(→Acknowledgement) |

|||

| Line 566: | Line 566: | ||

This research work was supported by National Key Research and Development Program of China (2016YFC0802102-03); Luzhou City Science and Technology Planning Project (2018-GYF-6); Sichuan Science and Technology Project: (20MZGC0090); Open Fund of National Joint Engineering Research Center for abrasion control and molding of metal materials (HKDNM201806); SWPU Youth Research and Innovation Team (2018CXTD12). | This research work was supported by National Key Research and Development Program of China (2016YFC0802102-03); Luzhou City Science and Technology Planning Project (2018-GYF-6); Sichuan Science and Technology Project: (20MZGC0090); Open Fund of National Joint Engineering Research Center for abrasion control and molding of metal materials (HKDNM201806); SWPU Youth Research and Innovation Team (2018CXTD12). | ||

| − | |||

==References== | ==References== | ||

Revision as of 13:38, 28 April 2021

Abstract

Aiming at the safety problem of the pipeline containing corrosion defects caused by ground overload, a novel method is developed to assess the safety of buried pipelines with corrosion defects and predict the failure pressure. The effects of parameters including internal pressure, ground overload, length of the loading area, corrosion defect depth, buried depth and soil Young’s modulus, are discussed. Ground overload greatly increases the von Mises stress and strain at the corrosion defect location and decreases the internal pressure threshold. The von Mises stress and strain are an obvious nonlinear relationship with internal pressure. The high stress and strain area expand along the diagonal direction of the defect area. The local stress and strain concentration at the corrosion defect increases with the increase of ground overload, length of the loading area and corrosion defect depth, which reduces the failure pressure of the pipeline. Increasing the buried depth and soil Young’s modulus would effectively reduce local stress and strain concentration, and increase the failure pressure of the pipeline. The pipeline settlement displacement increases with the increase of internal pressure, ground overload, length of the loading area, and decreases with the increase of pipeline buried depth and soil Young’s modulus.

Keywords: Pipeline, corrosion defect, ground overload, stress, strain, failure pressure

1. Introduction

Long-distance buried pipelines are an important way of oil and gas storage and transportation. Buried pipelines not only bear the gravity and internal pressure of transportation medium, but also inevitably have to withstand some ground loads, such as the roads, buildings, sediments, machineries and equipment [1]. With the continuous development of urban construction scale, unreasonable stacking overloading phenomenon often appear near the buried pipelines (i.e.stacking height, distance is unreasonable), which results in soil deformation, squeezing the buried pipeline and the superposition load at the top of the pipeline [2-3]. Ground overload may cause pipeline cross-section deformation or even rupture, which results in oil and gas leakage, hindering the cleanup pipe operation and defect detection operation, triggering and other safety accidents [4]. According to relevant reports, there were 27 pipeline damages in the transportation section of the Chengdu-Chongqing pipeline due to unreasonable stacking around pipelines in 2015 [5].

Many scholars have explored and studied the mechanical behavior of buried pipelines under static and dynamic pressure loads [2,6-7]. The main action form of ground overload is static positive pressure, and the load acts vertically directly above the buried pipeline [8]. Chen et al. used the classical Boussinesq method to integrate and calculate the additional load on the buried pipeline under the vertical heap load on the ground, and solved the deformation, bending moment and shear force of the buried pipeline based on the linear elastic foundation beam theory. However, this method ignores the pipe-soil interaction and cannot simulate the local deformation and buckling of the pipe [9]. Zhang et al. discussed the effect of the soil parameters of soil around buried pipelines by numerical methods and designed an underground pipeline protection device that can repair damaged pipe in time without stopping oil and gas transportation [1]. Trickey and Moore investigated the three-dimensional response of buried pipes under circular surface load using the FE method. The comparison of the new results with those of previous work by Poulos in 1974 indicated that his Mindlin solution calculations are somewhat conservative for deeply buried pipes compared with the finite-element solutions, but unconservative for a shallow buried pipe [10]. Based on the Hamilton Variation Principle (HVP) and the finite element (FE) theory, the dynamic plastic deformation of the pipeline under the dynamic compaction behavior during the ground construction was studied by Xu et al. [6]. Meesawasd et al. investigated the effects of buried depth, seismic and traffic loads for the stress distribution of buried pipelines, and demonstrated that weights, speeds and patterns of car size arrangement play their parts in causing variation of stress on the pipeline [11]. Yao et al. [12] conducted experiments and numerical simulations on raw water pipelines with ground loads. Researches showed that ground overload was not a single cause of raw water pipeline bursts, and the original state of the welds had an impact on the bursts. The failure aspects of buried pipeline caused by earthquake and degradation of metal due to corrosion were studied. In this case, corroded pipeline approaches to critical criteria in much less time [13].

X80 pipeline steel is currently the longest used high-steel grade pipeline material in the world. While X80 pipeline steel is being used on a large scale, accidents occasionally occur due to its high strength and low toughness characteristics. The area with volume surface defects (VSD) on pipeline is the most typical form of corrosion defects, mainly including internal corrosion defects and external corrosion defects [14]. The presence of VSD may reduce the thickness of the pipe wall and be accompanied with additional stress concentration, which usually greatly weakens the pipeline’s ability to withstand internal pressure and resist external loads, seriously threatening the safe operation of the pipeline.

The pipeline safety evaluation management system based on unreasonable stacking is an important component of the pipeline integrity management system. Over the past years, the author’s team has conducted numerous pipeline integrity evaluation studies [1,8,15]. Meanwhile, developed FE-based models to assess the mechanical behavior of pipelines in geohazard areas and predict pipeline failure pressures. To date, a series of numerical models and computational codes have been developed for pipeline defect assessment [16-18]. However, to the authors’ best knowledge, none of them has considered the mechanical response and failure pressure prediction under the ground overload. This work develops a novel method to assess safety and predict the failure pressure of corrosion defect pipelines under the ground overload.

In this paper, a FE model is developed to analyze the stress and strain distributions around the corrosion defect on the buried pipeline under the ground overload. A failure criteria based stress are used to predict the failure pressure of the corrosion defect pipeline. The effects of parameters including internal pressure, ground overload, length of the loading area, corrosion defect depth, buried depth, and soil Young’s modulus, are discussed. These results can provide a theoretical basis and reference for the safety assessment, repair and maintenance of buried pipelines.

2. Numerical modeling

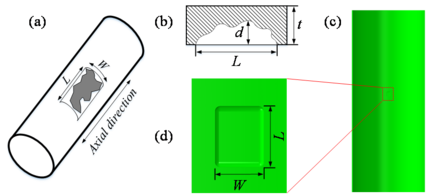

In this study, an X80 grade steel pipeline with corrosion defect is modeled. According to the previous analysis, the local stress state of buried corrosion defective pipelines is complicated under the action of unreasonable ground overload. Meanwhile, the focus of this paper is to conduct a safety assessment of buried corrosion defective pipelines under given conditions. Generally, the shape of corrosion defects is irregular. To quantify the shape of corrosion defects, it is necessary to reasonably simplify the model corrosion defects to apply the results to various geometric shapes [19-20]. In many industry standard specifications such as DNV and modified B31G, the maximum corrosion depth ( ), width () and length () are used to describe the pipeline corrosion defects. If the defect depth profile is relatively smooth and does not present multiple major peaks in depth, a corrosion defect can be considered as a regular shape [20]. The shape of the corrosion defect of buried pipelines is simplified as a rectangular volume defects and rounded the corners in this paper, as shown in Figure 1, which is a common used method in literature [13,17,21].

|

| Figure 1. Schematic diagram of corrosion defect pipeline |

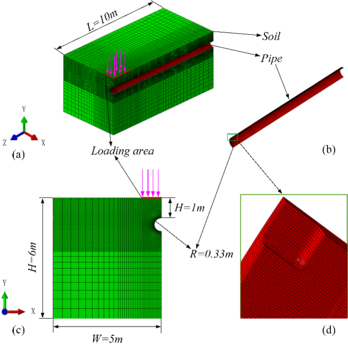

Numerical analysis of the buried pipeline under the ground loads is conducted by using the FE software ABAQUS6.14. The diameter of the pipeline is 0.66m, and the wall thickness is 8mm. The length of soil along the axial is selected 30 times the pipe diameter, and the height and width are 9 times and 15 times the pipe diameter, respectively, according to the previously published article [1]. Therefore, the whole size of the soil is , and the buried depth is 1m. Considering that the model and boundary conditions have obvious symmetry, a quarter model is used for calculation, in order to improve the calculation efficiency. The FE model of buried corrosion defect pipeline under ground overload is shown in Figure 2. The equivalent pressure is used to describe the ground overload, and the ground overload directly acts on the soil surface above the corrosion defect pipeline, as shown in Figures 2(a) and (c). The pipeline corrosion defect is simplified as a rectangle with rounded corners, and the detailed local shape is shown in Figure 2(d).

The bottom boundary conditions of the model are fixed constraints, and the symmetry constraint is used on the symmetry plane (i.e. the XY plane and the ZY plane). The upper surface of the model is free, and the normal displacement of the outer end faces is restricted to prevent the soil from collapsing. The contact pair algorithm is used to simulate the interface between the outer surface of the pipe and the surrounding soil. And set the friction coefficient as 0.4 [22]. The contact algorithm is widely accepted to simulate the nonlinear behavior of pipe-soil contact, and it can truly simulate the contact force of underground pipeline and soil [2,8].

|

| Figure 2. Finite element model containing corrosion defect |

The material properties of X80 are given in Table 1, and the stress-strain method of Ramberg-Osgood (R-O) power-hardening is used in the FE model to describe real stress-strain behavior of the high grades of pipe steels, as shown in Eq.(1) [23]

|

|

(1) |

where is a strain, is stress, is Young’s modulus, is yield strength, is ultimate tensile strength, and and are R-O model parameters, which depend on the materials. It is 0.079 and 12 for X80 steel, respectively.

| Steel | Yield strength (MPa) |

Ultimate tensile strength (MPa) |

Young’s modulus (GPa) |

Poisson’s ratio |

|---|---|---|---|---|

| X80 | 534.1 | 718.2 | 200 | 0.3 |

Pipeline backfill soil is a heterogeneous soil with high compressibility, viscoelasticity and low shear resistance [3]. Under ground overload, the buried pipeline is mainly subjected to the top soil pressure of the backfill generated by the self-weight of the backfill, which increases with the depth of the pipeline buried depth. The soil adopts the Drucker Prager constitutive model, and the shear strength of the soil is reflected by selecting the friction angle and cohesive force. The change of the yield surface is adjusted by setting the cohesive force [24]. It is suitable for pressure-sensitive soil, because it can well reflect the unequal tension and compression characteristics of rock and soil, and is widely used. The parameters of the soil around the pipe are given in Table 2 [25].

| Young’s modulus (MPa) |

Poisson’s ratio | Density (kg/m3) |

Friction Angle (°) |

Flow Stress ratio |

Cohesion (KPa) |

|---|---|---|---|---|---|

| 20 | 0.35 | 1840 | 30 | 1 | 29.3 |

Failure models of the buried pipeline are varied. Typical failure modes of the buried pipeline include strength failure, buckling failure and excessive deformation [10]. Under ground overload, large local stress and deformation will occur in the corrosion defect pipe. The main failure modes for corrosion defect pipeline are local strength failure and excessive deformation. Generally, the failure criterion of the pipeline is based on the elastic failure and plastic failure adopted the stress based failure criterion for defect pipeline failure pressure prediction under cyclic loads [7].

In this paper, failure criteria based stress is used to describe the failure of corroded pipes. The pipeline failure is considered to occur when the max von Mises stress exceeds the allowable value at the location of the pipeline corrosion defect. The failure criterion is:

|

|

(2) |

where is von Mises stress, refer to three principal stress on the pipeline, and where is the ultimate tensile strength.

The element type of the pipe and the surrounding soil adopts eight-node brick element with the reduced integral unit to improve the convergence efficiency for geometrically nonlinear modeling. In order to obtain a reasonable grid that ensure that the simulation results are sufficiently stable and reliable, multiple sets of grid independence tests are conducted. Meanwhile, local grid refinement is used in the corrosion defect area of the pipeline and the ground overload area, and the sparse grid is used in the area far from the important area. The maximum von Mises stress for different element number are shown in Table 3, and the loads and corrosion defect size are shown in Table 4. When the number of elements exceeds 112785, the maximum Mises stress area stabilizes. According to the above analysis, the number of elements finally selected 112785, and the smallest grid size sets as 1mm1mm0.8mm. In particular, in order to ensure the accuracy of the calculation, a four-layer grid is selected for the thickness of the corrosion defect wall, and highlighted in dark red in Figure 2(d).

| Number of elements | Maximum von Mises stress (MPa) |

|---|---|

| 30305 | 552.1 |

| 54105 | 556.2 |

| 86522 | 559.6 |

| 112785 | 578.1 |

| 128569 | 578.4 |

| 153674 | 578.6 |

The model uses single-factor analysis to discuss the safety assessment and failure pressure prediction of buried pipelines with corrosion defects under ground overload conditions. The basic parameters of the model are shown in Table 4.

| Variable | Value | |

|---|---|---|

| Load (MPa) | Ground overload (OLD) | 1 |

| Internal pressure (IP) | 7 | |

| Loading area (m) | widthlength | 0.81.8 |

| Buried depth (m) | H | 1 |

| Corrosion defect (mm) | dLW | 5.64032 |

3 Result and discussion

3.1 Model verification results

Being compared with theoretical calculations or experimental test data is an effective and reliable comparison verification method. In this paper, the model validation is conducted by using the experimental data obtained on an X60 steel pipeline containing a single corrosion defect, which was published by Freire [21]. The outer diameter of the pipe is 324 mm and nine groups of corrosion defect dimension pipes are used for comparative verification, as shown in Table 5.

| Case | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| t (mm) | 9.79 | 9.74 | 9.80 | 9.66 | 9.71 | 9.71 | 9.91 | 9.94 | 9.79 |

| l (mm) | 500 | 528 | 256 | 306 | 350 | 395 | 433 | 467 | 484 |

| t* (mm) | 2.80 | 2.60 | 2.72 | 2.9 | 2.78 | 2.80 | 2.60 | 2.72 | 2.80 |

| w (mm) | 95.3 | 95.3 | 95.3 | 95.3 | 95.3 | 95.3 | 95.3 | 95.3 | 95.3 |

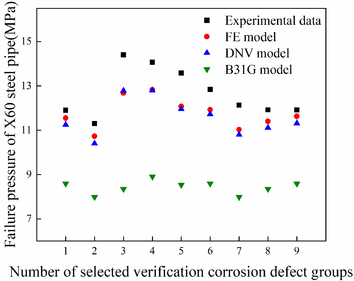

Verification and analysis by comparison is an effective means to verify the reliability of the developed failure pressure prediction finite element model. The existing methods for failure pressure prediction of corrosion-defective pipelines include ASME B31Gand DNV. Most of these codes are based on semi-empirical solutions of fracture mechanics and have been recognized by the industry. In this work, the failure pressure obtained through the developed model is also compared with the predicted by two assessment methods: DNV and B31G model. Figure 3 shows the comparison of the failure pressure prediction results among the established FE model, the published experimental test data, DNV and B31G modeling results. It can be clearly seen that the prediction result of the B31G method is obviously conservative, and the prediction result of the DNV method is closer to the experimental value. The relative error between experimental test data and the FE model results is within 5%. In addition, the relative error of the FE model results is less than 4%, compared with DNV model results. Therefore, the above verification results show that the established failure pressure prediction FE model can obtain reliable results.

|

| Figure 3. Validation of model prediction failure pressure results |

3.2 Internal pressure effect

The maximum von Mises stress and strain around the corrosion defect on X80 steel pipeline under different internal pressure (IP) for the presence and absence of ground overload (OLD) are shown in Figures 4(a) and (b). Both the maximum von Mises stress and strain of pipeline corrosion defects have been significantly increased, because of the presence of ground overload. When there is only internal pressure and the internal pressure is below 5MPa, the corrosion defects pipeline is in the elastic stage. When the internal pressure is greater than 5MPa, the maximum von Mises stress of the pipeline exceeds the yield stress and plastic deformation occurs. However, when the pressure is 1 MPa, the maximum von Mises stress of the pipeline exceeds the yield stress and plastic deformation occurs for the presence of ground overload. Meanwhile, both the maximum von Mises stress and strain of pipeline corrosion defects show obvious nonlinear behavior with the increase of internal pressure for two load conditions (i.e. IP+OLD). When the internal pressure is 1-3MPa, the external load plays a leading role in the pipeline deformation, and the overall ability of the pipeline to resist deformation is weak. Therefore, the plastic deformation around the corrosion-defective pipeline decreases with the increase of internal pressure. When the internal pressure is greater than 3MPa, the pipeline plastic deformation around the corrosion-defective pipeline increases with the increase of internal pressure. Therefore, the presence of ground overload decreases the internal pressure threshold, exceeding that local plastic deformation around corrosion defects on the pipeline occurs.

Along the axial direction of the pipeline, the pipeline is divided into three areas in the case of ground overload, namely the overload zone, the transition zone and the non-overload zone, respectively. The pipeline settlement displacement distribution along the axial direction under different internal pressures is shown in Figure 4(c). The maximum settlement displacement decreases with the increase of the internal pressure, which shows that the internal pressure improves the stiffness of the pipeline and increases the ability to resisting deformation of the pipeline. The maximum settlement displacement is located below the ground overload area, and there is an obvious transition zone. The settlement displacement gradually decreases with the increase of the axial length of the pipeline, and the minimum settlement is in the non-overloaded zone.

Figure 4(d) shows that the von Mises stress in the overload area is greater than the other two areas, and the maximum stress value appears in the center of the corrosion defect in the overload zone. As the previous analysis, the stress distribution along the axial direction of the pipeline also exhibits nonlinear behavior with different internal pressure. In the transition area, the stress transition becomes less obvious with the increase of internal pressure except the internal pressure is 1MPa. In the non-overload zone, the stress increases with the increase of internal pressure.

| Figure 4. Mechanical behavior of X80 corrosion-defective pipeline under different internal pressure |

Figure 5 shows the von Mises stress and strain distributions around the corrosion defect on the X80 steel pipeline under different internal pressure and ground overload. It should be noted that the unit of stress is Pa, and PEEQ is dimensionless. It can be seen that the stress concentration occurs in the corrosion defect area, and the maximum stress develops from the root of the corrosion area to the middle with the increase of the internal pressure. The stress distribution develops from the root to the middle along the length of the corrosion defect with the internal pressure increases. When the internal pressure is greater than 6MPa, low stress areas appear on both sides of the corrosion defect width direction, and the range of the low stress areas increases with the increase of internal pressure. According to the strain distribution, when the internal pressure is less than 3MPa, the maximum strain decreases with the increase of internal pressure. When the internal pressure is greater than 3MPa, the maximum strain increases with the increase of internal pressure, and the maximum value appears in the middle and diagonal area of corrosion defect.

Meanwhile, the failure pressure of X80 steel pipes with corrosion defects for the presence and absence of ground overload are compared. The failure pressure of the pipeline with the presence of ground overload is 16.35 MPa, and it can reach 17.1 MPa in the absence of ground overload. This indicates that ground overload can decrease the failure pressure of pipelines with corrosion defects and affect the safety production pressure of pipelines. Under the simultaneous action of corrosion defects and ground overload, the internal pressure threshold is reduced.

| Figure 5. Distributions of maximum von Mises stress and strain around X80 corrosion- defective pipelines under different internal pressure |

3.3 Ground overload effect

Figure 6(a) shows that both the maximum von Mises stress and strain around the corrosion defects of pipeline increase with the increase of ground overload. The von Mises stress and plastic deformation increase approximately linear upward trend with the increase of the ground overload when the ground overload exceeds 0.8 MPa. This indicates that ground overload has a direct effect on pipeline safety.

As shown in Figure 6(b), when the ground overload is greater than a certain level, a certain amount of warping deformation occurs at the center position of the corrosion defect, because of the large deformation of the soil squeezing pipe, as shown in the enlarged image Figure 6(b).

In the overload zone, the stress increases with the ground overload increasing, and the maximum value appears at the center of the corrosion zone (Figure 6(c)). In the transition zone, the stress distribution is an asymmetric S shape. The stress near the overload zone decreases with the increase of ground load. However, the stress near the non-overload zone increases with the increases of ground overload. In the non-overload zone, the stress distribution increases with the increases of ground overload, but tends to the same stable value at the far end of the pipeline.

Figure 6(d) shows the von Mises stress distribution of symmetrical section of the corrosion defect on X80 steel pipeline under different ground overload. It can be seen that there is a local high stress area at the top of the pipeline section (0°). The size and stress value of this area increases with the increase of ground overload. At the same time, the stress near the cross section 90°(270°) of the pipeline is the smallest, and the stress at the bottom of the pipeline smaller than the top. Therefore, ground overloads very harmful for the safe operation of pipelines, especially for pipelines with corrosion defects.

| Figure 6. Mechanical behavior of X80 corrosion-defective pipelines under different ground overloads |

In Figure 7, it can be seen that the stress concentration appears in the corrosion defect area, and the stress concentration obviously increases with the increase of the ground overload. When the ground overload is 2MPa, the maximum stress concentration reaches 688.6MPa, which is close to the ultimate tensile strength, as highlighted in dark red in Figure 7(a). When the load is less than 0.8MPa, the stress distribution develops from both sides of the corrosion defect to the middle along the width direction of the corrosion defect. The stress distribution develops from the center of the corrosion defect to the diagonal direction along the length of the corrosion defect when the ground overload is greater than 0.8MPa. The plastic deformation distribution also has the same trend. When the ground overload reaches 2MPa, the maximum plastic deformation appears at the center of the corrosion defect, as highlighted in dark red in Figure 7(b).

| Figure 7. Distributions of von Mises stress and strain at corrosion defects of X80 buried pipelines under different ground overloads |

The magnitude of the ground load will also affect the failure pressure of the corrosion-defective pipeline. According to failure criterion Eq.(2), the predicted value of the failure pressure of the corrosion-defective pipeline under different loads is shown in Table 6. The results show that the predicted failure pressure decreases with the increase of the ground overload. When the ground overload is greater than 2MPa, the failure pressure decreases significantly.

| OLD (MPa) | Failure pressure (MPa) |

|---|---|

| 0.4 | 16.91 |

| 0.8 | 16.64 |

| 1.2 | 16.22 |

| 1.6 | 16.13 |

| 2.0 | 15.63 |

3.4 Loading area effect

Both the maximum von Mises stress and strain around the corrosion defect of pipeline increase with the increase of the length of the loading area (Figure 8(a)). Moreover, there is also a significant non-linear relation between the above two. When the length of the loading area for less than 2.2 meters, the maximum stress and plastic deformation show an approximately linear upward trend. While it shows a downward trend with the length of loading area for greater than 2.2 meters. This indicates that when the ground overload area exceeds a certain range, the impact on pipeline corrosion defects is reduced. Therefore, the pipeline should be laid as far as possible to avoid areas with frequent human activities and frequent geological loads.

In Figure 8(b), the pipeline settlement displacement distribution along the axial direction increases with the length of the loading area increasing. When the length of the loading area reaches 3m, the maximum settlement displacement of the pipeline reaches 0.083m. As shown in Figure 8(c), when the length of the loading area reaches 2.2 m, the maximum stress appears at the center of the corrosion defect is 583.1MPa. Near the ground overload zone in the transition zone, the stress increases with the length of the loading area increasing. However, near the non-ground overload zone, the stress decreases with the length of the load increasing.

In Figure 8(d), the stress distribution approximately is apple-shaped, and the stress at the top of the pipeline is greater than the bottom. Meanwhile, high and low pressure zones alternately appear in the width direction on both sides of the pipeline corrosion defects. The minimum stress appears at both sides of the pipe. In general, there is a nonlinear relationship between the overall stress distribution law and the length of the loading area, which is very similar to Figure 8(a).

| Figure 8. Mechanical behavior of X80 corrosion-defective pipeline under different length of the loading area |

In Figure 9, when the length of the loading area is 1m, the stress concentration mainly is located at the center and both sides of the corrosion defect area. In other states, the stress concentration is mainly concentrated in the corrosion defect area. According to the strain distribution, the plastic deformation is mainly distributed at the bottom of the corrosion defect area, and the high plastic deformation is mainly distributed diagonally along the bottom of the corrosion defect. When the length of loading area less than 2.2m, the plastic deformation increases with the increase of the length of the loading area. However, the plastic deformation shows a downward trend with the length of the length of loading area, when the length of loading area greater than 2.2m.

| Figure 9. Distributions of maximum von Mises stress and strain around X80 corrosion- defective pipelines under different length of the loading area |

Table 7 shows the relationship between the predicted failure pressure and the length of the loading area. When the length of the loading area is less than 1.8m, the predicted failure pressure value remains unchanged. When the length of the loading area is greater than 2.2m, the failure pressure decreases with the length of the loading area increasing. Therefore, within a certain range, the length of the ground overload area has little effect on the failure pressure of the pipeline.

| Length(m) | Failure pressure (MPa) |

|---|---|

| 1.0 | 16.35 |

| 1.4 | 16.35 |

| 1.8 | 16.35 |

| 2.2 | 16.49 |

| 2.6 | 16.32 |

| 3 | 16.13 |

3.5 Defect depth effect

Both the maximum von Mises stress and strain around the corrosion defect of pipeline increases with the increase of corrosion defect depths, as shown in Figure 10(a). However, the maximum von Mises stress and strain of the corrosion defect pipeline shows an slowly increase with the increase of corrosion defect depths, and then rapidly increase when the corrosion depth is greater than 60%. Therefore, in the case of avoiding ground overload as much as possible, pipeline defects should be checked regularly to prevent the depth of corrosion defects further increasing, so as to ensure the safe operation of the pipeline.

In Figure 10(b), the pipeline settlement displacement along the axial direction does not vary significantly with the depth of corrosion defects increasing, which indicates that the depth of corrosion defects has little effect on the settlement displacement of the pipeline, under certain load conditions. Among them, the corrosion defect area has obvious warpage deformation, when the corrosion depth is 80%. As shown in Figure 10(c), the maximum stress increases with the increase of the corrosion depth in the overload zone, and maximum stress occurs at the center of the corrosion defect area.

The stress distribution is approximately apple-shaped under different corrosion defect depths, as shown in Figure 10(d). The stress value of the high stress area on the top of the pipeline increases with the increase of the corrosion defect depth. However, the stress value of the low stress area on both sides of the pipeline top decreases with the increase of the corrosion defect depth. The stress at the top of the pipeline is greater than the bottom, and the stress at 105° (255°) corresponding to both sides of the pipeline, is the smallest.

| Figure 10. Mechanical behavior of X80 corrosion-defective pipeline under different defect depths |

In Figure 11, the stress concentration appears in the corrosion defect area, and the stress concentration increases with the increase of the defect depth. When the corrosion defect depth is 20%, the stress concentration is not obvious. When the depth of the corrosion defect is greater than 40%, the stress concentration will obviously extend from the center of the corrosion area along the diagonal direction of the corrosion defect and occurs in the entire corrosion area, as highlighted in dark red in Figure 11(a). At the same time, it can be seen that there is a low stress area along the width and the axial direction around the corrosion area, which also proves the stress distribution law of Figures 11(c) and (d). The plastic deformation of the corrosion defect area on the pipeline also has the same trend.

| Figure 11. Distributions of maximum von Mises stress and strain around X80 corrosion- defective pipelines under different defect depths |

Table 8 shows the relationship between corrosion depths and predicted failure pressure under ground overload. The results show that the failure pressure of the pipeline decreases with the corrosion depth increasing. Therefore, pipeline defect detection should be carried out in time to avoid a further increase in pipeline corrosion depth, which results in pipeline failure pressure decreasing.

| Defect depth | Failure pressure (MPa) |

|---|---|

| 20% | 18.03 |

| 40% | 17.28 |

| 60% | 16.35 |

| 80% | 14.17 |

3.6 Buried depth effect

As shown in Figure 12(a), both the maximum von Mises stress and strain of corrosion defects on pipeline decrease with the increase of buried depth. When the buried depth is less than 1m, the maximum von stress decreases significantly with the increase of the buried depth, while the depth exceeds 1m, this downward trend decreases. This indicates that the protection capability of the pipeline does not increase significantly with the buried depth continues increased, when the buried depth of the pipeline reaches a certain value. The plastic deformation of the pipeline has the same changing trend with the buried depth of the pipeline increasing. Therefore, the appropriate depth of backfill should be selected, according to reasonable topography and landforms to decrease the probability of pipeline failure.

In Figure 12(b), when the buried depth is 0.4m, the pipeline settlement reaches the largest, and a certain degree of warping deformation occurs at the center of the corrosion defect location of the pipeline. In the overload zone and non-overload zone, the stress decreases with the increase of the buried depth, as shown in Figure 12(c). In the transition zone, the magnitude of the reduction of the stress value is very obvious, and the stress value is basically the same. Therefore, the shallower the buried depth, the easier to damage.

There is a high stress area that appears around the corrosion defect area, as shown in Figure 12(d). Low-stress areas and high-stress areas alternately appear along the width direction on both sides of the corrosion defect, the stress value of the high-stress area on both sides of the corrosion defect increases with the buried depth increasing. The minimum stress appears at about 90° (270°) of the pipe section. The stress at the bottom of the pipe is less than that at the top, so the top of the pipe is most easily damaged.

| Figure 12. Mechanical behavior of X80 corrosion-defective pipeline under different buried depths |

It can be seen that the stress concentration appears in the corrosion defect area, as highlighted in dark red inFigure 13(a). And the stress level decreases with the increase of the buried depths. The stress concentration area gradually decreases along the width and diagonal directions of the corrosion area. From the strain distribution, the plastic deformation distributes at the bottom of the corrosion defect, and the maximum plastic deformation occurs at the center of the bottom of the corrosion defect. The plastic deformation decreases with the buried depth increasing. The shallower the buried pipeline, the easier it to fail under ground overload. Therefore, buried pipelines should be buried more deeply in areas where ground overload may occur.

| Figure 13. Distributions of maximum von Mises stress and strain around X80 corrosion- defective pipelines under different buried depths |

Table 9 shows the relationship between the buried depth of the pipeline and the predicted failure pressure under ground overload. The failure pressure decreases, as the buried depth of the pipeline increases. Properly increasing the buried depth of the pipeline is beneficial to increase the failure pressure value of the pipeline.

| Buried depth (m) | Failure pressure (MPa) |

|---|---|

| 0.4 | 16.06 |

| 0.6 | 16.20 |

| 0.8 | 16.32 |

| 1.0 | 16.35 |

| 1.2 | 16.7 |

3.7 Soil Young’s modulus effect

In Figure 14(a), both the maximum von Mises stress and strain of pipeline corrosion defects decrease with the increase of soil Young’s modulus. Moreover, the maximum Mises stress and plastic deformation shows two different downward trends with the increase of soil Young’s modulus. When the soil Young’s modulus is greater than 20, the stress and plastic deformation change rate becomes lower, which indicates that the ability to resisting deformation of the soil will not change significantly with the soil Young’s modulus increase, when the soil Young’s modulus is over certain value.

The amount of settlement displacement decreases with the increase of soil Young’s modulus, as shown in Figure 14(b). When the soil Young’s modulus is 10MPa, the change rate of settlement displacement increases significantly, and the maximum settlement displacement reaches 0.1m. The stress distribution along the axial direction of the pipeline is shown in Figure 14(c), and the maximum stress occurs in the middle of the corrosion defect location. When the soil Young’s modulus is 10MPa, the stress value in the load zone is the largest. Meanwhile, in the non-loaded zone, the stress distribution is higher at a longer distance, because the soil is softer.

As shown in Figure 14(d), a high stress area appears around the corrosion defect area. When the soil Young’s modulus is 10MPa,an obvious high-stress area appears on both sides along the width direction of the corrosion defect. The overall stress distribution is similar to that described in the previous section. Low-stress areas and high-stress areas alternately appear along the width direction on both sides of the corrosion defect, and the stress value of the high-stress area on both sides of the corrosion defect increases with soil Young’s modulus increasing. Therefore, the appropriate backfill soil should be selected according to the reasonable topography and geomorphology.

| Figure 14. Mechanical behavior of X80 corrosion-defective pipeline under different soil Young’s modulus |

The von Mises stress and plastic deformation distribution both sides along with the width and length directions of the corrosion defect substrate area decreases with the increase of soil Young’s modulus, as shown in Figure 15. When the soil Young’s modulus is 10MPa, the maximum stress and plastic deformation reaches 632.9MPa and 0.01789, respectively. The maximum value of plastic deformation appears at the center of the corrosion defects, as highlighted in dark red in Figure 15(b). The higher the soil Young’s modulus, the harder the soil, and the stronger the ability to resisting deformation of soils under ground overload. Therefore, choosing a high soil Young’s modulus for pipeline backfilling will help to reduce the possibility of pipeline damage.

| Figure 15. Distributions of maximum von Mises stress and strain around X80 corrosion- defective pipelines under different soil Young’s modulus |

The type of stratum soil also affects the failure pressure of the pipeline. Table 10 shows the predicted failure pressure values of corrosion defect pipelines under different soil Young’s modulus. The results show that the failure pressure increases with the increase of the soil Young’s modulus. When the soil Young’s modulus is 10MPa, the failure pressure of the pipeline is only 15.71MPa, which indicates that it is easier to damage. Therefore, the soil type should avoid a soft soil layer when laying the pipeline.

| Young’s modulus (MPa) | Failure pressure (MPa) |

|---|---|

| 10 | 15.71 |

| 20 | 16.35 |

| 30 | 16.49 |

| 40 | 16.45 |

| 50 | 16.47 |

4. Conclusions

A FE model is established to analyze the local stress and strain distributions around the corrosion defect on the pressure pipeline under ground overload. The effects of internal pressure, ground overload, length of the loading area, defect depth, buried depth and soil Young’s modulus on mechanical behavior and failure pressure of buried corrosion defect pipelines are studied. The following conclusions are obtained:

1. The presence of ground overload results in the local von Mises stress and strain around the corrosion defect location increases greatly nonlinearly, cause the internal pressure threshold reduce. Stress and strain increase nonlinearly with the increase of internal pressure.

2. The von Mises stress, stress area, strain, strain area and settlement displacement of buried corrosion defect pipelines increase, and the failure pressure of pipeline decreases, with the increase of ground overload, length of the loading area and corrosion defect depth. However, the von Mises stress, stress area, strain, strain area and settlement displacement of buried corrosion defect pipelines decrease, and he failure pressure of the pipeline increases, with the increase of buried depth and soil Young’s modulus. High stress and high strain are located in the corrosion defect area and develop from the corrosion center along the diagonal direction of the corrosion defect.

Pipeline safety assessment under ground overload is an indispensable part of the pipeline integrity management program. The research results of this paper can be used to determine the local stress and strain of corrosion defects of different sizes under ground overload. Quantitative analysis of the stress, strain and failure pressure of buried pipelines with corrosion defects under ground overload will provide important suggestions on safe operating conditions and improve pipeline integrity management for the industry.

Acknowledgement

This research work was supported by National Key Research and Development Program of China (2016YFC0802102-03); Luzhou City Science and Technology Planning Project (2018-GYF-6); Sichuan Science and Technology Project: (20MZGC0090); Open Fund of National Joint Engineering Research Center for abrasion control and molding of metal materials (HKDNM201806); SWPU Youth Research and Innovation Team (2018CXTD12).

References

[1] Zhang J., Liang Z., Zhao G. Mechanical behaviour analysis of a buried steel pipeline under ground overload. Engineering failure analysis, 63:131-145, 2016.

[2] Alzabeebee S., Chapman D.N., Faramarzi A. A comparative study of the response of buried pipes under static and moving loads. Transportation Geotechnics, 15:39-46, 2018.

[3] Naeini S.A., Mahmoudi E., Shojaedin M.M., Misaghian M. Mechanical response of buried High-Density Polyethylene pipelines under normal fault motions. KSCE Journal of Civil Engineering, 20(6):2253-2261, 2016.

[4] Saadeldin R., Hu Y., Henni A. Numerical analysis of buried pipes under field geo-environmental conditions. International Journal of Geo-Engineering, 6(1), 2015.

[5] Qiao YY Study on the Influence of Heap Loading on the Force of Buried Gas Pipelines and Safety Evaluation Methods. MSc Thesis, Chengdu University of Technology, 2017.

[6] Xu T., Mao J., Liu Y., Yao A. Dynamic response and limit analysis of buried gas pipeline under ground consolidation load. Journal of Vibroengineering, 19(7):4989-5008, 2017.

[7] Fang, Yang, Li, Tan, Wang. Experimental and Numerical Study on Mechanical Analysis of Buried Corroded Concrete Pipes under Static Traffic Loads. Applied sciences, 9(23):5002, 2019.

[8] Liang Z., Yang Q., Zhang J.,Zhu B. Mechanical Analysis of Buried Polyethylene Pipelines under Ground Overload. Journal of Failure Analysis and Prevention, 19(1):193-203, 2019.

[9] Cai Z.Y, Zhang C.Y, Huang M.S. Analysis of the Influence of Ground Surcharge on Buried Pipelines with Variable Cross Sections. Rock and soil mechanics 32(S1): 408-412, 2011.

[10] Trickey S.A.,Moore I.D. Three-Dimensional Response of Buried Pipes under Circular Surface Loading. Journal of geotechnical and geoenvironment engineering, 133(2):219-223, 2007.

[11] Meesawasd N., Boonyasiriwat C., Kongnuan S., Chamchod F. Finite element modeling for stress analysis of a buried pipeline under soil and traffic loads. IEEE, 2016, pp. 385-390.

[12] Yao Y.H, Lei Z.Y, Shi L, Zhou J. Research on the Influence of Ground Load on Raw Water Conveyance Steel Pipe. Tunnel and rail transit. S1:52-55, 2019.

[13] Mohammad S. Kolbadi S. Effect of Ground Motions on Nonlinear Seismic Behavior of Corroded Buried Gas Pipeline. American Journal of Civil Engineering, 3(2):9, 2015.

[14] Barkanov EN, Dumitrescu A, Parinov IA. Non-destructive Testing and Repair of Pipelines, Academic Press, Latvia, 117-135, 2018

[15] Tian B., Liang Z., Zhang L. Pipeline Information Modeling: A New Tool for Pipeline Engineering. Revista Internacional de Métodos Numéricos para Cálculo y Diseño en Ingeniería, 36(1):1-8, 2020.

[16] Timashev S.A., Bushinskaya A.V. Markov approach to early diagnostics, reliability assessment, residual life and optimal maintenance of pipeline systems. Structural safety, 56:68-79, 2015.

[17] Sun J., Cheng Y.F. Assessment by finite element modeling of the interaction of multiple corrosion defects and the effect on failure pressure of corroded pipelines. Engineering structures, 165:278-286, 2018.

[18] Qin G., Cheng Y.F. Failure pressure prediction by defect assessment and finite element modelling on natural gas pipelines under cyclic loading. Journal of Natural Gas Science and Engineering, 81:103445, 2020.

[19] DNV-RP-F101 corroded pipelines. Det Norske Veritas, Norway, 2010.

[20] ASME Manual for determining the remaining strength of corroded pipelines. ASME B31G-2009. New York, USA, 2009.

[21] Freire J.L.F., Vieira R.D., Castro J.T.P., Benjamin A.C. PART 3: Burst tests of pipeline with extensive longitudinal metal loss. Experimental techniques, 30(6):60-65, 2006.

[22] Vazouras P., Karamanos S.A., Dakoulas P. Finite element analysis of buried steel pipelines under strike-slip fault displacements. Soil dynamics and earthquake engineering, 30(11):1361-1376, 2010.

[23] Motta R.S., Cabral H.L.D., Afonso S.M.B., Willmersdorf R.B., Bouchonneau N., Lyra P.R.M., de Andrade E.Q. Comparative studies for failure pressure prediction of corroded pipelines. Engineering failure analysis, 81:178-192, 2017.

[24] Drucker D.C, and Prager W. Soil mechanics and plastic analysis or limit design. Quarterly of Applied Mathematics. 10 (2): 157–165, 1952.

[25] Ma J. Numerical simulation of strength of buried polyethylene pipe under typical complex loading. MSc Thesis, Zhejiang University, 2013.

Document information

Published on 28/04/21

Accepted on 06/04/21

Submitted on 22/12/20

Volume 37, Issue 2, 2021

DOI: 10.23967/j.rimni.2021.04.003

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?