m (Scipediacontent moved page Draft Content 829682939 to Rodriguez et al 2018b) |

|||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> |

| − | < | + | A.R.Rodriguez, J.Cuenca, R. Ruiz, A.Calero</div> |

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <span style="text-align: center; font-size: 75%;">Fundación para la Investigación, Desarrollo y Aplicación de Materiales Compuestos (FIDAMC), Getafe</span></div> | ||

| + | |||

| + | {| style="width: 87%;border-collapse: collapse;" | ||

| + | |- | ||

| + | | colspan='2' style="vertical-align: top;"|<big>ZAero- Cero Defectos en la fabricación de piezas de material compuesto en la industria aeroespacial</big> | ||

| + | |- | ||

| + | | style="border-bottom: 1pt solid black;vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:Rodriguez_et_al_2018b-image1.png|54px]] </span> | ||

| + | | style="vertical-align: top;"| | ||

| + | |- | ||

| + | | style="border-top: 1pt solid black;border-bottom: 1pt solid black;vertical-align: top;"|<span style="text-align: center; font-size: 75%;">Historia del artículo:</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Recibido 5 de Mayo 2017</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">En la versión revisada 5 de Mayo 2017</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Aceptado 31 de Mayo 2017</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Accesible online 21 de Junio 2017</span> | ||

| + | | rowspan='4' style="vertical-align: top;"|<span style="text-align: center; font-size: 75%;">Durante el proceso de fabricación de una pieza de fibra de carbono en la industria aeronáutica, se producen defectos. Estos defectos se identifican a través de inspecciones realizadas en etapas intermedias y al final del proceso de fabricación. Debido a estos defectos se producen retrabajos e incluso inutilidades.</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Este Proyecto tiene como objetivo el control en línea de los defectos que se irán produciendo a lo largo de la fabricacion de un panel rigidizado de superficie sustentadora. El sistema de control ZAero consta de unos sensores integrados en la máquina de laminación y unos sensores usados durante la etapa de infusion y curado de resina. A través de estos sensores se detectarán los defectos que estén fuera del rango de aceptación y se producirá una respuesta. Esta respuesta podrá ser un retrabajo como en el caso de los defectos producidos en la etapa de laminación o</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">una variación de paramétros producidos en la etapa de infusión y curado de resina debido a la monitorización del proceso.</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Se realizará la fabricación de tres demonstradores, aumentando en cada demostrador el grado de complejidad. El sistema de control a través de sensores irá realizando un control de calidad y cuando se produzca una defecto que se encuentre fuera del rango de aceptacion se producirá una respuesta.</span> | ||

| + | |- | ||

| + | | style="border-top: 1pt solid black;vertical-align: top;"|<span style="text-align: center; font-size: 75%;">Palabras clave:</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Defectos cero</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Control de calidad en linea</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Deposición de fibra seca </span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Aeroespacial</span> | ||

| + | |||

| + | |||

| + | |- | ||

| + | | style="border-top: 1pt solid black;vertical-align: top;"| | ||

| + | |- | ||

| + | | colspan='2' style="vertical-align: top;"|<big>ZAero- Zero defect manufacturing of composite parts in the aerospace industry</big> | ||

| + | |- | ||

| + | | style="border-bottom: 1pt solid black;vertical-align: top;"|<span style="text-align: center; font-size: 75%;"> [[Image:Rodriguez_et_al_2018b-image2.png|54px]] </span> | ||

| + | | style="vertical-align: top;"| | ||

| + | |- | ||

| + | | style="border-top: 1pt solid black;border-bottom: 1pt solid black;vertical-align: top;"|<span style="text-align: center; font-size: 75%;">Keywords:</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Zero defects</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Inline quality control</span> | ||

| + | |||

| + | <span id='_GoBack'></span><span style="text-align: center; font-size: 75%;">Dry fiber placement</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Aerospace</span> | ||

| + | |||

| + | |||

| + | | rowspan='2' style="vertical-align: top;"|<span style="text-align: center; font-size: 75%;">During the manufacturing process of a carbon fiber (CFRP) part in the aircraft industry defects occur. These defects are identified through inspections carried out in intermediate steps and even at the end of the manufacturing process. Due to these defects reworks need to be performed and even futilities.</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">The aims of this project is the inline control of the defects that will be produced along the manufacturing of a stiffned surface panel. The ZAero control system consists on sensors integrated in the lay-up machine and sensors used during the infusion and resin curing processes. These sensors will detect defects that are outside the acceptance range and a response will occur. This response may be a rework as in the case of defects produced in the lamination stage or the variation of parameters produced in the infusion and resin curing stage due to the process monitoring.</span> | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">Three demonstrators will be manufactured. The degree of complexity will be increased in each demonstrator. The control system through sensors will make a quality control and when a defect that is outside the range of acceptance a response will occur.</span> | ||

| + | |||

| + | |||

| + | |- | ||

| + | | style="border-top: 1pt solid black;vertical-align: top;"| | ||

| + | |} | ||

| + | |||

| + | |||

| + | ==1 Introduction == | ||

| + | |||

| + | ZAero Project is framed within the program of aid to research and innovation of the European Union H2020 [<span id="fn-"></span>([[#fnc-|<sup></sup>]]) ]. | ||

| + | |||

| + | The consortium consists of the following partners: PROFACTOR, DASSAULT SYSTÈMES SE, MTORRES sistemas industriales, DANOBAT, IK4-IDEKO, AIRBUS DEFENSE&SPACE GmbH and FIDAMC. | ||

| + | |||

| + | The aim of ZAero “Zero defect manufacturing of composite parts in the aerospace industry” project is the development of inline quality control methods for carbon fibre parts production (CFRP) to achieve: | ||

| + | |||

| + | :* Inline quality controled by: | ||

| + | |||

| + | ::* Increased productivity flexibility. | ||

| + | |||

| + | ::* Higher production rated by 15%. | ||

| + | |||

| + | ::* Avoiding productivity losses due to in-situ manual inspection work. | ||

| + | |||

| + | :* Reduction of manual in-situ inspection processes during lay-up, after infusion and curing and end-of-line rework in order to reduce production cost by 15-20%. | ||

| + | |||

| + | :* Earlier re-work processes, inline monitoring and process control to reduce waste and scrap by 50%. | ||

| + | |||

| + | ==2 ZAero control system== | ||

| + | |||

| + | The ZAero system provides an inline and automatic system to detect defects during the manufacturing through sensors. The objective of the control system with sensors is to reach TRL 6-7 during the manufacturing trials at FIDAMC. | ||

| + | |||

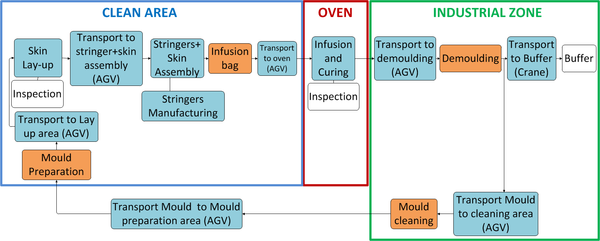

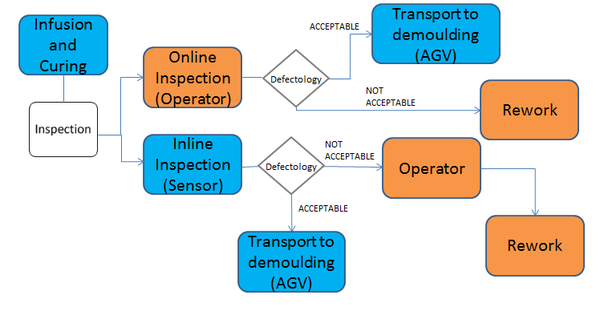

| + | The control is performed during the manufacturing process of a stiffened surface panel: | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image5.png|600px]] </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <span style="text-align: center; font-size: 75%;">'''Figure 1.''' Process Flow Chart</span></div> | ||

| + | |||

| + | The ZAero control system acts on 2 steps of the manufacturing processes: Lay-up and infusion-curing. | ||

| + | |||

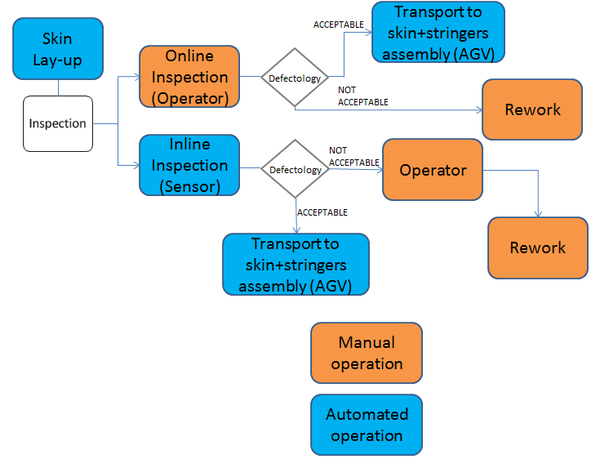

| + | :* In the case of lay-up every layer is automatically inspected inline by ZAero sensors. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image6.png|600px]] </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <span style="text-align: center; font-size: 75%;">'''Figure 2.''' Current working method (orange) and ZAero method (blue)</span></div> | ||

| + | |||

| + | The inline inspection that will perform the control system is shown in the Figure 3. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image7.png|600px]] <span style="text-align: center; font-size: 75%;">'''Figure 3.''' Steps in System control process</span></div> | ||

| + | |||

| + | Operators will inspect and act only when the error is detected by sensors. Several defects can be detected as angle deviation; late add, early cut and early add, late cut; missing tow; splices; gaps and overlaps; twist-DFP; fuzzball; defects in z-direction. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | |||

| + | {| | ||

| + | |- | ||

| + | | [[Image:Rodriguez_et_al_2018b-image8-c.png|294px]] | ||

| + | | [[Image:Rodriguez_et_al_2018b-image9-c.png|center|294px]] | ||

| + | |} | ||

| + | </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | |||

| + | {| | ||

| + | |- | ||

| + | | [[Image:Rodriguez_et_al_2018b-image10-c.png|174px]] | ||

| + | | [[Image:Rodriguez_et_al_2018b-image11.png|center|276px]] | ||

| + | |} | ||

| + | </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <span style="text-align: center; font-size: 75%;">'''Figure 4.''' Defects in Lay-up process: upper left) Gaps; upper right) Missing tow; bottom left) Butt Splice; bottom right) Twist in machine</span></div> | ||

| + | |||

| + | The control system has two sensors: | ||

| + | |||

| + | :* Fscan: Sensor technology that uses a specific laser profile scanner to acquire 3D profiles during the AFP process. | ||

| + | |||

| + | :* Lscan: Sensor technology using a reflection model of carbon fibre to measure fibre orientation. 3D information is not provided. | ||

| + | |||

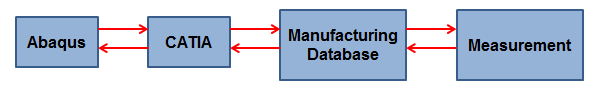

| + | :* In the infusion and curing processes the sensors monitor the temperature, flow rate and extent of the curing. If there is a variation of these parameters outside the acceptable limits, the ZAero system will act by correcting the parameters. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image12.png|600px]] </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <span style="text-align: center; font-size: 75%;">'''Figure 5.''' Current working method (orange) and ZAero method (blue)</span></div> | ||

| + | |||

| + | Porosity can be generated during the infusion and curing processes. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image13.png|486px]] </div> | ||

| + | |||

| + | Figure 6. Non destructive test. Example of Porosity | ||

| + | |||

| + | The sensor used to monitor infusion and curing processes is based on Electrical Time Domain Reflectometry (E-TDR) [2]. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image14-c.png|600px]] </div> | ||

| + | |||

| + | Figure 7. Schematic Illustration of E-TDR Technology | ||

| + | |||

| + | ==3 Materials and Technology== | ||

| + | |||

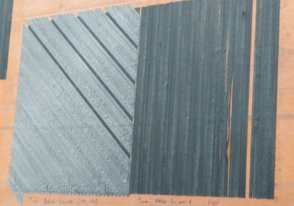

| + | Two different technologies of automated lay-up which have similar needs for inspection will used: | ||

| + | |||

| + | :* Dry Fiber Placement (DFP): | ||

| + | |||

| + | The machine will laminate with 8 tows of uniaxial material (12.7mm of width). Carbon fabric tows are very malleable themselves so as to make them manageable for manufacturing issues, they include binder onto their surfaces. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image15.png|360px]] </div> | ||

| + | |||

| + | Figure 8. MTorres Dry Fiber Placement machine (DFP) | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image16-c.png|300px]] </div> | ||

| + | |||

| + | Figure 9. Uniaxial material | ||

| + | |||

| + | :* Automated Dry Material Placement (ADMP): | ||

| + | |||

| + | Multiaxial material with a width of 600mm will be placed. The tow curvature is lower in comparison with weave fabrics. The material has better mechanical properties. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image17.png|366px]] </div> | ||

| + | |||

| + | Figure 10. Danobat Automated Dry Material Placement machine (ADMP) | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image18.png|294px]] </div> | ||

| + | |||

| + | Figure 11. Multiaxial material | ||

| + | |||

| + | The resin that will be used in the infusion and curing processes is a thermoset liquid epoxy resin. | ||

| + | |||

| + | Resin infusion processes techniques undergo both impregnation of the textile reinforcement and curing in the same moulding operation, thus providing cost reductions compared to prepreg technology. | ||

| + | |||

| + | The resin is enabling the parts to keep their final shape via chemical reaction (polymerization). Epoxy is a very versatile resin system, allowing a broad range of properties and processing capabilities. | ||

| + | |||

| + | ==4 Manufacturing Trials== | ||

| + | |||

| + | Three parts will be manufactured. The degree of complexity will be increased in each demonstrator. | ||

| + | |||

| + | ==='''4.1''' Demonstrator 1=== | ||

| + | |||

| + | This demonstrator part is mainly focused to test lay-up monitoring. | ||

| + | |||

| + | Defects will be induced during the manufacturing to assess the defect detection capabilities of the inline sensor systems. | ||

| + | |||

| + | A prototype system for inline quality control will be demonstrated. | ||

| + | |||

| + | ==='''4.2''' Demonstrator 2 === | ||

| + | |||

| + | Second demo is oriented not only towards lay-up inspection, but also for curing monitoring. The dimensions of Demo 2 will be 1700x1700mm. | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image19.png|600px]] </div> | ||

| + | |||

| + | Figure 12. Demonstrator 2 | ||

| + | |||

| + | The demo part proposed is based on double curvature in order to identify potential lay-up defects as excessively wide gaps, overlaps, fuzz balls, twisted yarns, or other defects. | ||

| + | |||

| + | An intermediate version of the inline quality support will be demonstrated. | ||

| + | |||

| + | ==='''4.3''' Demonstrator 3=== | ||

| + | |||

| + | The third demo part is designed as demo part 2, but including three integrated stringers. These stringers have been defined as 3 “T” shape stringers: | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image20.png|600px]] </div> | ||

| + | |||

| + | Figure 13. Demonstrator 3 | ||

| + | |||

| + | The integration of the stringers in the demo part is necessary in order to test a real case of a stiffened panel for the infusion process. | ||

| + | |||

| + | A full version of the inline quality support will be demonstrated. | ||

| + | |||

| + | ==5 Project Plan== | ||

| + | |||

| + | The duration of the project is 36 months (October 2016 to October 2019) [<span id="fn-"></span>([[#fnc-|<sup></sup>]]) ]. | ||

| + | |||

| + | 1<sup>st</sup> Demonstration will be planned to month 12 (October 2017). | ||

| + | |||

| + | 2<sup>nd</sup> Demonstration will be planned to month 24 (October 2018). | ||

| + | |||

| + | 3<sup>rd</sup> Demonstration will be planned to month 36 (October 2019). | ||

| + | |||

| + | ==6 Acknowledgements== | ||

| + | |||

| + | <div id="_Ref481484277" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | [[Image:Rodriguez_et_al_2018b-image21-c.png|306px]] </div> | ||

| + | |||

| + | This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 721362. | ||

| + | |||

| + | ==7 References== | ||

| + | |||

| + | <span style="text-align: center; font-size: 75%;">[<span id="fn-"></span>([[#fnc-|<sup></sup>]]) ]</span> ZAero-Grant Agreement([http://www.zaero-project.eu http://www.zaero-project.eu]). | ||

| + | |||

| + | [2] BUCHMANN, C., FILSINGER, J. and LADSTÄTTER, E.: Investigation of Electrical Time Domain Reflectometry for Infusion and Cure Monitoring in Combination with Electrically Conductive Fibers and Tooling Materials. Composites Part B: Engineering, 94: 389-398 (2016). | ||

Revision as of 07:30, 3 May 2022

1 Introduction

ZAero Project is framed within the program of aid to research and innovation of the European Union H2020 [() ].

The consortium consists of the following partners: PROFACTOR, DASSAULT SYSTÈMES SE, MTORRES sistemas industriales, DANOBAT, IK4-IDEKO, AIRBUS DEFENSE&SPACE GmbH and FIDAMC.

The aim of ZAero “Zero defect manufacturing of composite parts in the aerospace industry” project is the development of inline quality control methods for carbon fibre parts production (CFRP) to achieve:

- Inline quality controled by:

- Increased productivity flexibility.

- Higher production rated by 15%.

- Avoiding productivity losses due to in-situ manual inspection work.

- Reduction of manual in-situ inspection processes during lay-up, after infusion and curing and end-of-line rework in order to reduce production cost by 15-20%.

- Earlier re-work processes, inline monitoring and process control to reduce waste and scrap by 50%.

2 ZAero control system

The ZAero system provides an inline and automatic system to detect defects during the manufacturing through sensors. The objective of the control system with sensors is to reach TRL 6-7 during the manufacturing trials at FIDAMC.

The control is performed during the manufacturing process of a stiffened surface panel:

The ZAero control system acts on 2 steps of the manufacturing processes: Lay-up and infusion-curing.

- In the case of lay-up every layer is automatically inspected inline by ZAero sensors.

The inline inspection that will perform the control system is shown in the Figure 3.

Operators will inspect and act only when the error is detected by sensors. Several defects can be detected as angle deviation; late add, early cut and early add, late cut; missing tow; splices; gaps and overlaps; twist-DFP; fuzzball; defects in z-direction.

The control system has two sensors:

- Fscan: Sensor technology that uses a specific laser profile scanner to acquire 3D profiles during the AFP process.

- Lscan: Sensor technology using a reflection model of carbon fibre to measure fibre orientation. 3D information is not provided.

- In the infusion and curing processes the sensors monitor the temperature, flow rate and extent of the curing. If there is a variation of these parameters outside the acceptable limits, the ZAero system will act by correcting the parameters.

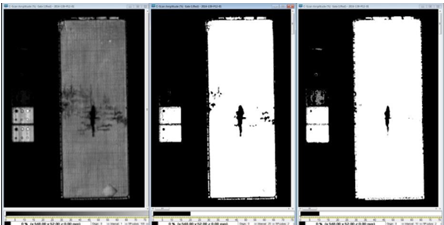

Porosity can be generated during the infusion and curing processes.

Figure 6. Non destructive test. Example of Porosity

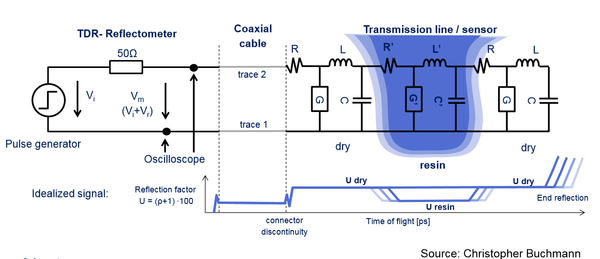

The sensor used to monitor infusion and curing processes is based on Electrical Time Domain Reflectometry (E-TDR) [2].

Figure 7. Schematic Illustration of E-TDR Technology

3 Materials and Technology

Two different technologies of automated lay-up which have similar needs for inspection will used:

- Dry Fiber Placement (DFP):

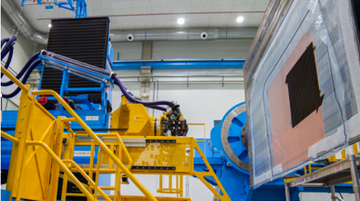

The machine will laminate with 8 tows of uniaxial material (12.7mm of width). Carbon fabric tows are very malleable themselves so as to make them manageable for manufacturing issues, they include binder onto their surfaces.

Figure 8. MTorres Dry Fiber Placement machine (DFP)

Figure 9. Uniaxial material

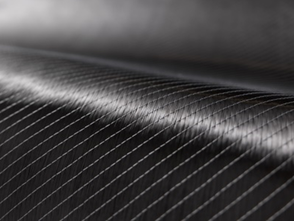

- Automated Dry Material Placement (ADMP):

Multiaxial material with a width of 600mm will be placed. The tow curvature is lower in comparison with weave fabrics. The material has better mechanical properties.

Figure 10. Danobat Automated Dry Material Placement machine (ADMP)

Figure 11. Multiaxial material

The resin that will be used in the infusion and curing processes is a thermoset liquid epoxy resin.

Resin infusion processes techniques undergo both impregnation of the textile reinforcement and curing in the same moulding operation, thus providing cost reductions compared to prepreg technology.

The resin is enabling the parts to keep their final shape via chemical reaction (polymerization). Epoxy is a very versatile resin system, allowing a broad range of properties and processing capabilities.

4 Manufacturing Trials

Three parts will be manufactured. The degree of complexity will be increased in each demonstrator.

4.1 Demonstrator 1

This demonstrator part is mainly focused to test lay-up monitoring.

Defects will be induced during the manufacturing to assess the defect detection capabilities of the inline sensor systems.

A prototype system for inline quality control will be demonstrated.

4.2 Demonstrator 2

Second demo is oriented not only towards lay-up inspection, but also for curing monitoring. The dimensions of Demo 2 will be 1700x1700mm.

Figure 12. Demonstrator 2

The demo part proposed is based on double curvature in order to identify potential lay-up defects as excessively wide gaps, overlaps, fuzz balls, twisted yarns, or other defects.

An intermediate version of the inline quality support will be demonstrated.

4.3 Demonstrator 3

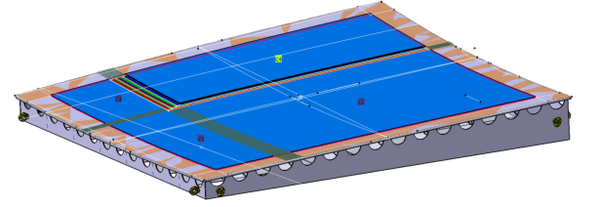

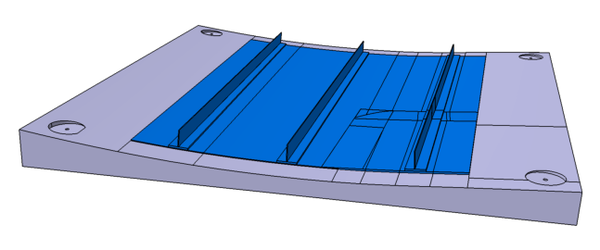

The third demo part is designed as demo part 2, but including three integrated stringers. These stringers have been defined as 3 “T” shape stringers:

Figure 13. Demonstrator 3

The integration of the stringers in the demo part is necessary in order to test a real case of a stiffened panel for the infusion process.

A full version of the inline quality support will be demonstrated.

5 Project Plan

The duration of the project is 36 months (October 2016 to October 2019) [() ].

1st Demonstration will be planned to month 12 (October 2017).

2nd Demonstration will be planned to month 24 (October 2018).

3rd Demonstration will be planned to month 36 (October 2019).

6 Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 721362.

7 References

[() ] ZAero-Grant Agreement(http://www.zaero-project.eu).

[2] BUCHMANN, C., FILSINGER, J. and LADSTÄTTER, E.: Investigation of Electrical Time Domain Reflectometry for Infusion and Cure Monitoring in Combination with Electrically Conductive Fibers and Tooling Materials. Composites Part B: Engineering, 94: 389-398 (2016).

Document information

Published on 29/04/18

Accepted on 29/04/18

Submitted on 29/04/18

Volume 02 - Comunicaciones Matcomp17 (2018), Issue Num. 2 - Aplicaciones y compuestos multifuncionales, 2018

DOI: 10.23967/r.matcomp.2018.04.020

Licence: Other

Share this document

Keywords

claim authorship

Are you one of the authors of this document?