m (Xmartinez moved page Draft Martinez 328618084 to Review 363079282827) |

(Editing modifications made by co-editor before manuscript publishing) (Tag: Visual edit) |

||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==1 Introduction== | ==1 Introduction== | ||

| Line 63: | Line 8: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image:Draft_Martinez_328618084-image1.png| | + | [[Image:Draft_Martinez_328618084-image1.png|550x550px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 84: | Line 29: | ||

'''Automated Fibre Placement (AFP):''' AFP places multiple individual tows onto a highly curved mandrel at high speed, using a robotic numerically controlled placement head, one ply (layer) at a time. AFP allows fabrication of highly customized parts (with thermoset, thermoplastic or dry fibre tows) where each ply can be placed at different angles to best carry the required loads. | '''Automated Fibre Placement (AFP):''' AFP places multiple individual tows onto a highly curved mandrel at high speed, using a robotic numerically controlled placement head, one ply (layer) at a time. AFP allows fabrication of highly customized parts (with thermoset, thermoplastic or dry fibre tows) where each ply can be placed at different angles to best carry the required loads. | ||

| − | + | AFP allows manufacturing structures with high fibre content and with high quality, reducing significantly the amount of material need (and the structure weight) to achieve a given strength and stiffness. | |

'''Automated Tape Laying (ATL): '''ATL is used for flat or mildly contoured parts. ATL usually lays down 3, 6, or 12 inches wide unidirectional tape, depending on whether the application is for flat structure or mildly contoured structure. ATL uses gantry style machines. Tape material can be both thermoplastic and thermoset. | '''Automated Tape Laying (ATL): '''ATL is used for flat or mildly contoured parts. ATL usually lays down 3, 6, or 12 inches wide unidirectional tape, depending on whether the application is for flat structure or mildly contoured structure. ATL uses gantry style machines. Tape material can be both thermoplastic and thermoset. | ||

| Line 95: | Line 40: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image:Draft_Martinez_328618084-image2.png| | + | [[Image:Draft_Martinez_328618084-image2.png|450x450px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 110: | Line 55: | ||

As well as evaluating different manufacturing procedures, FIBRE4YARDS will also take a close look into the '''materials''' used. Shipbuilding commonly uses thermoset resins, such as polyamides and vinylesters. However, most of the technologies analysed and developed in the project replace these resins for thermoplastic ones. Current manufacturing methods are not prepared for such resins and shipyards are reluctant to use them, however thermoplastic have several advantages compared to thermosets. Some of these advantages are: | As well as evaluating different manufacturing procedures, FIBRE4YARDS will also take a close look into the '''materials''' used. Shipbuilding commonly uses thermoset resins, such as polyamides and vinylesters. However, most of the technologies analysed and developed in the project replace these resins for thermoplastic ones. Current manufacturing methods are not prepared for such resins and shipyards are reluctant to use them, however thermoplastic have several advantages compared to thermosets. Some of these advantages are: | ||

| − | :* They can be welded, which facilitates the procedures required to connect different parts | + | :* They can be welded, which facilitates the procedures required to connect different parts. |

| − | + | ||

:* They can be recycled, which minimizes the environmental impact of the final structure. | :* They can be recycled, which minimizes the environmental impact of the final structure. | ||

| − | |||

:* They can be used in most of the automated procedures developed in the framework of FIBRE4YARDS project. | :* They can be used in most of the automated procedures developed in the framework of FIBRE4YARDS project. | ||

| Line 125: | Line 68: | ||

<div id="_GoBack" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_GoBack" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image:Draft_Martinez_328618084-image3.png| | + | [[Image:Draft_Martinez_328618084-image3.png|450x450px]] </div> |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 133: | Line 76: | ||

:* New plasticity law specially developed for the characterization of thermoplastic materials. This law will be used together with the serial-parallel mixing theory [2] to characterize the composite performance. | :* New plasticity law specially developed for the characterization of thermoplastic materials. This law will be used together with the serial-parallel mixing theory [2] to characterize the composite performance. | ||

| − | |||

:* New beam formulation, based on the dimensional hyper-reduction model proposed by J.A. Hernandez in [3], for the analysis of pultruded beams. | :* New beam formulation, based on the dimensional hyper-reduction model proposed by J.A. Hernandez in [3], for the analysis of pultruded beams. | ||

| − | |||

:* Constitutive model for the analysis of 3D printed materials that will take into account the characteristic orthotropic failure of these materials due to their fabrication process. This model will use the mapping space approach to define highly anisotropic materials [4]. | :* Constitutive model for the analysis of 3D printed materials that will take into account the characteristic orthotropic failure of these materials due to their fabrication process. This model will use the mapping space approach to define highly anisotropic materials [4]. | ||

| − | |||

:* Numerical procedure, based on a multi-model analysis, to characterize the mechanical performance of the ship connections. The model is based on the analysis of the connection with solid elements, which will provide a detailed characterization of its mechanical performance and failure modes, and the extrapolation of the connection performance to a shell model that can be incorporated in the global structural analysis of the ship. | :* Numerical procedure, based on a multi-model analysis, to characterize the mechanical performance of the ship connections. The model is based on the analysis of the connection with solid elements, which will provide a detailed characterization of its mechanical performance and failure modes, and the extrapolation of the connection performance to a shell model that can be incorporated in the global structural analysis of the ship. | ||

| Line 153: | Line 93: | ||

:* Installation of the appropriate sensors and network (IoT platform) for establishing data sources and retrieving and storing such data. | :* Installation of the appropriate sensors and network (IoT platform) for establishing data sources and retrieving and storing such data. | ||

| − | |||

:* Implementation of improved data visualization tools for wider/deeper statistical approaches, which will provide a better product quality. | :* Implementation of improved data visualization tools for wider/deeper statistical approaches, which will provide a better product quality. | ||

| − | |||

:* Implementation of Machine Learning technologies for conditions/parameters-based monitoring, to provide lower production costs. | :* Implementation of Machine Learning technologies for conditions/parameters-based monitoring, to provide lower production costs. | ||

| − | |||

:* Include numerical tools to simulate millions of events for predictive model implementation to provide reliable processes. | :* Include numerical tools to simulate millions of events for predictive model implementation to provide reliable processes. | ||

| − | |||

:* Use real time analytics (retro feedback) to improve processes speed and response. | :* Use real time analytics (retro feedback) to improve processes speed and response. | ||

| Line 165: | Line 101: | ||

:* Production floor: Permanently connected machines and production units constantly communicate their performance status and, together, respond autonomously to dynamic production requirements. This will empower cost-effective production and reduce costly downtime through predictive maintenance. | :* Production floor: Permanently connected machines and production units constantly communicate their performance status and, together, respond autonomously to dynamic production requirements. This will empower cost-effective production and reduce costly downtime through predictive maintenance. | ||

| − | |||

:* Across multiple production facilities of the same enterprise in a Manufacturing Execution Systems (MES) sharing production facility data (inventory levels, unexpected delays, and so on) and shifting tasks automatically among facilities. | :* Across multiple production facilities of the same enterprise in a Manufacturing Execution Systems (MES) sharing production facility data (inventory levels, unexpected delays, and so on) and shifting tasks automatically among facilities. | ||

| − | |||

:* Across the entire supply chain: Shipyard 4.0 proposes secure data transparency and high levels of automated collaboration across the upstream (supplier to integrator) and down stream (product to market). | :* Across the entire supply chain: Shipyard 4.0 proposes secure data transparency and high levels of automated collaboration across the upstream (supplier to integrator) and down stream (product to market). | ||

Revision as of 19:33, 30 October 2022

1 Introduction

Today, Fibre-Reinforced Polymers (FRP) are extensively used for building lightweight hull structures of vessels with length up to about 25 meters. In fact, most of the leisure crafts and sailing yachts, patrol and rescue vessels, and naval ships below 25 meters length are built in FRP materials. On the other hand, metals remain the main solution for vessels with a length above 50 meters yet [1]. However, the production capacity in numbers of FRP ships nowadays is not achieving its full potential due to high total production costs. One of the main reasons for this limitation is the lack of automated procedures, and the current semi-artisanal methods used in FRP shipbuilding.

To overcome this situation, FIBRE4YARDS project aims to develop and implement a new Shipyard 4.0 concept, in which advanced and innovative FRP manufacturing technologies are successfully introduced. The focus of the FIBRE4YARDS project is the entire value chain (the shipyards and their ecosystem) cooperatively working on small and medium length fibre-based ships in a digital environment.

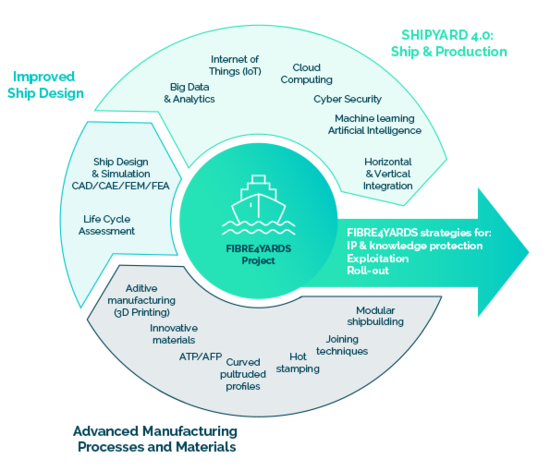

To achieve this objective, the FIBRE4YARDS relies in three main pillars, which will be developed during the project: The development of advanced manufacturing processes and materials for an automated modular ship construction; the development of simulation tools, together with life-cycle assessment procedures, for an optimal ship design; and the development of technologies that will facilitate the definition of a Shipyard 4.0 environment. These three pillars are summarized in Figure 1, and will be described in the following sections of this document.

FIBRE4YARDS is a consortium of 13 partners from 6 different european countries. The project partners are: CIMNE, COMPASSIS, TSI, IRURENA (all four from Spain), INEGI (Portugal), NAVAL GROUP, BUREAU-VERITAS, IRT JULES-VERNE, L-UP (from France), CURVE-WORKS and 10XL (from the Netherlands), POLITECHNIKA LODZKA (Poland), and INNOVATEKNEA (Hungary). The project is coordinated by CIMNE and its technically directed by COMPASSIS.

2 Advanced manufacturing processes and materials

The incorporation of advanced and automated manufacturing process and materials to ship construction will bring many advantages to the sector, such as the increase of production ratios and quality, the minimization of spare parts and materials, or the opportunity to adapt new geometries and solutions to improve the ship performance while reducing its weight.

One of the main objectives of FIBRE4YARDS is to develop new production methods, as well as to adapt existing ones used in other sectors (such as automotive or aerospace) in order to incorporate them to the shipyard. All new procedures will be incorporated thinking on a modular construction of the ship, which will facilitate the manufacturing of ship parts and components by ancillary industries, which can be specialized in a specific manufacturing process. This will minimize the investment costs of the shipyard and will bring specialized partners to the ship construction, improving the quality of the parts.

The technologies targeted by FIBRE4YARDS project are the following:

Curved Pultruded Profiles: Curing the pultruded profiles at exit of the die with UV radiation, enables the reduction of pulling forces, simplifies the dies required by the pultrusion process and, more importantly, allows the manufacturing of profiles with a curved longitudinal axis, using a robotic pulling system.

These profiles can be an excellent solution for longitudinal and transversal stiffeners for the ship hull, as their geometry can be adapted perfectly to any ship configuration.

Automated Fibre Placement (AFP): AFP places multiple individual tows onto a highly curved mandrel at high speed, using a robotic numerically controlled placement head, one ply (layer) at a time. AFP allows fabrication of highly customized parts (with thermoset, thermoplastic or dry fibre tows) where each ply can be placed at different angles to best carry the required loads.

AFP allows manufacturing structures with high fibre content and with high quality, reducing significantly the amount of material need (and the structure weight) to achieve a given strength and stiffness.

Automated Tape Laying (ATL): ATL is used for flat or mildly contoured parts. ATL usually lays down 3, 6, or 12 inches wide unidirectional tape, depending on whether the application is for flat structure or mildly contoured structure. ATL uses gantry style machines. Tape material can be both thermoplastic and thermoset.

Similarly to AFP, ATL allows the manufacturing of high quality composites. It is a common procedure in other industries such as aeronautical or for manufacturing windmill blades.

Adaptative Curved Moulds: These are moulds that can be adjusted numerically to any given geometry (see Figure 2). These are used for manufacturing composites by infusion.

One of the larger costs of composite shipbuilding, in terms of time and economy, is found in the moulds. Quite often these are used only once because of geometry variations from ship to ship. Having adaptive, reusable curved moulds will minimize enormously this cost, as the mould can be used for all ship geometries with a minimal time to adapt its geometry to the new configuration.

Thermoplastic Hot Stamping: In this process, 2D blank thermoplastic composite sheets, manufactured by a full automated line (e.g. ATL) can be hot stamped in a mould to give them any specific shape. This is a procedure with short production cycles that allows giving complex geometries to the composite with a high quality finish.

Thermoplastic hot stamping can be used to manufacture some ship components requiring high geometric accuracy, and will be especially useful for parts that require a large number of units. A possible example is the use of this technology to manufacture connection blocks where the different components are joined.

Additive Manufacturing: In Additive Manufacturing (3D printing) a 3D object is built from a CAD model by successively adding material layer by layer. This covers a variety of processes in which material is joined or solidified, such as Fused Deposition Modelling (FDM), stereolithography (SLA) and selective laser sintering (SLS). Actually, the composites made with additive manufacturing can contain short fibres or long fibres, which are deposited in the final part at the same time than the resin.

3D printing can be used to manufacture nearly any geometry without the need of a mould, which makes the procedure very versatile for the construction of ship parts or components. Currently the strength of the resulting material does not allow using this procedure for structural parts with high strength requirements. However, the finished structure can be reinforced with an ATL method to achieve the required strength and stiffness.

As well as evaluating different manufacturing procedures, FIBRE4YARDS will also take a close look into the materials used. Shipbuilding commonly uses thermoset resins, such as polyamides and vinylesters. However, most of the technologies analysed and developed in the project replace these resins for thermoplastic ones. Current manufacturing methods are not prepared for such resins and shipyards are reluctant to use them, however thermoplastic have several advantages compared to thermosets. Some of these advantages are:

- They can be welded, which facilitates the procedures required to connect different parts.

- They can be recycled, which minimizes the environmental impact of the final structure.

- They can be used in most of the automated procedures developed in the framework of FIBRE4YARDS project.

All the technologies defined can be used to manufacture ship components or sub-structures, which implies reformulating the way in which the ship is manufactured, as now it will require a modular construction. For this reason, a key task of FIBRE4YARDS project is to define the most adequate Connection Technology that can be used to assemble the different parts. Different connection procedures will be tested, by means of small coupons, in order to evaluate the ones for each technology. Based on the results obtained from this initial evaluation, component-scale connections will be analysed to validate the results and to establish a connection procedure for them.

3 Improved ship design

The new production technologies and methodologies will impact the design of the vessels, as this design is highly dependent on the material performance, and the material performance will vary depending on the he manufacturing method, especially in the case of composites. In order to have an optimal design, it is also necessary to take into account, from the early design stages, the manufacturing procedure, which in this case will be modular.

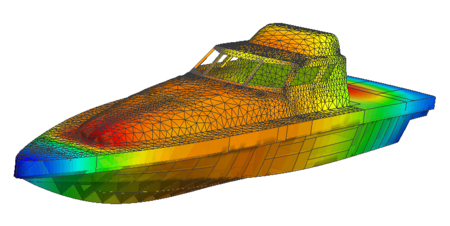

Based on the abovementioned assumptions, FIBRE4YARDS will develop a new design process, and new numerical tools, that will take into account the specificities of the technologies developed. These will be assessed based on two case studies: a patrol boat and catamaran. The former one is shown in Figure 3. These have been selected to validate all the technologies, and their implementation in small and medium shipyards. The use cases will have sufficient level of detail to cover the project’s objectives in a cost effective way. The design will be performed by engineering partners (COMPASSIS and TSI), in close consultation with technology providers (INEGI, IRURENA, CW and 10XL) and with the software developers (COMPASSIS and CIMNE).

Several numerical formulations will be developed in order to account for the different technologies, among them:

- New plasticity law specially developed for the characterization of thermoplastic materials. This law will be used together with the serial-parallel mixing theory [2] to characterize the composite performance.

- New beam formulation, based on the dimensional hyper-reduction model proposed by J.A. Hernandez in [3], for the analysis of pultruded beams.

- Constitutive model for the analysis of 3D printed materials that will take into account the characteristic orthotropic failure of these materials due to their fabrication process. This model will use the mapping space approach to define highly anisotropic materials [4].

- Numerical procedure, based on a multi-model analysis, to characterize the mechanical performance of the ship connections. The model is based on the analysis of the connection with solid elements, which will provide a detailed characterization of its mechanical performance and failure modes, and the extrapolation of the connection performance to a shell model that can be incorporated in the global structural analysis of the ship.

All these formulations will be implemented in the Finite Element Method (FEM) code TDYN, developed by COMPASSIS [5]. The use of this code for the analysis of the two targeted vessels will help defining an optimal procedure to include the manufacturing process and the characteristics of the manufactured parts in the design process.

The improvement of the ship design envisioned by FIBRE4YARDS does not only consider the use of state of the art and new developed numerical tools, but also to take into account the environmental impact of the solutions considered. For this reason, the project will conduct a Life Cycle Assessment (LCA) of the different technologies targeted by the project, and the materials used by those technologies.

The LCA will be conducted according to the ISO standards 14040-14044 [6] by LODZ UNIVERSITY OF TECHNOLOGY. The analysis will determine the environmental load (including health & safety impacts) associated with technologies applied in the project (different modules, components of the lightweight ships and materials) and indicate which process configuration will produce lower environmental impact over the whole life cycle (manufacturing, operation, dismantling, waste management, CO2 emission analysis).

4 Definition of a new shipyard 4.0

The 4th revolution in industry entails the digitization of manufacturing. Shipyard 4.0 will contain enhanced manufacturing, smart and autonomous systems, seamless digital intercompany cooperation, big data and machine learning. Shipyard 4.0 will increase production efficiency, reduce waste, decrease manufacturing costs, and gain new business beyond simply manufacturing automation at machine or even production level.

Shipyard 4.0 requires a collaborative multidisciplinary combination of competencies and expertise to bring maximum added value for smart FRP-based shipbuilding. FIBRE4YARDS will evaluate, assess and test the following technologies to be implemented in FRP shipyards, together with the advanced production processes:

- Installation of the appropriate sensors and network (IoT platform) for establishing data sources and retrieving and storing such data.

- Implementation of improved data visualization tools for wider/deeper statistical approaches, which will provide a better product quality.

- Implementation of Machine Learning technologies for conditions/parameters-based monitoring, to provide lower production costs.

- Include numerical tools to simulate millions of events for predictive model implementation to provide reliable processes.

- Use real time analytics (retro feedback) to improve processes speed and response.

Shipyard 4.0 envisions a horizontal integration on three levels in connected networks of cyber-physical and enterprise systems that will introduce new levels of automation, flexibility, and operational efficiency into production processes.

- Production floor: Permanently connected machines and production units constantly communicate their performance status and, together, respond autonomously to dynamic production requirements. This will empower cost-effective production and reduce costly downtime through predictive maintenance.

- Across multiple production facilities of the same enterprise in a Manufacturing Execution Systems (MES) sharing production facility data (inventory levels, unexpected delays, and so on) and shifting tasks automatically among facilities.

- Across the entire supply chain: Shipyard 4.0 proposes secure data transparency and high levels of automated collaboration across the upstream (supplier to integrator) and down stream (product to market).

Shipyard 4.0 will also consider a Vertical integration, which aims to tie together all logical layers within the organization from the field layer (i.e., the production floor) up through R&D, quality assurance, product management, IT, sales and marketing. Data will flow freely and transparently up and down these layers so that both strategic and tactical decisions can be data-driven. The vertically integrated Shipyard 4.0 enterprise will gain a crucial competitive edge by being able to respond appropriately and with agility to changing market signals and new opportunities.

In FIBRE4YARDS, the Shipyard 4.0 approach and its horizontal and vertical integration will be demonstrated on several manufacturing processes. The final goal is to make these processes more-automated, industrialized and predictive, based on in-situ real time data for high quality, fast-production, and low-cost FRP parts manufacturing for shipbuilding. Furthermore, IoT process and structure monitoring will provide indicators of the composite structure behaviour during the entire lifecycle of the ship: faults, ageing, predictive maintenance, or replacement. This improves quality control in production, lowers maintenance costs in operation and provides feedback to optimize structures design.

5 Bussiness plan and compliance with standards and regulations

FIBRE4YARDS project will develop a plan to roll-out the advanced production technologies developed, and the shipyard 4.0 concept beyond the initial consortium. The cost effectiveness and commercial potential of automated and serialized small and medium-length FRP-based vessels compared to standard FRP shipbuilding solutions will be analysed and quantitatively monitored during the project. Furthermore, a business plan covering the different phases of the life cycle, from design, shipbuilding and operation to the final dismantling of the vessel and identifying the business opportunities for the different actors of the chain, will be developed.

As important as the business plan, is the need of regulations that define the framework in which the new technologies developed should be used and incorporated in the shipyard. In this regard, FIBRE4YARDS aims to develop design and new production guidelines for FRP shipbuilding, based on cognitive manufacturing and advanced production methods. The development of these guidelines will be advised by the classification society involved in the project (BV), and thus will become the seeds of the future rules to certify small and medium-length FRP-based vessels construction, and a crucial input for the pertinent regulatory regimes.

6 Conclusions

The work proposed by FIBRE4YARDS project aims to redefine shipbuilding for small and medium shipyards. Automated FRP manufacturing technologies used in other sectors will be adapted to the specific necessities of shipbuilding, and new technologies will be developed to cover specific needs. With FIBRE4YARDS approach FRP ship construction will become modular, and will increase its efficiency and quality. All technologies developed will be implemented in a new shipyard 4.0, which will be digitally interconnected with all suppliers and technology providers. In order to make this new shipyard a reality, ship design must consider the new production processes, so the project will develop specific design tools to incorporate them. FIBRE4YARDS will also define a business plan to make possible the new shipyard defined, as well as will draw the main lines of the rules and standards required.

This paper has briefly described the work that will be done in the project. The achievement of all the targeted objectives is expected to propel the European ecosystem of small and medium shipyards, improving their competitivity and production capacity, and enhancing the quality and safety of the ships build.

Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 101006860.

References

[1] F. Rubino, A. Nisticò, F. Tucci, P. Carlone. Marine Application of Fiber Reinforced Composites: A Review. J. Mar. Sci. Eng. 2020, 8, 26. DOI: 10.3390/jmse8010026

[2] J. Jurado, X. Martinez, N. Nash, C. Bachour, I. Manolakis, A. Comer, D. Di Capua. Numerical and experimental procedure for material calibration using the serial/parallel mixing theory, to analyze different composite failure modes, Mechanics of Advanced Materials and Structures, 2019, DOI: 10.1080/15376494.2019.1675106

[3] J. A. Hernández. A multiscale method for periodic structures using domain decomposition and ECM-hyperreduction. Comput. Methods Appl. Mech. Eng., vol. 368, p. 113192, Aug. 2020. DOI: 10.1016/j.cma.2016.10.022

[4] E. Car, S. Oller, and E. Oñate, An anisotropic elastoplastic constitutive model for large strain analysis of fiber reinforced composite materials, Comput. Methods Appl. Mech. Eng., vol. 185, no. 2–4, pp. 245–277, 2000. DOI: 10.1016/S0045-7825(99)00262-5

[5] RamSeries FEM code, https://www.compassis.com/compass/en/ Productos/RamSeries. Accessed: 29/04/2022

[6] International Organization for Standardization. ISO 14044:2006 - Environmental management - Life cycle assessment - Requirements and guidelines. Online: https://www.iso.org/standard/38498.html. Accessed: 29/04/2022.

Document information

Published on 30/10/22

Accepted on 30/10/22

Submitted on 30/10/22

Volume 06 - AEMAC en PROYECTOS EUROPEOS (2022), Issue Num. 2 - Monográfico Proyectos Europeos (2), 2022

DOI: 10.23967/r.matcomp.2022.11.06

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?