Abstract

Combined with transmission mode of cycloid permanent magnet gear and ring plate mechanical gear, a three-shaft ring-plate permanent magnet gear transmission structure (TRMG) is proposed and the operating mechanism of structure is given. TRMG simulation model is established and the correctness is verified by transient finite element method. Based on momentum moment theorem, TRMG start-up process and start-up position of are analyzed theoretically. By calculating TRMG torque impulse, the optimal start-up range and start-up position of TRMG are determined.

Keywords: Multi-axle ring-plate permanent magnet gear, start-up characteristics, start-up position, dynamic characteristics

1. Introduction

Start-up characteristics refer to the dynamic characteristics of driven rotor at rated load condition from stationary to stable operation stage. Mechanical gearbox, as an important core component of electromechanical transmission system, bears a large impact load in start-up process. With the increase of service frequency, a series of faults such as oil leakage, shaft channeling and tooth damage often occur in mechanical gearbox [1,2].

The non-contact transmission of permanent magnet gear using air gap magnetic field solve the damage caused by starting process of mechanical gear, and realize the conversion requirements between low speed and high speed and low torque which has a broad application prospect [3-5].

Literature [6] based on the principle of mechanical Cycloid Gear transmission, a transmission structure of Cycloid permanent Magnetic Gear, CMG is proposed, which has high transmission ratio and high torque density (Transmission ratio≥20, Torque density≥180kNm/m3). Since then, scholars have studied the transmission structure, magnetization, bearing capacity and eddy current loss of CMG, and further improved the transmission ratio and torque density of structure (Transmission ratio≥100, Torque density≥280kNm/m3) [7-10].

Although CMG has large transmission ratio and torque density, its service life is relatively short due to a large unbalanced magnetic pull by internal rotor shaft. In addition, the start-up characteristics of CMG have not been studied in the above literatures [11,12].

In order to improve the service life of CMG rotating arm bearing and solve start-up characteristics, this paper proposes a three-shaft ring-plate permanent magnet gear transmission structure (TRMG) based on ring-plate mechanical gear transmission mode. Compared with CMG, TRMG moves the rotating arm bearing to the outside of the cycloid wheel to increase the number of rotating arm bearing, disperse the payload of rotating arm bearing and prolong the service life of rotating arm bearing. In addition, this paper uses theorem of momentum moment to analyze the start-up position of TRMG and determine the optimal start-up range and start-up position of TRMG.

2. TRMG Operation mechanism

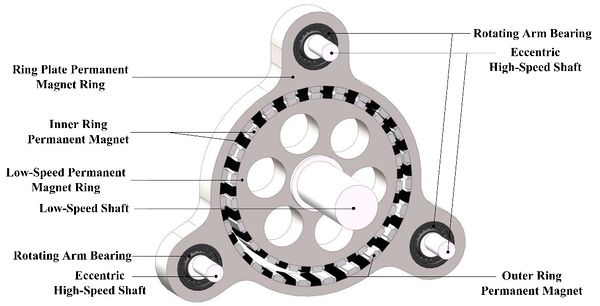

Figure 1 shows the mechanical structure of TRMG. In Figure 1, three eccentric high-speed shafts are connected with ring plate permanent magnet ring through rotating arm bearings. The ring plate permanent magnet ring consists of outer yoke iron and outer ring permanent magnet, and is located outside the low-speed permanent magnet ring. The low-speed permanent magnet ring is composed of inner yoke iron and inner ring permanent magnet, and a low-speed shaft is installed in the center.

|

| Figure 1. TRMG mechanical structure |

In Figure 1, the center distances of three eccentric high-speed shafts to low-speed shaft are equal to the eccentricity between ring plate permanent magnet ring and low-speed permanent magnet ring. The low-speed permanent magnet ring rotates around the center of low-speed shaft.

When the eccentric high-speed shaft moves the ring plate permanent magnet ring, the outer ring permanent magnet revolves around the inner ring permanent magnet. As the relative position of two permanent magnets changes, the permanent magnet embedded in low-speed permanent magnet ring is driven to rotate low-speed shaft by the change of magnetic field force.

Due to the large difference between the eccentricity and the radius of the low-speed permanent magnet ring, a large transmission ratio can be achieved.

Set transmission ratio of TRMG as , and pole pairs of inner ring permanent magnet and outer ring permanent magnet as and , respectively, then:

|

|

(1) |

Since the pole pairs of outer ring permanent magnet is always one more than that of inner ring permanent magnet, when the ring plate permanent magnet ring revolves around the low-speed permanent magnet ring once, the low-speed permanent magnet ring rotates a pair of magnetic poles in reverse.

3. TRMG start-up position analysis

Set the eccentric high-speed shaft be driving shaft (the active motion of ring plate permanent magnet ring), and the low-speed shaft be driven shaft (the connection load of low-speed permanent magnet ring), and the starting angle between ring plate permanent magnet ring and low-speed permanent magnet ring is , and the output torque of low-speed permanent magnet ring is . It can be seen from literature [13-15] that:

|

|

(2) |

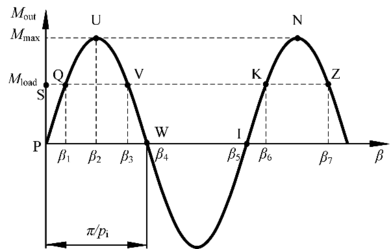

In Equation (2), is the static maximum torque. Figure 2 shows the relationship between and .

|

| Figure 2. Mout and β curve |

In Figure 2, when starting angle is , , or the output torque of point Q, V, K or Z is equal to the load torque . When the starting angle is , the output torque of point U is the static maximum torque . When the starting angle is 0, or , the structures of point P, W or I are in start-up equilibrium position.

Set the difference between output torque and load torque as , then:

|

|

(3) |

|

|

(4) |

|

|

(5) |

In Equations (4) and (5), is the inertia of low-speed permanent magnet ring, is its angular velocity and is the change of angular velocity.

When the relative rotation angle between the ring plate permanent magnet ring and the low-speed permanent magnet ring increases from 0 to , set the work done by on the rotor be , then:

|

|

(6) |

Substituting Equations (4) and (5) into Equation (6), and the equation (6) is transformed by equality, we can get:

|

|

(7) |

It can be seen from Figure 2 that the first integral in Equation (7) can be approximately regarded as the area of . When TRMG runs at curve PQ, the forward electromagnetic torque of low-speed permanent magnet ring is less than load torque, and the reverse acceleration can be obtained. Therefore, Equation (7) can be written as:

|

|

(8) |

Substitute Equation (3) into Equation (6), then:

|

|

(9) |

Equation (8) can be simplified as follows:

|

|

(10) |

In Equation (10), TRMG starts from static state, so .

According to Equation (10), if is larger, the reverse acceleration kinetic energy and reverse impulse obtained by low-speed permanent magnet ring are larger at this stage, and TRMG is more difficult to start, so it is called deceleration area.

Similarly, when the relative angle between the ring-plate permanent magnet ring and the low-speed permanent magnet ring increases from to , set the work done by on rotor be , then:

|

|

(11) |

The integral of first term in Equation (11) can be approximated as area. As TRMG runs at curve QV, the forward electromagnetic torque received by low-speed permanent magnet ring is greater than load torque, and the forward acceleration can be obtained. Therefore, Equation (11) can be expressed as:

|

|

(12) |

Equation (12) can be simplified as follows:

|

|

(13) |

According to Equation (13), if is larger, the forward acceleration kinetic energy and forward torque impulse obtained by rotor can more easily offset the reverse impulse when , and TRMG can more easily start-up, so it is called acceleration area.

4. TRMG start-up process analysis

Set the relative rotation angle of ring plate permanent magnet ring and low-speed permanent magnet ring is .

According to the operation mechanism of TRMG, due to TRMG is in equilibrium position before start-up, the output torque of TRMG is 0 as the force between air gap magnetic fields of the ring plate permanent magnet ring and the low-speed permanent magnet ring is balanced. At this point, the equilibrium position of TRMG can be divided into two kinds: one is that when TRMG is start-up, increases positively with increase. The other is that when TRMG is start-up, reverse increases with α increase.

Set the starting point of TRMG is started at equilibrium position of forward torque period, and the active rotor is generated a forward rotating magnetic field by the action of magnetic field air gap.

When , there is a slip between ring plate permanent magnet ring and low-speed permanent magnet ring, and the forward electromagnetic torque of low-speed permanent magnet ring is less than load torque, the low-speed permanent magnet ring speeds up in reverse rotation and generates a reverse impulse of . TRMG does not start properly at this stage.

When , the electromagnetic torque of low-speed permanent magnet ring is always larger than load torque, and the forward angular acceleration can be obtained and the forward impulse of can be generated. Since the low-speed permanent magnet ring has acquired the reverse impulse of to accelerate in reverse, the low-speed permanent magnet ring decelerates in reverse and then accelerate in forward direction by the action of forward torque impulse.

If , before increases to , the low-speed permanent magnet ring reaches synchronous speed of rotating magnetic field, and TRMG enters adjustment stage of speed and torque. By combined action of magnetic and mechanical damping, TRMG oscillation gradually attenuates, and the rotational speed and torque gradually become stable.

If , enters interval , the forward electromagnetic torque of low-speed permanent magnet ring is less than load torque, which makes it decelerate forward first and then accelerate backward. Due to the speed of low-speed permanent magnet ring is still less than synchronous speed of rotating magnetic field, and TRMG accelerates in reverse by combined action of reverse electromagnetic torque and load torque, which eventually leads to start-up failure.

The above analysis shows that:

(1) If TRMG start-up smoothly, the low-speed permanent magnet ring should reach synchronous speed by sufficient forward electromagnetic torque impulse in interval.

(2) If (acceleration area) remains same, adjust to reduce (deceleration area), so as to reduce the reverse torque impulse of low-speed permanent magnet ring, easy to start-up.

When , TRMG can start-up normally. When , TRMG may not start-up. When , TRMG cannot start-up, so the start-up position determines whether TRMG starts smoothly.

5. TRMG finite element simulation analysis

Due to ANSYS Maxwell simulation software cannot dynamically simulate the object rotating around eccentric axis, in order to verify the start-up position theory, the operation mode of TRMG is changed, and the TRMG operation process is judged by verifying the dynamic characteristics of the changed model.

5.1 TRMG model transformation

Referring to the various operation modes of cycloidal permanent magnet gear, TRMG can be changed into five operation modes:

(1) The ring plate permanent magnet ring rotates only around the axis of low-speed permanent magnet ring, and the low-speed permanent magnet ring rotates around its own axis. At this time, the direction of input and output speed is opposite.

(2) The low-speed permanent magnet ring rotates only around the axis of ring plate permanent magnet ring, and the ring plate permanent magnet ring rotates around its own axis. At this time, the direction of input and output speed is the same.

(3) The ring plate permanent magnet ring is fixed, and the low-speed permanent magnet ring rotates around its axis and revolves around the axis of the ring plate permanent magnet ring. At this time, the direction of input and output speed is opposite.

(4) The low-speed permanent magnet ring is fixed, and the ring plate permanent magnet ring rotates around its axis and revolves around the axis of the low-speed permanent magnet ring. At this time, the direction of input and output speed is the same.

(5) Both the ring plate and the low-speed permanent magnet ring rotate around their own shafts. At this time, the transmission mode is similar to that of the traditional internal meshing gear, and the input and output speed directions are the same.

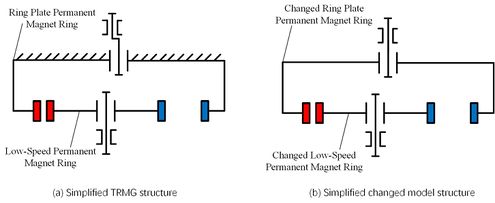

Among the 5 types mentioned above, (1) is the motion mode of TRMG, and (2)~(5) are the motion mode of TRMG after fixing different TRMG components. For (1), (2), (3) and (4), there are rotation movement around the eccentric axis, so Ansys Maxwell cannot be used for dynamic simulation. For the motion mode (5), the ring plate and the low-speed permanent magnet ring both move around their own shafts in a fixed axis, which can be accurately simulated dynamically. Therefore, we finally changed TRMG into model (5). If the dynamic characteristics of model (5) meet the design requirements of transmission ratio and torque density after modification, the dynamic characteristics of TRMG can also meet the same requirements under the same structural size, rated power and rated load conditions of the model. The mechanism diagram of TRMG and its changed model (5) is shown in Figure 3.

|

| Figure 3. Simplified TRMG and changed model structure |

According to the operation principle of planetary gear with small tooth difference, the simplified structure of TRMG and changed model are shown in Figure 3.

Set the transmission ratio of model (5) is , the speed of low-speed permanent magnet ring is , the speed of ring-plate permanent magnet ring is , and its revolution speed is . For transmission scheme (1), adding a rotational speed around the axis of low-speed permanent magnet ring to the whole mechanism can be converted into the changed structure (5) as shown in Figure 3 (b). The changed mechanism transmission ratio is:

|

|

(14) |

Since the plate permanent magnet ring does not rotate around its axis, .

5.2 Dynamic characteristics of TRMG equivalent model

Set TRMG transfer power , output speed , transmission ratio , TRMG structure parameters as shown in Table 1 can be obtained.

| Symbol | Description | Value (Unit) |

|---|---|---|

| Pole pairs of inner permanent magnet | 22 | |

| Pole pairs of outer permanent magnet | 23 | |

| Inner radius of outer yoke iron | 96(mm) | |

| Outer radius of ring plate permanent magnet ring | 100(mm) | |

| Inner radius of the ring plate permanent magnet ring | 94(mm) | |

| Outer radius of low-speed permanent magnet ring | 90(mm) | |

| Inner radius of low-speed permanent magnet ring | 84(mm) | |

| Outer radius of inner yoke iron | 88(mm) | |

| Inner yoke iron thickness | 15(mm) | |

| Outer yoke iron thickness | 15(mm) | |

| Eccentricity | 3(mm) | |

| Magnetization | -890000(A/m) | |

| Vacuum permeability | ||

| Relative permeability | 1.0997 | |

| Permanent magnet remanence | 1.21(M) |

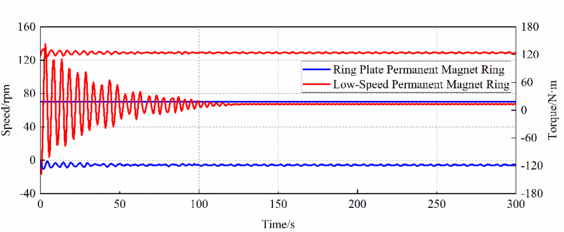

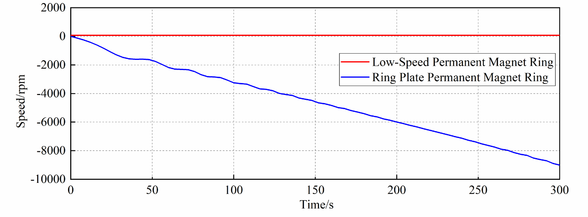

According to the changed model transmission ratio, the input speed of ring plate permanent magnet ring is , and the load torque of low-speed permanent magnet ring is . The dynamic characteristic curve of changed model is shown in Figure 4.

|

| Figure 4. TRMG characteristic curve |

From Figure 4, the electromagnetic torque and output speed of low-speed permanent magnet ring change regularly with time, finally converging to , around , and , meeting the design requirements. The ratio of input to output of speed and torque is about 22/23, which meets the transmission ratio design requirements in Equation (14).

5.3 TRMG start-up characteristic analysis

Changing the starting angle between ring plate permanent magnet ring and low-speed permanent magnet ring . In Figure 2, point P, Q, U and V as starting point which are the left of interval , , and .

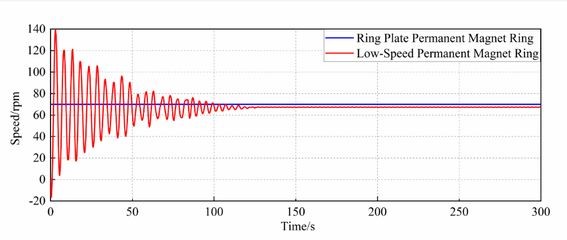

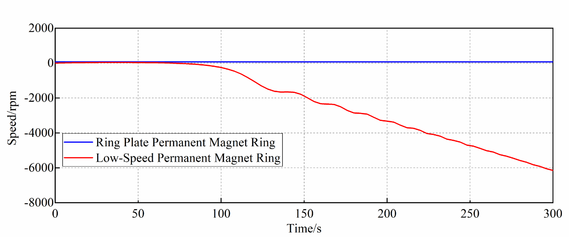

Figure 5 shows the speed and torque characteristic curve with starting point P.

|

| (a) Starting speed curve at point P |

|

| (b) Starting torque curve at point P |

| Figure 5. Speed and torque characteristic curve start with starting point P |

From Figure 5, it can be seen that from moment 0, the electromagnetic torque of low-speed permanent magnet ring gradually increases from 0 and changes periodically. Its rotating speed accelerates in opposite direction. So TRMG fails to start normally at point P. Because when , the forward electromagnetic torque of low-speed permanent magnet ring is smaller than load torque, and the low-speed permanent magnet ring accelerates to rotate in opposite direction. When , the forward impulse on the low-speed permanent magnet ring cannot offset the reverse impulse generated in interval , which prevents it from accelerating to the synchronous speed of rotating magnetic field. When , the reverse acceleration continues under the combined action of reverse electromagnetic torque and the load torque, which eventually leads to start-up failure.

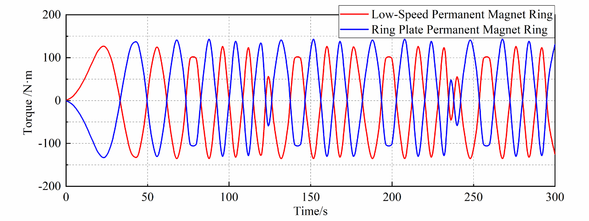

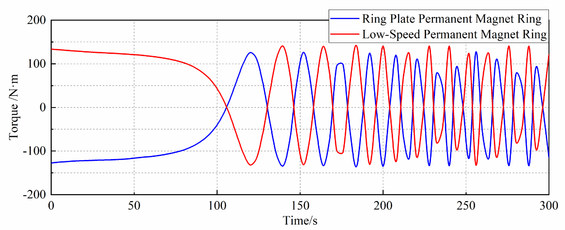

Figure 6 shows the speed and torque characteristic curve with starting point Q.

|

| (a) Starting speed curve at point Q |

|

| (b) Starting torque curve at point Q |

| Figure 6. Speed and torque characteristic curve start with starting point Q |

From Figure 6, it can be seen that from moment 0, the low-speed permanent magnet ring gradually increases and periodically changes from electromagnetic torque equal to load torque, and the speed gradually increases from 0 and stabilizes gradually after vibration. TRMG starts smoothly. This is because: when , the forward electromagnetic torque impulse of the low-speed permanent magnet ring is greater than the load torque from moment 0, and the deceleration area is avoided. So that the speed of the low-speed permanent magnet ring reaches synchronous speed of rotating magnetic field smoothly, and the speed and torque curve gradually converge.

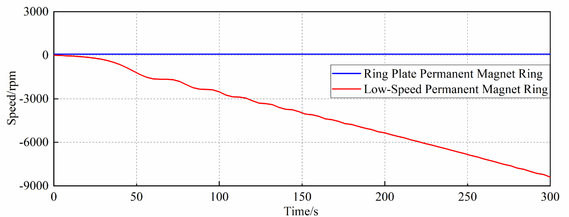

Figure 7 shows the speed and torque characteristic curve with starting point U.

|

| (a) Starting speed curve at point U |

|

| (b) Starting torque curve at point U |

| Figure 7. Speed and torque characteristic curve start with starting point U |

From Figure 7, it can be seen that from moment 0, the electromagnetic torque of the low-speed permanent magnet ring which is equal to the maximum torque, starts to decrease gradually and shows periodic changes. The speed first rotates forward and then decreases in reverse direction. This is because: when , the forward torque impulse of the low-speed permanent magnet ring is larger than the load torque and causing it rotates forward. But its forward impulse is not sufficient to reach the synchronous speed of rotating magnetic field. Therefore, when continues to increase and enters interval, the low-speed permanent magnet ring continues to accelerate in opposite direction, which ultimately leads to the failure of TRMG start-up.

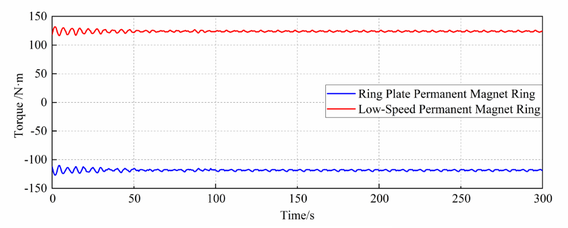

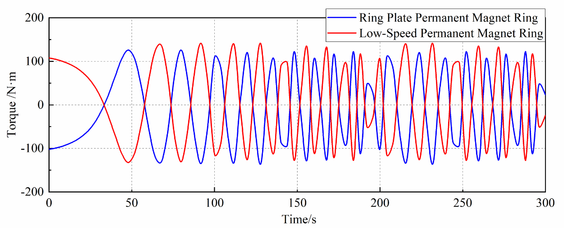

Figure 8 shows the speed and torque characteristic curve with starting point V.

|

| (a) Starting speed curve at point V |

|

| (b) Starting torque curve at point V |

| Figure 8. Speed and torque characteristic curve start with starting point V |

From Figure 8, it can be seen that from moment 0, the electromagnetic torque of low-speed permanent magnet ring shows periodic changes and starts to decrease gradually from equal to the load torque. The speed accelerates reversely from 0. This is because: when , the electromagnetic torque of the low-speed permanent magnet ring is less than the load torque, and the torque difference gradually increases with increasing, which makes the low-speed permanent magnet ring reverse speed up rotation. After TRMG enters negative electromagnetic torque period, TRMG accelerates reverse rotates under the action of load torque and negative electromagnetic torque, which eventually leads to start-up failure.

6. Conclusions

(1) Based on structure mechanism of mechanical ring-plate drive mechanism, TRMG magnetic structure is proposed, and the operation mechanism and changed model of the model are elaborated. The dynamic verification model by finite element software shows that the simulation results are equivalent to the theoretical design output, which proves the established model is correct.

(2) Through the analysis of the starting position, it can be seen that interval in Figure 2 is the optimal starting interval of TRMG, and point Q is the optimal starting point.

(3) If TRMG can be started successfully, the deceleration interval of low-speed permanent magnet ring should be minimized. and increase acceleration interval to achieve synchronous speed of coupled magnetic field.

Acknowledgement

This work was funded by the National Natural Science Foundation of China (Grant No.51375063), and also sponsored by the Natural Science Research Project of Liaoning Province Education Department (Grant No.JDL2020001) and partly funded by the Technological Innovation Research Foundation Project of Dalian (Grant No.2018J12SN071).

References

[1] Chen X.F., LI J.M., Cheng H., Li B., He Z.J. Research and application of condition monitoring and fault diagnosis technology in wind turbines. Journal of Mechanical Engineering, 47(9):45-52, 2011.

[2] Kang Y.F., Luan J.Y., Tian Y., Zheng H.Q., Cao J.H. Application of the order tracking analysis in gear wearing. Journal of Vibration and Shock, 25(4):112-113+118+180, 2006.

[3] Jing L.B., Zhang Y., Huang Z., Chen J.L. Development course and research question ofmMagnetic gear. Journal of Mechanical Transmission, 43(1):165-170, 2019.

[4] Atallah K., Rens J., Mezani S., Howe D. A novel “pseudo” direct-drive brushless permanent magnet machine. IEEE Transactions on Magnetics, 44(11):4349-4352, 2008.

[5] Rens J., Atallah K., Calverley S.D., Howe D. A novel magnetic harmonic gear. IEEE Transactions on Industry Applications, 46(1):206-212, 2010.

[6] Jorgensen F., Andersen T., Rasmussen P. The cycloid permanent magnetic gear. IEEE Transactions on Industry Applications, 6(44):1659-1665, 2008.

[7] Rens J., Clark R., Calverley S., Howe D. Design, analysis and realization of a novel magnetic harmonic gear. IEEE Transactions on Industry Applications, 46(1):206-212, 2009.

[8] Davey K., Hutson T., Mcdonald L., Hutson G. The design and construction of cycloidal magnetic gears. 2017 International Conference on Electrical Machines and Drives Conference (IEMDC), pp. 1-6, 2017.

[9] Huang H., Qu R., Bird J. Performance of Halbach cycloidal magnetic gears with respect to torque density and gear ratio. 2019 IEEE International Electric Machines & Drives Conference (IEMDC), pp. 1977-1984, 2019.

[10] Hao W.N., Zhou J. The cycloid magnetic gear based on Halbach array. Journal of Mechanical Strength, 39(1):226-229, 2017.

[11] Wu S.Z., He W.D., Zhang Y.H. Analysis of force and contact characteristics of rotating arm bearings for RV transmissions mechanism. Journal of South China University of Technology (Natural Science Edition), 48(6):25-33, 2020.

[12] Zhao D.L., Dang W.J., Sun W.P., Guo P.C. Influence of unbalanced magnetic pull on rub-impact rotor-bearing system. Journal of Huazhong University of Science and Technology (Natural Science Edition), 47(10):34-39, 2019.

[13] Jian L., Chau K.T. Analytical calculation of magnetic field distribution in coaxial magnetic gears. Progress In Electromagnetics Research, 92:1-16, 2009.

[14] Lubin T., Mezani S., Rezzoug A. Analytical computation of the magnetic field distribution in a magnetic gear. IEEE Transactions on Magnetics, 46(7):2611-2621, 2010.

[15] Deng Z., Nas I., Dapino M.J. Torque analysis in coaxial magnetic gears considering nonlinear magnetic properties and spatial harmonics. IEEE Transactions on Magnetics, 55(2):1-11, 2019.Document information

Published on 21/10/21

Accepted on 08/10/21

Submitted on 02/08/21

Volume 37, Issue 4, 2021

DOI: 10.23967/j.rimni.2021.10.001

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?