| Line 137: | Line 137: | ||

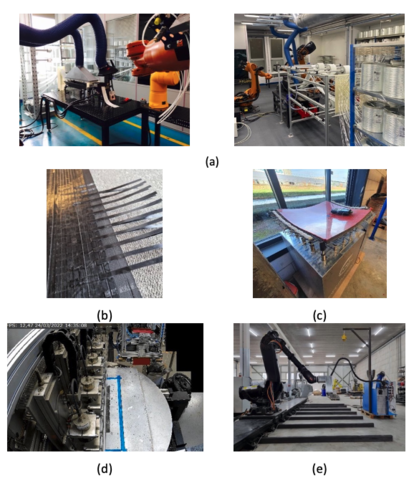

:* FGF based its modifications on solving the problems related to the manufacturing of large parts (<span id='cite-_Ref135034102'></span>[[#_Ref135034102|Figure 2]]e). | :* FGF based its modifications on solving the problems related to the manufacturing of large parts (<span id='cite-_Ref135034102'></span>[[#_Ref135034102|Figure 2]]e). | ||

| − | [[Image:Review_795206965599-image7.png|414px]] | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> |

| + | [[Image:Review_795206965599-image7.png|414px]] </div> | ||

<span id='_Ref135034102'></span><div id="_Ref121503219" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <span id='_Ref135034102'></span><div id="_Ref121503219" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

Revision as of 15:26, 20 June 2023

1. Introduction

Most of the current pleasure crafts and sailing yachts, passenger and car ferries, patrol and rescue crafts, and naval ships below 50 m long are built in Fibre-Reinforced Polymer (FRP) materials. This is mainly because composites are a key element in lightning structures due to their elevated strength-to-weight characteristics, excellent corrosion resistance and low maintenance costs [1]. So, whilst by volume, Europe's shipbuilding market share is now “only” around 19% in terms of value of the global total [2], it has an undisputed potential to be the market leader in the sector of small and medium-length composite ships, due to its specialization in high-quality and high-technology vessels and production methods. In fact, almost all composite naval ships, luxury pleasure craft, cruise ships and most Ro-Pax vessels are currently built in Europe.

However, the production capacity in numbers of FRP ships nowadays is not achieving its full potential due to high total production costs. One of the main reasons for this limitation is the lack of automated procedures, and the current semi-artisanal methods used in FRP shipbuilding [3]. Indeed, the high dependence on the operator, affects the quality and consistency of the fabricated composite parts (poor manufacturing can lead to high defect levels, fibre distortion, incorrect fibre alignment, low fibre volume fractions, inability to achieve expected mechanical performance, and in-service failure).

To maintain or even expand the competitive position of the European Union (EU) shipbuilding industry and in particular small and medium-sized shipyards, it is essential to improve, optimize and automate the production processes for FRP ship parts. This needs to happen throughout the entire value chain to achieve the aforementioned full potential.

The European project FIBRE4YARDS (No 101006860) [4] addresses this challenge through the implementation of the Shipyard 4.0 concept and applying the following innovative FRP manufacturing technologies to the shipbuilding (Table 1):

These technologies can be divided into 3 groups: mature processes working for other industries; processes still working in a lab-scale environment; and processes close to industrialization. However, none of them is established yet in the shipbuilding industry. Thus, during the adaptation process, the decision-making stage must follow some specific steps. In this paper, based on the experience during the FIBRE4YARDS project, implementation guidelines on adapting new composite manufacturing processes to shipbuilding are presented.

2. Implementation guidelines

The following sections present the implementation guidelines obtained from the work carried out by each technology of the FIBRE4YARDS project. The different steps are based on the experience of adapting these technologies to shipbuilding. However, these guidelines can be extended for other technologies and/or other markets.

2.1. Analysis of the market and contrast of the value proposition

The knowledge of the market where the technology will focus is essential to analyse if the value proposition responds to its necessities. In this sense, the following questions have been identified as the most important ones to be answered:

- Is the market familiar with the proposed materials? If so, what are the current manufacturing techniques? What does your technology bring new? If not, why do they not use these materials?

- What are the barriers in the market? Can your technology break those barriers?

- What is the market volume? Can your technology withstand the demand of the market or is high enough to enter the market?

- What is the interest of the stakeholders (shipyards) in your technology? Do they know your value proposition?

As FRP materials are extensively used for building lightweight vessels, the stakeholders already know the materials and will only focus on the value proposition of the analysed technologies. By analysing the current manufacturing methods (hand lay-up, vacuum bag, prepreg lay-up, spray-up, resin transfer moulding and vacuum-assisted resin infusion [5]), the technology provider could find an entry opportunity in the shipbuilding industry.

Regarding barriers, after a deep analysis of the market through interviews with shipyards, it can be concluded that the barriers to FRP materials in shipbuilding can be divided into opportunities or weaknesses for the implementation of new FRP manufacturing processes.

- Opportunities: labour intensity, work health and safety, scalability, location, quality.

- Weakness: fire safety, supply, repair, and insurance.

As can be noticed, all the weaknesses reported are related to materials and not to the manufacturing processes. In fact, the barriers regarding manufacturing and quality present high opportunities for the analysed technologies.

With regards to market volume, based on IHS Markit’s Sea-web database, fishing vessels, yachts, and naval auxiliary and passenger ships are the most FRP selling ships (with more than 200, 150, and 50 between 2015 and 2021, respectively). Thus, these types of vessels seem to be the most adequate from a market volume point of view.

Finally, to know the interest of the stakeholders, a survey was sent to shipyards. It has been found that new construction (NC) and Refit shipyards find some technologies more interesting than others when NC & Refit shipyards are interested in all the technologies. The conclusion obtained was that the first ones are used to work with fixed production procedures. Whereas seconds have a more general view and see opportunities for a wider range of production methods. On the other hand, some technologies are less known in shipyards and make them difficult to see the advantages that can bring their use in production. This emphasizes the importance of dissemination.

2.2. Analysis of the initial state of the technology and application selection

Reviewing and collecting data about the technology will help technology providers to select suitable applications in the target market. In this sense, the correct application selection is crucial to success since all the efforts must be focused on it. In fact, the best way to outreach to early adopted stakeholders is by proving your value proposition through a minimum valuable product (MVP) or demonstrator.

The first point where the technology providers must focus is on the technical capacities of their technology. This is essential to compare it with current manufacturing techniques, and to select the suitable application. Aspects such as standard output, cycle time, high volume production sustainability and feasibility of automation give information about the number of parts that the technology will be able to manufacture in a cost-effective way (linked with market volume). On the other hand, aspects such as maximum part size, thickness, number of controlled surfaces, material type and the configuration of the product will give information about the type of product that the technology can manufacture. Other points to be considered are the mechanical properties, the geometrical accuracy, and the cost of the product, which will be essential to determine the final application.

Following this analysis, the different applications have been identified for each technology:

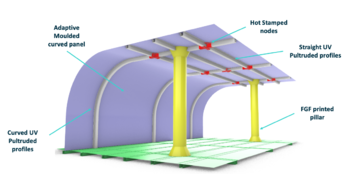

- Adaptative moulds: this technology suits for manufacturing the curved panels of the hull or the superstructure.

- Hot Stamping: the high mechanical properties and the flexibility in the shape of the hot stamping products, make this technology very suitable for connection nodes.

- ATP: continuous fibre reinforcements can be applied directly to reinforce some parts or even for manufacturing parts that support high longitudinal loads, such as boat keel.

- UV Pultrusion: the curved and straight profiles of technology can be applied for stiffeners, stringers or even beams since they present high mechanical properties.

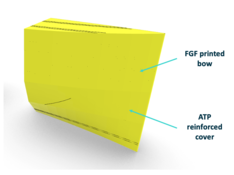

- FGF: the flexibility of shapes makes this technology suitable for many applications, and even is possible to manufacture the whole vessel (small ships). However, the mechanical properties of the final product restrict their use, so printing strategies must be explored to find the best solution.

With this conclusion, a final demonstrator with the contribution of each technology has been designed. In Figure 1 can be seen the design of the demonstrators where all the technologies present their value proposition.

|

|

2.3. Adapting technology to the application

Once the target application has been identified, the next step is to analyse the feasibility of the current technologies to produce the required products and modify them in consequence. Thus, this point will differ depending on the starting point of each technology and the selected application. This fact is evident when the modifications of each technology are analysed:

- The adaptative moulds technology was focused on modifications to improve the business case of the modular building of composite ships (Figure 2c).

- Hot Stamping was more focused on the implementation of Industry 4.0 tools (Figure 2d).

- FGF based its modifications on solving the problems related to the manufacturing of large parts (Figure 2e).

2.4. Optimisation of the product production

The main goal of the optimisation of the manufacturing process is to fulfil the requirements of the new target market. Even when the manufacturing technology is providing products to other markets, the incorporation in a different one implies a review of the actual production system. During this study, the optimisation has been conducted through three main pillars: scalability, digitalisation and the compromise between productivity, costs and properties of the product.

2.4.1. Scalability

Scalability directly affects the optimisation of the manufacturing processes, since the production of bigger parts implies new challenges for the technology providers. Thus, technology providers must check if the geometrical quality of the parts and the production strategies have been affected by the scaling-up process:

- Can the repeatability of the manufactured parts be ensured?

- What are the new tolerances of manufactured parts?

- Is the same strategy able to manufacture the new parts?

- Is the required tooling scalability feasible?

- Are the production parameters different from the initial ones?

In the case of UV Pultrusion, the size of the part directly affects the production process due to the increment of the pulling forces. Thus, the efforts of optimisation were focused on the process parameters ensuring the repeatability and the geometrical accuracy of the parts (Figure 3a). On the other hand, the adaptative moulds technology presents issues related to the scalability of their tooling, especially on their heating surfaces and the new heating system designed during the modification phase. After the optimisation phase, the embedded heating mechanism is scalable and robust with a direct impact on productivity (Figure 3b).

|

|

| (a) | (b) |

2.4.2. Digitalisation

In the new era of manufacturing processes, digitalization becomes part of the strategic agendas of technology providers. Thus, digitalization is imperative when implementing new technologies in the shipbuilding industry. To apply the methodologies of Industry 4.0 in the manufacturing processes some questions must be answered:

- What are the main parts to be monitored to control the process?

- How can the Industry 4.0 tools be applied in the process?

- How can confidential information be differentiated from the one required by the customer? How do we protect confidential information? Cybersecurity?

All the technology providers are working on this point. However, hot stamping process optimisation has especially pushed this concept. As an example, Figure 4 presents the Synoptic Dashboards developed during the optimisation.

2.4.3. Compromise between productivity, costs and properties

The final price of your product is fixed by the market, and therefore, the manufacturing costs must be within the acceptable range. However, the properties of the final product are a key aspect to be considered. Thus, the cost reduction must not be translated to a reduction in the quality of the final product which could leave the technology out of the market.

It could be said that the increase in productivity is the one that presents a higher impact on costs. Thus, this is the point that all the technologies must work on during the optimisation phase. Perhaps, the most representative example is the work carried out by FGF technology. They worked on optimising the material flow through the extruders. To that end, the extruders were recalibrated to find the exact output at slow and high printing speeds. In addition, several printing strategies have been analysed to find the best compromise between productivity, cost and final properties (Figure 5).

|

|

|

2.5. Measure the improvements and market validation

The measurement of the obtained results is just as important as the performed modifications and optimisation stages. It has no sense to work on the first points of this guide if the results are not contrasted with the initial objectives. Therefore, the last point must be the measurement of the improvements achieved and the feedback of the stakeholders, in this case, the shipyards.

- Most of the improvements of UV Pultrusion process are related to the scalability of the process. The maximum part size has been increased by an order of magnitude and the thickness of the parts has been increased by 50%.

- The automation of work preparation on curved panels reduces the work preparation time by 50%. While the development of on-the-mould heating increases productivity and reduces the energy consumption to roughly 1/3 that of an oven.

- The production of small vessels with FGF is now available with a more reliable process due to the scalability process carried out and the work performed on productivity.

- Most of the upgrades measured in Hot Stamping are related to control and monitoring improvements. New sensors and dashboards implementation reduce the direct labour cost by 50%.

- The optimisation of ATP process reduces the process throughput from 5 kg/h to 10kg/h. In addition, bigger parts can be manufactured (8 meters).

3. Conclusions

Incorporating disruptive technologies into new markets is a challenge since there are many social, cultural and technical aspects to consider. Thus, the decision-making stage must follow some specific steps: from the first analysis of the business and technical feasibility to the final measurements of the achieved improvements. In this paper, some guidelines have been proposed to follow this decision-making stage. All the steps have been added based on the experience during the FIBRE4YARDS project. The main conclusions are listed below:

- The barriers of the market can be presented as opportunities or weaknesses. Thus, it is important to analyse them to seize opportunities and strengthen weaknesses.

- The perception of the stakeholders will help technology providers to define the early clients and to develop strategies to approach them.

- Reviewing and collecting data about the technology will help technology providers to select suitable applications in the target market. At least, four main aspects must be considered: feasibility, geometrical accuracy, mechanical properties and costs.

- The selection of a suitable application is essential to approach stakeholders since the credibility of technology providers increases with a demonstrator or MVP.

- Adapting technology strongly depends on the previous steps (market, initial state and application).

- Scalability, digitalisation and compromise between cost and properties have been identified as the most important factors in the adaptation of manufacturing technologies in the case of shipbuilding industry.

- Measure the improvements and contrast them with stakeholders will show the necessity or not of pivoting to other steps of the guidelines.

Acknowledgements

The authors thank European Commission for providing financial support through the Fibre4Yards project (this project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 101006860) for this study.

References

[1] J. Graham-Jones and J. Summerscales, Marine applications of advanced fibre-reinforced composites. Woodhead Publishing, 2015.

[2] European Comission, Blue Economy Report 2022, vol. 19, no. 3. 2022.

[3] F. Rubino, A. Nisticò, F. Tucci, and P. Carlone, “Marine application of fiber reinforced composites: A review,” J. Mar. Sci. Eng., vol. 8, no. 1, 2020.

[4] FIBRE composite manufacturing technologies FOR the automation and modular construction in shipYARDS | FIBRE4YARDS Project | H2020 | CORDIS | European Commission. URL: [https : https :] / /cordis.europa.eu/project/id/101006860.

[5] M. K. Buragohain, Composite structures: design, mechanics, analysis, manufacturing, and testing. CRC press, 2017.

Document information

Published on 15/10/23

Accepted on 30/06/23

Submitted on 18/05/23

Volume 08 - COMUNICACIONES MATCOMP21 (2022) Y MATCOMP23 (2023), Issue Núm. 2 - Fabricación y Aplicaciones Industriales - Sostenibilidad y Reciclaje., 2023

DOI: 10.23967/r.matcomp.2024.02.06

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?