(→3.3 Study on sealing performance of rubber cylinder) |

|||

| Line 140: | Line 140: | ||

{| class="wikitable" style="margin: 1em auto 0.1em auto;border-collapse: collapse;width:auto;" | {| class="wikitable" style="margin: 1em auto 0.1em auto;border-collapse: collapse;width:auto;" | ||

|-style="background:white;" | |-style="background:white;" | ||

| − | |style="text-align: center;padding:10px;"| [[Image:Draft_Zhou_918280958-image4.png| | + | |style="text-align: center;padding:10px;"| [[Image:Draft_Zhou_918280958-image4.png|700px]] |

|- | |- | ||

| style="background:#efefef;text-align:left;padding:10px;font-size: 85%;"| '''Figure 4'''. Setting simulation results | | style="background:#efefef;text-align:left;padding:10px;font-size: 85%;"| '''Figure 4'''. Setting simulation results | ||

| Line 155: | Line 155: | ||

|+ | |+ | ||

|- | |- | ||

| − | |style="text-align: center | + | |style="text-align: center;"| [[Image:Draft_Zhou_918280958-image5.png|370px]] |

| − | |style="text-align: center | + | |style="text-align: center;"| [[Image:Draft_Zhou_918280958-image6.png|center|370px]] |

|} | |} | ||

|- | |- | ||

| Line 172: | Line 172: | ||

|+ | |+ | ||

|- | |- | ||

| − | |style="text-align: center | + | |style="text-align: center;"| [[Image:Draft_Zhou_918280958-image7.png|470px]] |

| − | |style="text-align: center | + | |style="text-align: center;"| [[Image:Draft_Zhou_918280958-image8.png|center|464px]] |

|} | |} | ||

|- | |- | ||

Revision as of 14:26, 23 May 2023

Abstract

In order to solve the problem of "gas explosion" at the end of common rubber cylinder in the process of high temperature, high pressure and gas drive operation, the rubber cylinder with new structure suitable for 51/2in casing pipe is developed. The "M" type single rubber cylinder structure is adopted in the new structure rubber cylinder, and the "gas explosion" problem of the end gas in the low-pressure side is solved by setting the double-layer staggered slotted steel cover to prevent outburst. The finite element method is used to simulate the setting of the rubber cylinder, and the structural parameters of the new rubber cylinder are obtained by single factor analysis and orthogonal optimization, simulation test and seal test were carried out to verify the sealing performance of the rubber cylinder. According to the actual working condition, the simulation test results and seal test results show that the sealing capacity of the packer reaches 50MPa under the temperature resistance of 120℃, and the end steel cover is fully opened to wrap the rubber cylinder, which meets the operation requirements of high temperature and high pressure gas injection packer.

Keywords: Gas injection seal, new structural rubber cylinder, outburst prevention, gas explosion prevention, finite element, seal test

1. Introduction

Packer is one of the key parts in slicing production of oil and gas fields. As the core part of packer, the rationality of rubber cylinder structure design and the reliability of sealing performance are the necessary guarantee for the effective implementation of slicing mining technology. With the further development of exploration and development in Shengli Oilfield, more and more high-temperature and high-pressure wells are encountered, which puts forward higher requirements for the temperature and pressure resistance of packer rubber barrel. As an effective method to improve oil recovery rate, CO2 flooding is more and more widely used in the industry. Conventional packer and high pressure packer can not meet the requirements of high temperature and high pressure. At present, there is a lack of packer rubber cylinder suitable for high temperature and high pressure in domestic gas seal. Therefore, it is very important to research and develop the rubber cylinder of air tight packer under high temperature and high pressure.

Aiming at the structure of 51/2in casing gas injection packer with two-way three force loading [1,2], in order to solve the special "gas explosion" [3] problem under gas injection seal, a new structure of rubber cylinder is designed, and the sealing performance of rubber cylinder under high temperature and high pressure is improved through single factor analysis and orthogonal optimization. The specific work is as follows.

2. Structural design

2.1 Design of outburst prevention structure against gas explosion

For the gas injection packer, there is a phenomenon that the gas gradually seeps into the rubber after bearing the high pressure difference and produces "gas explosion" at the low pressure side, which makes the rubber cylinder seal invalid and reduces the service life of the rubber cylinder. Therefore, the anti-outburst structure [4] at the end of the rubber cylinder not only needs to prevent the end of the rubber cylinder from protruding to the annular space on both sides of the end ring in the process of setting and sealing inspection, but also can ensure the rigid support of most rubber materials at the end of rubber cylinder.

The traditional spring ring, metal mesh envelope, single-layer steel cover and other anti-outburst structures are difficult to meet the requirements of fully rigid support of rubber materials at the end under gas injection seal. Therefore, a staggered slotted double-layer protective cover with a thickness of 1 mm and an interval of 30° and a width of 0.5mm is used (Figure 1). After the expansion, the gap of the upper steel cover is blocked by the non-slotted part of the lower layer, forming a complete rigid package for the rubber material on the end face, reducing the gas contact area on the high-pressure side and reducing the infiltration of the gas on the high-pressure side of the rubber cylinder from the inside of the rubber cylinder, and makes the rubber material of the shoulder of the low pressure side get a good rigid support, so as to solve the "gas explosion" problem. Considering the corrosion problem of CO2 gas, the double protective cover is made of stainless steel.

|

| Figure 1. 30° partial double-layer slotted steel cover |

2.2 Structural design of rubber Cclinder

At present, the packer rubber cylinder used in the industry mostly adopts the combination mode of single rubber cylinder, double rubber cylinder and three rubber cylinder [5]. According to the working conditions of bidirectional loading and gas injection seal, compared with multi rubber cylinders, single rubber cylinder has the advantages of simple structure and no spacer ring, and its contact area with casing is larger, and the contact stress distribution is uniform. Therefore, the single rubber cylinder is chosen as the main structure of the rubber cylinder.

According to the structural characteristics of the single rubber cylinder, combined with the actual production requirements of high temperature and high pressure gas injection seal, the setting characteristics of bidirectional loading, and considering the process requirements, two symmetrical obtuse top angle grooves are designed at the inner side of the rubber cylinder, and the right angle top angle groove is designed at the middle part of the outer side of the rubber cylinder, so that the overall shape is (Figure 2). The end ring is fitted with the steel cover to make the overall loading force uniform. For the packer with 51/2in casing, the inner diameter and outer diameter of the rubber barrel are determined as ф74mm and ф114mm respectively according to the field process requirements. The rubber material is hydrogenated nitrile. In order to ensure that the double-layer steel cover on both sides does not protrude before opening, the hardness of rubber cylinder is HS85.

3. Optimization of structural parameters

3.1 Determination of optimization parameters

In the design of rubber cylinder, the main parameters of half part design of rubber cylinder are shown in Figure 2. Based on the current experience [6,7] of rubber cylinder optimization, the total height of rubber cylinder has a great influence on the sealing performance of rubber cylinder. Therefore, the total height of rubber cylinder is initially determined as the main optimization parameter. Secondly, the sub height ZH1 at the top corner of the inner groove of the rubber cylinder and the double dip angles of the inner groove of the rubber cylinder have a high influence on the shape of the rubber cylinder, which can be determined as the parameters to be optimized. Considering that the height of the outburst proof structure will affect the opening degree of the steel cover, the relative height FTH of the steel cover is set as the optimization parameter to optimize. The groove at the right angle bottom in the middle of the outer side of the rubber cylinder has little influence on the overall structure performance, so the original size of the rubber cylinder remains unchanged.

|

| Figure 2. Rubber cylinder design and parameter setting |

3.2 Establishment of finite element model

ANSYS software is used to analyze the rubber cylinder model. Because there are 30° gaps in the anti outburst structure of rubber cylinder, a 1/12 3D part of the whole model is built, and the circumferential symmetric boundary conditions are set on the symmetry planes of both sides to simplify the solution model and improve the solution speed. The shape of rubber, sleeve, central tube and end ring is regular, so solid185 eight node element is used to mesh hexahedron, which can improve the speed and accuracy of the solution; because there is a 0.5mm slot in the anti outburst steel cover, the 20 node solid186 element is used for tetrahedral mesh generation to improve the solution accuracy. TARGE 170 and CONTA 174 elements are used for face-to-face contact. Rubber is a kind of super elastomer with complex constitutive relationship. There are many criteria for describing the mechanical characteristics of rubber at home and abroad. Mooney Rivlin model is widely used because of its simple model and few calculation parameters. According to reference [8], the hardness of HS85 hydrogenated nitrile is 1.711 for C10 and 0.567 for C01 at 120℃. The finite element model is established as shown on the left of Figure 3.

|

| Figure 3. Finite element model |

The outer side of the casing and the inner side of the central tube are both fully restrained. Because there is a groove in the middle of the rubber cylinder structure used, it will contact each other in the setting process. Considering the structural symmetry, the full mold is used to establish and fix the middle symmetry plane according to the ideal situation. In order to ensure the uniform force on the rubber cylinder, the radial degree of freedom is limited on the inner end of the end ring, and 7.6t setting load is applied on the end ring. Set the ambient temperature as 120℃, and take the friction coefficient as 0.3. The boundary conditions of the model are set as shown in the right of Figure 3. The initial design geometric parameters of the model are shown in Table 1.

| Size Structure | Internal diameter di/mm | External diameter do/mm | Height h/mm | ||

|---|---|---|---|---|---|

| Bushing | 121.4 | 139.7 | / | ||

| Central tube | 51 | 74 | / | ||

| End ring | 74 | 112 | 20 | ||

| Structural parameters of rubber cylinder /mm | |||||

| ZH | ZH1 | J1/° | J2/° | FTH | |

| Rubber cylinder | 140 | 50 | 116 | 165 | 39 |

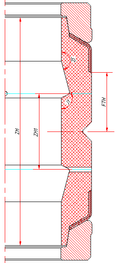

3.3 Study on sealing performance of rubber cylinder

The contact stress between rubber tube and casing is an important factor to evaluate the sealing performance of rubber cylinder. In this paper, through the single factor rotation of different structural parameters of the rubber cylinder, the influence of each factor on the sealing performance of the rubber cylinder is studied by comparing the minimum contact stress value of the peak circumferential position in the setting stage of the rubber cylinder, and the optimal value of each parameter is determined. At the same time, the maximum axial force on the contact edge between the inner steel cover and the rubber cylinder is compared to measure the expansion and opening degree of the steel cover, so as to evaluate the anti-outburst and anti "gas explosion" performance of the steel cover.

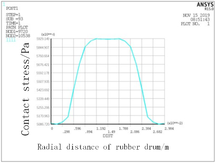

First of all, control other design parameters unchanged, and analyze the size change of the total height of the rubber cylinder (ZH). The finite element setting simulation results are shown in Figure 4.

|

| Figure 4. Setting simulation results |

Take the total height of the rubber cylinder as the independent variable, and simulate the broken line diagram with the interval of 2mm from 130mm to 148mm, as shown in Figure 5. It can be seen from the figure that with the increase of the rubber cylinder height, the contact stress tends to decrease, which is as low as 3.8MPa at the height of 148mm; while when the height of the rubber cylinder is below 130mm, the unit distortion of the rubber cylinder occurs and the bearing capacity is insufficient. The axial stress first increases and then decreases, and the stress is larger between 134mm and 140mm, and reaches the peak at 140mm. Considering the sealing effect and outburst prevention effect, the orthogonal combination levels of 134, 138 and 140 mm were selected.

| ||

| Figure 5. Single factor influence of total heigh |

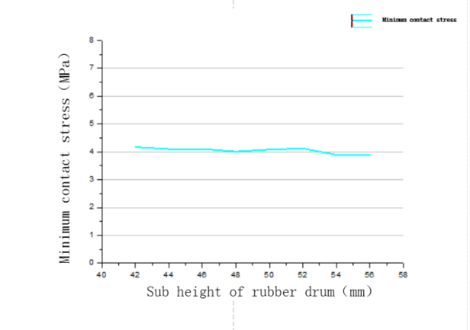

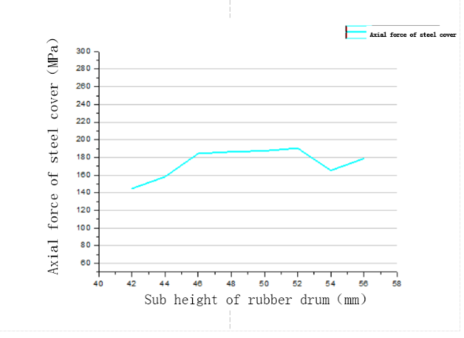

In the range of the total height of the rubber cylinder, the single factor optimization of the rubber cylinder height interval of 2 mm is carried out. The simulation results of the independent variables of 42 mm~56 mm are shown in Figure 6. It can be seen from the figure that with the increase of the height of the rubber cone, the minimum contact stress first decreases slightly, then increases to a high value, and then decreases greatly; meanwhile, the axial stress of the steel cover increases first and then decreases, and maintains a high level at 48, 50, 52 mm. Considering the sealing performance of the rubber cylinder and the outburst prevention performance of the steel cover, the orthogonal test was carried out with three horizontal values of 48 mm, 50 mm and 52 mm.

| ||

| Figure 6. Single factor effect of sub height |

The single factor rotation analysis was carried out on the inclination angles of the rubber cylinder groove (J1 and J2). The relationship between the dimensions and the sealing performance of the rubber cylinder and the outburst prevention performance of the steel cover is shown in Table 2. It can be seen that whether the minimum contact stress of the rubber cylinder or the axial force of the steel cover, the original size 116° is in the highest range, and the sealing performance and outburst prevention performance are the best. Therefore, 116° is selected for the new rubber cylinder, and the size will not be changed. With the increase of the value of J2 (the maximum value of structure and processing limit angle 2 is 172°), the contact stress of rubber cylinder and the axial force of steel cover show a steady upward trend, and its sealing performance and outburst prevention performance are getting better and better with the increase of size. Comprehensive analysis, the size of J2 was 165°, 170° and 172° for orthogonal optimization analysis.

| J1/° | Contact stress /MPa | Axial stress of steel cover edge /MPa | J2/° | Contact stress /MPa | Axial stress of steel cover edge /MPa |

| 106 | 3.83 | 132.0 | |||

| 111 | 3.97 | 142.6 | 160 | 3.11 | 116.4 |

| 116 | 4.08 | 187.4 | 165 | 4.08 | 187.4 |

| 121 | 3.79 | 181.4 | 170 | 4.56 | 267.7 |

| 126 | 4.00 | 171.0 | 172 | 6.12 | 296.2 |

The relationship between the relative height of rubber cylinder steel cover and the performance of rubber cylinder was studied. After calculation, the height of the rubber cylinder anti outburst steel cover should not be changed too much, otherwise there will be problems that the steel cover is too small to contact the outer sleeve or the rigidity is too large to open. Therefore, the simulated range of the steel cover from the height of ± 4mm is calculated as shown in the Table 3. It can be seen from the data in the table that with the increase of FTH height, the contact stress of rubber cylinder increases as a whole, and the maximum axial stress appears at the original size FTH = 39mm. Comprehensive analysis shows that the height of steel cover has the best performance in the original size, so it is no longer selected as the optimal size.

| FTH/mm | Contact stress /MPa | Axial stress of steel cover edge /MPa |

| 35 | 3.57 | 154.6 |

| 39 | 4.08 | 187.4 |

| 41 | 4.16 | 156.7 |

| 43 | 4.21 | 94.7 |

Based on the single factor optimization results of the combined rubber cylinder, considering the actual factors and the test cost, the main influencing factors are the total height of the rubber cylinder, the height of the rubber cylinder and the inclination angle of the groove 2. L9(34)orthogonal table is selected to carry out the orthogonal optimization design of the combined rubber cylinder structure. The design of the head is shown in Table 4. Factor A is the total height ZH, B is the height of the rubber cylinder ZH1, C is the angle of the rubber cylinder J2, and D is the error column. The design of factor level table is shown in Table 5.

| Column number | 1 | 2 | 3 | 4 |

| Factor | A | B | C | D |

| Factor

Level |

Height of rubber cylinder | Sub height of rubber cylinder | Inclination angle of rubber cylinder groove 2 |

| 1 | 140 | 50 | 165 |

| 2 | 138 | 52 | 170 |

| 3 | 134 | 48 | 172 |

Based on the orthogonal experimental design table, the experimental design was carried out with the contact stress and axial stress as the objective functions. The test table and simulation results are shown in Table 6. Taking the minimum contact stress as the main index, the orthogonal test results are analyzed intuitively, as shown in Table 7. The analysis of variance is shown in Table 8.

| Test number | 1 | 2 | 3 | 4 | Contact stress /MPa | Axial stress of steel cover edge /MPa |

| A | B | C | D | |||

| 1 | 1 | 1 | 1 | 1 | 4.08 | 187.4 |

| 2 | 1 | 2 | 2 | 2 | 4.59 | 224.2 |

| 3 | 1 | 3 | 3 | 3 | 5.62 | 361.1 |

| 4 | 2 | 1 | 2 | 3 | 4.38 | 257.2 |

| 5 | 2 | 2 | 3 | 1 | 5.23 | 338.0 |

| 6 | 2 | 3 | 1 | 2 | 4.16 | 204.0 |

| 7 | 3 | 1 | 3 | 2 | 5.80 | 348.4 |

| 8 | 3 | 2 | 1 | 3 | 4.09 | 187.2 |

| 9 | 3 | 3 | 2 | 1 | 4.89 | 252.3 |

| Level | K1 | 4.763333 | 4.753333 | 4.622667 | 4.733333 |

| K2 | 4.590000 | 4.636667 | 4.620000 | 4.850000 | |

| K3 | 4.926667 | 4.890000 | 5.550000 | 4.696667 | |

| R | 0.336667 | 0.253333 | 0.930000 | 0.153333 | |

| Better level | A3 | B3 | C3 | D2 | |

| Primary and secondary order of factors | 2 | 3 | 1 | 4 | |

| Source of difference | Sum of squares | freedom | Variance estimates | F value | P | Significance |

| Factor A | 0.170067 | 2 | 0.085033 | 4.421144 | 0.184463 | Main factors |

| Factor B | 0.096467 | 2 | 0.048233 | 2.507799 | 0.285079 | Secondary factor |

| Factor C | 3.1986 | 2 | 1.5993 | 83.15251 | 0.011883 | Key factors |

| error | 0.038467 | 2 | 0.019233 | |||

| total | 3.5036 | 8 |

According to the intuitive test results and variance analysis, the three factors f values to be optimized are all greater than 1, which has a significant impact on the setting contact stress of the rubber cylinder. The priority of the structural factors is as follows: the inclination angle of the rubber cylinder groove 2, the total height of the rubber cylinder, and the height of the rubber cylinder. The optimal level of each factor is as follows: the total height of rubber cylinder is 3 (134mm), the height of rubber cylinder is 3 (48mm), the inclination angle of rubber cylinder groove is 2 and the level is 3 (172°). The combination of three horizontal dimensions is combination 7 (a3b1c3d2), and the minimum contact stress of its setting is 5.80MPa, which is 42.2% higher than that before optimization. In the evaluation of the anti outburst performance of the steel cover, the axial force values of combination 3, 5 and 7 are higher. Considering the contact stress and axial force index, combination 7 is selected as the optimal design structure size. The structural parameters are shown in Table 9.

| ZH/mm | ZH1/mm | J1/° | J2/° | FTH/mm |

| 134 | 50 | 116 | 172 | 36 |

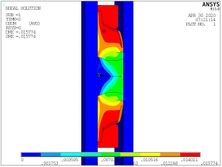

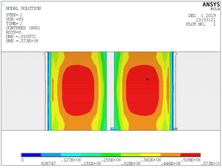

4. Simulation of Rubber Cylinder under Pressure

After the optimization of design parameters, the actual pressure bearing condition of rubber tube structure is simulated. The sealing pressure difference is set as 50MPa, and the ambient temperature is 120℃. The bidirectional simulation sealing test of rubber cylinder is carried out (the solution of loading conditions is shown in the upper left of Fig. 7). The sealing test results are shown in Fig. 7. It can be seen from the overall deformation diagram of the rubber cylinder that the anti-outburst steel covers on both sides of the rubber cylinder have been fully expanded and close to the sleeve, which has realized the complete rigid support for the rubber material at the end of the low pressure side, and reduced the infiltration of gas at the high pressure side through the rubber cylinder material, thus preventing the occurrence of "gas explosion". As for the contact stress between the casing and the rubber cylinder, it can be seen from the radial path distribution of the maximum contact stress at the bottom right of Fig. 7 that the minimum contact stress of the rubber cylinder is more than 50MPa, and the maximum contact stress is greater than 1.1 times of the sealing pressure difference [9], which can meet the requirements of 50 MPa air tight sealing and pressure resistance at 120℃.

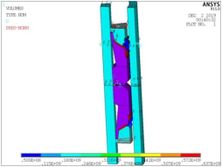

5. Test analysis

Comprehensive consideration of the design objectives, setting method and working mode of the test fixture is designed to design the rubber cylinder experiment scheme. The rubber cylinder is used for the setting test at room temperature of 7.6T and the test fixture corresponding to JY445 packer is performed at 120℃and 50 MPa. The dynamic strain gauge (measuring accuracy up to 0.001) is used to test the contact stress value of the setting test of the rubber cylinder. The real rubber cylinder and JY445 double-end loading test fixture are shown in Fig. 8.

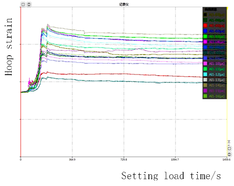

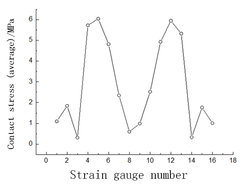

5.1 Rubber drum setting test

The setting test of rubber cylinder was carried out at normal temperature. Sixteen strain gauges were pasted axially at the outer casing of the test fixture, and the strain value of outer casing was tested by dynamic strain gauge at the setting stage. The setting load of 14.6mpa (7.6T) was loaded by opening the dynamic strain tester, and the setting pressure gauge reading was about 14.6mpa. Voltage 30 min after shut down the instrument data save, each strain gauge measuring the link to the strain changing with load time curve as shown in Fig. 9 (a), the contact stress distribution of axial as shown in Fig. 9 (b), test results show that the tooling without pressure, sealed performance is good, the plastic cylinder test is set by the axial stress distribution and plastic tube simulation test basic same, the validity of the finite element model is verified.

The fluid simulation analysis of the first channel is carried out, and the functional relationship between the flow pressure and the opening under different opening degrees is obtained. It can adjust different opening degrees through the pressure sensor, so as to achieve the required pressure of the water distributor, carry out real-time control and adjust the opening of the water nozzle, realize the water flow adjustment under different pressures, and complete balanced water injection.

5.2 Sealing test of rubber drum

The test equipment was connected to the sealing pressure pipeline and put into the heating tank for high temperature insulation at 120 ℃(Fig. 10). First, the forward sealing test was carried out, and the sealing pressure difference of 50 MPa was loaded by five steps of segmented sealing load, and the pressure was stabilized for 10min each time. After the pressure was stabilized to 50 MPa for 10min, the final loading pressure dial reading was 52MPa. Positive sealing success; Reverse sealing test of rubber cylinder was carried out. The pressure difference of 50mpa was tested by five steps of sub-level sealing load, and the pressure was stabilized for 10min each time. After the pressure was stabilized to 50mpa for 10min, the final pressure dial reading was 51MPa, indicating a successful reverse sealing test. The test results show that the positive and negative bearing capacity of the optimized rubber cylinder is 50 MPa, and the sealing pressure difference is well sealed, and the scratches of the double steel cover are obvious, indicating that the double steel cover is completely expanded and fitted to the outer wall of the casing, which can prevent the hidden danger of "gas explosion" under the gas injection seal, and achieve the design goal.

6. Conclusion

The main structure of the rubber cylinder of high pressure gas injection packer designed in this paper is "M" type single rubber cylinder. At the same time, double-layer staggered slotted steel cover is set at the end to prevent the hidden danger of "gas explosion" under the gas injection seal. Through the single factor analysis and three factors and three levels orthogonal optimization of the design size parameters of the rubber cylinder, the influence order of the size factors is the angle of the groove of the rubber cylinder 2, the total height of the rubber cylinder and the height of the rubber cylinder. Sealing simulation analysis and sealing test are carried out for the rubber cylinder with the optimal size combination. The results show that the rubber cylinder has good sealing performance at 120℃ and 50MPa, at the same time, the double-layer staggered slotting steel cover anti-penetration structure at the end completely expands and fits the outer wall of the casing, which greatly reduces the contact area between rubber and gas of the rubber cylinder, and effectively prevents the hidden danger of "gas explosion" under the gas injection seal, which can meet the requirements of oilfield operation.

Acknowledgement

This research is supported by Sinopec Shengli Oilfield Petroleum Engineering Technology Research Institute.

Reference

[1] Wang Shijie. Development of Bidirectional Three Force Loading Gas Injection Packer[J]. Petroleum Machinery. 2016, 44(12):90-92.

[2] Liu Jianxin, Wang Shijie .etc. Bi Directional Compression Packer for Separate Layer Gas Injection in CO2 Flooding[J]. Petroleum Machinery. 2017, 45(4): 87-89.

[3] Zhang feng. Study on Influencing Factors of Sealing Performance of Downhole Packer in Oilfield[J]. Drilling and production technology. 2018, 41 (4) :77 -79.

[4] Zhang Debiao, Hou Jun, Ma,Weiguo, Cai Zilong. Influence of Outburst Prevention Structure on Sealing Performance of Packer[J]. Petroleum Machinery. 2010, 12:53-55.

[5] Wan Xiaoyong, Li Haitao, Huang Chuanyan.etc. Optimization and Experimental Study on High Temperature Resistant Rubber Cylinder of Retrievable Hydraulic Packer[J]. Petroleum Machinery. 2018, 46(12):94-99.

[6] Liu Yonghui,Fu Jianhong,Li Yuanhua.etc. Optimization Analysis of Packer Rubber Cylinder Structure Parameters [J]. Mechanical Engineer. 2007(7):66-67.

[7] Fang Qun, Qian Yue. Size Optimization of Packer Sealant Cylinder[J]. Mechanical Engineer. 2018(4).

[8] Zhao Xiaolong, Diao Xiaoyong, Jiang Guoliang.etc. Determination of Constitutive Model Parameters for Hydrogenated Nitrile Rubber [J]. Synthetic Rubber Industry. 2019(9):352-356.

[9] Liu Chunyu. Sealing Evaluation of Packer and Discussion on Related Structure Design[J]. China Equipment Engineering. 2018(1):205-206.

Document information

Published on 26/05/23

Accepted on 18/05/23

Submitted on 05/04/23

Volume 39, Issue 2, 2023

DOI: 10.23967/j.rimni.2023.05.004

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?