(Created page with " <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> S. de Juan<sup>a</sup>, V. Ventosinos<sup>b</sup>, T. Fournier<sup>c</sup>, E. Robert<sup>d<...") |

(Tag: Visual edit) |

||

| Line 1: | Line 1: | ||

| − | + | <span id="_GoBack"></span> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | <span | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

==1 Introduction== | ==1 Introduction== | ||

| Line 119: | Line 41: | ||

| − | + | <math>\rho= R\left ( \frac{A}{l} \right ) \qquad (1) </math> | |

| − | + | ||

| − | (1) | + | |

Where ''R'' is the ohmic resistance, ''A ''the section of the specimen and ''l'' the length. | Where ''R'' is the ohmic resistance, ''A ''the section of the specimen and ''l'' the length. | ||

| Line 127: | Line 47: | ||

Employing the resistivity of the materials, the electrical conductivity was obtained by Eq.2: | Employing the resistivity of the materials, the electrical conductivity was obtained by Eq.2: | ||

| − | + | <math>\sigma=\left ( \frac{1}{\rho} \right ) \qquad (2) </math> | |

| − | + | ||

| − | + | ||

| − | (2) | + | |

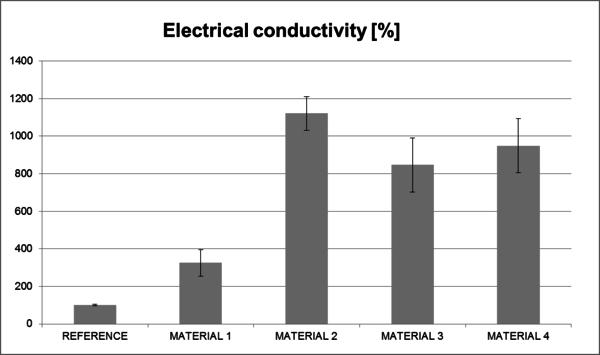

The results were plotted in Figure 1 as a percentage of the reference material value where the error bars are the standard deviation of every batch of experiments. | The results were plotted in Figure 1 as a percentage of the reference material value where the error bars are the standard deviation of every batch of experiments. | ||

Revision as of 08:58, 7 May 2022

1 Introduction

The increasing concern of aircraft manufacturers in the substitution of metal parts by polymeric elements is a strong driver for the last material developments. Lightweight metal alloys are widely employed in aeronautics for their outstanding performance and advantages in manufacturing and in service behavior. Nevertheless, these components need very often hazardous surface treatments [1] for corrosion protection and do not present the best properties-to-weight ratio available.

Thus, aircraft industry is experiencing an increasing trend in the amount of metal parts that have been already substituted by composites. The use of carbon-fiber reinforced polymers (CFRP) in airliners has grown significantly in the last years, and nowadays it accounts near the 50% of the total weight of the most recent models such as the Boeing 787 [2] or Airbus 350 XWB [3].

These materials can show outstanding specific stiffness, high mechanical strength, strong chemical resistance and good fire safety among others. Furthermore, their tunable anisotropy derived from the diverse stacking sequence combination possibilities is employed by the designers to create components with unique properties [4]. Also, most of CFRP employed in aeronautics are composed of unidirectional or woven continuous fibers embedded in thermoset matrices, especially when referring to structural elements of crafts.

In the other side, thermoplastic-based composites (TPC) attracted the attention of manufacturers due to the end-of-life recyclability of the components, the one-step manufacturing processes involved and the increased fracture toughness of these materials as compared to thermosets. Furthermore, the recent developments in material chemistry led to the production of grades of thermoplastic such as PAEK (Poly Aryl-Ether-Ketone) family that fulfill the highest safety flight standards in terms of fire retardancy and smoke toxicity, which are mandatory performance for cabin interior systems [5].

However, the multifunctionality of airborne components is an established approach for lowering weight of the aircraft. Multifunctional materials often present high mechanical properties in combination with a side feature which would eliminate additional elements to cover the needs of the set. In particular, electrical conductivity is very commonly required in ducts for allowing releasing the electrostatic charges produced by the fluids in their movement.

The most common approach for enhancing the electrical conductivity of TPC’s is the use of conductive fillers which might create an electrical path in the bulk of the isolating material [6,7]. Conductive particles filling the resin are a very effective strategy to increase the electrical feature when a sufficient percentage over the percolation limit is well dispersed in the material [8]. In addition, it is observed that fillers of any kind can lead to a reinforcement side effect on mechanical properties which is normally desirable.

Liebherr Aerospace SAS, as an international leader in manufacturing of airborne systems, is putting its effort in researching for new materials that meet extreme condition requirements at once. In particular, valve bodies of cabin air conditioning systems are subjected to high mechanical stress at high temperatures, while challenged to sustain enough electrical conductivity to drive the electrostatic currents away to avoid sparking. Since the electrical conductivity of commercial grades of TPC’s is still insufficient for this specific purpose, these requirements are currently fulfilled by electric brides that permit an electrical path through the system.

Within the objective of improving Europe’s industrial competitiveness, ECOFUNEL project was promoted by the European Commission as a Research and Innovation Action to carry out the necessary activities for obtaining enhanced conductivity grades of injection molding thermoplastics capable to fulfill the requirements of Liebherr Aerospace SAS, the Topic Manager (TM) of the project, in this particular field. The Consortium composed by FIDAMC, CTAG and CANOE is now obtaining new material formulations employing the abovementioned approaches that could be promising candidates for manufacturing an actual-size prototype of valve body that will meet all the requirements.

2 Experimental

2.1 Materials and specimens

Within ECOFUNEL project, four different formulations of enhanced thermoplastic compounds were designed, created and studied in order to overcome the low electrical conductivity of commercial grades. The new materials were tested to evaluate their electrical performance, but also the effect of the modifications on the mechanical properties. The values obtained were compared with the current market available TPC grade employed for the particular uses of the Topic Manager.

In order to accomplish the characterization campaign of the materials, two different types of samples were created by injection molding:

- ISO 527 Type 1A:2012 – Dog bone shape samples

- ISO 180 – Flexural bars

The samples were used for obtaining the mechanical properties by tensile test and electrical performance respectively. Tensile test was carried out with a MTS universal testing machine according to ISO 527-2 standard. A load cell of 100kN was employed for the tests and strain of the specimens was measured employing a Epsilon extensometer with high temperature capabilities.

Electrical testing was performed employing a Keithley 2040 Ohmmeter by four-wire set up with a voltage input of 20V and a compliance current of 1mA. In order to assure a good contact between the probes and the samples, the measurement surfaces of the samples were coated employing silver paint leaving to set for at least 24h prior to testing.

2.2 Results

Conductivity test

Conductivity measurements were conducted at room temperature on five flexural specimens of each material employing an own-designed setup composed of a clamping tooling with metallized electrodes. Ohmic resistance was manually collected, and converted into electrical resistivity employing the equation:

Where R is the ohmic resistance, A the section of the specimen and l the length.

Employing the resistivity of the materials, the electrical conductivity was obtained by Eq.2:

The results were plotted in Figure 1 as a percentage of the reference material value where the error bars are the standard deviation of every batch of experiments.

As seen in the graph all the new formulations proposed present higher electrical performance as compared to that of the reference material. Even being the worse performing one, Material 1 presents over three times the conductivity of the reference. Furthermore, the three remaining materials show outstanding properties ranging 800-1100% that of the commercially available grades. In particular, Material 2 is observed to present the highest conductivity among all, one order of magnitude over the reference.

Mechanical test

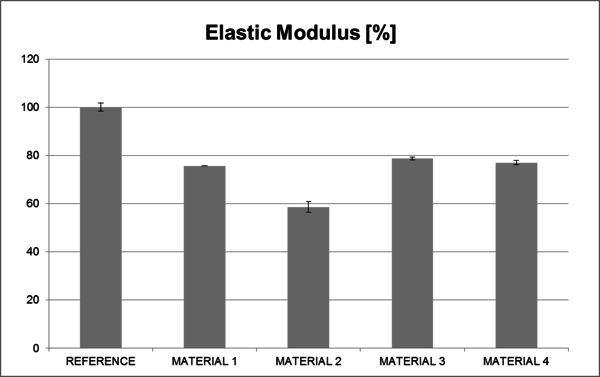

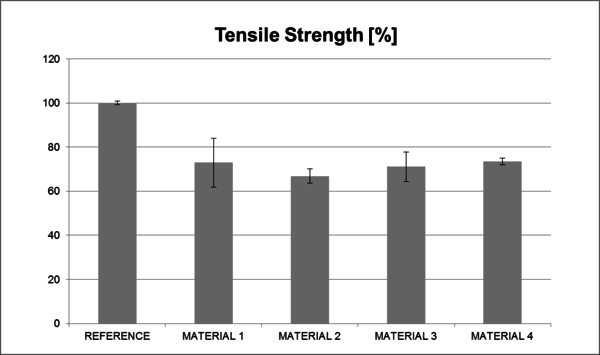

Mechanical tests were performed at room temperature 23 ± 2ºC, 50 ± 5% of relative humidity, and at a constant speed of 1mm/min as mentioned in the standard to avoid any effect of embrittlement of the materials. Elastic Modulus and Tensile Strength were obtained from the tests and plotted in Figure 2 and 3, where the standard deviation of the tests are the error bars.

The stiffness of all the new material formulations is observed to be lower than that of the reference. The Elastic Modulus of the compounds drops to values near 58% for Material 2 whereas Materials 1, 3 and 4 keep this property ranging 75-79%.

Tensile Strength was also recorded as the maximum stress overcome by the samples. This property of the new formulations is also lower than that shown by the reference material. The lowest value is 67% again shown by Material 2 which seems to be the worst performing among all in matter of mechanical properties. Anyway, tensile strength of the rest of materials ranges 71-73% which is slightly above the minimum observed.

Manufacturability

Since the market available injection molding grades are normally optimized to the processing conditions, they very rarely present problems during manufacturing. When obtaining new formulations the materials may show extremely low or high melt viscosity that can compromise the injection molding process. Thus, manufacturability is another key factor to pay attention to since a wrong processability of the materials can ruin the process.

| Material | REF | MAT 1 | MAT 2 | MAT 3 | MAT 4 |

| MFI [%] | 100 | 54.2 | 56.3 | 50.8 | 5.7 |

| Ease to be processed | EXCELLENT | GOOD | GOOD | GOOD | BAD |

In this particular study it was observed that the commercial grade presents the best characteristics to be processed, whereas Material 4 is highly difficult to process. The rest of the compounds are in a medium level and can be processed by only taking into account several specific parameters.

3 Conclusions

Several TPC were successfully designed and created by the ECOFUNEL Consortium for their assessment as candidates for the production of a full-scale demonstrator. All materials were evaluated in mechanical and electrical properties employing standard tensile testing machine and common ohmmeter equipment and procedures.

The new ad-hoc formulations presented better electrical performance as compared with the reference material, whereas all of them showed lower mechanical properties. The reference material seems to be fully designed to present the highest mechanical performance while exhibiting certain grade of electrical conductivity. In the other hand, since the main focus of the project was to keep electrical level of materials as high as possible, the mechanical feature of the material designs was considered the balance parameter to keep in view.

Preliminarily, Material 4 seems the most interesting for the purposes of the TM since it presents outstanding electrical conductivity, near 8.5 times more than that of the reference. In addition, this material keeps mechanical performance at a sufficient level, showing a modulus and a tensile strength only 23% and 26% lower respectively as compared to reference. However, this material is hard to process and it is one of the key aspects that may be attended when selecting the new materials.

On the other hand, Material 3 shows similar mechanical performance as Material 4 but presenting slightly lower electrical conductivity (7.5 times more than the reference). In addition, this material exhibits ease to be processed showing no big issues when being employed for manufacturing.

Thus, Material 3 is considered as the best candidate created for the purpose, and more samples will be produced to be furtherly investigated. For the next testing campaign, the selected material will be subjected to advanced characterization in order to assess its implementation. This next step will include:

- Tensile at wide range of temperatures.

- Electrical performance under certain conditions.

- Resistance to chemicals.

- Fire testing.

Acknowledgements

The ECOFUNEL participants would like to remark that this project has received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 Research and Innovation Programme under the grant agreement num. 738047.

References

[1] Jacobs, J. A., & Testa, S. M. (2005). Overview of chromium (VI) in the environment: background and history. Chromium (VI) handbook, 1-21.

[2] Carbonfiber.gr.jp. (2019). Aircraft and Aerospace Fields. [online] Available at: https://www.carbonfiber.gr.jp/english/field/craft.html [Accessed 13 May 2019].

[3] Airbus A350: Composites on Trial Part I. [online] Available at: http://scribol.com/technology/aviation/airbus-a350-composites-on-trial-part-i/ [Accessed 13 May 2019].

[4] Clyne, T. W., & Hull, D. (2019). An introduction to composite materials. Cambridge university press.

[5] Benson, C. M., Fernandez-Cerezo, G., Holborn, P. G., & Mba, D. (2016). Fire suppression systems in aircraft: Their past, present & future. Fire Investigation, 1(3), 34-41.

[6] Jia, L. C., Yan, D. X., Cui, C. H., Jiang, X., Ji, X., & Li, Z. M. (2015). Electrically conductive and electromagnetic interference shielding of polyethylene composites with devisable carbon nanotube networks. Journal of Materials Chemistry C, 3(36), 9369-9378.

[7] Kuester, S., Merlini, C., Barra, G. M., Ferreira Jr, J. C., Lucas, A., de Souza, A. C., & Soares, B. G. (2016). Processing and characterization of conductive composites based on poly (styrene-b-ethylene-ran-butylene-b-styrene)(SEBS) and carbon additives: A comparative study of expanded graphite and carbon black. Composites Part B: Engineering, 84, 236-247.

[8] Chen, Y., Pan, F., Wang, S., Liu, B., & Zhang, J. (2015). Theoretical estimation on the percolation threshold for polymer matrix composites with hybrid fillers. Composite structures, 124, 292-299.

Document information

Published on 07/05/22

Accepted on 07/05/22

Submitted on 07/05/22

Volume 03 - Comunicaciones Matcomp17 (2019), Issue Núm. 4 - País invitado: Colombia. Materiales Multifuncionales. Reciclaje y Sostenibilidad, 2022

DOI: 10.23967/r.matcomp.2022.05.005

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?