(Tag: Visual edit) |

|||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==1 Introduction== | ==1 Introduction== | ||

| Line 95: | Line 29: | ||

<span id='_Ref452457467'></span><span id='_Toc452381136'></span><div id="_Toc459969150" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <span id='_Ref452457467'></span><span id='_Toc452381136'></span><div id="_Toc459969150" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 1.''' SA THS Tip metallic structure</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 1.''' SA THS Tip metallic structure.</span></div> |

==='''2.2''' LR THS Tip=== | ==='''2.2''' LR THS Tip=== | ||

| Line 111: | Line 45: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 2.''' LR THS Tip metallic structure</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 2.''' LR THS Tip metallic structure.</span></div> |

Upper and lower tip skin panels are fastened to the torsion box and leading edge by means of a single row or removable screws and nuts. | Upper and lower tip skin panels are fastened to the torsion box and leading edge by means of a single row or removable screws and nuts. | ||

| Line 127: | Line 61: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 3.''' SA / LR THS Tips configuration proposals</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 3.''' SA / LR THS Tips configuration proposals.</span></div> |

==='''2.4''' Load Cases=== | ==='''2.4''' Load Cases=== | ||

| Line 182: | Line 116: | ||

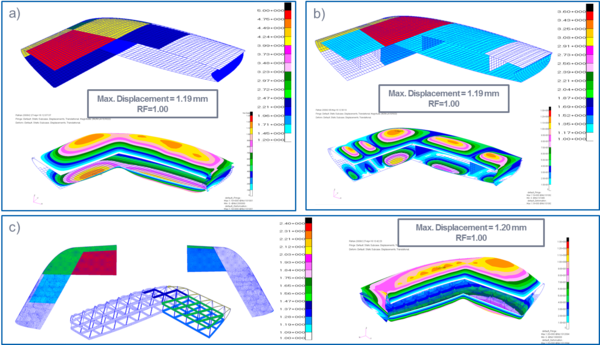

'''Figure 4''' shows the results associated with SA proposals. The aerodynamic stiffness/deflection criteria was found as sizing driver, defining the thicknesses for each alternative. | '''Figure 4''' shows the results associated with SA proposals. The aerodynamic stiffness/deflection criteria was found as sizing driver, defining the thicknesses for each alternative. | ||

| − | + | [[File:Gil_et_al_2018c-image17.png|centre|600x600px]] | |

| − | [[ | + | |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 189: | Line 122: | ||

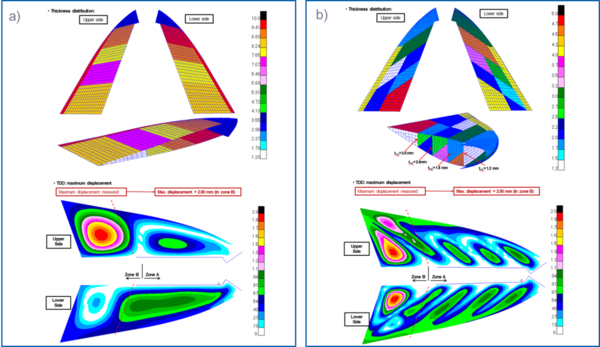

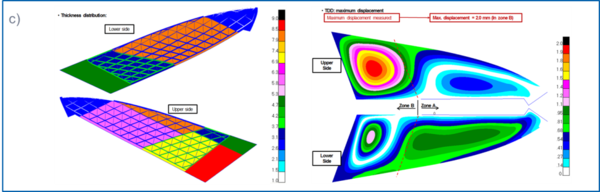

For the LR configuration, '''Figure 5''' illustrates the results. The aerodynamic stiffness/deflection criteria was, as in SA case, the sizing driver. | For the LR configuration, '''Figure 5''' illustrates the results. The aerodynamic stiffness/deflection criteria was, as in SA case, the sizing driver. | ||

| − | + | [[File:Gil_et_al_2018c-image20.png|centre|600x600px]] | |

| − | [[ | + | [[File:Gil_et_al_2018c-image21.png|centre|600x600px]] |

| − | + | ||

| − | [[ | + | |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figure 5.''' LR THS Tip – Sizing results for the different proposals</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figure 5.''' LR THS Tip – Sizing results for the different proposals.</span></div> |

==='''3.2''' Lightning Strike Protection=== | ==='''3.2''' Lightning Strike Protection=== | ||

| Line 252: | Line 183: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | <span style="text-align: center; font-size: 75%;">'''Figura 6.''' Manufacturing studies</span></div> | + | <span style="text-align: center; font-size: 75%;">'''Figura 6.''' Manufacturing studies.</span></div> |

==='''1.1''' Preliminary test under development=== | ==='''1.1''' Preliminary test under development=== | ||

Revision as of 16:58, 5 October 2022

1 Introduction

The injection moulding process is a well-known manufacturing process in the automotive industry for producing plastic injection moulds from plastic materials. The material is fed into a heated barrel, mixed, and forced into a mould cavity by a reciprocating screw or a ram injector, where the injection moulded part cools and hardens to the configuration of the mould cavity. The injection moulding process presents several advantages in terms of recurring cost, lead time and parts repetitivity. On the other hand, injection plastics present low stiffness properties and the required clamping force to close the mould increases with the part surface or size and the injection pressure.

Assuming the previous state of the art, the Trimmable Horizontal Stabilizer (THS) tips are selected as potential application of this technology in the aerospace industry due to their low structural responsibility and relative small size. The objective of this work is to study the structural performance of a THS tip part made of injection thermoplastic materials reinforced with short fibers, manufactured in one-shot by means of injection moulding process. Furthermore, this study aims to identify which type of configuration or architecture is more efficient in terms of weight for different aircraft size, taking into account the structural requirements. Additionally, in order to assess the scale factor, Single Aile (SA) and Long Range (LR) are taken as reference of different size aircrafts.

2 THS Tip Trade- off Study

Three different configurations for the SA and LR THS tips, made of injection thermoplastic materials reinforced with short fibers, were studied in this work:

- Configuration 1: an outer shell made of one sole skin.

- Configuration 2: an outer shell (skin) reinforced with integrated ribs/spars.

- Configuration 3: an outer shell (skin) stiffened with an integrated iso-grid system.

2.1 SA THS Tip

SA THS tip (see Figure 1) is a metallic sheet construction comprised of the following parts:

- 2 formed aluminium skin panels welded at the middle section.

- 5 aluminium form reinforcing ribs with lightening holes and riveted to the skin.

The tip is joined to the THS torsion box and leading edge by means of countersunk rivets.

2.2 LR THS Tip

LR THS tip is a metallic typical box construction made up by spars and ribs to which the external skin panels are fastened to, comprising the following parts (see Figure 2):

- Aluminium skin panels of different thicknesses.

- Aluminium ribs and spars in chord and wingspan directions containing lightening holes. They are attached to the skin panels by means of blind fasteners.

Upper and lower tip skin panels are fastened to the torsion box and leading edge by means of a single row or removable screws and nuts.

2.3 Configuration proposals for injection moulding process

These configurations consisted of a single part forming the tip skin and integrating different internal elements or not, as shown in Figure 3 were studied.

As preliminary approach, these tips are supposed to be manufactured in one-shot by injection moulding process and attached to the torsion box and leading edge by the same fastener system as the reference, in order to ensure the interchangeability with current design.

As baseline, the external surface was protected against Lightning Strike events by means of Expanded Copper Foil (ECF) also integrated during the injection process.

2.4 Load Cases

The tips were loaded under a variable pressure distribution along its own chord and span. Two different type of load cases based on SA and LR THS tips envelopes were evaluated depending on the failure modes, phenomena and design details to be considered

2.4.1 Critical Ultimate Load Cases

Maximum values of ultimate load pressures for the critical load cases were considered in order to demontrace compliance to static strength

2.4.2 Cruise Load Cases

Cruise airloads were taken into account to demonstrate that the maximum deflection of the tip did not exceed the aerodynamic tolerances for external surfaces under cruise condition (according to the programme Technical Design Directives).

Maximum values of limit load pressure for cruise condition were taken from the pressure curve at box and tip joint span sections provided by the aerodynamic department.

2.5 Materials

Material selected for the different tip configurations made by injection moulding process was a high performance Short Carbon Fiber Thermoplastic.

Material was considered as isotropic for the preliminary analysis in this work.

2.6 Sizing methodology

The following hypotheses were made in order to simplify the calculations and reduce the number of uncertainties on the whole process:

- Minimum thickness of 1,0 mm was considered due to the limitation in pressure required in the injection moulding process for thinner sections.

- The internal elements configurations were designed making it compatible with moulding and demoulding solutions, taking into account the possibility of using flexible moulds.

- Thickness was variable along skin and internal elements and not necessarily symmetrical, it means, upper and lower skin were sized with different thickness distribution.

- Quasi-equilateral triangular isogrid was selected due to its optimal efficiency in terms of loads distribution.

- As stated before, SCFTP material was considered as isotropic in the calculations, because the micro-structure of the part (fibre orientation and concentration) depended on the injection process which was not known yet. The properties in transverse direction to the fiber orientation could decrease up to 40% and this anisotropic behaviour shall be taken into account in further analysis.

- Thermal loads were not considered in the calculations, as all the tip structure was made up from the same thermoplastic material with equivalent coefficients of thermal expansion. No degradation was expected in material stiffness properties within the operation temperature range from -55 to 90 ºC (lower than the material Glass Transition Temperature, Tg = 140 ºC).

- Tips were considered as simply supported along the attachment lines to the torsion boxes and leading edges.

Detailed Finite Element Models (DFEM) were created for each of the configurations showed in Figure 3. THS Tips are categorized as structure D and structure C for the SA and LR respectively. Taking into account this categorization, the following failure modes, phenomena and design details were considered:

- Aerodynamic stiffness/deflection under cruise limit loads.

- Static strength at ultimate load levels.

- Joint analysis at ultimate load levels.

- Protection against lightning strike events.

3 Results

3.1 Sizing results

Figure 4 shows the results associated with SA proposals. The aerodynamic stiffness/deflection criteria was found as sizing driver, defining the thicknesses for each alternative.

For the LR configuration, Figure 5 illustrates the results. The aerodynamic stiffness/deflection criteria was, as in SA case, the sizing driver.

3.2 Lightning Strike Protection

Tips are one of the most impacted areas by lightning strike attachments with long hang-on. The protection philosophy used for the composite tip of the torsion box in the standard LR THS was applied, i.e., Expanded Copper Foil (ECF). Further improved solutions as metallization or solid copper foil were under development.

3.3 Mass estimation

Weight estimations were performed for SA and LR THS Tips Note that the weight estimations of the new sized configurations were FEM weights, while the reference tips weights were the real ones. Additionally, it must be remarked that only static sizing FEM weights were considered. Reinforcement at stringer feet, extra thickness due to demoulding angles and other extra weight should be added due to design and manufacturing requirements.

Tendencies of the weight impact for the different configurations under study as per Figure 3 are indicated in Table 1 for SA and LR

| Configuration | SA Weight Impact | LR Weight Impact |

| Only Skin | +12% | +110% |

| 4 Intergrated Ribs | -16% | -7% |

| Isogrid | -13% | +92% |

3.4 Manufacturing assessment

Initial manufacturing studies were performed during the project.

After finishing the first engineering activities, some manufacturing studies and flow simulations were developed in order to assess the injection process (see Figure 6). Some results from this research were the following ones:

- Size of the parts under study are close to the upper limit for this kind of process

- Minimizing the thickness variations was identified as a must in order to avoid internal defects.

- Thicknesses of the reinforcements should be less than 60% of the shell thickness.

- Low thicknesses (~1mm) in wide areas implied issues for the plastic flow and the filling process.

- Demoulding trials should be performed in order to validate the manufacturing process.

1.1 Preliminary test under development

An initial material coupon test campaign in order to have a first assessment on the joint behavior of this material type is in process, mainly bearing and pull-trough coupons.

In addition fatigue un-notched coupons are being tested under different types of loading and stress profile.

4 Conclusions and way forward

SA and LR THS Tips analyses offer the following conclusions:

- For the tips, the sizing driver is the fulfilment of aerodynamic tolerances for external surfaces.

- The solutions based on skin with isogrid and skin reinforced with ribs are the most efficient solutions in terms of weight for the SA. In terms of cost, the discussion is open due to the configuration complexity and the tooling non-recurring costs.

- The solution based on skin reinforced with ribs is the most efficient solution in terms of weight for the LR. Nevertheless, it is not competitive in comparison with the state of the art solution for this aircraft.

As way forward, the following activities are defined:

- A detailed study on different SCFTP materials regarding different failure modes such as bearing and pull-through allowables, along with creep modulus and notched fatigue specimens are needed to have a complete picture complementary to this work.

- Simulation and test of fibre orientation and non-homogeneities in function of the mould and injection design must be performed to have an initial assessment on the anisotropy effect for SA scope.

- Alternative solutions for Lightning Strike Protection can be considered.

Acknowledgments

The previous project was included in the project FACTORIA, funded by the Ministerio de Economía y Competitividad, by means of the Centro Tecnológico Industrial (CDTI), in the Strategic Programme CIEN 2016.

References

[1] Internal References. Confidential.

Document information

Published on 29/04/18

Accepted on 29/04/18

Submitted on 29/04/18

Volume 02 - Comunicaciones Matcomp17 (2018), Issue Num. 2 - Aplicaciones y compuestos multifuncionales, 2018

DOI: 10.23967/r.matcomp.2018.04.002

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?