D printed specimens were modelled using SolidWorks software, exported as an STL file and imported to the 3D printing software. The geometry of the tensile and flexural specimens are shown in Figure [1].

2.2 Process parameters

Mechanical properties of parts fabricated using FDM technologies depend on the optimal selection of process parameters. This task is not easy as FDM involves a large number of variables that control the 3D printing process. The mechanical performance of FDM processed components primarily depends on five important control variables such as, build orientation, layer thickness, raster angle, raster width, and air gap [4,5,7,8,9].

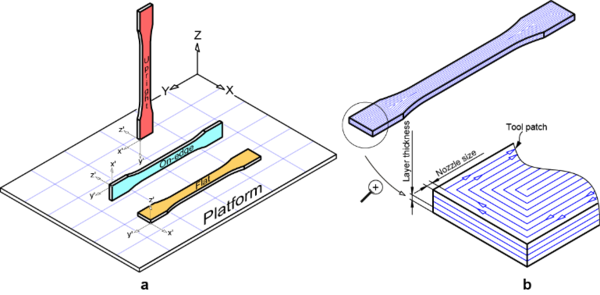

Build orientation has a major role on the structural properties of FDM parts. It refers to how and which direction a sample is placed on the 3D printing build platform. Due to the layered nature of the FDM process, 3D printed materials exhibit anisotropic behaviour that makes structural performance highly dependent on build orientation. The effects of build orientation on mechanical performance of FDM parts have been previously studied [1,4,5,10,38,39] and the highest tensile strength is obtained when the fused filament deposition coincided with the pull direction [6]. However, a range of orientations may be found along this pull direction, which have not been analysed in other studies. In this study, three build orientations were assessed, see Figure 2a : Flat (F) and On-Edge (O), where the fused filament deposition was positioned in the same direction as the pull direction for the tensile case and Upright (U), in which layers were deposited perpendicular to the pull direction.

One of the most important and controversial parameters to determinate the quality of a part fabricated using FDM is the layer thickness (Lt), see Figure 2b. Rankouhi et al. [6] stated that, although layer thickness has been studied extensively, see for examples References [1,9,11,32,38], it should be further analysed, due to the disparity of results. In this work, different layer thickness values were considered in order to analyse the influence of this parameter. These values were selected according to the Witbox 3D printer range. In comparison, in the case of the Dimension Elite 3D printer, only two layer thickness values were analysed due to restrictions in the selection of this parameter. In both cases, layer thickness was measured in the Z direction.

The influence of the raster pattern, air gap, raster angle or raster width in the mechanical performance of FDM printed parts has been extensively studied [23,28]. There is a broad spectrum of infill patterns, making it difficult to analyse the influence of raster pattern. In this work, solid samples filled with a perimeter raster were analysed, which is where the tool paths are the offsets from the perimeter with a distance of the nozzle size, see Figure 2b. Hence, the selected shell thickness was selected long enough to fill the sample, with a raster angle of 0º.

Furthermore, the effect of feed rate (Fr) in the mechanical performance of PLA or ABS samples has not been extensively studied [28]. This process variable is also directly related to build time, and consequently, to manufacturing cost. In a FDM process, if the feed rate is modified, the flow rate of the extruded material must be changed in order to keep a constant width of the perimeter lines. In this study, the influence of the feed rate on mechanical properties was evaluated. Three different feed rates were considered for the WitBox printer. Flow rate was adjusted accordingly. In the case of the Dimension Elite 3D printer, feed rate could not be modified and a fixed feed rate of 43 mm/s was selected. Some parameters, such as air gap, raster angle or temperature, were fixed for all the samples in order to focus on the influence of the previous three parameters (build orientation, layer thickness and feed rate). A complete set of 5 specimens of each of the combinations of variables was printed on both 3D printers.

2.3 Experimental set-up

The experimental series were carried out at the University of Castilla-La Mancha (Spain). Each sample set consisted of five specimens for a given group of process parameters, with a total of 420 specimens (tensile and bending specimens), 360 PLA and 60 of ABS, respectively. Average strength and stiffness values of the mechanical test were taken as the results. Since the physical properties of many materials (especially thermoplastics) can vary depending on ambient temperature, tests were carried out according to the standards for room temperature.

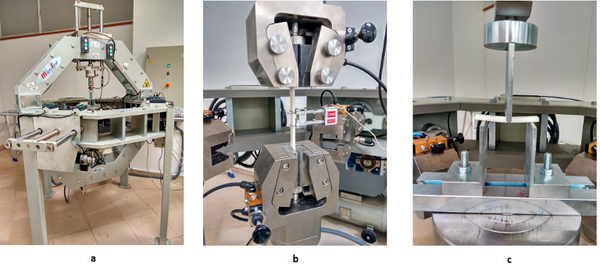

The uniaxial tensile tests were performed following the standard ASTM D638-10 standard [45]. A 50 kN universal electro-mechanical testing machine at a fixed loading rate of 2 mm/min was used for the tensile test, see Figure 3a. Figure 3b shows the set-up of a tensile specimen and test fixture. Strain was measured using a MTS 634.14 high-performance axial extensometer. The experimental data were processed following the recommendations of the previous standard, for the determination of the maximum tensile strength and the tensile Young's modulus. Young's modulus was determined considering the linear part of the stress-strain curve and the slope was estimated by a linear fit. Tensile strength was calculated as a ratio between the maximum load reached during the test and the cross-sectional area.

The 3-point bending tests were performed following the ASTM D790-10 procedure [46] using a three point bending test fixture. Figure 3c shows the set-up of a 3-point bending specimen and test fixture, where the radius of the loading nose and the radii of the support noses were 3 mm. The flexural modulus of elasticity was determined following the previous standard.

3 Results and discussion

An extensive test series was designed to assess the effects of different ranges of three main process parameters (build orientation, layer thickness and feed rate) on the mechanical properties of printed specimens under tensile and flexural loading. Average and standard deviation of the test results of the maximum strengths and stiffnesses for the printed PLA samples are tabulated for the tensile tests and for 3-point bending tests in Table 2 for Fr=43 mm/s.

| Table 2. Average tensile and 3-point bending test results of PLA and ABS samples with a feed rate of 43 mm/s. Standard deviation is depicted in brackets | ||||

| PLA | ||||

| Lt=0.18 mm | Lt=0.24 mm | |||

| Build O. | (MPa) | E (MPa) | (MPa) | E (MPa) |

| Upright | 41.1 (1.7) | 3726.7 (169.6) | 40.5 (3.3) | 3451 (175.5) |

| On-edge | 64.9 (1.8) | 4004.3 (73.1) | 78.1 (0.3) | 4025.5 (58.5) |

| Flat | 77.3 (0.8) | 4017.3 (37.1) | 72.3 (0.2) | 3769.9 (34.8) |

| Build O. | (MPa) | E (MPa) | (MPa) | E (MPa) |

| Upright | 29.9 (0.8) | 1402 (2.5) | 31 (0.4) | 1339 (18) |

| On-edge | 62 (1.5) | 1447 (208) | 61.7 (3.9) | 1717.6 (130.4) |

| Flat | 53.4 (3.6) | 1550 (100.6) | 46 (0.5) | 1546.3 (84) |

| ABS | ||||

| Lt=0.18 mm | Lt=0.24 mm | |||

| Build O. | (MPa) | E (MPa) | (MPa) | E (MPa) |

| Upright | 21 (0.99 | 1931 (21) | 21.9 (0.8) | 1999.5 (22.5) |

| On-edge | 38.5 (0.29 | 2417 (20) | 39.4 (0.1) | 2373 (16) |

| Flat | 26.4 (0.3) | 1541.7 (29.1) | 26.9 (0.4) | 1557.5 (53.5) |

| Build O. | (MPa) | E (MPa) | (MPa) | E (MPa) |

| Upright | 19.5 (0.5) | 642.6 (2) | 18.6 (0.9) | 648 (20.4) |

| On-edge | 33.4 (0.9) | 961 (13.5) | 30.9 (2.7) | 883.6 (41) |

| Flat | 25.4 (0.2) | 712.3 (27) | 26.3 (0.9) | 758.3 (50.5) |

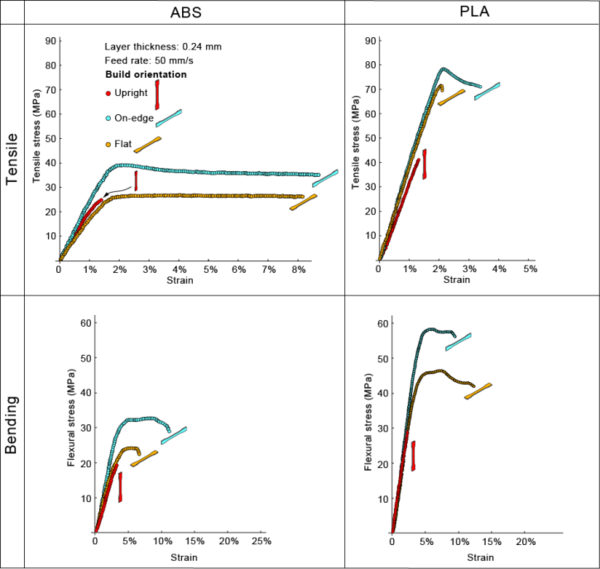

ABS tensile and flexural specimens were fabricated with the industrial 3D printer Dimension Elite for comparative purposes. Due to the limitation of this industrial 3D printer, only a feed rate of 43 mm/s and two different layer thickness (Lt=0.18 mm and 0.24 mm) could be selected. A total of 60 ABS specimens were fabricated and tested. Average and standard deviation of the tensile and flexural test results for the ABS samples are shown in Table 2. The results have shown that PLA samples exhibited strength and stiffness values that are about twice the values of ABS samples. However, even if PLA samples were stronger than ABS samples, they were more brittle. Indeed, the deformation at fracture was about 2-4% for the tensile PLA samples and more than 8% for the ABS ones, see Figure 4. PLA offers better thermomechanical characteristics than ABS, having a stronger mechanical resistance and a lower thermal expansion.coefficient. On the other hand, the most important disadvantage of PLA compared with ABS is the lower durability due to its biodegradability [5].

4 Functional structure test results

A two-part arbitrary functional structural assembly was designed and manufactured using the process parameters selected for the 3D printed samples described in the previous section. The goal of this section was to demonstrate the practicality of the previous results in terms of the selection of the optimum process parameters for maximizing the mechanical performance of a structural functional component and to minimize manufacturing costs. This assembly was selected as a functional static load-bearing structural component. Figure 5 depicts the geometry of the proposed structural assembly and its main dimensions. Table 3 shows the average and standard deviation of the maximum load at failure for the selected combinations of build orientation, layer thickness, and feed rate process parameters, respectively.

As expected from the tensile test results of Table 3, functional load bearing samples with Lt=0.06 mm depicted higher mechanical strength compared to samples with Lt=0.24 mm.

On the other hand, in the case of the upright orientation, an increase in mechanical strength was observed whith increased layer thickness. The effects of build orientation were also as expected, with on-edge build orientation resulting in the highest value for force at failure, followed by flat orientation. In addition, the effects of feed rate were also as expected, with a reduction of the force at failure and an increase in feed rate. Furthermore, the maximum strength for the on-edge and flat orientations were slightly affected by the feed rate. Hence, the combination of layer thickness, build orientation and feed rate have a significant effect on the final strength of the functional assembly, showing variations in terms of average values between different process parameter sets in the range of 149-341 N, respectively.

| Table 3. Average maximum load of tensile test results of the PLA functional assembly with different process parameters ranges. Standard deviation is show in brackets | |||

| Lt=0.06 mm | |||

| Fr=20 mm/s | Fr=50 mm/s | Fr=80 mm/s | |

| Build Orientation | Fmax(N) | Fmax(N) | Fmax(N) |

| Upright | 194 (26.3) | 163 (22.1) | 149 (19.6) |

| On-edge | 341 (32.7) | 339 (20.7) | 328 (14.5) |

| Flat | 335 (26.9) | 329 (21.2) | 320 (53.4) |

| Lt=0.24mm | |||

| Fr=20 mm/s | Fr=50 mm/s | Fr=80 mm/s | |

| Build Orientation | Fmax(N) | Fmax(N) | Fmax(N) |

| Upright | 223 (29.7) | 192 (18.9) | 174 (17.6) |

| On-edge | 334 (31.9) | 328 (5.3) | 323 (23.6) |

| Flat | 327 (10.5) | 321 (19.1) | 317 (31.9) |

5 Conclusions

In this work, the characterization and the assessment of the effect of different process parameters on the mechanical properties of PLA samples fabricated with a low cost desktop 3D printer using FDM technique were examined. Evaluation of the mechanical properties is necessary if functional parts are manufactured using low cost 3D printers. The purpose of this study was to provide practical suggestions for optimal process parameter selection to improve the mechanical performance of 3D printed parts. The literature review has underscored the amount of research aimed at improving the mechanical properties and part quality of ABS parts fabricated by FDM. However, the relationship between process parameters and the quality and mechanical properties of parts has received little attention, particularly for PLA printed materials fabricated with FDM technology. In addition, very little work has been done both in terms of material characterization and FDM process optimization. In this study, different ranges of three main process parameters were analysed: build orientation, layer thickness and feed rate. In addition, manufacturing costs were evaluated as a function of the printing time. Tensile and three-point bending test series were carried out to determine the mechanical response of the printed specimens following the ASTM standard recommendations.

The analysis of the experimental results reveals the impact of process parameters on the mechanical performance of PLA samples. The results have shown that components printed using FDM technology are anisotropic in nature, and build orientation had a significant impact on the mechanical properties of the PLA samples. Therefore to maximize part strength and stiffness, an on-edge orientation is desirable, where possible, as it has been shown to have the highest strength and stiffness, the best failure performance (ductile fracture and maximum plastic strain) and optimum manufacturing costs as a function of the printing time. Furthermore, in this case, the optimal selection of process parameters to maximize failure performance was high feed rate values with low layer thickness values or the opposite combination (low feed rate values with high layer thickness values). In both cases, tensile and flexural strength and stiffness, failure behaviour and manufacturing costs were very similar. Whereas, if the upright orientation is selected, high layer thickness values and low feed rate values are recommended in order to maximize strength and reduce manufacturing costs.

As the geometry of parts fabricated by FDM technology may be complex, it is desirable to select a combination of process parameters that provide the resulting mechanical properties as isotropic as possible with the lowest printing time. This conclusion was also corroborated by testing a functional structural assembly as a practical 3D printed part..

The lack of experimental data in the literature as well as the study of potential variables such as extruder temperature, shell thickness or build material, underscore the need for further research to improve our understanding of the optimal settings and the mechanical behaviour of 3D printed components Moreover, studies are required to assess the impact on strength, wear or thermal and electrical properties of 3D printed materials in order to determine the applicability to high-performance 3D printed parts. Finally, the analysis of the effects of process parameters on the mechanical performance of FDM parts is of special interest for the fabrication of continuous fibre reinforced 3D printed structures using FDM technology [2,3,7,19,40,41].

Acknowledgements

This research was supported by the Spanish Ministerio de Economía y Competitividad (Plan Nacional I+D+i), under research grants DPI2015-65472-R and DPI2015-77715R, co-financed by the ERDF (European Regional Development Fund) and Grants GI20163590 and GI20174014financed by Univerisity of Castilla-La Mancha

References

[1] B. M. Tymrak, M. Kreiger, J. M. Pearce, Mechanical properties of components fabricated with open-source 3D printers under realistic environmental conditions, Materials and Design 58 (2014) 242–246.

[2] M. Sugavaneswaran, G. Arumaikkannu, Analytical and experimental investigation on elastic modulus or reinforced additive manufactured structure, Materials and Design 66 (2015) 29–36.

[3] G.W. Melenka, B. K. O. Cheung, J. S. Schofield, M. R. Dawson, J. P. Carey, Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures, Composite Structures 153 (2016) 866–875.

[4] M. Domingo, J. M. Puigriol, A. A. Garcia, J. Lluma, S. Borros, G. Reyes, Mechanical property characterization and simulation of fused deposition modeling polycarbonate parts, Materials and Design 83 (2015) 670–677.

[5] C. Casavola, A. Cazzato, V. Moramarco, C. Pappalettere, Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory, Materials and Design 90 (2016) 453–458.

[6] B. Rankouhi, S. Javadpour, F. Delfanian, T. Letcher, Failure analysis and mechanical characterization of 3D printed ABS respect to later thickness and orientation, Journal of Failure Analysis and Prevention 16 (2016) 467–481.

[7] F. Ning, W. Cong, Y. Hu, H. Wang, Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: effects of process parameters on tensile properties, Journal of Composites Materials 28 (2016) 1–12.

[8] A. Lanzotti, M. Grasso, G. Staiano, M. Martorelli, The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3D printer, Rapid Prototyping journal 21 (2015) 604–617.

[9] A. K. Sood, R. K. Ohdar, S. S. Mahapatra, Parametric appraisal of mechanical property of fused deposition modelling processed parts, Materials and Design 31 (2010) 287–295.

[10] R. Zou, Y. Xia, S. Liu, P. Hu, W. Hou, Q. Hu, C. Shan, Isotropic and anisotropic elasticity and yielding of 3D printed material, Composites Part B 99 (2016) 506–513.

[11] R. Anhita, S. Arunachalam, P. Radhakrishnan, Critical parameters influencing the quality of prototypes in fused deposition modelling, Journal of Materials Processing Technology 118 (2001) 385–388.

[12] M. Vaezi, C. K. Chua, Effects of layer thickness and binder saturation level parameters on 3D printing process, International Journal of Advanced Manufacturing Technology 53 (2011) 275–284.

[13] F. H. Liu, Fabrication of bioceramic bone scaffolds for tissue engineering, Journal of Materials Engineering and Performance 23 (2014) 3762–3769.

[14] C. Jiang, G. F. Zhao, A preliminary study of 3D printing on rock mechanics, Rock Mechanics and Rock Engineering 48 (2015) 1041–1050.

[15] T. M. Rankin, N. A. Giovinco, D. J. Cucher, G. Watts, B. Hurwitz, D. G. Armstrong, Three-dimensional printing surgical instruments: are we there yet?, Journal of Surgical Research 189 (2014) 193–197.

[16] M. Castilho, I. Pires, B. Gouveia, J. Rodrigues, Structural evaluation of sca_olds prototypes produced by three-dimensional printing, International Journal of Advanced Manufacturing Technology 56 (2011) 561–569.

[17] D. J. Thomas, Z. Tehrani, B. Redfearn, 3D printed composite microfluidic pump for wearable biomedical applications, Additive Manufacturing 9 (2016) 30–38.

[18] K. Bassett, R. Cariveau, D. S. K. Ting, 3D printed wind turbines part 1: design considerations and rapid manufacture potential, Sustainable Energy Technologies and Assessments 11 (2015) 186–193.

[19] R. Matsuzaki, M. Ueda, M. Namiki, K. Joeong, H. Asahara, K. Horiguchi, T. Nakamura, A. Todoroki, Y. Hirano, Three dimensional printing of continuous fibre composites by in-nozzle impregnation, Scientific Reports 6 (2016) 23058.

[20] J. M. Chacon, J. C. Bellido, A. Donoso, Integration of topology optimized designs into CAD/CAM via an IGES translator, Structural and Multidisciplinary Optimization 50 (2014) 1115–1125.

[21] A. Donoso, J. C. Bellido, J. M. Chacon, Numerical and analytical method for the design of piezoelectric modal sensors/actuators for shell-type structures, International Journal for Numerical Methods in Engineering 81 (2010) 1700–1712.

[22] J. M. Chacon, F. P. Garcia, M. Papaelias, Railroad inspection based on ACFM employing a non-uniform B-spline approach, Mechanical Systems and Signal Processing 42 (2013) 605–617.

[23] W. Wu, P. Geng, G. Li, D. Zhao, H. Zhang, J. Zhao, Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS, Materials 8 (2015) 5834–5846.

[24] B. P. Conner, G. P. Manogharan, A. N. Martof, L. M. Rodomsky, C. M. Rdomsky, D. C. Jordan, J. W. Limperos, Making sens of 3D printing: Creating a map of additive manufacturing products and services, Additive manufacturing 1-4 (2014) 64–76.

[25] A. R. Torrado, C. M. Shemelya, J. D. English, Y. Lin, R. B. Wicker, D. A. Roberson, Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing, Additive manufacturing 6 (2015) 16–29.

[26] J. Kotlinski, Mechanical properties of commercial rapid prototyping materials, Rapid prototyping Journal 20 (2014) 499–510.

[27] F. van der Klift, Y. Koga, A. Todoroki, M. Ueda, Y. Hirano, R. Matsuzaki, 3D printing of continuous carbon fibre reinforced thermo-plastic CFRTP tensile test specimens, Open journal of composite materials 6 (2016) 18–27.

[28] O. A. Mohamed, S. H. Masood, J. L. Bhowmik, Optimization of fused deposition modeling process parameters: a review of current research and future prospects, Advances in Manufacturing 3 (2015) 42–53.

[29] A. Farzadi, M. Solati-Hasjin, M. Asadi-Eydivand, N. A. A. Osman, E_ect of layer thickness and printing orientation on mechanical properties and dimensional accuracy of 3D printed porous samples for bone tissue engineering, PLoS ONE 9.

[30] E. Ullu, E. Korkmaz, K. Yay, O. B. Ozdoganlar, L. B. Kara, Enhancing the structural performance of additively manufactured objects through build orientation optimization, Journal of Mechanical Design 137 (2015) 111410–111419.

[31] J. F. Rodriguez, J. P. Thomas, J. E. Renaud, Design of fused-deposition ABS components for stiffness and strength, Journal of Mechanical Design 125 (2003) 545–551.

[32] B. H. Lee, J. Abdullah, Z. A. Khan, Optimization of rapid prototyping parameters for production of flexible ABS object, Journal of Materials Processing Technology 169 (2005) 54–61.

[33] J. F. Rodriguez, J. P. Thomas, J. E. Renaud, Mechanical behavior of acrylonitrile butadiene styrene ABS fused deposition materials. Experimental investigation, Rapid prototyping Journal 7 (2001) 148–158.

[34] G. W. Melenka, J. S. Schofield, M. R. Dawson, J. P. Carey, Evaluation of dimensional accuracy and material properties of the makerbot 3D desktop printer, Rapid prototyping Journal 21 (2015) 618–627.

[35] M. A. Caminero, S. Pavlopoulou, M. Lopez-Pedrosa, B. G. Nicolaisson, C. Pinna, C. Soutis, Analysis of adhesively bonded repairs in composites: Damage detection and prognosis, Composites Structures 95 (2013) 500–517.

[36] M. A. Caminero, M. Lopez-Pedrosa, C. Pinna, C. Soutis, Damage monitoring and analysis of composite laminates with an open hole and adhesively bonded repairs using digital image correlation, Composites Part B 53 (2013) 76–91.

[37] M. A. Caminero, G. P. Rodriguez, V. Munoz, E_ect of stacking sequence on charpy impact and flexural damage behavior of composite laminates, Composite Structures 136 (2016) 345–357.

[38] S. H. Ahn, M. Montero, D. Odell, S. Roundy, P. K. Wright, Anisotropic material properties of fused deposition modelling ABS, Rapid Prototyping journal 8 (2002) 248–257.

[39] C. S. Lee, S. G. Kim, S. H. Ahn, Measurement of anisotropic compressive strength of rapid prototyping parts, Journal of Materials Processing Technology 8 (2002) 248–257.

[40] Z. Li, A. Haigh, C. Sotis, A. Gibson, R. Sloan, N. Kariman, Detection and evaluation of damage in aircraft composites using electromagnetically coupled inductors, Composite Structures 140 (2016) 252–261.

[41] F. Ning,W. Cong, J. Qiu, J.Wei, S.Wang, Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling, Composites Part B 80 (2015) 369–378.

[42] BQ, BQ witbox, https://www.bq.com/es/witbox-2.

[43] Ultimaker, CURA software, https://ultimaker.com/en/products/cura-software.

[44] Stratasys, Catalystex software, http://www.stratasys.com/3d-printers/design-series/dimension-1200es.

[45] D638, ASTM standard test method for tensile properties of plastics, Annual book of ASTM standards 10 (2010) 1–16.

[46] D790, ASTM standard test method for flexural properties of unreinforced and reinforced plastics and electrical insulating materials, Annual book of ASTM standards 10 (2010) 1–11.

[47] F. Mujika, On the effect of shear and local deformation in three-point bending test, Polymer Testing 26 (2007) 869–877.

[48] T. M. Wang, J. T. Xi, Y. Yin, A model research for prototype warp deformation in the FDM process, The International Journal of Advanced Manufacturing Technology 33 (2007) 1087–1096.

[49] Q. Sun, G. M. Rizvi, C. T. Bellehumeur, P. Gu, Effect of processing conditions on the bonding quality of FDM polymer filaments, Rapid prototyping Journal 14 (2008) 72–80.

Document information

Published on 31/03/22

Accepted on 31/03/22

Submitted on 30/03/22

Volume 03 - Comunicaciones Matcomp17 (2019), Issue Núm. 3 - Procesos de Fabricación II y Materiales Avanzados, 2022

DOI: 10.23967/r.matcomp.2022.03.010

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?