(Tag: Visual edit) |

|||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=='''1''' Introduction== | =='''1''' Introduction== | ||

| Line 345: | Line 289: | ||

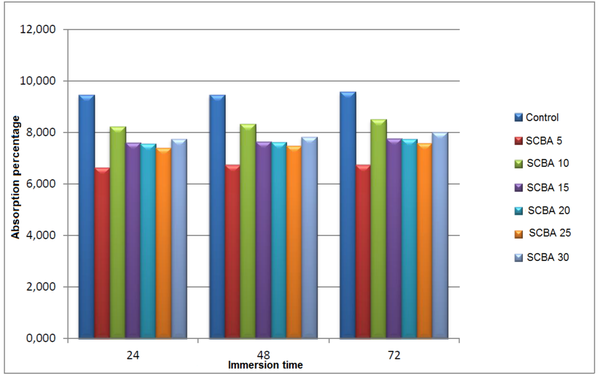

<span id='_Hlk481740546'></span>This test was performed on specimens after 28 curing days, measurements were taken 24, 48 and 72 hours from the start of the test. '''Figure 1''' shows the percentage of absorption (%) in relation to the time (hour) which the measurement was taken for the SCBA-content specimens. | <span id='_Hlk481740546'></span>This test was performed on specimens after 28 curing days, measurements were taken 24, 48 and 72 hours from the start of the test. '''Figure 1''' shows the percentage of absorption (%) in relation to the time (hour) which the measurement was taken for the SCBA-content specimens. | ||

| − | + | [[File:Moraes_et_al_2019a-image5.png|centre|600x600px]] | |

| − | [[ | + | |

<div id="_Hlk481747655" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Hlk481747655" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 356: | Line 299: | ||

It’s possible to observe the effect of the fineness in the blended admixtures, it leads to a dryer mortar, but improves the durability of the cementitious matrix by lowering the water absorption. | It’s possible to observe the effect of the fineness in the blended admixtures, it leads to a dryer mortar, but improves the durability of the cementitious matrix by lowering the water absorption. | ||

| − | + | [[File:Moraes_et_al_2019a-image6.png|centre|600x600px]] | |

| − | [[ | + | |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

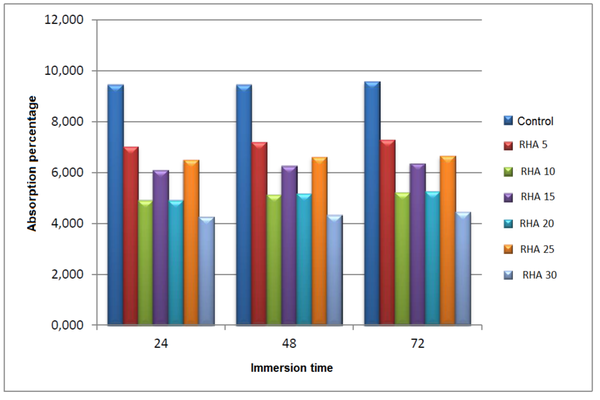

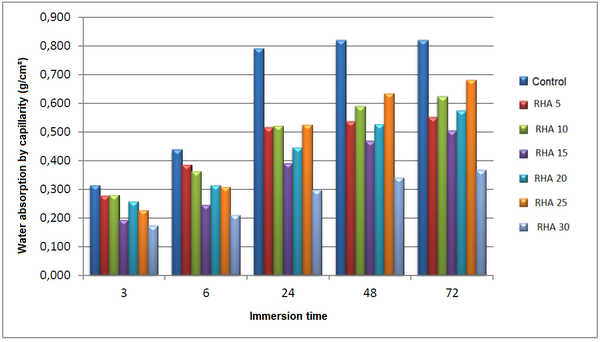

| − | <span style="text-align: center; font-size: 75%;">'''Figure 2. '''Water absorption x immersion time (hour) - RHA specimens</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 2. '''Water absorption x immersion time (hour) - RHA specimens.</span></div> |

<div id="_Hlk481749591" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Hlk481749591" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 368: | Line 310: | ||

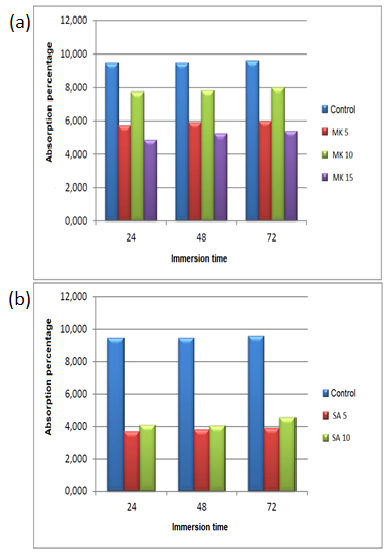

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

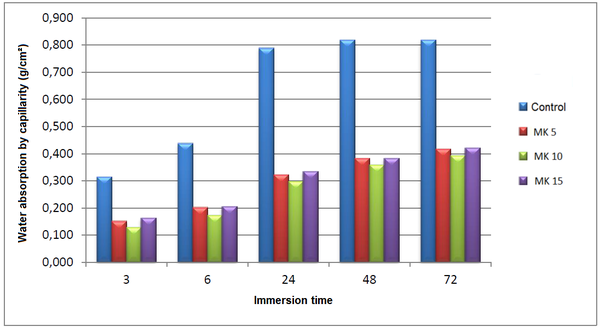

| − | <span style="text-align: center; font-size: 75%;">'''Figure 3. '''Water absorption x immersion time (hour) - MK (a) and SA (b) specimens</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 3. '''Water absorption x immersion time (hour) - MK (a) and SA (b) specimens.</span></div> |

The admixtures containing MK also showed lower absorption than the control mortar as shown in Figure 3 (a). The mortars containing SA presents the specimens with lower water absorption as shown in Figure 3 (b). | The admixtures containing MK also showed lower absorption than the control mortar as shown in Figure 3 (a). The mortars containing SA presents the specimens with lower water absorption as shown in Figure 3 (b). | ||

| Line 375: | Line 317: | ||

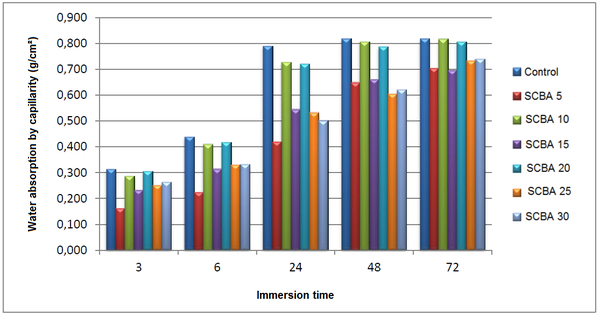

This test was performed on specimens after 28 curing days, measurements were taken 3, 6, 24, 48 and 72 hours from the start of the test. The water absorption by capillarity (g/cm²) x immersion time (hour) for the SCBA-content specimens is shown in '''Figure 4.''' | This test was performed on specimens after 28 curing days, measurements were taken 3, 6, 24, 48 and 72 hours from the start of the test. The water absorption by capillarity (g/cm²) x immersion time (hour) for the SCBA-content specimens is shown in '''Figure 4.''' | ||

| − | + | [[File:Moraes_et_al_2019a-image8.png|centre|600x600px]] | |

| − | [[ | + | |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 4. '''Water absorption by capillarity (g/cm²) x immersion time (hour) - SCBA specimens</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 4. '''Water absorption by capillarity (g/cm²) x immersion time (hour) - SCBA specimens.</span></div> |

The admixtures containing 10% and 20% of cement replacement by SCBA presented a similar water absorption as mortar with no pozzolan. SCBA 5, 15, 25 and 30 maintained a lower water absorption. | The admixtures containing 10% and 20% of cement replacement by SCBA presented a similar water absorption as mortar with no pozzolan. SCBA 5, 15, 25 and 30 maintained a lower water absorption. | ||

Samples containing the RHA pozzolan exhibited a lower water absorption by capillarity and immersion. | Samples containing the RHA pozzolan exhibited a lower water absorption by capillarity and immersion. | ||

| − | + | [[File:Moraes_et_al_2019a-image9.png|centre|600x600px]] | |

| − | [[ | + | |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 5. '''Water absorption by capillarity (g/cm²) x immersion time (hour) - RHA specimens</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 5. '''Water absorption by capillarity (g/cm²) x immersion time (hour) - RHA specimens.</span></div> |

| − | + | [[File:Moraes_et_al_2019a-image10.png|centre|600x600px]] | |

| − | [[ | + | |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 402: | Line 341: | ||

The finesses of the pozzolan provides dryer mortars, but also improves the durability of the matrices, which is possible to observe as the pozzolans which presented a lower diameter in the consistence test, also showed a lower water absorption. | The finesses of the pozzolan provides dryer mortars, but also improves the durability of the matrices, which is possible to observe as the pozzolans which presented a lower diameter in the consistence test, also showed a lower water absorption. | ||

| − | + | [[File:Moraes_et_al_2019a-image13.png|centre|600x600px]] | |

| − | [[ | + | |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

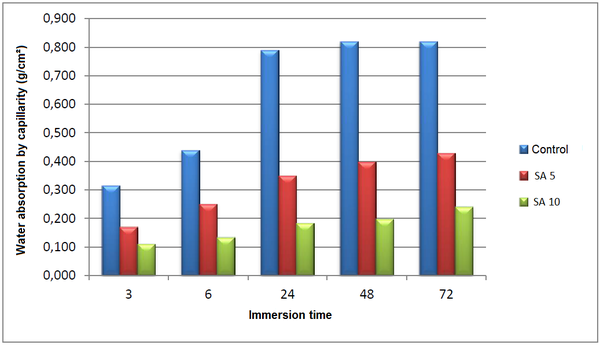

| − | <span style="text-align: center; font-size: 75%;">'''Figure 8. '''Water absorption by capillarity (g/cm²) x immersion time (hour) - SA specimens</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 8. '''Water absorption by capillarity (g/cm²) x immersion time (hour) - SA specimens.</span></div> |

=='''4''' Conclusions == | =='''4''' Conclusions == | ||

Revision as of 21:10, 27 October 2022

1 Introduction

Pozzolan is a material known since the Roman Empire, which were mixed with lime to produce compounds with cementitious properties. Currently, these pozzolans are classified as “natural pozzolan”, since there were basically a kind of volcano tuff, extracted mainly of the Pozzuoli region, hence the name pozzolan [1]. The “artificial pozzolan” is a pozzolan derived from human activities, a byproduct or waste from different industries. This work studied four artificial pozzolans from different sources as partial replacement of Portland cement in mortars: sugar cane bagasse ash (SCBA), rice husk ash (RHA), metakaolin (MK) and silica fume (SA).

Brazil is the sugar cane world’s biggest producer, also the major producer of sugar and ethanol [2]. To transform the sugar cane in those two products, milling is a part of the process, resulting in a byproduct known as sugar cane bagasse, which is burnt to generate energy, becoming the polluting residue sugar cane bagasse ash. The SCBA presents physic-chemical properties appropriate for its use as an alternative cement partial replacement in building constructions [3] and reduces the carbon dioxide’s emissions when used in blended cementitious matrices [4].

The rice husk is a byproduct of the rice agroindustry, is also use to generate energy through its burning, as result of this process the rice husk is reduced into ashes, the rice husk ash (RHA). The use of the ash as cement replacement contributed to a higher mechanical strength and a lower water absorption due to its high pozzolan activity and particle size [5].

Metakaolin (MK) is a byproduct from the calcination of kaolinite-rich clays, it is an aluminum-siliceous material with high pozzolan activity, which improves the properties of hardened concrete, lowering the porosity and providing a higher mechanical strength [6].

Silica fume is also derived from industries, more specifically the silicon metal or iron silicon industry. This mineral admixture enhances the mechanical behavior of concrete and reduces its total porosity [7].

The pozzolan improves the cementitious matrices’ mechanical behavior and durability by acting physically, due to its fineness, and chemically, known as pozzolanic reaction, in the blended admixtures. Furthermore, contributes to sustainability by providing an appropriate finality for materials initially classified as disposable and potentially pollutants.

In this way the aim of this research is to study the SCBA, RHA, MK and SA as a sustainable mineral admixtures for cement partial replacement by means of compressive strength, workability and water absorption analyses, comparing the pozzolan-content mortars with a control mixture, no Portland cement replacement.

2 Experimental Section

The materials used in this research were the Brazilian cement CP V – ARI, presenting no pozzolan, sugar cane bagasse ash (SCBA), a noncommercial material, produced by auto-combustion process in a furnace, then milled and sieved, rice husk ash (RHA), metakaolin (MK) and silica fume (SA), obtained commercially.

The cement was replaced by each pozzolan in a rate of 0% (control), 5%, 10%, 15%, 20%, 25% and 30% (by mass). The proportion of water/ cementitious material was 0.5 and the ratio of cementitious material to sand was 1:2.5. Specimens of 5 cm x 5 cm x 5 cm were molded for the hardened mortar analyses.

The compressive strength was tested in a EMIC Universal Machine after 3, 7, 28 and 90 curing days at 25°C. A statistical treatment was performed in the mechanical results following the Brazilian standard NBR 7215 [8]. The consistency was performed in a flow table according to the Brazilian standard NBR 13276 [9].

Water absorption analyses were carried out regarding to capillarity and immersion of the specimens after 28 curing days at 25°C. The tests were performed by following the Brazilian standards NBR 9779 [10] and NBR 9778 [11], respectively.

3 Results

3.1 Compressive strength of mortars

The strength results of the mortars containing SCBA are shown in Table 1. The SCBA XX nomenclature represents the cement replacement percentage by mass, thus SCBA 5 represents that 5% of the cement mass was replaced by SCBA.

| Specimens/Curing age | 3 | 7 | 28 | 90 | |

| Control | 39,17 | 40,89 | 50,57 | 59,53 | |

| SCBA 5 | 28,77 | 34,02 | 48,62 | 49,73 | |

| SCBA 10 | 35,34 | 35,84 | 45,33 | 50,86 | |

| SCBA 15 | 33,24 | 36,84 | 48,16 | 51,61 | |

| SCBA 20 | 29,55 | 30,29 | 40,31 | 51,61 | |

| SCBA 25 | 23,46 | 32,34 | 38,26 | 47,65 | |

| SCBA 30 | 28,15 | 30,49 | 39,39 | 45,42 | |

All mortars presented a continuous increasing with curing time, although the mortars containing SCBA presented a lower compressive strength when compared with the control mortar, it happens for all percentages of replacement at all ages, similar results were found in the literature [12].

The mortars containing RHA presented better results as shown in Table 2. In early ages, is possible to observe higher mechanical strength from the control mortar, which is common in pozzolanic studies. After 28 curing days, most of RHA-containing mortars presented a better compressive strength than the control mortar. This lateness in resistance gain is probably due to time which the cement hydrates and form calcium hydroxide which reacts with the pozzolan to produce more hydrated products.

| Specimens/Curing age | 3 | 7 | 28 | 90 | |

| Control | 39,17 | 40,89 | 50,57 | 59,53 | |

| RHA 5 | 25,69 | 52,13 | 53,23 | 66,6 | |

| RHA 10 | 36,48 | 41,51 | 57,09 | 62,24 | |

| RHA 15 | 33,62 | 40,52 | 52,77 | 63,29 | |

| RHA 20 | 25,68 | 31,46 | 46,55 | 54,52 | |

| RHA 25 | 28,41 | 35,98 | 41,76 | 52,59 | |

| RHA 30 | 28,51 | 38,06 | 53,91 | 59,6 | |

Mortars containing more than 15% cement replacement by MK resulted in very dry matrices, which resulted in very irregular specimens, due to its difficult molding. Table 3 shows the results of the percentages which were possible to mold.

| Specimens/Curing age | 3 | 7 | 28 | 90 | |

| Control | 39,17 | 40,89 | 50,57 | 59,53 | |

| MK 5 | 30,77 | 46,06 | 48,95 | 57,2 | |

| MK 10 | 41,08 | 44,87 | 45,65 | 57,64 | |

| MK 15 | 43,66 | 44,51 | 51,03 | 62,11 | |

After 28 curing days, the only dosage which overcome the control was the MK 15, but the other specimens presented similar results as the control mortar. Silica fume presented similar problem as the MK, it was only possible to mold specimens with cement replacement above 10%. This problem probably is due to fineness of both pozzolans. Table 4 shows the compressive strength results.

| Specimens/Curing age | 3 | 7 | 28 | 90 | |

| Control | 39,17 | 40,89 | 50,57 | 59,53 | |

| SA 5 | 36,03 | 47,26 | 63,77 | 66,76 | |

| SA 10 | 35,53 | 49,89 | 53,44 | 58,2 | |

In early ages, the SA specimens presented similar results as the control mortar. After 7 curing days, the SA containing mortars overcomes the specimens with no pozzolans.

It is possible to observe that large majority of the pozzolans containing specimens presented similar compressive strength as the control after 28 curing days. The pozzolans contributed to the mechanical behavior, since no compressive strength decay proportionally to the cement replacement. Sustainable, the four pozzolans presented optimistic results.

3.2 Consistency

The influence of the pozzolans on the consistency of the mortars is shown in Figure 6, which shows the opening diameter (cm) x dosage of the mortar. It’s possible to observe an inversely proportional relation between the diameter and the percentage of replacement, which means that the workability decreases as the pozzolan percentage increases.

The SCBA and RHA curves present a soft variation from a dosage to another, whereas the MK and SA diameter decreases abruptly as the cement replacement increases, which reflects in the moldering difficulty.

3.3 Water Absorption by Immersion

This test was performed on specimens after 28 curing days, measurements were taken 24, 48 and 72 hours from the start of the test. Figure 1 shows the percentage of absorption (%) in relation to the time (hour) which the measurement was taken for the SCBA-content specimens.

The samples containing SCBA presented lower water absorption than the control mortar. Figure 2 shows the water absorption of the mortars containing RHA.

The mortars containing RHA as a mineral admixture presented less water absorption comparing to the control.

It’s possible to observe the effect of the fineness in the blended admixtures, it leads to a dryer mortar, but improves the durability of the cementitious matrix by lowering the water absorption.

The admixtures containing MK also showed lower absorption than the control mortar as shown in Figure 3 (a). The mortars containing SA presents the specimens with lower water absorption as shown in Figure 3 (b).

3.4 Water Absorption by Capillarity

This test was performed on specimens after 28 curing days, measurements were taken 3, 6, 24, 48 and 72 hours from the start of the test. The water absorption by capillarity (g/cm²) x immersion time (hour) for the SCBA-content specimens is shown in Figure 4.

The admixtures containing 10% and 20% of cement replacement by SCBA presented a similar water absorption as mortar with no pozzolan. SCBA 5, 15, 25 and 30 maintained a lower water absorption.

Samples containing the RHA pozzolan exhibited a lower water absorption by capillarity and immersion.

MK 10 presented the higher water absorption by immersion and lowest by capillarity as shown in Figure 7.

The SA results also presented an inverted configuration of the observed in absorption by immersion as shown in Figure 8.

The finesses of the pozzolan provides dryer mortars, but also improves the durability of the matrices, which is possible to observe as the pozzolans which presented a lower diameter in the consistence test, also showed a lower water absorption.

4 Conclusions

The blended admixture presented a continuous increasing with curing time. The pozzolans contributed to the mechanical behavior, since no compressive strength decay proportionally to the cement replacement. In long ages, mortars containing pozzolans presented similar or higher compressive strength than the no replacement specimens. The fineness in the blended admixtures leads to a dryer mortar, but improves the durability of the cementitious matrix, the specimens containing

pozzolans obtained lower water absorption than the control mortar. Sustainable, is viable to use the pozzolans in compendious matrices.

Acknowledgments

The authors acknowledge the Brazilian agency FAPESP for the financial support.

References

[1] A. M. al-Swaidani, S. D. Aliyan, N. Adarnaly. Engineering Science and Technology, an International Journal, 19, pág. 970-979 (2016).

http://dx.doi.org/10.1016/j.jestch.2015.12.006

[2] BRASIL. Ministério da Agricultura. Cana-de-açúcar. Available on: [<http://www.agricultura.gov.br/vegetal/culturas/cana-de-acucar>. <http://www.agricultura.gov.br/vegetal/culturas/cana-de-acucar>.]

[3] G.C. Cordeiro, R.D. Toledo Filho, L.M. Tavares, E.M.R. Fairbairn, Cement & Concrete Composites, 30, pág. 410-418 (2008).

10.1016/j.cemconcomp.2008.01.001

[4] E.M.R. Fairbairn, B. B. Americano, G.C. Cordeiro, T. P. Paula, R.D. Toledo Filho, M. M. Silvoso, Journal of Environmental Management, 91, pág. 1864 – 1871(2010)

10.1016/j.jenvman.2010.04.008

[5] M. Jamil, M.N.N. Khan, M.R. Karim, A.B.M.A. Kaish, M.F.M. Zain, Construction and Building Materials, 128, pág. 185 – 198(2016)

http://dx.doi.org/10.1016/j.conbuildmat.2016.10.029

[6] H. Paiva, A.S. Silva, A. Velosa, P. Cachim, V.M. Ferreira, Construction and Building Materials, 140, pág. 374 – 384(2017)

http://dx.doi.org/10.1016/j.conbuildmat.2017.02.120

[7] Y. Senhadji, G. Escadeillas, M.Mouli, H. Khelafi, Benosman. Powder Technology, 254, pág. 314 – 323 (2014).

http://dx.doi.org/10.1016/j.powtec.2014.01.046

[8] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 7215: Cimento Portland – determinação da resistência à compressão. Rio de Janeiro: ABNT, 1997. 8 p. Versão corrigida.

[9] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 13276: Argamassa para assentamento e revestimento de paredes e tetos - Determinação do índice de consistência. Rio de Janeiro: ABNT, 2002. 3 p. Versão corrigida.

[10] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 9779: argamassas e concretos endurecidos - determinação de absorção de água por capilaridade. Rio de Janeiro: ABNT, 2012. 3 p.

[11] ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR 9778: argamassas e concretos endurecidos - determinação de absorção de água, índice de vazios e massa específica. Rio de Janeiro: ABNT, 2005. 4 p.

[12] PEREIRA, A. M. Análise da viabilidade da utilização da cinza do bagaço de cana-de-açúcar como aglomerante para a produção de matrizes cimentantes. Ilha Solteira: [s.n.], 2014. 207 f. Dissertation (master) – Universidade Estadual Paulista, Faculdade de Engenharia de Ilha Solteira, Ilha Solteira, 2014.

Document information

Published on 14/04/19

Accepted on 14/04/19

Submitted on 14/04/19

Volume 03 - Comunicaciones Matcomp17 (2019), Issue Núm. 2 - Aplicaciones, uniones y reparaciones de los materiales compuestos, 2019

DOI: 10.23967/r.matcomp.2019.04.010

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?