(→6. Results) |

|||

| (94 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

| + | <!-- metadata commented in wiki content | ||

| − | |||

| − | + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | |

| + | <big>Optimization Study For The Cross-Section Of A Concrete Gravity Dam: Genetic Algorithm Model And Application.</big></div> | ||

| − | == | + | Federal Institute of Education, Science and Tecnology of Goias. Street 64, corner street 11 – Parque Lago, 73813-816, Formosa, Goias, Brazil. |

| − | < | + | |

| + | Federal Technological University of Paraná (DACOC/UTFPR). Rua Deputado Heitor Alencar Furtado, 5000, Campus Ecoville, Curitiba, Paraná, Brazil. | ||

| + | |||

| + | [mailto:leilsonjoaquim@gmail.com; leilsonjoaquim@gmail.com;] [mailto:agnovieira@yahoo.com.br agnovieira@yahoo.com.br]; [mailto:danielag@utfpr.edu.br danielag@utfpr.edu.br] | ||

| + | --> | ||

| + | ==Abstract == | ||

| + | |||

| + | Concrete gravity dams have trapezoidal shape in their cross section and shall guarantee the global stability against acting loads like hydrostatic and uplift pressures through his gravitational actions (self-weight and others). This study focuses on the shape optimization of concrete gravity dams using genetic algorithms. In this case, the dam cross section area is considered as the objective function and the design variables are the geometric parameters of the gravity dam. The optimum cross-section of a concrete gravity dam is achieved by the Genetic Algorithm (GA) through a Matlab routine developed by the author. Sliding, overturning and floating verifications are implemented in the program. In order to assess the efficiency of the proposed methodology for gravity dams optimization, one application is presented adopting the concrete gravity dam of Belo Monte Hydropower Plant (HPP), considering normal loading condition and others assumptions presented. | ||

| + | |||

| + | '''Keywords''': Optimization, concrete gravity dams, genetic algorithm, design optimization | ||

| + | |||

| + | ==1. Introduction== | ||

| + | |||

| + | Concrete gravity dams are hydraulic structures widely used as water reservoir to hydroelectric power plants in general. These structures have trapezoidal shape in their cross section and shall guarantee the global stability against hydrostatic and uplift pressures by means of gravitational actions (as self-weight and others) [32]. Hence, finding a proper design for the cross-section can remarkably reduce the construction costs [3]. | ||

| + | |||

| + | For stability requirements, the dam must be safe against overturning, sliding and floating. Moreover, the acting stresses in the concrete of the dam or in the foundation material shall attend the limits stabilized by design criteria. The potential failure plans as concrete-foundation contact, horizontal plans through the dam body or through the foundation, can be considered, according to the rupture mechanisms identified by the geotechnical model [11]. | ||

| + | |||

| + | In order to assure the structural global stability and the allowable stress criteria for the concrete gravity dam design, as discussed in Gutstein [19] and [20] a trial and error procedure process is usually carried out from a preliminary cross section defined in the design initial phases, followed by stability and stress analysis studies. Then, if the chosen cross section does not meet the security criteria, it shall be modified and analyzed again. Also, once safety criteria are met, a new study can be conducted with the purpose of optimizing the design (minimizing the dam cross section area). | ||

| + | |||

| + | To achieve this purpose, several alternatives can be used to obtain a number of feasible shapes. Finally, the cross section with minimum area (also with lower cost), that meets the structural considerations and design criteria, is selected as the final shape. In order to reliably achieve an optimal shape for dams in this study, instead of this trial and error procedure, optimization techniques have been effectively utilized [23,24,34]. | ||

| + | |||

| + | Genetic Algorithms (GA) are heuristic search approaches applicable to a wide range of optimization problems [4]. This flexibility makes them attractive for many optimization problems in practice. They represent one branch of the field of study called evolutionary computation, which imitate the biological processes of reproduction and natural selection to solve for the fittest solutions [7]. | ||

| + | |||

| + | GA can solve a broad class of engineering problems encountered in practice, involving a large number of design parameters (integer, discrete, continuous and integer/discrete-continuous) and a large number of constraints. It has been highly successful as one of evolutionary computation techniques in searching for a broad class of stacking sequence, size, topology optimization problems for composite structures [18,29,30,31]. | ||

| + | |||

| + | Designing and constructing concrete gravity dams can be considered as a typical optimization problem, since the cross section geometry with lowest area that meets the design criteria is searched for, with the final aim of reducing cost [35]. | ||

| + | |||

| + | Optimizing this cost requires cross-section optimization. The main aim of this paper is to present and discussed an optimization study for concrete gravity dams based on GA and Matlab application. The present work brings a simple implementation using GA in Matlab for usual loading condition, contrasting with the complexity presented in [2,3,13,14,23,24,35] which bring approaches with high complexity computational methods. | ||

| + | |||

| + | The dam's geometry and the acting loads must be considered in its design analysis procedure. In order to reduce the computational cost of the optimization process, the stopping criteria is limited to satisfactory values. To demonstrate the efficiency of GAs in finding the optimum design of concrete gravity dams, the cross-section from Belo Monte Hydropower Plant is presented as an example of application, considering normal loads and hypothetical resistance parameters for the foundation. | ||

| + | |||

| + | ==2. Stability analysis of concrete gravity dams== | ||

| + | |||

| + | [[#img-1|Figure 1]] shows the usual loads acting in a dam considering drainage. Water pressure is the major external load acting on such a dam. The horizontal water pressure, exerted by the weight of the water stored on the upstream side on the dam can be estimated from rule of hydrostatic pressure distribution. | ||

| + | |||

| + | In other to meet the safety requirements, the dam cross section is verified against floating, overturning and sliding. | ||

| + | |||

| + | Floating safety factor has the function to guarantee the stability of structure against the forces that tend to make the body float. It is calculated by Equation (1) [12] | ||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

| + | |- | ||

| + | | style="text-align: center;" | <math>FSF=\, \frac{\sum _{}^{}V}{\sum _{}^{}U\, }</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (1) | ||

| + | |} | ||

| + | |||

| + | where <math>FSF</math> is the safety factor against floating, should be greater than 1.3, <math> \sum V</math> the resultant vertical force and <math> \sum U</math> the total uplift force. | ||

| + | |||

| + | The overturning of a gravity dam may be calculated by dividing the total resisting moments by the total moments tending to cause overturning about the downstream toe, it is defined as the ratio between the resisting moments and overturning moments [33] | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

| + | |- | ||

| + | | style="text-align: center;" | <math>FSO=\, \frac{\sum _{}^{}{M}_{r}}{\sum _{}^{}{M}_{o}}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (2) | ||

| + | |} | ||

| + | |||

| + | <math>FSO</math> is the safety factor against overturning, should be greater than 1.5, <math display="inline">{M}_{r}</math> the moments resisting and <math display="inline">{M}_{o}</math> the moments overturning. | ||

| + | |||

| + | A dam will fail in sliding at its base, or at any other level, if the horizontal forces causing sliding are greater than the resistance available to it at that level. The resistance against sliding may be due to friction alone, or due to friction and shear strength of the joint. The sliding stability is based on a safety factor as a measure of determining the resistance of the structure against sliding [12] | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

| + | |- | ||

| + | | style="text-align: center;" | <math>FSS=\, \frac{\mathrm{\mu}\sum _{}^{}V}{\sum _{}^{}H}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (3) | ||

| + | |} | ||

| + | |||

| + | |||

| + | <math>FSS</math> is the safety factor against sliding which should also be greater than 1.0, <math>\mu</math> the reduced coefficient of friction, <math>\sum V</math> the total vertical force acting on dam and <math>\sum H</math> the total horizontal force acting on dam. | ||

| + | |||

| + | <div id='img-1'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Esq car.png|577x577px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 1'''. Concrete gravity dam: cross-Section, analysis plan and imposed forces | ||

| + | |} | ||

| + | |||

| + | |||

| + | According to Eletrobras [12], the calculation of the uplift pressure acting in the analysis plan is made considering the uplift pressure reduction (<math>{H}_{dm}</math>) in the drainage curtain according to (4): | ||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

| + | |- | ||

| + | | style="text-align: center;" | <math>{H}_{dm}=\left\{ \begin{matrix}{H}_{j}+\frac{1}{3}\ast \left( {H}_{m}-{H}_{j}\right) \, for\, \, {H}_{j}>\, {h}_{g}\\{h}_{g}+\frac{1}{3}\ast \left( {H}_{m}-{h}_{g}\right) \, for\, \, {H}_{j}<\, {h}_{g}\end{matrix}\right\}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (4) | ||

| + | |} | ||

| + | |||

| + | where <math>{h}_{g}</math> is the gallery height, <math>{H}_{m}</math> the upstream water level, <math>{H}_{j}</math> the downstream water level and all of them in relation to the concrete-rock contact (analysis plan). Those expressions considerer the 66% drainage curtain efficiency adopted for the Bureau of Reclamation [33]. | ||

| + | |||

| + | ==3. Geometrical model of concrete gravity dams and problem formulation== | ||

| + | |||

| + | Based on the model of concrete gravity dam depicted in [[#img-2|Figure 2]], the cross-section of concrete gravity dam studied is defined by the four parameters given by Equation (5) | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

| + | |- | ||

| + | | style="text-align: center;" | <math>X=\lbrace {h}_{b},{b}_{c\, },\, {b}_{x},\, {h}_{t}\rbrace </math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (5) | ||

| + | |} | ||

| + | |||

| + | where <math>{b}_{c}</math> is a parameter required to define the dam crest. Also, the downstream slope is specified by the <math>{b}_{x}</math> and <math>{h}_{t}</math> design variables and h<sub>b </sub>is the dam’s height. | ||

| + | |||

| + | <div id='img-2'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Seccccc.png|312x312px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 2'''. Geometrical model of concrete gravity dam | ||

| + | |} | ||

| + | |||

| + | |||

| + | The process of evaluating the overall stability of a concrete dam, makes use of the static equations to evaluate the equilibrium of rigid body of the part. In order to automate the calculation of the global stability of a concrete gravity dam, an evaluation program was developed in the Matlab language. This program will be used as a starting point of the research. | ||

| + | |||

| + | The evaluation program has the ability to calculate overall stability and dam stress from the dimensions and conditions provided by the designer. This algorithm returns the values of the safety factors, calculated by Equations (2), (3) and (4). | ||

| + | |||

| + | After completing the calculations, the program displays the values obtained for FSF, FSO and FSS with a message indicating whether these values meet the design criteria, or whether the study section should be resized. | ||

| + | |||

| + | Gravity dam optimization problem is explained in this section. The cross-sectional area of the dam is considered as an objective function to be minimized. An optimization problem subjected to design constraints can be expressed as follows: | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | Find <math display="inline">{\overset{\rightarrow}{X}}^{L}\leq \overset{\rightarrow}{X}\leq {\overset{\rightarrow}{X}}^{U}</math></div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | Minimize <math display="inline">f\left( \overset{\rightarrow}{X}\right)</math> </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | Subject to <math display="inline">g\left( \overset{\rightarrow}{X}\right) \leq 0\,</math> </div> | ||

| + | |||

| + | where <math display="inline">f\left( \overset{\rightarrow}{X}\right)</math> and <math display="inline">g\left( \overset{\rightarrow}{X}\right)</math> are the objective function and the constraints, respectively. <math display="inline">{\overset{\rightarrow}{X}}^{L}</math> and <math display="inline">{\overset{\rightarrow}{X}}^{U}</math> are the lower bound and the upper bound of the design variables, <math display="inline">\overset{\rightarrow}{X}</math>, respectively [23]. | ||

| + | |||

| + | In this optimization problem of concrete gravity dams, the cross-section area of gravity dam body is considered as objective function, <math display="inline">f\left( \overset{\rightarrow}{X}\right)</math> , that should be minimized. The cross-section area of concrete gravity dam can be determined as follows: | ||

| + | |||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

| + | |- | ||

| + | | style="text-align: center;" | <math>f\left( \overset{\rightarrow}{X}\right) =f\left( A\right) =\left( {h}_{b}\ast {b}_{c\, }\right) +</math><math>\frac{\left( {b}_{x}-{b}_{c\, }\right) \ast \left( {h}_{b}-\, {h}_{t}\right) }{2}</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (6) | ||

| + | |} | ||

| + | |||

| + | where <math display="inline">f\left( A\right)</math> is cross-section area, and <math>{h}_{b}</math>, <math>{b}_{c}</math>, <math>{b}_{x}</math> and <math>{h}_{t}</math> are the design variables showed in Figure 2. | ||

| + | |||

| + | In the present study, the behavior and stability constraints are considered as the problem constraints, <math display="inline">g\left( \overset{\rightarrow}{X}\right)</math>. The behavior constraints consist on the safety factor against floating, overturning and sliding, calculated by Equations (2), (3) and (4) | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | <math>1.3-FSF\leq 0</math> | ||

| + | |} | ||

| + | </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | <math>1.5-FSO\leq 0\,</math> | ||

| + | |} | ||

| + | </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | {| class="formulaSCP" style="width: 100%; text-align: center;" | ||

| + | |- | ||

| + | | <math>1.0-FSS\leq 0</math> | ||

| + | |} | ||

| + | </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <math display="inline">\,</math> <math display="inline">\,</math> </div> | ||

| + | |||

| + | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| + | <math display="inline">\,</math> <math display="inline">\,</math> </div> | ||

| + | |||

| + | ==4. The Optimization Algorithm (Optdam)== | ||

| + | |||

| + | ===4.1 Genetic Algorithm (GA)=== | ||

| + | |||

| + | Genetic algorithm (GA) is a method for solving both constrained and unconstrained optimization problems that is based on natural selection, the process that drives biological evolution. It is an optimization and search technique based on the principles of genetics and natural selection [21]. An individual is any point fitness function can be evaluated [1]. | ||

| + | |||

| + | The value of the fitness function for an individual is its score. A population is an array of individuals. At each iteration, the genetic algorithm performs a series of computations on the current population to produce a new population. Each successive population is called a new generation. The best fitness value for a population is the smallest fitness value for any individual in the population [15]. | ||

| + | |||

| + | To create the next generation, the genetic algorithm selects certain individuals in the current population, called parents, and uses them to create individuals in the next generation, called children. Typically, the algorithm is more likely to select parents that have better fitness values [28]. | ||

| + | |||

| + | A GA allows a population composed of many individuals to evolve under specified selection rules to a state that maximizes the fitness (minimizes the cost function). The genetic algorithm repeatedly modifies a population of individual solutions [27]. | ||

| + | |||

| + | Evolution is the basis of Genetic Algorithms. The current variety and success of species is a good reason for believing in the power of evolution. Species are able to adapt to their environment. They have developed to complex structures that allow the survival in different kinds of environments. Mating and getting offspring to evolve belong to the main principles of the success of evolution. These are good reasons for adapting evolutionary principles to solving optimization problems [25]. | ||

| + | |||

| + | It presumes that the potential solution of a problem is an individual and can be represented by a set of parameters. These parameters are regarded as the genes of a chromosome and can be structured by a string of values in binary form. A positive value, generally known as fitness value, is used to reflect the degree of “good-ness” of the chromosome for solving the problem, and this value is closely related to its objective value [26]. | ||

| + | |||

| + | At each step, the genetic algorithm selects individuals at random from the current population to be parents and uses them to produce the children for the next generation. They combine survival of the fittest among string structures with a structured yet randomized information exchange search algorithm with some of innovative flair of human search [16]. Over successive generations, the population evolves toward an optimal solution. | ||

| + | |||

| + | It can be applied to solve a variety of optimization problems that are not well suited for standard optimization algorithms, including problems in which the objective function is discontinuous, nondifferentiable, stochastic, or highly nonlinear. The genetic algorithm can address problems of mixed integer programming, where some components are restricted to be integer-valued [10]. | ||

| + | |||

| + | The genetic algorithm differs from a classical, derivative-based, optimization algorithm in two main ways. First, classical algorithms generate a single point at each iteration. The sequence of points approaches an optimal solution, GA generates a population of points at each iteration and the best point in the population approaches an optimal solution. The second difference is that classical algorithms selects the next point in the sequence by a deterministic computation. Instead, GA selects the next population by computation which uses random number generators. | ||

| + | |||

| + | ===4.2 Penalty function=== | ||

| + | |||

| + | In generic search methods, most applications of GAs to constraint optimization problems have used the penalty function approach of handling constraints. The penalty function approach involves a number of penalty parameters which must be set right in any problem to obtain feasible solutions [22]. | ||

| + | |||

| + | It uses the penalty function in Equation (7), where infeasible solutions are compared based only on their constraint violation [8] | ||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

| + | |- | ||

| + | | | ||

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

| + | |- | ||

| + | | style="text-align: center;" | <math>{F\left( \overset{\rightarrow}{X}\right) =\left\{ \begin{matrix}f\left( \overset{\rightarrow}{X}\right) ,\, \, \&if\, {g}_{j}\left( \overset{\rightarrow}{X}\right) \geq 0\quad {\forall }_{j}=1,2,\ldots m,\, \\{f}_{max}+\sum _{j=1}^{m}{R}_{j}\left\langle {g}_{j}\left( \overset{\rightarrow}{X}\right) \right\rangle \, Otherwise\end{matrix}\right. }</math> | ||

| + | |} | ||

| + | | style="width: 5px;text-align: right;white-space: nowrap;" | (7) | ||

| + | |} | ||

| + | |||

| + | where <math display="inline">F\left( \overset{\rightarrow}{X}\right)</math> is the penalty function, <math display="inline">f\left( \overset{\rightarrow}{X}\right)</math> and <math display="inline">g\left( \overset{\rightarrow}{X}\right)</math>, as shown in section 3, are the objective function and the constraints, respectively. Hence, <math display="inline">\left\langle {g}_{j}\left( \overset{\rightarrow}{X}\right) \right\rangle</math> denotes the absolute value of the operand, if the operand is negative and returns a value zero, otherwise. The parameter <math display="inline">{R}_{j}</math>is the penalty parameter of the <math>{j}_{h}</math> inequality constraint. The purpose of a penalty parameter <math display="inline">{R}_{j}</math> is to make the constraint violation <math display="inline">{g}_{j}\left( \overset{\rightarrow}{X}\right)</math> of the same order of magnitude as the objective function value <math display="inline">f\left( \overset{\rightarrow}{X}\right)</math> [9]. | ||

| + | |||

| + | The parameter <math display="inline">{f}_{max}</math> is the objective function value of the worst feasible solution in the population. Thus, the fitness of an infeasible solution not only depends on the amount of constraint violation, but also on the population of solutions at hand. However, the fitness of a feasible solution is always fixed and is equal to its objective function value. | ||

| + | |||

| + | ===4.3 Optdam=== | ||

| + | |||

| + | Bearing in mind the importance of studying dams and application for evolutionary computing methods of optimization, the aim now is to comment on the Optdam program developed in Matlab. This program allows finding an optical dam’s cross section. The program was developed to cover general cross sections of dams in terms of geometry as showed in [[#img-2|Figure 2]]. | ||

| + | |||

| + | First, a set of solutions is initialized and denoted as the initial population. This initialization is recommended to randomly cover the whole solution space or to model and incorporate expert knowledge. The representation determines the initialization process. Initial population is shown in [[#img-3|Figure 3]] [16]. | ||

| + | <div id='img-3'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Iniiiiiiiii.png|207x207px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 3'''. Initial Population | ||

| + | |} | ||

| + | |||

| + | |||

| + | After initial population, GA scores each member of the current population by computing its fitness value, scales the raw fitness scores to convert them into a more usable range of values, then selects members, called parents, based on their fitness. | ||

| + | |||

| + | Some of the individuals in the current population that have lower fitness are chosen as elite [17]. These elite individuals are taken as parents for the next population. Hence, children are produced either by making random changes to a single parent, mutation, or by combining the vector entries of a pair of parents, crossover. Therefore, GA replaces the current population with the children to form the next generation [5] and [6]. The conception of the new generations is presented in [[#img-4|Figure 4]]. | ||

| + | <div id='img-4'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Muttttttttttttt.png|252x252px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 4'''. Creating the next generation | ||

| + | |} | ||

| + | |||

| + | |||

| + | In summary, the GA in Matlab uses three main types of rules at each step to create the next generation from the current population: | ||

| + | |||

| + | :* Selection rules select the individuals, called parents, that contribute to the population at the next generation. | ||

| + | |||

| + | :* Crossover rules combine two parents to form children for the next generation. | ||

| + | |||

| + | :* Mutation rules apply random changes to individual parents to form children. | ||

| + | |||

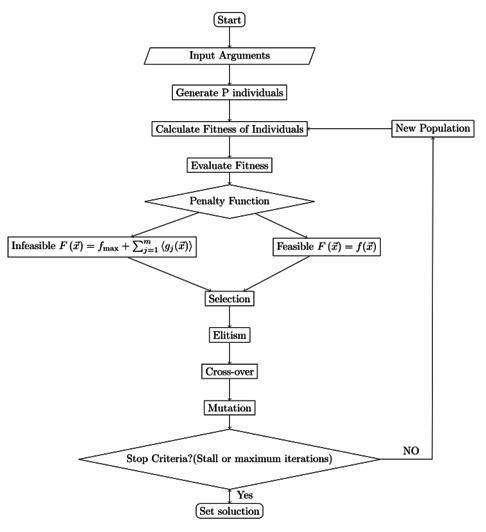

| + | The algorithm stops when one of the stopping criteria is met. [[#img-5|Figure 5]] shown the convergence process. The GA parameters of Optdam program are shown in [[#tab-1|Table 1]]. [[#img-6|Figure 6]] shows a flowchart illustrating the process. | ||

| + | <div id='img-5'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Poppppp.png|625x625px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 5'''. Convergence process | ||

| + | |} | ||

| + | |||

| + | |||

| + | <div class="center" style="font-size: 75%;">'''Table 1'''. GA Information | ||

| + | </div> | ||

| + | <div id='tab-1'></div> | ||

| + | {| style="margin: 1em auto 0.1em auto;border-collapse: collapse;font-size:85%;width:50%;" | ||

| + | |- | ||

| + | | colspan="3" style="border: 1pt solid black;text-align: center;" |'''GA Parameters''' | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;" |Parameters | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Adopted | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Population type | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Double vector | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Population size | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|100 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Fitness scaling | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Rank | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Elite count | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|40 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Cross-over fraction | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|0.8 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Mutation function | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Constraint dependent | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Cross-over function | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Constraint dependent | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Migration direction | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|forward | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Migration fraction | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|0.2 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Migration interval | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|20 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Initial penalty | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|10 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Penalty factor | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|100 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Maximum number of generations | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|100 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Stall generations | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|50 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Function tolerance | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|10<sup>-6</sup> | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Constraint tolerance | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|10<sup>-3</sup> | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Stall time | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|60 (s) | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Compile timeout | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|180 (s) | ||

| + | |} | ||

| + | |||

| + | <div id='img-6'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Dbafbavc.png|532x532px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 6'''. Optimization algorithm | ||

| + | |} | ||

| + | |||

| + | ==5. Example: Idealized cross-section of the Belo Monte HPP== | ||

| + | |||

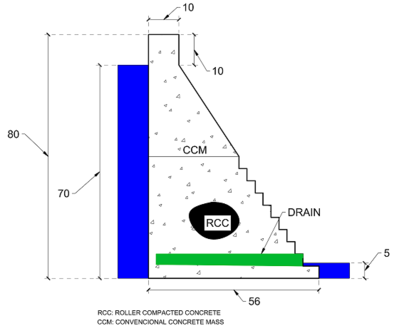

| + | The Belo Monte Hydropower Plant has a retaining wall between the main intake and the earth/rockfill dam, which is usually designed following the same criteria as a concrete gravity dam. In order to present the applicability of the Optdam programa in a practical situation, an optimization study using Optdam program is applied on cross-section of the retaining wall. The initial design of Belo Monte cross-section is shown in [[#img-7|Figure 7]]. | ||

| + | <div id='img-7'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Belooooooooooooo.png|399x399px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 7'''. Belo Monte. Cross-section of a Belo Monte retaining wall. Dimension in meters | ||

| + | |} | ||

| + | |||

| + | |||

| + | The material properties for the calculation were taken from commonly used values for dams built in the Belo Monte region. They are included in [[#tab-2|Table 2]]. | ||

| + | |||

| + | <div class="center" style="font-size: 75%;">'''Table 2'''. Materials properties | ||

| + | </div> | ||

| + | <div id='tab-2'></div> | ||

| + | {| style="width: 50%;margin: 1em auto 0.1em auto;border-collapse: collapse;font-size:85%;" | ||

| + | |- | ||

| + | | colspan='3' style="border: 1pt solid black;text-align: center;"|'''The properties of materials''' | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Material''' | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Value''' | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Unit''' | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Concrete’s Young Modulus | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|240.00 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|MPa | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Concrete resistance | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|25.00 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|MPa | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Poison’s ratio of concrete | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|0.2 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|- | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Mass density of concrete | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|2500 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Kg/<math>{\rm m}^3</math> | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Speed of pressure wave | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|1440 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|m/s | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Wave reflection coefficient | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|0.9 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|- | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Rock friction angle | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|<math>\pi /5</math> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|rad | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Partial friction safety factor | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|1.5 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|- | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Reduced coefficient of friction | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|0.7 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|- | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Elasticity modulus of rock | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|27.580 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|MPa | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Poison’s ratio of foundation | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|0.2 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|- | ||

| + | |} | ||

| + | |||

| + | |||

| + | The analyzed section presents the geometric parameters shown in [[#tab-3|Table 3]] which also includes other important parameters for optimizing the section, such as hydrostatic loads and the search space defined from the minimum dimensions defined by the project specifications (such as free-board). | ||

| + | |||

| + | In this way, the lower boundary of the section is defined by the hydrological parameters, topographic conditions, terrain and other specific constraints that change. Hence, the upper boundary is defined by the designer, based on experience. In case little information is available, wide ranges can be adopted, since the program is able to search for the optimal. | ||

| + | |||

| + | Since the actual values of the hydrological parameters and other constraints are not known, for the example discussed here the dimensions for the lower boundary were hypothetically defined. In the other hand, the values of the upper border were defined by the values of the real section executed. | ||

| + | |||

| + | [[#tab-3|Table 3]] also shows the safety factors obtained for the initial cross section. Since they are higher than those recommended by the design criteria, the geometry can be optimized, finding safety factors close to the minimum required. | ||

| + | |||

| + | <div class="center" style="font-size: 75%;">'''Table 3'''. Dam information | ||

| + | </div> | ||

| + | <div id='tab-3'></div> | ||

| + | {| style="width: 60%;margin: 1em auto 0.1em auto;border-collapse: collapse;font-size:85%;" | ||

| + | |- | ||

| + | | colspan='3' style="border: 1pt solid black;text-align: center;"|'''Geometry parameters''' | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Parameter''' | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Value''' | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Unit''' | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Cross section area | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|2410 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|<math>{\rm m}^2</math> | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Concrete volume | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|2410000 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|<math>{\rm m}^3</math> | ||

| + | |- | ||

| + | | colspan='3' style="border: 1pt solid black;text-align: center;vertical-align: top;"|Hydrostatic loads | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Parameter | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Value | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Unit | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Upstream water | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|70 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|m | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Downstream water | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|5 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|m | ||

| + | |- | ||

| + | | colspan='3' style="border: 1pt solid black;text-align: center;"|Search Space | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Design variable | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Lower bound (m) | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Upper bound (m) | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"| <math>h_b</math> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|75 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|80 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|b<sub>c</sub> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|2 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|10 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"| <math>b_x</math> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|16 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|56 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"| <math>h_t</math> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|2 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|10 | ||

| + | |- | ||

| + | | colspan='3' style="border: 1pt solid black;text-align: center;"|Safety factors | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Factor | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Design criteria request | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Achieved values | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|FSF | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|3.00 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|4.52 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|FSO | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|1.50 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|2.08 | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|FSS | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|1.00 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|1.32 | ||

| + | |} | ||

| + | |||

| + | |||

| + | It is worth noting that this is an example that refers to a dam designed and executed, not being configured as a case study, since the values of the constants (cohesion, angle of friction, specific gravity of concrete, etc.) among other specificities of the project are not known with exactness. | ||

| + | |||

| + | ==6. Results== | ||

| + | |||

| + | The optimum design of the cross-section based on retaining-wall of Belo Monte HPP is given in [[#tab-4|Table 4]]. By comparing the solution obtained for the cross-section with the GA it's possible to note that the concrete volume can be significantly reduced. | ||

| + | |||

| + | <div class="center" style="font-size: 75%;">'''Table 4'''. Optimization results | ||

| + | </div> | ||

| + | <div id='tab-4'></div> | ||

| + | {| style="width: 60%;margin: 1em auto 0.1em auto;border-collapse: collapse;font-size:85%;" | ||

| + | |- | ||

| + | | colspan='3' style="border: 1pt solid black;text-align: center;"|'''Optimum designs of the dam obtained by Optdam (GA)''' | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Design variable''' | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Value''' | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|'''Unit''' | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"| <math>h_b</math> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|78 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|m | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"| <math>b_c</math> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|7 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|m | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"| <math>b_x</math> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|43 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|m | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"| <math>h_t</math> | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|7 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|m | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|FSF | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|4.5062 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|- | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|FSO | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|1.5001 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|- | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|FSS | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|1.0030 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|- | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Cross section area | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|1824 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|<math>{\rm m}^2</math> | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|Concrete savings | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|586000 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|<math>{\rm m}^3</math> | ||

| + | |- | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|savings percentage | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|24.31 | ||

| + | | style="border: 1pt solid black;text-align: center;vertical-align: top;"|% | ||

| + | |} | ||

| + | |||

| + | |||

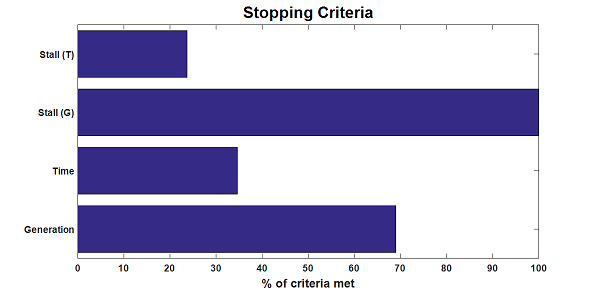

| + | In order to limit the computational cost and to streamline the section optimization process, four stop criteria were defined for Optdam. They are presented in [[#tab-1|Table 1]] along with the other program information. In order to make the program's functionality clearer, the stopping criteria are further analyzed here. The Optdam’s stopping criteria are stall generations, stall time, maximum number of generations and compile timeout. | ||

| + | |||

| + | Stall generations defines the number of generations in which there is no significant gain in the optimization of the objective function. Stall time defines the timeout in which there are generations without significant gain in optimization. Maximum number of generations specifies the maximum number of iterations the genetic algorithm performs and compile timeout defines the maximum time the program can take to find the optimal solution. [[#img-8|Figure 8]] shows the operation of the stop criteria in the example. | ||

| + | |||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Stoooooooooooo.png|595x595px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 8'''. Stopping criteria | ||

| + | |} | ||

| + | |||

| + | |||

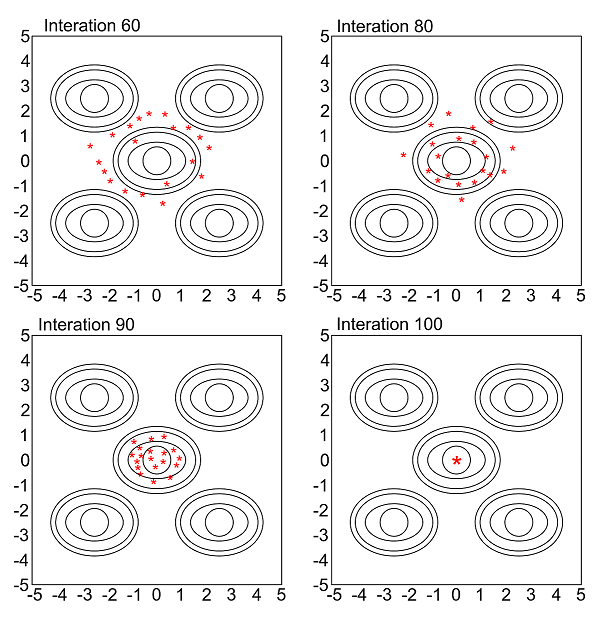

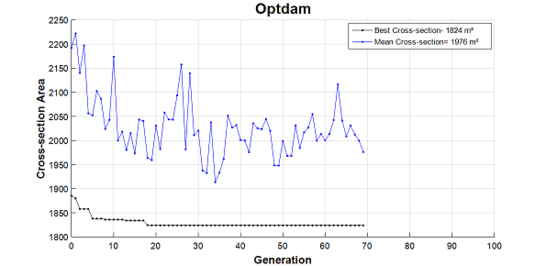

| + | Due to the rapid convergence of GA, already in the first generations tends to obtain satisfactory results. This makes the number of fifty stall generations a high measure of reliability that global minimum has been achieved. Since stall generations is the decisive stopping criterion, it is noted that the stopping criteria validate each other. The graph in [[#img-9|Figure 9]] presents the best cross section area value of the objective function in each generation versus the generation number. The best values and mean values are highlighted for each iteration. | ||

| + | <div id='img-9'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Gggggggggggggggggggga.png|546x546px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 9'''. GA operation | ||

| + | |} | ||

| + | |||

| + | |||

| + | It can be concluded that the methodology is robust for the problem at hand (reduction of area): As mentioned before, the best individuals in the first generations already feature low values of the cross section area. | ||

| + | |||

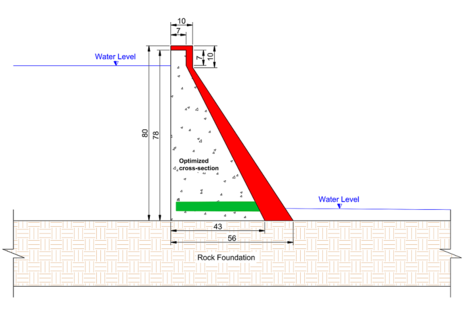

| + | [[#img-10|Figure 10]] shows the optimized cross section within the actual section. The red area shows the savings of area obtained in the use of Optdam. The optimal shape shown in [[#img-10|Figure 10]] implies a 24.31% reduction in cross-section area, considering the shear resistance adopted. | ||

| + | <div id='img-10'></div> | ||

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: auto;max-width: auto;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Fashahf.png|467x467px]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 10'''. Optimized section. Dimensions in meters | ||

| + | |} | ||

| + | |||

| + | ==7. Conclusions== | ||

| + | |||

| + | Cross-section optimization is one goal of dam designers. Dam designing must be such that not only satisfies sustaining condition, but also leads to minimum costs and excessive concrete volumes. An efficient optimization procedure is introduced to find the optimal shapes of concrete gravity dams using genetic algorithm in Matlab software. The concrete gravity dam body is treated as a two-dimensional structure. | ||

| + | |||

| + | An example based on a real structure has been presented. Results demonstrated the ability of these algorithms for this type of continuous optimization problem. Status of optimally designed dam for the algorithm is also provided for better assessment of safety factors. It is shown that all the constraints are satisfied. | ||

| + | |||

| + | This research provides useful optimization formulations for concrete gravity dams and can be extended to other hydraulic structures. The final result is a genetic algorithm program for shape optimization of concrete gravity dams, that is simple from a mathematical point of view and is able to work with dams under different load and boundary conditions. In the presented example, the proposed method resulted in more than 20% reduction in cross-section area and consequently resulted in more than 20% reduction in with low computational effort. | ||

| + | |||

| + | However, it is worth mentioning that the program developed here makes use of the global stability conditions as limiting for the evaluation and selection of the cross sections, being this necessary but not sufficient condition in a concrete dam design by gravity. | ||

| + | |||

| + | Although some authors suggest that once the overall stability criteria are met, the stress criterion will also be satisfied [19], in real design situations, the cross-section obtained with Optdam should be later evaluated for stress criteria (usually using finite elements) and specific conditions that vary with each project (earthquakes, silting, etc.). | ||

| + | |||

| + | ==Acknowledgments== | ||

| + | |||

| + | The research described in this paper was financially supported by the Federal Institute of Education, Science and Technology of Goias. | ||

| + | |||

| + | ==References== | ||

| + | |||

| + | <div class="auto" style="text-align: left;width: auto; margin-left: auto; margin-right: auto;font-size: 85%;"> | ||

| + | |||

| + | [1] Ackley, David. A Connectionist machine for genetic hillclimbing. Vol. 28. Springer Science & Business Media, Boston, 2012. | ||

| + | |||

| + | [2] Ali, Pr Dr Ahmed AM, Pr Dr Rafa HS Al-Suhaili, Shamil AK Behaya. A genetic algorithm optimization model for the gravity dam section under seismic excitation with reservoir-dam-foundation interactions. Amer J Eng Res.,6: 2320-0847, 2014. | ||

| + | |||

| + | [3] Baghlani, Abdolhossein, Mohsen Sattari, Mohammad Hadi Makiabadi. Application of genetic programming in shape optimization of concrete gravity dams by metaheuristics. Cogent Engineering., 01:2331-1916, 2014. | ||

| + | |||

| + | [4] Bento, Eduardo Prevedello, Nelson Kagan. Algoritmos genéticos e variantes na solução de problemas de configuração de redes de distribuição. Controle e Automação., 03:1807-0345, 2008. | ||

| + | |||

| + | [5] Conn, Andrew R., Nicholas IM Gould, Philippe Toint. A globally convergent augmented Lagrangian algorithm for optimization with general constraints and simple bounds. SIAM Journal on Numerical Analysis, 02:0036-1429, 1991. | ||

| + | |||

| + | [6] Conn, Andrew R., Luís N. Vicente. Bilevel derivative free optimization and its application to robust optimization. Opti. Meth. and Soft., 03:1029-4937, 2009. | ||

| + | |||

| + | [7] Davis L.D. Handbook of Genetic Algorithms. Artificial Intelligence., 100:0004-3702, 1998. | ||

| + | |||

| + | [8] Deb, Kalyanmoy. An efficient constraint handling method for genetic algorithms. Comp. Met. in app. mech. and eng., 04:0045-7825, 2000. | ||

| + | |||

| + | [9] Deb, Kalyanmoy. Optimization for engineering design: Algorithms and examples. Vol. 1, PHI Learning Pvt. Ltd., New Delhi, 2012. | ||

| + | |||

| + | [10] Deep, Kusum, Krishna Pratap Singh, Mitthan Lal Kansal, C. Mohan. A real coded genetic algorithm for solving integer and mixed integer optimization problems. App. Math. and comp. 04:0096-3003, 2009. | ||

| + | |||

| + | [11] Durieux, Johan Hendrik, B. W. J. Van Rensburg. Development of a practical methodology for the analysis of gravity dams using the non-linear finite element method.Journal of the african int. of civil. eng., 02:3301-3312, 2009. | ||

| + | |||

| + | [12] Eletrobrás, Centrais Elétricas Brasileiras S.A. Critérios de projeto civil de usinas hidrelétricas. Vol. 1, CBDB, Rio de Janeiro, 2003. | ||

| + | |||

| + | [13] Ghaffari, Yousef, Fereshteh Nouri Zonouz, Vahid Mahdavifar, Ramin Taghinezhad, Vafa Soltangharaei. Shape Optimization of Gravity Dam Using Genetic Algorithm. Int. Jour. od scien. an eng. invest., 07: 2251-8843, 2008. | ||

| + | |||

| + | [14] Gen, Mitsuo, Lin Lin. Genetic Algorithms. Wiley Encyclopedia of Comp. Scie. Eng., 56:1097-0037, 2007. | ||

| + | |||

| + | [15] Gen, Mitsuo, Runwei Cheng, Lin Lin. Network models and optimization: Multiobjective genetic algorithm approach. Vol. 1, Springer Science & Business Media, London, 2008. | ||

| + | |||

| + | [16] Goldberg, David E., John H. Holland. Genetic algorithms and machine learning. Vol. 3. Springer Science & Business Media, London, 1988. | ||

| + | |||

| + | [17] Goldberg, David E. Genetic algorithms, virtual alphabets and blocking. Complex Syst. Journal, 04:0891-2513, 1991. | ||

| + | |||

| + | [18] Gurba, W., Muc, A. Genetic algorithm in finite element analysis in optimization of composite structures. Composite Structures, 54:0263-8223, 2001. | ||

| + | |||

| + | [19] Gutstein, Daniela. Estudo das tensões em fundações de barragens de gravidade de concreto pelo método de elementos finitos. Masters dissertation, UFSC, Santa Catarina, 2003. | ||

| + | |||

| + | [20] Gutstein, Daniela. Projeto de estruturas de barragens de gravidade de concreto por meio de métodos computacionais: visão geral e metodologia. Doctoral Thesis. UFSC, Santa Catarina, 2003. | ||

| + | |||

| + | [21] Haupt, Randy L., Sue Ellen Haupt. Practical genetic algorithms. Vol. 2, John Wiley & Sons, Inc., Hoboken, New Jersey, 2004.. | ||

| + | |||

| + | [22] Homaifar, Abdollah, Charlene X. Qi, Steven H. Lai. Constrained optimization via genetic algorithms. Simulation, 04:1741-3133, 1994. | ||

| + | |||

| + | [23] Khatibinia, M., H. Chiti, A. Akbarpour, H. R. Naseri. Shape optimization of concrete gravity dams considering dam water foundation interaction and nonlinear effects. IJOCE, 01:2228-7558, 2016. | ||

| + | |||

| + | [24] Khosravi, Sh, M. Khatibinia. Optimal Shape Design of Concrete Gravity Dams Including. IJOCE, 02:2228-7558, 2018. | ||

| + | |||

| + | [25] Kramer, Oliver. Genetic algorithm essentials. Vol. 679. Springer, London, 2017. | ||

| + | |||

| + | [26] Man, Kim-Fung, Kit-Sang Tang, Sam Kwong. Genetic algorithms: concepts and applications in engineering design. IEEE, 05:0278-0046, 1996. | ||

| + | |||

| + | [27] Michalewicz, Zbigniew, Stephen J. Hartley. Genetic algorithms data structures evolution programs. Mathematical Intelligencer. Vol. 1, University of Dortmund, 1996. | ||

| + | |||

| + | [28] Mitchell, Melanie. An Introduction to genetic algorithms. Vol. 1, MIT press, Massachusetts, 1998. | ||

| + | |||

| + | [29] Muc, A. Transverse shear effects in discrete optimization of laminated compressed cylindrical shells. Composite Structures, 38:0263-8223, 1997. | ||

| + | |||

| + | [30] Muc, A. A fuzzy set analysis for a fracture and fatigue damage response of composite materials. Composite Structures, 54:0263-8223, 2001. | ||

| + | |||

| + | [31] Muc, A.. Evolutionary design of engineering constructions. LAJSS, 04:1679-7825, 2018. | ||

| + | |||

| + | [32] USACE, US. Gravity Dam Design Engineering (engineer manual). Vol.1, Army Corps of Engineers, Washithon, 2016. | ||

| + | |||

| + | [33] USBR - United States Bureau of Reclamation. Design of gravity dams. Vol. 1, United States Department of the Interior, Denver, 1976. | ||

| + | |||

| + | [34] Vianna, Luis Claudio Coelho. Otimização de seções transversais de concreto armado: aplicação a pórticos.Doctoral Thesis, Universidade de São Paulo, São Paulo, 2003. | ||

| + | |||

| + | [35] Yazd, Hamidreza Golkar Hamzee, Seyed Jafar Arabshahi, Mojtaba Tavousi, Abbas Alvani. Optimal designing of concrete gravity Dam using particle swarm optimization algorithm (PSO). Indian jour. of scien. and tech., 12:0974-5645, 2015. | ||

| + | |||

| + | </div> | ||

Latest revision as of 13:15, 28 May 2021

Abstract

Concrete gravity dams have trapezoidal shape in their cross section and shall guarantee the global stability against acting loads like hydrostatic and uplift pressures through his gravitational actions (self-weight and others). This study focuses on the shape optimization of concrete gravity dams using genetic algorithms. In this case, the dam cross section area is considered as the objective function and the design variables are the geometric parameters of the gravity dam. The optimum cross-section of a concrete gravity dam is achieved by the Genetic Algorithm (GA) through a Matlab routine developed by the author. Sliding, overturning and floating verifications are implemented in the program. In order to assess the efficiency of the proposed methodology for gravity dams optimization, one application is presented adopting the concrete gravity dam of Belo Monte Hydropower Plant (HPP), considering normal loading condition and others assumptions presented.

Keywords: Optimization, concrete gravity dams, genetic algorithm, design optimization

1. Introduction

Concrete gravity dams are hydraulic structures widely used as water reservoir to hydroelectric power plants in general. These structures have trapezoidal shape in their cross section and shall guarantee the global stability against hydrostatic and uplift pressures by means of gravitational actions (as self-weight and others) [32]. Hence, finding a proper design for the cross-section can remarkably reduce the construction costs [3].

For stability requirements, the dam must be safe against overturning, sliding and floating. Moreover, the acting stresses in the concrete of the dam or in the foundation material shall attend the limits stabilized by design criteria. The potential failure plans as concrete-foundation contact, horizontal plans through the dam body or through the foundation, can be considered, according to the rupture mechanisms identified by the geotechnical model [11].

In order to assure the structural global stability and the allowable stress criteria for the concrete gravity dam design, as discussed in Gutstein [19] and [20] a trial and error procedure process is usually carried out from a preliminary cross section defined in the design initial phases, followed by stability and stress analysis studies. Then, if the chosen cross section does not meet the security criteria, it shall be modified and analyzed again. Also, once safety criteria are met, a new study can be conducted with the purpose of optimizing the design (minimizing the dam cross section area).

To achieve this purpose, several alternatives can be used to obtain a number of feasible shapes. Finally, the cross section with minimum area (also with lower cost), that meets the structural considerations and design criteria, is selected as the final shape. In order to reliably achieve an optimal shape for dams in this study, instead of this trial and error procedure, optimization techniques have been effectively utilized [23,24,34].

Genetic Algorithms (GA) are heuristic search approaches applicable to a wide range of optimization problems [4]. This flexibility makes them attractive for many optimization problems in practice. They represent one branch of the field of study called evolutionary computation, which imitate the biological processes of reproduction and natural selection to solve for the fittest solutions [7].

GA can solve a broad class of engineering problems encountered in practice, involving a large number of design parameters (integer, discrete, continuous and integer/discrete-continuous) and a large number of constraints. It has been highly successful as one of evolutionary computation techniques in searching for a broad class of stacking sequence, size, topology optimization problems for composite structures [18,29,30,31].

Designing and constructing concrete gravity dams can be considered as a typical optimization problem, since the cross section geometry with lowest area that meets the design criteria is searched for, with the final aim of reducing cost [35].

Optimizing this cost requires cross-section optimization. The main aim of this paper is to present and discussed an optimization study for concrete gravity dams based on GA and Matlab application. The present work brings a simple implementation using GA in Matlab for usual loading condition, contrasting with the complexity presented in [2,3,13,14,23,24,35] which bring approaches with high complexity computational methods.

The dam's geometry and the acting loads must be considered in its design analysis procedure. In order to reduce the computational cost of the optimization process, the stopping criteria is limited to satisfactory values. To demonstrate the efficiency of GAs in finding the optimum design of concrete gravity dams, the cross-section from Belo Monte Hydropower Plant is presented as an example of application, considering normal loads and hypothetical resistance parameters for the foundation.

2. Stability analysis of concrete gravity dams

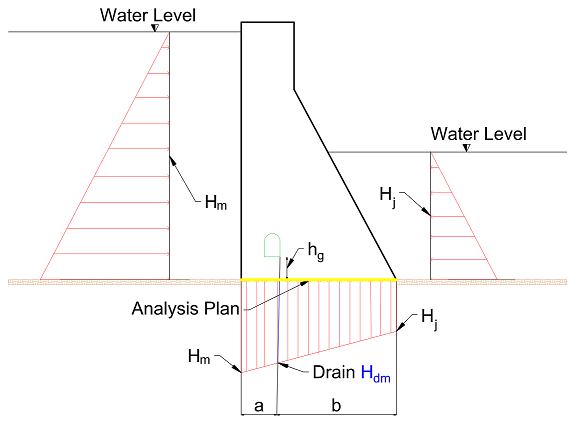

Figure 1 shows the usual loads acting in a dam considering drainage. Water pressure is the major external load acting on such a dam. The horizontal water pressure, exerted by the weight of the water stored on the upstream side on the dam can be estimated from rule of hydrostatic pressure distribution.

In other to meet the safety requirements, the dam cross section is verified against floating, overturning and sliding.

Floating safety factor has the function to guarantee the stability of structure against the forces that tend to make the body float. It is calculated by Equation (1) [12]

|

|

(1) |

where is the safety factor against floating, should be greater than 1.3, the resultant vertical force and the total uplift force.

The overturning of a gravity dam may be calculated by dividing the total resisting moments by the total moments tending to cause overturning about the downstream toe, it is defined as the ratio between the resisting moments and overturning moments [33]

|

|

(2) |

is the safety factor against overturning, should be greater than 1.5, the moments resisting and the moments overturning.

A dam will fail in sliding at its base, or at any other level, if the horizontal forces causing sliding are greater than the resistance available to it at that level. The resistance against sliding may be due to friction alone, or due to friction and shear strength of the joint. The sliding stability is based on a safety factor as a measure of determining the resistance of the structure against sliding [12]

|

|

(3) |

is the safety factor against sliding which should also be greater than 1.0, the reduced coefficient of friction, the total vertical force acting on dam and the total horizontal force acting on dam.

|

| Figure 1. Concrete gravity dam: cross-Section, analysis plan and imposed forces |

According to Eletrobras [12], the calculation of the uplift pressure acting in the analysis plan is made considering the uplift pressure reduction () in the drainage curtain according to (4):

|

|

(4) |

where is the gallery height, the upstream water level, the downstream water level and all of them in relation to the concrete-rock contact (analysis plan). Those expressions considerer the 66% drainage curtain efficiency adopted for the Bureau of Reclamation [33].

3. Geometrical model of concrete gravity dams and problem formulation

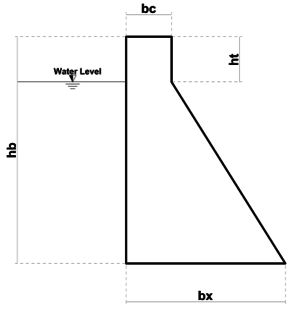

Based on the model of concrete gravity dam depicted in Figure 2, the cross-section of concrete gravity dam studied is defined by the four parameters given by Equation (5)

|

|

(5) |

where is a parameter required to define the dam crest. Also, the downstream slope is specified by the and design variables and hb is the dam’s height.

|

| Figure 2. Geometrical model of concrete gravity dam |

The process of evaluating the overall stability of a concrete dam, makes use of the static equations to evaluate the equilibrium of rigid body of the part. In order to automate the calculation of the global stability of a concrete gravity dam, an evaluation program was developed in the Matlab language. This program will be used as a starting point of the research.

The evaluation program has the ability to calculate overall stability and dam stress from the dimensions and conditions provided by the designer. This algorithm returns the values of the safety factors, calculated by Equations (2), (3) and (4).

After completing the calculations, the program displays the values obtained for FSF, FSO and FSS with a message indicating whether these values meet the design criteria, or whether the study section should be resized.

Gravity dam optimization problem is explained in this section. The cross-sectional area of the dam is considered as an objective function to be minimized. An optimization problem subjected to design constraints can be expressed as follows:

where and are the objective function and the constraints, respectively. and are the lower bound and the upper bound of the design variables, , respectively [23].

In this optimization problem of concrete gravity dams, the cross-section area of gravity dam body is considered as objective function, , that should be minimized. The cross-section area of concrete gravity dam can be determined as follows:

|

|

(6) |

where is cross-section area, and , , and are the design variables showed in Figure 2.

In the present study, the behavior and stability constraints are considered as the problem constraints, . The behavior constraints consist on the safety factor against floating, overturning and sliding, calculated by Equations (2), (3) and (4)

4. The Optimization Algorithm (Optdam)

4.1 Genetic Algorithm (GA)

Genetic algorithm (GA) is a method for solving both constrained and unconstrained optimization problems that is based on natural selection, the process that drives biological evolution. It is an optimization and search technique based on the principles of genetics and natural selection [21]. An individual is any point fitness function can be evaluated [1].

The value of the fitness function for an individual is its score. A population is an array of individuals. At each iteration, the genetic algorithm performs a series of computations on the current population to produce a new population. Each successive population is called a new generation. The best fitness value for a population is the smallest fitness value for any individual in the population [15].

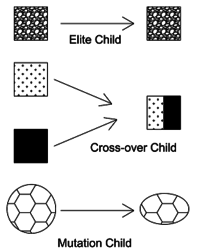

To create the next generation, the genetic algorithm selects certain individuals in the current population, called parents, and uses them to create individuals in the next generation, called children. Typically, the algorithm is more likely to select parents that have better fitness values [28].

A GA allows a population composed of many individuals to evolve under specified selection rules to a state that maximizes the fitness (minimizes the cost function). The genetic algorithm repeatedly modifies a population of individual solutions [27].

Evolution is the basis of Genetic Algorithms. The current variety and success of species is a good reason for believing in the power of evolution. Species are able to adapt to their environment. They have developed to complex structures that allow the survival in different kinds of environments. Mating and getting offspring to evolve belong to the main principles of the success of evolution. These are good reasons for adapting evolutionary principles to solving optimization problems [25].

It presumes that the potential solution of a problem is an individual and can be represented by a set of parameters. These parameters are regarded as the genes of a chromosome and can be structured by a string of values in binary form. A positive value, generally known as fitness value, is used to reflect the degree of “good-ness” of the chromosome for solving the problem, and this value is closely related to its objective value [26].

At each step, the genetic algorithm selects individuals at random from the current population to be parents and uses them to produce the children for the next generation. They combine survival of the fittest among string structures with a structured yet randomized information exchange search algorithm with some of innovative flair of human search [16]. Over successive generations, the population evolves toward an optimal solution.

It can be applied to solve a variety of optimization problems that are not well suited for standard optimization algorithms, including problems in which the objective function is discontinuous, nondifferentiable, stochastic, or highly nonlinear. The genetic algorithm can address problems of mixed integer programming, where some components are restricted to be integer-valued [10].

The genetic algorithm differs from a classical, derivative-based, optimization algorithm in two main ways. First, classical algorithms generate a single point at each iteration. The sequence of points approaches an optimal solution, GA generates a population of points at each iteration and the best point in the population approaches an optimal solution. The second difference is that classical algorithms selects the next point in the sequence by a deterministic computation. Instead, GA selects the next population by computation which uses random number generators.

4.2 Penalty function

In generic search methods, most applications of GAs to constraint optimization problems have used the penalty function approach of handling constraints. The penalty function approach involves a number of penalty parameters which must be set right in any problem to obtain feasible solutions [22].

It uses the penalty function in Equation (7), where infeasible solutions are compared based only on their constraint violation [8]

|

|

(7) |

where is the penalty function, and , as shown in section 3, are the objective function and the constraints, respectively. Hence, denotes the absolute value of the operand, if the operand is negative and returns a value zero, otherwise. The parameter is the penalty parameter of the inequality constraint. The purpose of a penalty parameter is to make the constraint violation of the same order of magnitude as the objective function value [9].

The parameter is the objective function value of the worst feasible solution in the population. Thus, the fitness of an infeasible solution not only depends on the amount of constraint violation, but also on the population of solutions at hand. However, the fitness of a feasible solution is always fixed and is equal to its objective function value.

4.3 Optdam

Bearing in mind the importance of studying dams and application for evolutionary computing methods of optimization, the aim now is to comment on the Optdam program developed in Matlab. This program allows finding an optical dam’s cross section. The program was developed to cover general cross sections of dams in terms of geometry as showed in Figure 2.