m (Materiales.Compuestos moved page Draft Compuestos 148374014 to Review 193771734973) |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 12: | Line 12: | ||

One of the common problems in the composite materials is the monitoring of the matrix polymerization as well as stresses monitoring. Usually the polymerization process monitoring is performed by different sensors like the pressure transducers and dielectric sensors [22]. However employed sensors require direct contact with the resin and of its electronic associated [22]. | One of the common problems in the composite materials is the monitoring of the matrix polymerization as well as stresses monitoring. Usually the polymerization process monitoring is performed by different sensors like the pressure transducers and dielectric sensors [22]. However employed sensors require direct contact with the resin and of its electronic associated [22]. | ||

| + | [[File:Draft_Compuestos_148374014-image5-c.png|centre|458x458px]] | ||

| + | ''' ''' | ||

| − | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | |

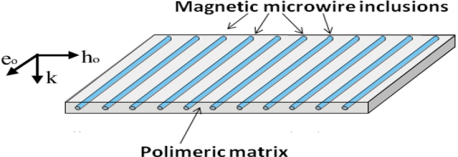

| − | + | <span style="text-align: center; font-size: 75%;">'''Figure 1.''' Sketch of a FRC with embedded microwires.</span></div> | |

| − | '''Figure 1.''' Sketch of a FRC with embedded microwires . | + | |

One of the proposed solutions for non-destructive FRC monitoring is use of the piezoelectric fibers with diameters of 10 to 100 μm [23]. However, this solution requires electrical field supply plates occupying a significant area. | One of the proposed solutions for non-destructive FRC monitoring is use of the piezoelectric fibers with diameters of 10 to 100 μm [23]. However, this solution requires electrical field supply plates occupying a significant area. | ||

| Line 69: | Line 70: | ||

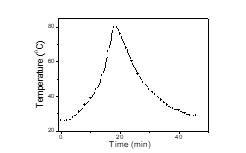

As can be observed from the Figure 2, the matrix polymerization produces a heating of the composite up to 80 <sup>o</sup>C. | As can be observed from the Figure 2, the matrix polymerization produces a heating of the composite up to 80 <sup>o</sup>C. | ||

[[File:Captura de pantalla 2022-07-10 133246.png|centre|246x246px]] | [[File:Captura de pantalla 2022-07-10 133246.png|centre|246x246px]] | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 2.''' Evolution of temperature upon the polymerization.</span> | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> |

| + | <span style="text-align: center; font-size: 75%;">'''Figure 2.''' Evolution of temperature upon the polymerization.</span></div> | ||

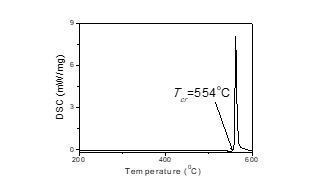

In order to ensure that employed microwires maintain it amorphous structure we performed the DSC studies of the crystallization temperature in order to evaluate the crystallization temperature. As can be observed from Fig.3 the crystallization temperatures, ''T<sub>cr</sub>'', (determined as the beginning of the first crystallization peak) is about 554 <sup>o</sup>C (see Figure 3). Therefore all the changes observed in the experiments must be attributed to the magnetoelastic behavior of employed microwires only. | In order to ensure that employed microwires maintain it amorphous structure we performed the DSC studies of the crystallization temperature in order to evaluate the crystallization temperature. As can be observed from Fig.3 the crystallization temperatures, ''T<sub>cr</sub>'', (determined as the beginning of the first crystallization peak) is about 554 <sup>o</sup>C (see Figure 3). Therefore all the changes observed in the experiments must be attributed to the magnetoelastic behavior of employed microwires only. | ||

[[File:Captura de pantalla 2022-07-10 133322.png|centre|313x313px]] | [[File:Captura de pantalla 2022-07-10 133322.png|centre|313x313px]] | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 3.''' DSC curves of as-prepared Fe<sub>3.8</sub>Co<sub>65.4</sub>Ni<sub>1</sub>B<sub>13.8</sub>Si<sub>13</sub>Mo<sub>1.35</sub>C<sub>1.65 </sub>microwires</span> | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> |

| + | <span style="text-align: center; font-size: 75%;">'''Figure 3.''' DSC curves of as-prepared Fe<sub>3.8</sub>Co<sub>65.4</sub>Ni<sub>1</sub>B<sub>13.8</sub>Si<sub>13</sub>Mo<sub>1.35</sub>C<sub>1.65 </sub>microwires.</span></div> | ||

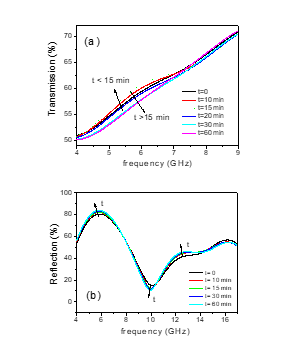

As described above, we performed in-situ experiments of composites placed inside the un-echoic chamber with the glass-coated microwires embedded in a polymerized composite. We measured the transmission, ''T'', and reflection, ''R'', parameters of the composite containing Co-rich microwires (Fe<sub>3.8</sub>Co<sub>65.4</sub>Ni<sub>1</sub>B<sub>13.8</sub>Si<sub>13</sub>Mo<sub>1.35</sub>C<sub>1.65</sub>) using the free space system. | As described above, we performed in-situ experiments of composites placed inside the un-echoic chamber with the glass-coated microwires embedded in a polymerized composite. We measured the transmission, ''T'', and reflection, ''R'', parameters of the composite containing Co-rich microwires (Fe<sub>3.8</sub>Co<sub>65.4</sub>Ni<sub>1</sub>B<sub>13.8</sub>Si<sub>13</sub>Mo<sub>1.35</sub>C<sub>1.65</sub>) using the free space system. | ||

| Line 82: | Line 85: | ||

[[File:Captura de pantalla 2022-07-10 133401.png|centre|348x348px]] | [[File:Captura de pantalla 2022-07-10 133401.png|centre|348x348px]] | ||

| − | '''Figure 4.''' The Transmission, T (a) and reflection, R (a) parameters measured using free-space system during the composite polymerization. | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> |

| + | <span style="text-align: center; font-size: 75%;">'''Figure 4.''' The Transmission, T (a) and reflection, R (a) parameters measured using free-space system during the composite polymerization.</span></div> | ||

[[File:Captura de pantalla 2022-07-10 133430.png|centre|284x284px]] | [[File:Captura de pantalla 2022-07-10 133430.png|centre|284x284px]] | ||

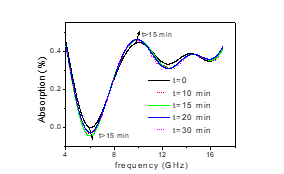

| − | <span style="text-align: center; font-size: 75%;">'''Figure 5.''' The Absorption, A, evaluated from data on T and R during the composite polymerization</span> | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> |

| + | <span style="text-align: center; font-size: 75%;">'''Figure 5.''' The Absorption, A, evaluated from data on T and R during the composite polymerization.</span></div> | ||

Observed changes of electromagnetic properties can be related to two main phenomena arising during the composite matrix polymerization: heating and mechanical stresses. | Observed changes of electromagnetic properties can be related to two main phenomena arising during the composite matrix polymerization: heating and mechanical stresses. | ||

| Line 94: | Line 99: | ||

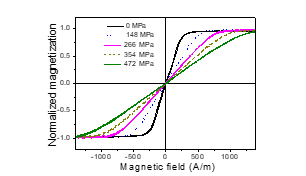

However, hysteresis loops of studied samples are considerably affected by applied tensile stresses as shown in Figure 6. | However, hysteresis loops of studied samples are considerably affected by applied tensile stresses as shown in Figure 6. | ||

[[File:Captura de pantalla 2022-07-10 133506.png|centre|306x306px]] | [[File:Captura de pantalla 2022-07-10 133506.png|centre|306x306px]] | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 6'''. Effect of applied stress on hysteresis loops of as-prepared Fe<sub>3.8</sub>Co<sub>65.4</sub>Ni<sub>1</sub>B<sub>13.8</sub>Si<sub>13</sub>Mo<sub>1.35</sub>C<sub>1.65</sub>microwires</span> | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> |

| + | <span style="text-align: center; font-size: 75%;">'''Figure 6'''. Effect of applied stress on hysteresis loops of as-prepared Fe<sub>3.8</sub>Co<sub>65.4</sub>Ni<sub>1</sub>B<sub>13.8</sub>Si<sub>13</sub>Mo<sub>1.35</sub>C<sub>1.65</sub>microwires.</span></div> | ||

As expected, as-prepared Fe<sub>3.8</sub>Co<sub>65.4</sub>Ni<sub>1</sub>B<sub>13.8</sub>Si<sub>13</sub>Mo<sub>1.35</sub>C<sub>1.65</sub> microwire present linear almost non-hysteretic loop (see Fig2). This –non-hysteretic loop maintains it linear shape upon applied tensile stress, however considerably <sub>H</sub>''<sub>k</sub>'' rising upon tensile stress can be appreciated. | As expected, as-prepared Fe<sub>3.8</sub>Co<sub>65.4</sub>Ni<sub>1</sub>B<sub>13.8</sub>Si<sub>13</sub>Mo<sub>1.35</sub>C<sub>1.65</sub> microwire present linear almost non-hysteretic loop (see Fig2). This –non-hysteretic loop maintains it linear shape upon applied tensile stress, however considerably <sub>H</sub>''<sub>k</sub>'' rising upon tensile stress can be appreciated. | ||

Latest revision as of 18:32, 26 November 2022

1 Introduction

Amorphous magnetic materials can present an unusual combination of excellent magnetic properties (e.g. high magnetic permeability, giant magnetoimpedance, GMI, effect, magnetic bistability, Matteucci and Widemann effects, ) and superior mechanical properties (plasticity, flexibility) making them suitable for numerous industrial applications [1-6]. Aforementioned soft magnetic properties are originated by the absence of the magnetocrystalline anisotropy and defects (dislocations, grain boundaries…) typical for crystalline magnets [1-3, 6-8]. Furthermore the preparation method involving rapid melt quenching is quite fast and cheap and above mentioned magnetic softness can be realized without any complex post-processing treatments [3-5].

The development of novel applications of amorphous materials requires new functionalities, i.e. reduced dimensions, enhanced corrosion resistance or biocompatibility [8]. Therefore, great attention has been paid to development of alternative fabrication methods allowing preparation of amorphous materials at micro-nano scale involving melt quenching [6-8].

Glass-coated microwires prepared using the Taylor-Ulitovsky method fit to most of aforementioned expectation: such magnetic microwires have micro-nanometric diameters (typically 0.5-50 μm) covered by thin, insulating, biocompatible and flexible glass-coating [7-11] and can present excellent magnetic softness or magnetic bistability [7, 9, 11].

These features of glass-coated microwires allow development of new exciting applications in various magnetic sensors [12-16], as well as in smart composites with tunable magnetic permittivity [17-19]. One more advantage of glass-coated microwires is excellent mechanical properties [5].

Recently, the stress dependence of hysteresis loops and GMI effect are proposed for the mechanical stresses monitoring in fiber reinforced composites (FRC) containing microwires inclusions or using magnetoelastic sensors based on stress dependence of various magnetic properties [18, 20,21].

One of the common problems in the composite materials is the monitoring of the matrix polymerization as well as stresses monitoring. Usually the polymerization process monitoring is performed by different sensors like the pressure transducers and dielectric sensors [22]. However employed sensors require direct contact with the resin and of its electronic associated [22].

One of the proposed solutions for non-destructive FRC monitoring is use of the piezoelectric fibers with diameters of 10 to 100 μm [23]. However, this solution requires electrical field supply plates occupying a significant area.

One of the promising solutions addressing the problem of non-destructive FRC monitoring is a novel sensing technique involving free space microwave spectroscopy utilizing ferromagnetic microwire inclusions presenting the high frequency impedance quite sensitive to tensile stress and magnetic field [17, 18, 24]. Mentioned above glass-coated microwires with metallic nucleus diameters of 0.5 - 50 μm presenting excellent mechanical and corrosive properties fit perfectly requirements of this technique making it suitable for remote stresses and temperature monitoring in FRCs [17,18,24].

In this work we provide our recent results on study of the stresses arising during the polymerization of the matrix in FRCs on permittivity of the FRC with embedded microwire inclusions.

Consequently, in this paper, we present new experimental results on direct monitoring of the polymerization process in the FRC preparation using embedded Co-based glass-coated microwires.

2 Experimental method and techniques

2.1 Materials

Glass-coated Fe3.8Co65.4Ni1B13.8Si13Mo1.35C1.65 (metallic nucleus diameter, d=18.8 μm, total diameter, D=22.2 μm, ρ =d/D= 0.88) microwires with low negative magnetostriction coefficients, λs, have been prepared by Taylor-Ulitovsky technique described elsewhere [7,8,11,12]

As previously reported by us, as-prepared Fe3.8Co65.4Ni1B13.8Si13Mo1.35C1.65 microwires present good magnetic softness, high GMI effect and low negative magnetostriction coefficients, λs, of about -01x10-6 [25,26].

The temperature during the polymerization process has been measured by a standard thermocouple.

For the composite matrix we used a vinylester resin (DERAKANE 8084) resin, accelerated with Cobalt Octoate (0,3 pph) and catalyzed with Methyl Ethyl Ketona (MEK 60%, 1,5 pph). DERAKANE 8084 epoxy vinyl ester resin is an elastomer modified resin designed to offer increased adhesive strength, superior resistance to abrasion and severe mechanical stress, while providing greater toughness and elongation.

The liquid resin exhibit the following properties: the density at 25°C is of 1.02 g/mL, the dynamic viscosity at 25°C is of 360 MPa and the styrene content is of 40%.

All technical resin information appears in its technical data sheet (Document 1820 V5 F2, Language ES “draft”, © 2017 Ashland Inc.).

The composites with ordered glass coated amorphous wires embedded in the thermoset matrix polymerization were prepared (Fig.1).

The polymerizing matrix provides external stimuli for the microwire inclusions (Figure 1), which affects the magnetic properties and the GMI effect of microwires.

2.2 Experimental methods

Consequently, we used the free space measurement system previously described in details in [18,24]. The reflection (R) and transmission (T) coefficients were measure in free-space. The experimental set-up consists of a pair of broadband horn antennas (1-17 GHz) and a vector network analyzer. The composite was placed in 20 x 20 cm2 window to avoid the edge effects. This window limits the applicable frequency range in 4-17 GHz. More detailed description of the free space systems is given in our previous publications [18,24].

Hysteresis loops of single microwires have been measured using fluxmetric method previously described in details elsewhere [27]. In order to evaluate the influence of the external parameters (i.e. applied stress) similarly to that we recently described [28,29] we represent the hysteresis loops ad normalized magnetization, M/M0 versus magnetic field, H, where M is the magnetic moment at given magnetic field and M0 is the magnetic moment of the sample at the maximum magnetic field amplitude, Hm.

The stress has been applied during the annealing as well as during the sample cooling with the furnace.

The value of applied stresses within the metallic nucleus has been evaluated as previously described [25] :

(1)

where k =E2/E1, E1 and E2 are the Young’s modules at room temperature for the metallic alloy and the glass respectively, P is the applied mechanical load, and Sm and Sgl are the cross sections of the metallic nucleus and glass coating respectively. The value of applied stresses evaluated using eq. (1) was up to 472 MPa.

The DSC measurements were performed using DSC 204 F1 Netzsch calorimeter in Ar atmosphere at a heating rate of 10 K/min up to temperature, T, of 900 oC.

3 Experimental results and discussion

During the polymerization process of the resin, volume shrinkage of about 8.2 % occurs and solid cured resin is obtained. The mechanical properties of the cured resin are the following: tensile strength of 76 MPa, tensile modulus of 2,9 GPa, and tensile elongation of 8-10%. However, apart of the matrix shrinkage considerable heating takes place.

Therefore, in order to understand the processes during the polymerization of the composite that can affect the microwires we have measured the evaluation of temperature using a thermocouple. Obtained temperature changes during the polymerization represented at temperature, T, versus time, t, are sown in Figure 2.

As can be observed from the Figure 2, the matrix polymerization produces a heating of the composite up to 80 oC.

In order to ensure that employed microwires maintain it amorphous structure we performed the DSC studies of the crystallization temperature in order to evaluate the crystallization temperature. As can be observed from Fig.3 the crystallization temperatures, Tcr, (determined as the beginning of the first crystallization peak) is about 554 oC (see Figure 3). Therefore all the changes observed in the experiments must be attributed to the magnetoelastic behavior of employed microwires only.

As described above, we performed in-situ experiments of composites placed inside the un-echoic chamber with the glass-coated microwires embedded in a polymerized composite. We measured the transmission, T, and reflection, R, parameters of the composite containing Co-rich microwires (Fe3.8Co65.4Ni1B13.8Si13Mo1.35C1.65) using the free space system.

As can be appreciated from Figure 4, considerable variation of the T-parameter is observed in the range frequency, f, of 4-7 GHz upon thermoset matrix polymerization (Figure 4). A non-monotonic variation of T-parameter upon polymerization is observed (Figure 4a). Additionally, some changes of R-parameter are also observed in a wide f- range (Figure 4b).

From T and R parameters the absorption, A, parameter can be evaluated. Similarly to T and R parameters some changes in A(f) dependence during the polymerization are observed (see Figure 5).

Observed changes of electromagnetic properties can be related to two main phenomena arising during the composite matrix polymerization: heating and mechanical stresses.

As we mentioned above, apart of the matrix heating, the polymerization is accompanied by change of density and shrinkage. Although generally the distribution of the internal stresses arising at polymerization is non-homogeneous [30] an important fact is that the matrix shrinks as it cools. Therefore we can assume that the matrix shrinkage produces compressive stresses in magnetic nucleus of glass-coated microwires.

Observed T(f) dependencies with are non- monotonic: some increase of T observed up to t=15 min (at f ≈4-7 GPa) followed by T decrease at t>15 min. Such evolution of T-parameter can be therefore associated to the heating and consequent cooling of the FRC.

However, hysteresis loops of studied samples are considerably affected by applied tensile stresses as shown in Figure 6.

As expected, as-prepared Fe3.8Co65.4Ni1B13.8Si13Mo1.35C1.65 microwire present linear almost non-hysteretic loop (see Fig2). This –non-hysteretic loop maintains it linear shape upon applied tensile stress, however considerably Hk rising upon tensile stress can be appreciated.

To understand the effect of heating on magnetic properties we must consider the character of the internal mechanical stresses in magnetic microwires. In fact the main part of the mechanical stresses is originated by the difference in the thermal expansion coefficients of metallic alloy and glass-coating [31-34]. As shown elsewhere [35], the main part of the metallic nucleus of the microwire (up to r ~ 0.85 R, where R is the metallic nucleus radius, r- metallic nucleus radius) has a tensile stresses. Therefore, the difference in thermal expansion coefficients of metallic alloy and glass-coating upon heating becomes smaller allowing the reduction of the internal stresses. This assumption has been recently confirmed by direct observation of the heating effect on hysteresis loop of Co-rich microwires with vanishing magnetostriction coefficient [35]. The transformation of the hysteresis loop from linear to rectangular upon heating was explained by the easy anisotropy direction change from circumferential to axial upon heating.

In contrast to the temperature that non-monotonously changes during the polymerization we assume that the compressive stresses due to the matrix shrinkage change monotonously. Therefore we assume that the changes observed in Figs 5 and 6 are originated by both heating and matrix shrinkage during the polymerization.

Eventually the same technique can be used for the remote monitoring of stress or temperature not only during the polymerization, but also for real time non-destructive monitoring of local stresses and temperature during the exploitation of the composites.

4 Conclusions

We propose a novel sensing technique for non-destructive and non-contact monitoring of the composites utilizing ferromagnetic glass-coated microwire inclusions with magnetic properties sensitive to tensile stress and temperature.

To demonstrate it we have studied in-situ the impact of matrix polymerization on the evolution of the transmission and reflection parameters of the composites with microwire inclusions.

We observed considerable variation of the T-parameter (in the range of 4-7 GHz) and R-parameter upon composite polymerization using the free space technique.

Observed dependencies are discussed considering the matrix shrinkage during the polymerization and heating during the matrix polymerization and their influence on magnetic properties of glass-coated microwires.

Obtained experimental results yield new and important insights suitable for development of novel sensing technique for non-destructive and non-contact monitoring of the FRCs utilizing ferromagnetic glass-coated microwire inclusions.

Consequently a novel sensing technique for non-destructive and non-contact monitoring of the composites utilizing ferromagnetic glass-coated microwire inclusions with quite soft magnetic properties and tunable magnetic permittivity sensitive to tensile stress and temperature is proposed

Agradecimientos

This work was supported by Spanish MCIU under PGC2018-099530-B-C31 (MCIU/AEI/FEDER, UE), by the Basque Country Government under the Elkartek (RTM 4.0) project and by the University of Basque Country under scheme of “Ayuda a Grupos Consolidados” (Ref.: IT954- 16). The authors thank for technical and human support provided by SGIker of UPV/EHU (Medidas Magneticas Gipuzkoa) and European funding (ERDF and ESF).

Referencias

[1] J. Durand, “Magnetic Properties of Metallic Glasses” in Topics in Applied Physics Volume 53, 1983, Glassy Metals II. Atomic Structure and Dynamics, Electronic Structure, Magnetic Properties, Editors: H. Beck and H.-J. Giintherodt, Springer-Verlag, Berlin Heidelberg New York Tokyo.

[2] G. Herzer, Amorphous and Nanocrystalline Materials, in: Encyclopedia of Materials: Science and Technology, pp. 149–157, Elsevier Science Ltd. (2001) ISBN: 0-08-0431526.

[3] A.P. Zhukov, The remagnetization process of bistable amorphous alloys, Mater. Design, 5 (1993) pp. 299-305

[4] M. Hagiwara, A. Inoue, and T. Masumoto, “Mechanical properties of Fe–Si–B amorphous wires produced by in-rotating-water spinning method”, Metall. Trans. A 13 (1982) pp. 373-382.

[5] T. Goto, M. Nagano and N. Wehara, “Mechanical properties of amorphous Fe80P16C3B1 filament produced by glass-coated melt spinning”, Trans. JIM, 18 (1977) pp. 759-764.

[6] D. C. Jiles, Recent advances and future directions in magnetic materials, Acta Mater., 51 (2003) pp. 5907-5939.

[7] A. Zhukov, M. Ipatov and V. Zhukova, “Advances in Giant Magnetoimpedance of Materials”, in Handbook of Magnetic Materials, ed. K.H.J. Buschow, Vol. 24, ch. 2 (2015) pp. 139-236.

[8] High Performance Soft Magnetic Materials (editor A. Zhukov), Springer Series in Materials Science, vol 252, Springer International Publishing, 2017, Page numbers: 216p, ISBN: 0933-033X, DOI: 10.1007/978-3-319-49707-5.

[9] H. Chiriac, S. Corodeanu, M. Lostun, G. Ababei, and T.-A. Óvári, Rapidly solidified amorphous nanowires, J. Appl. Phys., vol. 107, (2010) 09A301.

[10] D. Kozejova, L. Fecova, P. Klein, R. Sabol, R. Hudak, I. Sulla, D. Mudronova, J. Galik, R. Varga, “Biomedical applications of glass-coated microwires”, J. Magn. Magn. Mater., 470, (2019) pp. 2-5.

[11] A. Talaat, J. Alonso, V. Zhukova, E. Garaio, J. A. García, H. Srikanth, M. H. Phan and A. Zhukov, Ferromagnetic glass-coated microwires with good heating properties for magnetic hyperthermia, Sci. Reports, 6 (2016) 39300

[12] A. Zhukov, M. Ipatov, M. Churyukanova, A. Talaat, J. M. Blanco and V. Zhukova, Trends in optimization of giant magnetoimpedance effect in amorphous and nanocrystalline materials, J. Alloys Compd., 727 (2017) pp. 887-901.

[13] A. F. Cobeño, A. Zhukov, J. M. Blanco, V. Larin and J. Gonzalez, Magnetoelastic sensor based on GMI of amorphous microwire, Sens. Actuators A, 91, (2001) pp. 95-98.

[14] A. Zhukov, A.F. Cobeño, J. Gonzalez, J.M. Blanco, P. Aragoneses and L. Dominguez, Magnetoelastic sensor of level of the liquid based on magnetoelastic properties of Co-rich microwires, Sens. Actuators A, 81/1-3, (2000) pp. 129-133.

[15] D. Makhnovskiy, N. Fry, A. Zhukov, On different tag reader architectures for bistable microwires, Sens. Actuators A-Phys., 166, (2011) pp. 133-140.

[16] D. Praslička, J. Blažek, M. Šmelko, J.Hudák, A. Čverha, I. Mikita, R.Varga and A. Zhukov, Possibilities of Measuring Stress and Health Monitoring in Materials Using Contact-Less Sensor Based on Magnetic Microwires, IEEE Trans. Magn., 49(1) (2013) pp. 128-131.

[17] F.X. Qin, H.X. Peng, M.H. Phan, L.V. Panina, M. Ipatov, A. Zhukov, Effects of wire properties on the field-tunable behaviour of continuous-microwire composites, Sens. Actuators A, 178 (2012) pp. 118– 125.

[18] D. Makhnovskiy, A. Zhukov, V. Zhukova, J. Gonzalez, Tunable and self-sensing microwave composite materials incorporating ferromagnetic microwires, Advances in Science and Technology, 54 (2008) pp. 201-210.

[19]. F Qin, HX Peng, Ferromagnetic microwires enabled multifunctional composite materials, Prog. Mater. Sci. 58 (2) (2013)183-259.

[20] M. Churyukanova, S. Kaloshkin, E. Shuvaeva, A.Stepashkin, M. Zhdanova, A. Aronin, O. Aksenov, P. Arakelov, V. Zhukova, А. Zhukov, Non-contact method for stress monitoring based on stress dependence of magnetic properties of Fe-based microwires, J. Alloys Compd., 748, 5 (2018) pp. 199-205.

[21] J. Olivera, M. González, J. V. Fuente, R. Varga, A. Zhukov and J. J. Anaya, An Embedded Stress Sensor for Concrete SHM Based on Amorphous Ferromagnetic Microwires, Sensors, 14 (2014) pp. 19963-19978.

[22] J. C. Manchado, S. Allue, J. M. Cuevas, J. R. Dios, “Monitorizacion del proceso de rtm e infusión mediante sensores dieléctricos”, Revista de plásticos modernos: Ciencia y tecnología de polímeros, ISSN 0034-8708, Nº. 587, (2005) pp. 432-438.

[23] L. J. Nelson, Smart piezoelectric Fibre composites, Mat. Sci. and Tech., 18 (2002), pp. 1245-1256.

[24] L. Panina, M. Ipatov, V. Zhukova, J. Gonzalez and A. Zhukov, “Tuneable composites containing magnetic microwires”, ch. 22, pp.431-460 DOI: 10.5772/21423 in Book: Metal, ceramic and polymeric composites for various uses, Edited by John Cuppoletti, 2011, DOI: 10.5772/1428 ISBN: 978-953-307-353-8 (ISBN 978-953-307-1098-3) InTech - Open Access Publisher (www.intechweb.org), Janeza Trdine, 9, 51000 Rijeka, Croatia.

[25] V. Zhukova, J. M. Blanco, M. Ipatov, M. Churyukanova, S. Taskaev and A. Zhukov, Tailoring of magnetoimpedance effect and magnetic softness of Fe-rich glass-coated microwires by stress- annealing, Sci. Reports, 8 (2018) 3202

[26] A. Zhukov, M. Churyukanova, S. Kaloshkin, V. Sudarchikova, S. Gudoshnikov,M. Ipatov, A. Talaat, J.M. Blanco and V. Zhukova, “ Magnetostriction of Co-Fe-based amorphous soft magnetic microwires”, J. Electr. Mater. (2016), 45(1), pp 226-234

[27] A. Zhukov, M. Vázquez, J. Velázqez, A. Hernando and V. Larin, Magnetic properties of Fe-based glass-coated microwires, J. Magn. Magn. Mater. 170 (1997) 323-330

[28] A. Zhukov, A. Talaat, M. Ipatov, J.M. Blanco, V. Zhukova, “Tailoring of magnetic properties and GMI effect of Co-rich amorphous microwires by heat treatment”, J. Alloys Compounds 615 (2014) 610–615

[29]. A.Zhukov, K.Chichay, A.Talaat, V.Rodionova, J.M.Blanco, M.Ipatov, V. Zhukova, “Manipulation of magnetic properties of glass-coated microwires by annealing”, J. Magn. Magn. Mater. 383 (2015) 232–236

[30] J. A. Nairn, P. Zoller, Matrix solidification and the resulting residual thermal stresses in composites, J. Mater. Science, 20, Issue 1 (1985) pp. 355–367.

[31] A. S. Antonov, V. T. Borisov, O. V. Borisov, A. F. Prokoshin and N. A. Usov, Residual quenching stresses in glass-coated amorphous ferromagnetic microwires, J. Phys. D: Appl. Phys., 33 (2000) pp. 1161-1168.

[32] H. Chiriac, T.A. Ovari and Gh. Pop, Internal stress distribution in glass-covered amorphous magnetic wires, Phys. Rev. B, 42 (1995) 10105.

[33] A. Zhukov, J. Gonzalez, A. Torcunov , E. Pina, M.J Prieto, A. F. Cobeño, J.M. Blanco, V. Larin and S. Baranov, Ferromagnetic resonance and Structure of Fe-based Glass-coated Microwires, J. Magn. Magn. Mater., 203 (1999) pp. 238-240.

[34]S. A. Baranov, V. S. Larin and A. V. Torcunov, “Technology, Preparation and Properties of the Cast Glass-Coated Magnetic Microwires”, Crystals, 7 (2017) 136

[35]. H. Chiriac, T.-A- Ovari and A. Zhukov, ”Magnetoelastic anisotropy of amorphous microwires ”, J. Magn. Magn. Mater. 254-255 (2003) 469-471

Document information

Published on 10/07/22

Accepted on 10/07/22

Submitted on 10/07/22

Volume 04 - Comunicaciones Matcomp19 (2020), Issue Núm. 4 - Aplicaciones de los materiales compuestos. Nuevos procesos de fabricación y materiales compuestos avanzados., 2022

DOI: 10.23967/r.matcomp.2022.07.024

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?