Abstract ===

In this paper, a number of innovative technologies are presented that have the potential to improve the efficiency and utilization of hydropower. These technologies include new turbine designs, improved efficiency, small hydro.

Keywords: hydropower, efficiency, small hydro turbines

2 Introduction: New Era for Hydropower

Hydropower, the harnessing of energy from moving water, has long been a cornerstone of renewable energy generation. However, the industry is poised for a significant transformation driven by a surge of innovative technologies. This paper introduces a collection of these advancements with the potential to revolutionize hydropower efficiency and utilization.

In the following sections, a range of groundbreaking technologies will be presented. Novel turbine designs promise to capture the power of water with unprecedented effectiveness. Advancements in efficiency will optimize energy extraction, minimizing wasted potential. The exploration of small hydro solutions will unlock the power of previously untapped water sources. By exploring these advancements, this paper lays the groundwork for understanding how hydropower can become an even more critical player in the global energy landscape. The following paragraphs will provide a detailed exploration of each technology, examining its principles, applications, and potential impact

Figure 1: Gordon Dam in Tasmania

3 Improvements in turbine design: BIM and CFD

Building Information Modeling (BIM) has emerged as a powerful tool for enhancing the design, construction, and operation of hydropower facilities. Its integration with Computational Fluid Dynamics (CFD) simulations offers a comprehensive approach to modeling and analyzing Francis turbines, leading to improved performance, efficiency, and reliability. BIM provides a structured and collaborative framework for creating and managing digital representations of Francis turbines, encompassing their geometric details, material properties, and operational characteristics. This digital twin serves as a central repository of information, facilitating seamless data exchange among various stakeholders throughout the project lifecycle.

Key Benefits of BIM in Francis Turbine Modeling:

- * Enhanced Design Accuracy: BIM enables the creation of highly accurate 3D models of Francis turbines, capturing intricate details and complex geometries that are challenging to represent using traditional CAD methods. This precision ensures that design errors are minimized, leading to a more optimized and reliable turbine design.

- * Improved Collaboration and Communication: BIM fosters collaboration among engineers, designers, and construction teams by providing a shared platform for visualizing and reviewing turbine models. This collaborative approach streamlines the design process, reduces miscommunication, and ensures that all parties are working from the same information.

- * Efficient Construction and Maintenance: BIM models can be directly utilized for generating construction drawings, fabrication plans, and installation guides. This streamlined approach enhances construction efficiency, reduces waste, and minimizes the risk of errors during installation. Additionally, BIM models can be used for maintenance planning, facilitating timely inspections and repairs.

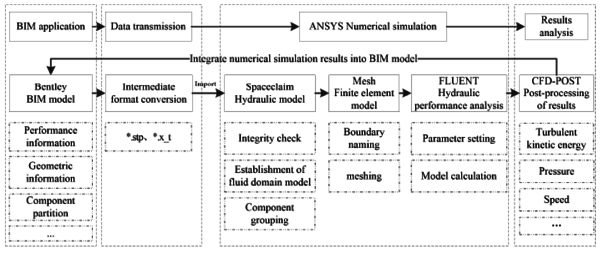

Figure 2: BIM and CFD modelling of a Francis turbine [1]

Integration with CFD Simulations

- * CFD simulations play a crucial role in analyzing the fluid flow patterns and performance characteristics of Francis turbines. By integrating BIM models with CFD software, engineers can create a virtual environment to simulate the turbine's operation under various conditions. This integration enables:

- * Performance Optimization: CFD simulations can predict the turbine's efficiency, power output, and cavitation behavior under different operating conditions. This information is invaluable for optimizing the turbine's design to maximize performance and minimize energy losses.

- * Flow Analysis and Visualization: CFD simulations provide detailed visualizations of fluid flow patterns within the turbine, including velocity, pressure, and turbulence distributions. These insights help engineers identify areas of potential flow separation, cavitation, and efficiency losses, enabling them to refine the turbine's design for improved performance.

- * Troubleshooting and Predictive Maintenance: CFD simulations can be used to troubleshoot operational issues and predict potential problems before they occur. By analyzing the turbine's behavior under various scenarios, engineers can proactively identify maintenance needs and schedule maintenance activities accordingly, extending the turbine's lifespan and reducing downtime.

In [1] it can be summarized an application method of BIM for the design of Francis turbines (Figure 2).

In terms of applicability, the proposed models can be reproduced and applied to specific hydraulic turbine designs, like the Pelton turbine. The combination of BIM and CFD offers a broad range of applications, proving its value in optimizing design, operation and maintenance (O&M) management, and other tasks. This method can assist designers in finding the optimal design solution and guide O&M personnel in making informed decisions.

Additionally, to improve the model's practical value, future design optimization should explore how to integrate parametric driving design with core hydraulic design principles. Finally, achieving automatic synchronous coupling between the numerical simulation results and the BIM model presents a promising area for future research.

4 Efficiency enhancement: Variable speed

Hydropower plants often experience fluctuating operating conditions. These variations can significantly reduce overall plant efficiency and lead to problems like flow instability and cavitation, ultimately shortening the lifespan of hydropower equipment.

The concept of variable speed hydropower gained scientific attention in the 1980s. While technically feasible, fully-fed synchronous machines were not cost-effective at that time. Gish et al. (1981) explored the potential of using doubly-fed induction machines (DFIM) in hydropower plants [2].

Variable-speed hydro turbines (VSH) are a type of hydroelectric turbine that can operate at a variable speed. This allows them to more efficiently generate electricity over a wider range of water flows and power demands. VSHs are becoming increasingly popular as a way to improve the efficiency and flexibility of hydroelectric power plants.

This allows VSHs to operate more efficiently than fixed-speed turbines,

Figure 3: Comparison between a fixed speed-variable speed turbine

which can only operate at a single speed. VSHs can also be used to generate more electricity from a given amount of water, as they can operate at the most efficient speed for the current water flow conditions. There are two main configurations for variable speed hydropower plants:

- * Converter-fed synchronous machine

- * Doubly-fed induction machine

Benefits for Power Systems with VariablThe increasing integration of non-synchronous VRE sources makes variable speed hydropower particularly advantageous. These plants offer:

- * Improved control of active and reactive power output

- * Increased spinning reserve capacity

Variable speed technology also benefits pumped storage facilities. These units can control both active and reactive power in pump mode, and they can start up and switch between modes much faster than conventional pumped storage units.

By adjusting the rotational speed of the plant's units independent of their synchronous speed, hydropower plants can better adapt to changing river flows. This approach, enabled by power electronic converters, enhances overall plant efficiency, extends equipment life, and allows for greater contribution to ancillary services within the power system.

5 New developments for small hydropower applications

File:Draft Calvi 590091600-image3.png Hydrokinetic turbines are devices that convert the kinetic energy of moving water into electricity. They are a type of renewable energy that can be used to generate power for homes, businesses, and communities.

Hydrokinetic turbines are similar to wind turbines, but they use water instead of air to generate electricity. They can be installed in rivers, tides, and ocean currents. The speed of the water flowing past the turbine blades determines how much electricity is generated.

There are three main types of hydrokinetic turbines:

- * Vertical axis turbines:These turbines have blades that spin vertically in the water. They are typically used in slow-moving currents.

- * Horizontal axis turbines:These turbines have blades that spin horizontally in the water. They are typically used in faster-moving currents.

Figure 4: Hydrokinetic turbine systems

File:Draft Calvi 590091600-image4.png

Figure 5: Hydrokinetic turbine – Velocity Vs. Power

- Ducted turbines:These turbines are enclosed in a shroud, which helps to increase the flow of water past the blades. They can be used in both slow- and fast-moving currents.

Hydrokinetic turbines have a number of advantages over other renewable energy sources, such as solar and wind power. They are not affected by the weather, and they can generate electricity 24 hours a day, 7 days a week. They are also relatively quiet and have a low visual impact.

However, hydrokinetic turbines also have some disadvantages. They can be expensive to install, and they can be harmful to marine life. They are also not suitable for all locations, as they require a strong current to generate electricity.

Overall, hydrokinetic turbines are a promising renewable energy source that has the potential to generate a significant amount of clean electricity. As the technology continues to develop, the cost of hydrokinetic turbines is expected to decrease, and their efficiency is expected to increase. This will make them a more viable option for generating electricity in the future.

Here are some of the benefits of using hydrokinetic tu rbines:

- * Clean energy: Hydrokinetic turbines do not produce any emissions, so they are a clean source of energy.

- * Renewable energy: Hydrokinetic turbines use a renewable resource, water, so they will not run out.

- * Reliable energy: Hydrokinetic turbines can generate electricity 24 hours a day, 7 days a week, even in bad weather.

- *

Domestic energy: Hydrokinetic turbines can be installed in rivers, tides, and ocean currents near where the electricity is needed, which can reduce transmission losses.

Here are some of the challenges of using hydrokinetic turbines:

- * High initial cost: The cost of installing hydrokinetic turbines can be high.

- * Environmental impacts: Hydrokinetic turbines can harm fish and other marine life.

- * Site limitations: Hydrokinetic turbines can only be installed in locations with strong currents.

Figure 5: Hydrostatic Pressure Machine

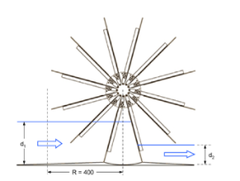

Another technology to achieve the shift towards clean energy, is the Hydrostatic Pressure Machine (HPM), a promising option that could meet these needs. Inspired by the design of a water mill's hydraulic wheel, the HPM features a horizontal rotating shaft. This design opens doors to a wide range of applications. The HPM could not only revitalize abandoned mill sites but also be installed in irrigation canals, where it can function as a water level regulator similar to a weir.

HPC uses the hydrostatic pressure differences between upstream and downstream of the machine. This allows for high efficiencies with very low load differences. The simplest HPC, the hydrostatic pressure wheel, consists of a wheel with radial blades that act as a barrier and that move with the velocity of the flow. The difference in hydrostatic force F1 - F2, proportional to the speed v1 generates the power P. The efficiency becomes a function of the ratio d2 / d1. This principle is rather unusual, but experiments have shown good agreement with the theory.

6 References

[1]. Sun, S.; Liu, X.; Zhang, R.;Liu, C.;Wang, A. Numerical Simulation and Analysis ofHydraulic Turbines Based on BIM formSustainable Development. Sustainability 2023, 15, 16168. https://doi.org/10.3390/su152316168.

[2]. Ioannis Kougiasa,∗, George Aggidisb, François Avellanc, Sabri Denizd, Urban Lundine,

Alberto Moroa, Sebastian Munteanf, Daniele Novarag, Juan Ignacio Pérez-Díazh, Emanuele Quarantai, Philippe Schildj, Nicolaos Theodossiouk, Analysis of emerging technologies in the hydropower sector, Renewable and Sustainable Energy Reviews, 2019.

[3]. C.M. Niebuhra, M. van Dijka, V.S. Nearyb, J.N. Bhagwanc: A review of hydrokinetic turbines and enhancement techniques for canal installations: Technology, applicability and potential

[4]. http://www.hylow.eu/

Information about the Author

Engineer working at Enel Green Power S.p.A., with experience and theoretical knowledge about hydroelectric plants and dams.

He has been participating in +30 projects in Italy and abroad since 2013. His primary education is civil engineering, with a Master's degree obtained at Politecnico di Torino in 2010, with achievement of a professional certificate at Stanford University in 2014 (Energy Innovation and Emerging Technologies). Hydraulic Engineering Certified Expert (EQF8) by CERTING (CNI, Italy) since 2019.

He was included in the list of highly qualified European Engineers in 2022, being awarded the title of EUR ING, and appointed Fellow of The RSA in 2023.

Document information

Accepted on 23/05/24

Submitted on 15/05/24

Licence: CC BY-NC-SA license