| (18 intermediate revisions by the same user not shown) | |||

| Line 308: | Line 308: | ||

The variety of solutions differ in the values of the coefficients <math display="inline">a</math>, <math display="inline">{b}_{0}</math>, <math display="inline">{b}_{1}</math> and <math display="inline">{b}_{2}</math>. These solutions are classified into different Pearson distribution types depending on the quantities <math display="inline">{\beta }_{1}</math> and <math display="inline">{\beta }_{2}</math>. In other words, the type of distribution to which the data belong is entirely determined by the square of the skewness <math display="inline">{\beta }_{1}</math> presented in Eq. <span id='cite-_Ref30513951'></span>[[#_Ref30513951|(2)]] and the kurtosis <math display="inline">{\beta }_{2}</math> expressed in Eq. <span id='cite-_Ref30514082'></span>[[#_Ref30514082|(3)]]. The Pearson distribution types correspond to common probability distributions. The following types and their common distribution associated arise: type I (beta distribution), type II (symmetrical beta distribution), type III (gamma distribution), type IV (Cauchy distribution), type V (inverse-gamma distribution), type VI (beta prime distribution), type VII (Student's tdistribution) and the limit of type I, III, IV, V (normal distribution). | The variety of solutions differ in the values of the coefficients <math display="inline">a</math>, <math display="inline">{b}_{0}</math>, <math display="inline">{b}_{1}</math> and <math display="inline">{b}_{2}</math>. These solutions are classified into different Pearson distribution types depending on the quantities <math display="inline">{\beta }_{1}</math> and <math display="inline">{\beta }_{2}</math>. In other words, the type of distribution to which the data belong is entirely determined by the square of the skewness <math display="inline">{\beta }_{1}</math> presented in Eq. <span id='cite-_Ref30513951'></span>[[#_Ref30513951|(2)]] and the kurtosis <math display="inline">{\beta }_{2}</math> expressed in Eq. <span id='cite-_Ref30514082'></span>[[#_Ref30514082|(3)]]. The Pearson distribution types correspond to common probability distributions. The following types and their common distribution associated arise: type I (beta distribution), type II (symmetrical beta distribution), type III (gamma distribution), type IV (Cauchy distribution), type V (inverse-gamma distribution), type VI (beta prime distribution), type VII (Student's tdistribution) and the limit of type I, III, IV, V (normal distribution). | ||

| − | Once the Pearson distribution type is determined, the two, three or four parameters of the particular distribution type can be calculated as a function of the expected value, variance, skewness and kurtosis, i.e. from the first four moments. The formulas to calculate the parameters for each type of Pearson distribution are given in [34]. As an example, the formulas for the Pearson distribution type I that corresponds to the beta distribution are included here. A random variable <math display="inline">x</math> following a beta distribution <math display="inline">Beta\left( \alpha ,\beta \right)</math> with the shape parameters <math display="inline">\alpha</math> and <math display="inline">\beta</math> , can be further parametrized as <math display="inline">\frac{x-\lambda }{{a}_{2}-{a}_{1}}</math> with the scale parameter <math display="inline">\left( {a}_{2}-\right. </math><math>\left. {a}_{1}\right)</math> and with a location parameter <math display="inline">\lambda</math> . The shape parameters <math display="inline">\alpha \,</math> and <math display="inline">\beta</math> are calculated according to the Pearson distribution family as expressed in Eq. <span id='cite-_Ref31624338'></span>[[#_Ref31624338|(11)]] | + | Once the Pearson distribution type is determined, the two, three or four parameters of the particular distribution type can be calculated as a function of the expected value, variance, skewness and kurtosis, i.e. from the first four moments. The formulas to calculate the parameters for each type of Pearson distribution are given in [34]. As an example, the formulas for the Pearson distribution type I that corresponds to the beta distribution are included here. A random variable <math display="inline">x</math> following a beta distribution <math display="inline">Beta\left( \alpha ,\beta \right)</math> with the shape parameters <math display="inline">\alpha</math> and <math display="inline">\beta</math>, can be further parametrized as <math display="inline">\frac{x-\lambda }{{a}_{2}-{a}_{1}}</math> with the scale parameter <math display="inline">\left( {a}_{2}-\right. </math><math>\left. {a}_{1}\right)</math> and with a location parameter <math display="inline">\lambda</math>. The shape parameters <math display="inline">\alpha \,</math> and <math display="inline">\beta</math> are calculated according to the Pearson distribution family as expressed in Eq. <span id='cite-_Ref31624338'></span>[[#_Ref31624338|(11)]] |

{| class="formulaSCP" style="width: 100%;border-collapse: collapse;width: 100%;text-align: center;" | {| class="formulaSCP" style="width: 100%;border-collapse: collapse;width: 100%;text-align: center;" | ||

| Line 354: | Line 354: | ||

<div id="_Ref533008240"></div> | <div id="_Ref533008240"></div> | ||

| − | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: | + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 45%;" |

|- | |- | ||

| − | | style="padding:10px;" | [[File:Review_912708961870_9348_FIG1.png| | + | | style="padding:10px;" | [[File:Review_912708961870_9348_FIG1.png|310px|frameless|center|]] |

|- style="text-align: center; font-size: 75%;" | |- style="text-align: center; font-size: 75%;" | ||

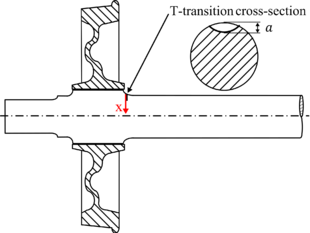

| − | | colspan="1" style="padding:10px;" | '''Figure 1'''. General axle view of a non-powered wheelset with a postulated crack in the T-transition | + | | colspan="1" style="padding:10px;" | '''Figure 1'''. General axle view of a non-powered wheelset with a postulated crack in the T-transition |

|} | |} | ||

| − | A semicircular initial crack <math display="inline">{a}_{ini}</math> of 2 mm was postulated at the T-transition, as indicated in the cross-section of the <span id='cite-_Ref535402764'></span>[[#_Ref535402764| | + | A semicircular initial crack <math display="inline">{a}_{ini}</math> of 2 mm was postulated at the T-transition, as indicated in the cross-section of the <span id='cite-_Ref535402764'></span>[[#_Ref535402764|Figure 1]]. The crack grows describing the crack propagation direction defined according to the radial coordinate system <math display="inline">x</math> at the axle surface in <span id='cite-_Ref535402764'></span>[[#_Ref535402764|Figure 1]]. The crack kept a semielliptical shape while growing up to a final crack depth <math display="inline">\, {a}_{fin}</math> of 50 mm. The fatigue crack growth material parameters used in the NASGRO model were those collected in [25]. |

| − | + | ||

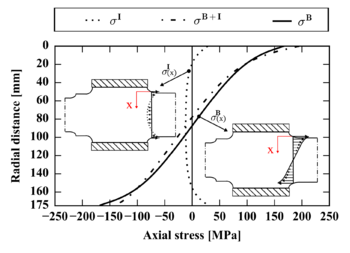

| − | [[ | + | For the present study, the following two types of loads were considered: the bending moment loading mainly due to the vehicle weight and cargo and the press-fit loading produced by the wheel mounting with interference. The bending moment in the railway axle was assumed as a random input variable normally distributed with a standard deviation equal to the 5% of the mean value. The parameters of the bending moment distribution were: mean value <math display="inline">{\mu }_{M}=</math><math>70.32\, [MN\, mm]</math> and variance <math display="inline">{\sigma }_{M}^{2}=</math><math>12.37\, {\left[ MN\, mm\right] }^{2}</math>. The bending moment level selected <math display="inline">M</math> corresponded to the highest load amplitude in the spectrum of a railway axle which is caused by the weight of the wagon and cargo, 22.5 tonnes per axle, plus additional forces, generated when the train goes through curved track, over crossovers, switches, rail joints, braking efforts, etc. Additionally, the wheel was press-fitted with 0.286 mm interference in diameter. The reference bending stress amplitude for the mean value of bending moment and the interference stress normal to the crack surface needed for the stress intensity factor <math display="inline">{K}_{max}</math> and <math display="inline">{K}_{min}</math> evaluation were calculated via the finite element method (FEM). The stresses at the interference <math display="inline">{\sigma }^{I}</math>, at the reference bending moment <math display="inline">{\sigma }^{B}</math> and at the combination of both <math display="inline">{\sigma }^{B+I}</math> are shown in [[#_Ref532978010|Figure 2]]. In this adapted version of the original figure in [25], a schematic representation of the axial stress distributions originated at the T-transition in a solid axle under a pure press-fit with interference and under a pure bending load case is also included for clarity. |

| − | <div id="_Ref532978010" | + | <div id="_Ref532978010"></div> |

| − | '' | + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 50%;" |

| + | |- | ||

| + | | style="padding:10px;" | [[File:Review_912708961870_7715_FIG2.png|350px|center|]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;" | '''Figure 2'''. Schematic representation and calculated stress distributions at the T-transition in axial direction at the press-fit with interference, at the bending and at the superposition of both load cases | ||

| + | |} | ||

| Line 375: | Line 379: | ||

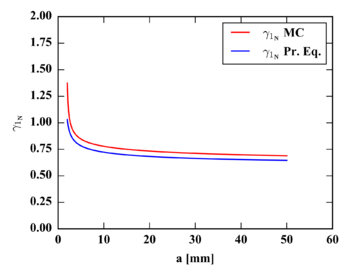

The full second-order approach presented was applied to calculate the third moment and the fourth central moments of <math display="inline">{dN}^{i}</math> at every crack depth, Eq. <span id='cite-_Ref535414666'></span>[[#_Ref535414666|(6)]], with the two random input variables <math display="inline">{K}_{max}^{i}</math> and <math display="inline">{K}_{min}^{i}</math>. Then, the skewness <math display="inline">{\gamma }_{{1}_{N}}</math> and the kurtosis <math display="inline">{\beta }_{{2}_{N}}</math> of the fatigue life <math display="inline">N</math> were obtained from the <math display="inline">{i}^{th}\,</math> moments, providing a continuous result along the crack depth <math display="inline">a</math>. The results provided by the proposed methodology were compared with the results of 10 000 MC simulations. The skewness and kurtosis results provided by the MC were obtained by further processing the MC simulations performed in [25]. | The full second-order approach presented was applied to calculate the third moment and the fourth central moments of <math display="inline">{dN}^{i}</math> at every crack depth, Eq. <span id='cite-_Ref535414666'></span>[[#_Ref535414666|(6)]], with the two random input variables <math display="inline">{K}_{max}^{i}</math> and <math display="inline">{K}_{min}^{i}</math>. Then, the skewness <math display="inline">{\gamma }_{{1}_{N}}</math> and the kurtosis <math display="inline">{\beta }_{{2}_{N}}</math> of the fatigue life <math display="inline">N</math> were obtained from the <math display="inline">{i}^{th}\,</math> moments, providing a continuous result along the crack depth <math display="inline">a</math>. The results provided by the proposed methodology were compared with the results of 10 000 MC simulations. The skewness and kurtosis results provided by the MC were obtained by further processing the MC simulations performed in [25]. | ||

| − | To check the accuracy of the method in terms of skewness, the <math display="inline">{\gamma }_{{1}_{N}}</math> history values provided by the MC and the Pr. Eq. are compared in | + | To check the accuracy of the method in terms of skewness, the <math display="inline">{\gamma }_{{1}_{N}}</math> history values provided by the MC and the Pr. Eq. are compared in [[#_Ref534994051|Figure 3]]. |

| − | [[File:Review_912708961870_4356_FIG3.png| | + | <div id="_Ref534994051"></div> |

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 50%;" | ||

| + | |- | ||

| + | | style="padding:10px;" | [[File:Review_912708961870_4356_FIG3.png|350px|frameless|center|]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;" | '''Figure 3'''. Skewness of <math display="inline">N</math> history values provided by the Monte Carlo (MC) and by the probabilistic NASGRO equation (Pr.Eq.) | ||

| + | |} | ||

| − | |||

| − | |||

| + | The values of the skewness curves for 5-50 mm crack depths are listed in [[#_Ref534653856|Table 1]]. | ||

| − | + | <div id="_Ref534653856" class="center" style="font-size: 75%;">'''Table 1'''. Skewness of '' <math display="inline">N</math>'' provided by Monte Carlo (MC) and by the probabilistic NASGRO equation (Pr. Eq.)</div> | |

| − | + | {| class="wikitable" style="margin: 1em auto 0.1em auto;border-collapse: collapse;font-size:85%;width:auto;" | |

| − | + | |-style="text-align:center" | |

| − | + | ! !! MC !! Pr. Eq. !! Pr. Eq.-MC | |

| − | + | |-style="text-align:center" | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | | | + | |

| − | | | + | |

| − | + | ||

| <math>a</math> | | <math>a</math> | ||

| <math>{\gamma }_{{1}_{N}}</math> | | <math>{\gamma }_{{1}_{N}}</math> | ||

| <math>{\gamma }_{{1}_{N}}</math> | | <math>{\gamma }_{{1}_{N}}</math> | ||

| <math>Error</math> | | <math>Error</math> | ||

| − | |- | + | |-style="text-align:center" |

| − | + | | [mm] | |

| − | | | + | | [dimensionless] |

| − | | | + | | [dimensionless] |

| − | | | + | | [%] |

| − | |- | + | |-style="text-align:center" |

| − | + | | <span style="text-align: center; ">5</span> | |

| − | | | + | | <span style="text-align: center; ">0.844</span> |

| − | | | + | | <span style="text-align: center; ">0.781</span> |

| − | | | + | | <span style="text-align: center; ">-7.52%</span> |

| − | |- | + | |-style="text-align:center" |

| − | | <span style="text-align: center | + | | <span style="text-align: center;">10</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center;">0.777</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">0.722</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">-7.14%</span> |

| − | |- | + | |-style="text-align:center" |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">20</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">0.733</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">0.682</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">-6.91%</span> |

| − | |- | + | |-style="text-align:center" |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">30</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">0.712</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">0.664</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">-6.70%</span> |

| − | |- | + | |-style="text-align:center" |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">40</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">0.698</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">0.653</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">-6.47%</span> |

| − | |- | + | |-style="text-align:center" |

| − | + | | <span style="text-align: center; ">50</span> | |

| − | | | + | | <span style="text-align: center; ">0.689</span> |

| − | | | + | | <span style="text-align: center; ">0.646</span> |

| − | + | | <span style="text-align: center; ">-6.24%</span> | |

|} | |} | ||

The skewness computed from the MC simulations distribution is considered as the framework of reference for comparison. It is observed that the skewness values are always positive, indicating that the right tail, in a sense, is longer and or heavier than the left one. Additionally, it can be seen that as the crack depth increases the skewness decreases reaching a value greater than 0.6 in both calculations. The error in the Pr. Eq. ranges from 7.5% to 6.2%, reducing as the crack depth increases. The Pr. Eq. provides a slightly lower magnitude than the MC for every crack depth. | The skewness computed from the MC simulations distribution is considered as the framework of reference for comparison. It is observed that the skewness values are always positive, indicating that the right tail, in a sense, is longer and or heavier than the left one. Additionally, it can be seen that as the crack depth increases the skewness decreases reaching a value greater than 0.6 in both calculations. The error in the Pr. Eq. ranges from 7.5% to 6.2%, reducing as the crack depth increases. The Pr. Eq. provides a slightly lower magnitude than the MC for every crack depth. | ||

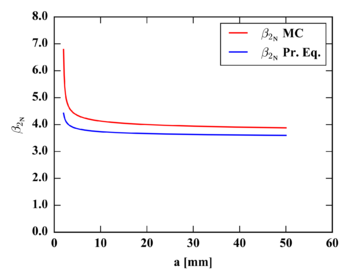

| − | To check the accuracy of the method in terms of kurtosis, the <math display="inline">{{\beta }_{2}}_{N}</math> history values provided by the MC and the Pr. Eq. are compared in | + | To check the accuracy of the method in terms of kurtosis, the <math display="inline">{{\beta }_{2}}_{N}</math> history values provided by the MC and the Pr. Eq. are compared in [[#_Ref31628917|Figure 4]]. |

| − | [[File:Review_912708961870_5937_FIG4.png| | + | <div id="_Ref31628917"></div> |

| − | + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 50%;" | |

| − | + | |- | |

| − | '' | + | | style="padding:10px;" | [[File:Review_912708961870_5937_FIG4.png|350px|frameless|center|]] |

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;" | '''Figure 4'''. Kurtosis of <math display="inline">N</math> history values provided by the Monte Carlo (MC) and by the probabilistic NASGRO equation (Pr.Eq.) | ||

| + | |} | ||

The values of the kurtosis curves for 5-50 mm crack depths are listed in <span id='cite-_Ref31629029'></span>[[#_Ref31629029|Table 2]]. | The values of the kurtosis curves for 5-50 mm crack depths are listed in <span id='cite-_Ref31629029'></span>[[#_Ref31629029|Table 2]]. | ||

| + | <div id="_Ref31629029" class="center" style="font-size:75%;"> | ||

| + | '''Table 2'''. Kurtosis of <math display="inline">N</math> provided by Monte Carlo (MC) and by the probabilistic NASGRO equation (Pr. Eq.)</div> | ||

| − | + | {| class="wikitable" style="margin: 1em auto 0.1em auto;border-collapse: collapse;font-size:85%;width:auto;" | |

| − | + | |-style="text-align:center" | |

| − | + | ! !! MC !! Pr. Eq. !! Pr. Eq.-MC | |

| − | + | |-style="text-align:center" | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | | | + | |

| − | | | + | |

| − | + | ||

| <math>a</math> | | <math>a</math> | ||

| <math>{{\beta }_{2}}_{N}</math> | | <math>{{\beta }_{2}}_{N}</math> | ||

| <math>{{\beta }_{2}}_{N}</math> | | <math>{{\beta }_{2}}_{N}</math> | ||

| <math>Error</math> | | <math>Error</math> | ||

| − | |- | + | |-style="text-align:center" |

| − | + | | [mm] | |

| − | | | + | | [dimensionless] |

| − | | | + | | [dimensionless] |

| − | | | + | | [%] |

| − | |- | + | |-style="text-align:center" |

| − | + | | <span style="text-align: center; ">5</span> | |

| − | | | + | | <span style="text-align: center; ">4.33</span> |

| − | | | + | | <span style="text-align: center; ">3.84</span> |

| − | | | + | | <span style="text-align: center; ">-11.33%</span> |

| − | |- | + | |-style="text-align:center" |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">10</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">4.13</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">3.73</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">-9.53%</span> |

| − | |- | + | |-style="text-align:center" |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">20</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">4.00</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">3.66</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">-8.38%</span> |

| − | |- | + | |-style="text-align:center" |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">30</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">3.94</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">3.63</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">-7.83%</span> |

| − | |- | + | |-style="text-align:center" |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">40</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">3.90</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">3.61</span> |

| − | | <span style="text-align: center | + | | <span style="text-align: center; ">-7.47%</span> |

| − | |- | + | |-style="text-align:center" |

| − | + | | <span style="text-align: center; ">50</span> | |

| − | | | + | | <span style="text-align: center; ">3.88</span> |

| − | | | + | | <span style="text-align: center; ">3.60</span> |

| − | | | + | | <span style="text-align: center; ">-7.22%</span> |

|} | |} | ||

| Line 504: | Line 505: | ||

Once again, the kurtosis provided by the MC simulations is considered as the framework of reference. It is observed that the larger the crack the lower kurtosis and, in both calculations, a stabilization in magnitude is reached. The error in the probabilistic equation ranges from 11% to 7%, decreasing as the crack depth increases. The maximum difference of the Pr. Eq. calculates a kurtosis about 0.5 smaller. | Once again, the kurtosis provided by the MC simulations is considered as the framework of reference. It is observed that the larger the crack the lower kurtosis and, in both calculations, a stabilization in magnitude is reached. The error in the probabilistic equation ranges from 11% to 7%, decreasing as the crack depth increases. The maximum difference of the Pr. Eq. calculates a kurtosis about 0.5 smaller. | ||

| − | At this point, the first part of the methodology presented in | + | At this point, the first part of the methodology presented in Section <span id='cite-_Ref31790969'></span>[[#_Ref31790969|2.1]] is completed. As a result, the first to fourth moments of the underlying lifespan probability distribution are available after applying the full second-order approach. The expected value, first raw moment, and the variance, second central moment are taken from [25], whereas the skewness and the kurtosis, third and fourth central standardized moments, respectively, have been calculated above. Recapitulating, the moments of fatigue life <math display="inline">N</math> provided by the probabilistic NASGRO equations for a crack depth equal to 50 mm are enclosed in [[#_Ref31629726|Table 3]]. |

| + | <div id="_Ref31629726" class="center" style="font-size:75%;"> | ||

| + | '''Table 3'''. Expected value, standard deviation, skewness and kurtosis of <math display="inline">N</math> provided by the probabilistic NASGRO equations (Pr. Eq.)</div> | ||

| − | + | {| class="wikitable" style="margin: 1em auto 0.1em auto;border-collapse: collapse;font-size:85%;width:auto;" | |

| − | + | |-style="text-align:center" | |

| − | + | ! !! Pr. Eq. !! Pr. Eq. !! Pr. Eq. !! Pr. Eq. | |

| − | + | |-style="text-align:center" | |

| − | + | ||

| − | + | ||

| − | | | + | |

| − | + | ||

| − | + | ||

| − | | | + | |

| − | + | ||

| <math>a</math> | | <math>a</math> | ||

| <math>{\mu }_{N}</math> | | <math>{\mu }_{N}</math> | ||

| Line 523: | Line 519: | ||

| <math>{\gamma }_{{1}_{N}}</math> | | <math>{\gamma }_{{1}_{N}}</math> | ||

| <math>{{\beta }_{2}}_{N}</math> | | <math>{{\beta }_{2}}_{N}</math> | ||

| − | |- | + | |-style="text-align:center" |

| − | + | | [mm] | |

| − | | | + | | [Cycles] |

| − | | | + | | [Cycles] |

| − | | | + | | [dimensionless] |

| − | | | + | | [dimensionless] |

| − | |- | + | |-style="text-align:center" |

| − | + | | <span style="text-align: center;">50</span> | |

| − | | | + | | <span style="text-align: center; >398 853</span> |

| − | | | + | | <span style="text-align: center; ">56 103</span> |

| − | | | + | | <span style="text-align: center; ">0.646</span> |

| − | + | | <span style="text-align: center; ">3.60</span> | |

|} | |} | ||

| Line 540: | Line 536: | ||

Note that the square root of the variance, i.e. the standard deviation <math display="inline">{\sigma }_{N}</math>, was reported instead of the variance <math display="inline">{\sigma }_{N}^{2}</math>. This is because the standard deviation is more meaningful to interpret since it is expressed in units of the original variable. | Note that the square root of the variance, i.e. the standard deviation <math display="inline">{\sigma }_{N}</math>, was reported instead of the variance <math display="inline">{\sigma }_{N}^{2}</math>. This is because the standard deviation is more meaningful to interpret since it is expressed in units of the original variable. | ||

| − | The next part of the methodology addresses the problem of constructing a PDF from prescribed moments as described in | + | The next part of the methodology addresses the problem of constructing a PDF from prescribed moments as described in Section <span id='cite-_Re'></span>[[#_Re|2.2]]. In this case, it is possible to construct probability distributions with more than two parameters given that the first four moments are available. To check the benefits of the uncertainty propagation methodology presented in terms of life distributions, three scenarios were considered: (i) the lifespan was assumed to be normally distributed; (ii) the lifespan was assumed to be log-normally distributed; (iii) the Pearson distribution family was used to model the lifespan, thus avoiding the need of assuming a distribution in advance. The first two scenarios were discussed in [25], however, the latter one was not investigated as it requires the first four moments and only the expected value and the variance were calculated in the previous procedure. In the present work the third scenario considering the Pearson distribution family is also explored. The Pearson family is compared with the other two scenarios to verify that the proposed improvements contribute to a better knowledge of the distribution of fatigue life. For that purpose, the three probability density functions were constructed as described below from the moments in [[#_Ref31629726|Table 3]]. |

| − | In case (i), the probability density function for the lifespan <math display="inline">N</math> is assumed to be normally distributed, and therefore it is derived from the well-known probability density function for the standard normal distribution <math display="inline">\varphi \left( x\right)</math> . Specifically, the probability density function is parameterized in terms of a location parameter which is directly the expected value of the fatigue life <math display="inline">N</math>, and a scale parameter which is directly the square root of the variance, i.e. the standard deviation of the random output variable fatigue life <math display="inline">N</math>. As a result, the lifespan <math display="inline">N</math> distributed normally is characterised by the probability density function <math display="inline">{f}_{N}\left( N;{\mu }_{N},{\sigma }_{N}\right)</math> , where <math display="inline">{\mu }_{N}</math> and <math display="inline">{\sigma }_{N}</math> are fixed parameters. | + | In case (i), the probability density function for the lifespan <math display="inline">N</math> is assumed to be normally distributed, and therefore it is derived from the well-known probability density function for the standard normal distribution <math display="inline">\varphi \left( x\right)</math>. Specifically, the probability density function is parameterized in terms of a location parameter which is directly the expected value of the fatigue life <math display="inline">N</math>, and a scale parameter which is directly the square root of the variance, i.e. the standard deviation of the random output variable fatigue life <math display="inline">N</math>. As a result, the lifespan <math display="inline">N</math> distributed normally is characterised by the probability density function <math display="inline">{f}_{N}\left( N;{\mu }_{N},{\sigma }_{N}\right)</math>, where <math display="inline">{\mu }_{N}</math> and <math display="inline">{\sigma }_{N}</math> are fixed parameters. |

| − | In case (ii), the probability density function for the lifespan <math display="inline">N</math> is assumed to be log-normally distributed, and therefore it is derived from the standardized form for the log-normal probability density function <math display="inline">f\left( x;\sigma \right)</math> with <math display="inline">\sigma</math> as a shape parameter. Commonly, the probability density function is further parameterized in terms of a location parameter <math display="inline">\lambda</math> and a scale parameter <math display="inline">{e}^{\mu }</math>. The location parameter <math display="inline">\lambda</math> was set equal to zero, hence only two parameters remain to be estimated. The physical meaning of the location parameter is realistic since it indicates that crack growth occurs after any given cycle and so the support of the distribution is nonnegative. The shape <math display="inline">\sigma</math> and the scale <math display="inline">{e}^{\mu }</math> parameters of the log-normal are functions of the expected value and the variance of the fatigue life <math display="inline">N</math>. As a consequence, the lifespan <math display="inline">N</math> distributed log-normally is described by the probability density function <math display="inline">{f}_{N}\left( N;\sigma ,\lambda ,{e}^{\mu }\right)</math> where <math display="inline">\sigma</math> , <math display="inline">\lambda</math> and <math display="inline">{e}^{\mu }</math> are fixed parameters. | + | In case (ii), the probability density function for the lifespan <math display="inline">N</math> is assumed to be log-normally distributed, and therefore it is derived from the standardized form for the log-normal probability density function <math display="inline">f\left( x;\sigma \right)</math> with <math display="inline">\sigma</math> as a shape parameter. Commonly, the probability density function is further parameterized in terms of a location parameter <math display="inline">\lambda</math> and a scale parameter <math display="inline">{e}^{\mu }</math>. The location parameter <math display="inline">\lambda</math> was set equal to zero, hence only two parameters remain to be estimated. The physical meaning of the location parameter is realistic since it indicates that crack growth occurs after any given cycle and so the support of the distribution is nonnegative. The shape <math display="inline">\sigma</math> and the scale <math display="inline">{e}^{\mu }</math> parameters of the log-normal are functions of the expected value and the variance of the fatigue life <math display="inline">N</math>. As a consequence, the lifespan <math display="inline">N</math> distributed log-normally is described by the probability density function <math display="inline">{f}_{N}\left( N;\sigma ,\lambda ,{e}^{\mu }\right)</math> where <math display="inline">\sigma</math>, <math display="inline">\lambda</math> and <math display="inline">{e}^{\mu }</math> are fixed parameters. |

| − | In case (iii), the Pearson distribution type was automatically determined based on the quantities <math display="inline">{{\beta }_{1}}_{N}=</math><math>{{\gamma }_{1}^{2}}_{N}</math> and <math display="inline">{{\beta }_{2}}_{N}</math> as it is described in | + | In case (iii), the Pearson distribution type was automatically determined based on the quantities <math display="inline">{{\beta }_{1}}_{N}=</math><math>{{\gamma }_{1}^{2}}_{N}</math> and <math display="inline">{{\beta }_{2}}_{N}</math> as it is described in Section <span id='cite-_Ref31636819'></span>[[#_Ref31636819|2.2]]. In this example, the procedure leads to the Pearson type I that corresponds to the beta distribution. Afterwards, the parameters of the beta distribution were estimated making the statistical moments of the constructed lifespan distribution match the first four prescribed moments predicted by the Pr. Eq. In this case, the probability density function for the lifespan <math display="inline">N</math> beta-distributed is derived from the standardized form for the beta probability density function <math display="inline">f\left( x;\alpha ,\beta \right)</math> in Eq. <span id='cite-_Ref31636896'></span>[[#_Ref31636896|(14)]] with <math display="inline">\alpha</math>, <math display="inline">\beta</math> as shape parameters and where <math display="inline">\, \Gamma</math> is the gamma function <math display="inline">\Gamma \left( x\right) =</math><math>\left( x-1\right) !</math>. Once again, the probability density function is further parameterized by introducing two parameters representing the location and the scale. The shape parameters <math display="inline">\alpha</math> and <math display="inline">\beta</math>, the scale and the location parameter <math display="inline">\lambda</math> were calculated by using the closedform expressions derived in Section <span id='cite-_Ref31636819'></span>[[#_Ref31636819|2.2]] that express the parameters as function of the first four moments of the fatigue life <math display="inline">N</math> distribution. Recall that in these expressions the expected value <math display="inline">{\mu }_{N}</math> or first raw moment is denoted as <math display="inline">{\mu '}_{1}</math>. As a result, the lifespan <math display="inline">N</math> following a beta distribution is characterized by the probability density function <math display="inline">{f}_{N}\left( N;\alpha ,\beta ,\lambda ,{a}_{2}-\right. </math><math>\left. {a}_{1}\right)</math> given in Eq. <span id='cite-_Ref39844746'></span>[[#_Ref39844746|(15)]] |

{| class="formulaSCP" style="width: 100%;border-collapse: collapse;width: 100%;text-align: center;" | {| class="formulaSCP" style="width: 100%;border-collapse: collapse;width: 100%;text-align: center;" | ||

|- | |- | ||

| Line 565: | Line 561: | ||

| − | Note that in the <math display="inline">{f}_{N}\left( N;\alpha ,\beta ,\lambda ,{a}_{2}-{a}_{1}\right)</math> probability density function the <math display="inline">\alpha</math> , <math display="inline">\beta</math> , <math display="inline">\lambda</math> and <math display="inline">{a}_{2}-</math><math>{a}_{1}</math> are fixed parameters. | + | Note that in the <math display="inline">{f}_{N}\left( N;\alpha ,\beta ,\lambda ,{a}_{2}-{a}_{1}\right)</math> probability density function the <math display="inline">\alpha</math>, <math display="inline">\beta</math>, <math display="inline">\lambda</math> and <math display="inline">{a}_{2}-</math><math>{a}_{1}</math> are fixed parameters. |

The resulting parameters for the normal, the log-normal and the beta PDFs are collected in <span id='cite-_Ref31637441'></span>[[#_Ref31637441|Table 4]]. | The resulting parameters for the normal, the log-normal and the beta PDFs are collected in <span id='cite-_Ref31637441'></span>[[#_Ref31637441|Table 4]]. | ||

| + | <div id="_Ref31637441" class="center" style="font-size:75%;"> | ||

| + | '''Table 4'''. Shape, location and scale parameters computed from the first four moments of the lifespan <math display="inline">N</math> for a crack depth equal to 50 mm</div> | ||

| − | + | {| class="wikitable" style="margin: 1em auto 0.1em auto;border-collapse: collapse;font-size:85%;width:auto;" | |

| − | + | |-style="text-align:center" | |

| − | + | ||

| − | + | ||

|- | |- | ||

| − | + | ! Probability Distr. !! Shape !! Location !! Scale | |

| − | + | |-style="text-align:center" | |

| − | + | | text-align: center;"|<span style="text-align: center; ">Normal</span> | |

| − | | | + | | text-align: center;"|<span style="text-align: center; ">-</span> |

| − | + | | text-align: center;"|<span style="text-align: center; ">398 853 </span> <math display="inline">\left( = {\mu }_{N}\right)</math> | |

| − | | | + | | style="text-align: center;"|<span style="text-align: center; ">56 103 </span> <math display="inline">\left( {=\sigma }_{N}\right)</math> |

| − | | | + | |-style="text-align:center" |

| − | | | + | | style="text-align: center;"|<span style="text-align: center; ">Log-normal</span> |

| − | | style=" | + | | style="text-align: center;"|<span style="text-align: center; ">0.140 </span> <math display="inline">\left( = \sigma \right)</math> |

| − | |- | + | | style="text-align: center;"|<span style="text-align: center; ">0 </span> <math display="inline">\left( = \lambda \right)</math> |

| − | | style="text-align: center;"|<span style="text-align: center | + | | style="text-align: center;"|<span style="text-align: center; ">394 964 </span> <math display="inline">\left( = {e}^{\mu }\right)</math> |

| − | | style="text-align: center;"|<span style="text-align: center | + | |-style="text-align:center" |

| − | | style="text-align: center;"|<span style="text-align: center | + | | rowspan="2" style="text-align: center;"|<span style="text-align: center; ">Pearson type I (Beta)</span> |

| − | | style="text-align: center;"|<span style="text-align: center | + | | style="text-align: center;"|<span style="text-align: center; ">8.49 </span> <math display="inline">\left( = \alpha \right)</math><span style="text-align: center; ">,</span> |

| − | |- | + | | style="text-align: center;"|<span style="text-align: center; ">232 076 </span> |

| − | | rowspan="2" style=" | + | | style="text-align: center;"|<span style="text-align: center; ">4 825 029 </span> |

| − | | style="text-align: center;"|<span style="text-align: center | + | |-style="text-align:center" |

| − | | style="text-align: center;"|<span style="text-align: center | + | | style="text-align: center;"|<span style="text-align: center; ">237.33 </span> <math display="inline">\left( = \beta \right)</math> |

| − | | style="text-align: center;"|<span style="text-align: center | + | | style="text-align: center;"|<span style="text-align: center; "> </span> <math display="inline">\left( = \lambda \right)</math> |

| − | |- | + | | style="text-align: center;"|<span style="text-align: center; "> </span> <math display="inline">\left( {=a}_{2}-{a}_{1}\right)</math> |

| − | | style=" | + | |

| − | | style=" | + | |

| − | | style=" | + | |

|} | |} | ||

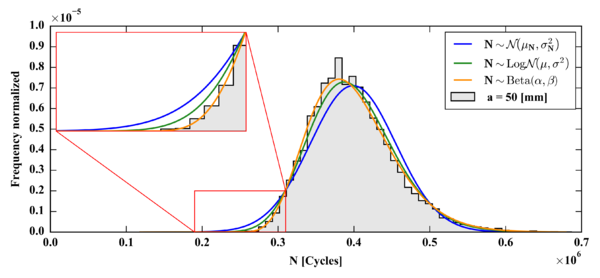

| − | The normal distribution, the log-normal distribution, the beta distribution and the MC histogram of the fatigue life <math display="inline">N</math> for a crack depth equal to 50 mm are compared in | + | The normal distribution, the log-normal distribution, the beta distribution and the MC histogram of the fatigue life <math display="inline">N</math> for a crack depth equal to 50 mm are compared in [[#_Ref31637565|Figure 5]]. |

| − | [[File:Review_912708961870_3760_FIG5.png|600px|frameless|center|]] | + | <div id="_Ref31637565"></div> |

| + | {| style="text-align: center; border: 1px solid #BBB; margin: 1em auto; width: 60%;" | ||

| + | |- | ||

| + | |style="padding:10px;"| [[File:Review_912708961870_3760_FIG5.png|600px|frameless|center|]] | ||

| + | |- style="text-align: center; font-size: 75%;" | ||

| + | | colspan="1" style="padding:10px;"| '''Figure 5'''. Histogram of fatigue life <math display="inline">N</math> provided by the Monte Carlo (MC) and PDFs of the normal, the log-normal and the beta distributions constructed from the moments provided by the probabilistic NASGRO equations (Pr.Eq.) for 50 mm crack depth | ||

| + | |} | ||

| − | |||

| − | |||

| − | + | The histogram of fatigue life <math display="inline">N</math> provided by the MC simulations is taken as a benchmark for the comparison of the three PDFs constructed. The differences between the normal distribution and the MC histogram highlight the degree of nonnormality and nonsymmetry of the underlying lifespan distribution. The lognormal distribution includes a certain degree of asymmetry and therefore it is a more convenient choice over the symmetrical normal distribution. It can be observed that the lognormal is advantageous to the normal distribution in describing the lower and higher tails of the lifespan, although the degree of asymmetry in the lognormal is not directly defined. On the other hand the beta distribution was determined from the Pearson distribution family according to the quantities related to shape <math display="inline">{\beta }_{1}</math> and <math display="inline">{\beta }_{2}</math>. It can be observed that the beta distribution agrees well with the MC histogram for all of the lifespan range, including the tails and also the peak. The superiority of the beta distribution over the normal and the lognormal distributions to represent the MC results is clear, especially when describing the lower tail of the distribution of lives, which is of great importance in reliability and in damage tolerance assessment. The behaviour of the normal and the lognormal distributions in the lower tail region slightly underestimate the lifespan. This aspect is clearly observed in the inset of <span id='cite-_Ref31637565'></span>[[#_Ref31637565|Figure 5]] which shows a zoom of the lower tail. The better tail performance of the beta distribution can be attributed to the fact that the first four moments of the lifespan <math display="inline">N</math> are matched when estimating the parameters of the Pearson distribution. That is to say that the PDF using the Pearson distribution family is sensitive to variations in skewness and kurtosis. Besides, the Pearson distribution type is selected depending on the moments that are related to the shape of the underlying distribution, and afterwards the corresponding probability distribution parameters are calculated. On the contrary, the construction of the normal and lognormal distributions do not take into account the skewness or kurtosis changes given that their third and fourth moments are not matched to the calculated lifespan <math display="inline">N</math> moments. In fact, the normal distribution has <math display="inline">0</math> skewness and a kurtosis equal to <math display="inline">3</math> inherently, and the skewness and the kurtosis of the lognormal distribution are determined indirectly once the distribution is defined in terms of the expected value and variance of the lifespan <math display="inline">N</math>. Consequently, the quality of the normal and lognormal PDFs is influenced by the similarity between them and the actual lifespan distribution, which is not always known. In other words, the quality can only be good if the lifespan is close to the selected distribution. It must be emphasized that in some applications the normal or the log-normal assumption may be enough, however, the Pearson distribution family still offers a perceptible improvement as the goodness and quality of the PDF constructed is not compromised by an a priori selection or assumption of a probability distribution. | |

| − | The histogram of fatigue life <math display="inline">N</math> provided by the MC simulations is taken as a benchmark for the comparison of the three PDFs constructed. The differences between the normal distribution and the MC histogram highlight the degree of nonnormality and nonsymmetry of the underlying lifespan distribution. The lognormal distribution includes a certain degree of asymmetry and therefore it is a more convenient choice over the symmetrical normal distribution. It can be observed that the lognormal is advantageous to the normal distribution in describing the lower and higher tails of the lifespan, although the degree of asymmetry in the lognormal is not directly defined. On the other hand the beta distribution was determined from the Pearson distribution family according to the quantities related to shape <math display="inline">{\beta }_{1}</math> and <math display="inline">{\beta }_{2}</math>. It can be observed that the beta distribution agrees well with the MC histogram for all of the lifespan range, including the tails and also the peak. The superiority of the beta distribution over the normal and the lognormal distributions to represent the MC results is clear, especially when describing the lower tail of the distribution of lives, which is of great importance in reliability and in damage tolerance assessment. The behaviour of the normal and the lognormal distributions in the lower tail region slightly underestimate the lifespan. This aspect is clearly observed in the inset of <span id='cite-_Ref31637565'></span>[[#_Ref31637565| | + | |

Additionally, a KolmogorovSmirnov test [36] was used to measure quantitatively the goodness of fit between the constructed probability distributions and the MC results. The test statistic quantifies the distance between the cumulative distribution functions of the constructed distribution and the cumulative MC histogram of reference, and therefore the lowest value indicates the best representation of the underlying distribution. The test statistics obtained were 0.052, 0.027 and 0.017 for the normal, log-normal and beta distributions, respectively. These values confirm the advantage of the beta distribution over the normal and the log-normal distributions to represent the MC results. | Additionally, a KolmogorovSmirnov test [36] was used to measure quantitatively the goodness of fit between the constructed probability distributions and the MC results. The test statistic quantifies the distance between the cumulative distribution functions of the constructed distribution and the cumulative MC histogram of reference, and therefore the lowest value indicates the best representation of the underlying distribution. The test statistics obtained were 0.052, 0.027 and 0.017 for the normal, log-normal and beta distributions, respectively. These values confirm the advantage of the beta distribution over the normal and the log-normal distributions to represent the MC results. | ||

| Line 638: | Line 634: | ||

The authors acknowledge the Spanish Ministry of Economy, Industry and Competitive through the National Programme for Research Aimed at the Challenges of Society that financially supported the project RTC-2016-4813-4. | The authors acknowledge the Spanish Ministry of Economy, Industry and Competitive through the National Programme for Research Aimed at the Challenges of Society that financially supported the project RTC-2016-4813-4. | ||

| − | |||

| − | |||

==References== | ==References== | ||

| + | <div class="auto" style="text-align: left;width: auto; margin-left: auto; margin-right: auto;font-size: 85%;"> | ||

| + | |||

| − | [1] Cervello S. Fatigue properties of railway axles: New results of full-scale specimens from Euraxles project. Int J Fatigue | + | [1] Cervello S. Fatigue properties of railway axles: New results of full-scale specimens from Euraxles project. Int J Fatigue, 86:2–12, 2016. [https://doi.org/10.1016/j.ijfatigue.2015.11.028. https://doi.org/10.1016/j.ijfatigue.2015.11.028.] |

| − | [2] Novosad M, Fajkoš R, Řeha B, Řezníček R. Fatigue tests of railway axles. Procedia Eng | + | [2] Novosad M., Fajkoš R., Řeha B., Řezníček R. Fatigue tests of railway axles. Procedia Eng, 2:2259–68, 2010. [https://doi.org/10.1016/j.proeng.2010.03.242. https://doi.org/10.1016/j.proeng.2010.03.242.] |

| − | [3] Beretta S, Carboni M. Variable amplitude fatigue crack growth in a mild steel for railway axles: Experiments and predictive models. Eng Fract Mech | + | [3] Beretta S., Carboni M. Variable amplitude fatigue crack growth in a mild steel for railway axles: Experiments and predictive models. Eng Fract Mech, 78:848–62, 2011. [https://doi.org/10.1016/j.engfracmech.2010.11.019. https://doi.org/10.1016/j.engfracmech.2010.11.019.] |

| − | [4] Mädler K, Geburtig T, Ullrich D. An experimental approach to determining the residual lifetimes of wheelset axles on a full-scale wheel-rail roller test rig. Int J Fatigue | + | [4] Mädler K., Geburtig T., Ullrich D. An experimental approach to determining the residual lifetimes of wheelset axles on a full-scale wheel-rail roller test rig. Int J Fatigue, 86:58–63, 2016. [https://doi.org/10.1016/j.ijfatigue.2015.06.016. https://doi.org/10.1016/j.ijfatigue.2015.06.016.] |

| − | [5] UIC B 169 RP 36:2013-12 Defect Tolerance Concept (DTC) Permitted defects and surface properties for axles under maintenance. UIC Standard | + | [5] UIC B 169 RP 36:2013-12 Defect Tolerance Concept (DTC) Permitted defects and surface properties for axles under maintenance. UIC Standard, 2013. |

| − | [6] Pokorný P, Náhlík L, Hutař P. Comparison of | + | [6] Pokorný P., Náhlík L., Hutař P. Comparison of different load spectra on residual fatigue lifetime of railway axle. Procedia Eng, 74:313–6, 2014. [https://doi.org/10.1016/j.proeng.2014.06.269. https://doi.org/10.1016/j.proeng.2014.06.269.] |

| − | [7] Pokorný P, Hutař P, Náhlík L. Residual fatigue lifetime estimation of railway axles for various loading spectra. Theor Appl Fract Mech | + | [7] Pokorný P., Hutař P., Náhlík L. Residual fatigue lifetime estimation of railway axles for various loading spectra. Theor Appl Fract Mech, 82:25–32, 2016. [https://doi.org/10.1016/j.tafmec.2015.06.007. https://doi.org/10.1016/j.tafmec.2015.06.007.] |

| − | [8] Traupe M, Landaberea A. EURAXLES - A global approach for design, production and maintenance of railway axles: WP2 - development of numerical models for the analysis of railway axles. Mater Werkst | + | [8] Traupe M., Landaberea A. EURAXLES - A global approach for design, production and maintenance of railway axles: WP2 - development of numerical models for the analysis of railway axles. Mater Werkst, 48:687–98, 2017. [https://doi.org/10.1002/mawe.201600570. https://doi.org/10.1002/mawe.201600570.] |

| − | [9] Zerbst U, Beretta S, Köhler G, Lawton A, Vormwald M, Beier | + | [9] Zerbst U., Beretta S., Köhler G., Lawton A., Vormwald M., Beier H.Th., et al. Safe life and damage tolerance aspects of railway axles – A review. Eng Fract Mech, 98:214–71, 2013. [https://doi.org/10.1016/j.engfracmech.2012.09.029. https://doi.org/10.1016/j.engfracmech.2012.09.029.] |

| − | [10] Zerbst U, Klinger C, Klingbeil D. Structural assessment of railway axles – A critical review. Eng Fail Anal | + | [10] Zerbst U., Klinger C., Klingbeil D. Structural assessment of railway axles – A critical review. Eng Fail Anal, 35:54–65, 2013. [https://doi.org/10.1016/j.engfailanal.2012.11.007. https://doi.org/10.1016/j.engfailanal.2012.11.007.] |

| − | [11] Paris | + | [11] Paris P.C., Erdogan F. A critical analysis of crack propagation laws. J Basic Eng, 85:528–33, 1963. [https://doi.org/10.1115/1.3656900. https://doi.org/10.1115/1.3656900.] |

| − | [12] Akama M, Ishizuka H. Reliability analysis of Shinkhansen vehicle axle using probabilistic fracture mechanics. JSME Int J Ser Mech Mater Eng | + | [12] Akama M., Ishizuka H. Reliability analysis of Shinkhansen vehicle axle using probabilistic fracture mechanics. JSME Int J Ser Mech Mater Eng, 38(3):378–83, 1995. [https://doi.org/10.1299/jsmea1993.38.3_378. https://doi.org/10.1299/jsmea1993.38.3_378.] |

| − | [13] Bea | + | [13] Bea J.A. Simulación del crecimiento de grietas por fatiga aleatoria mediante elementos probabilistas. PhD Thesis, Universidad de Zaragoza, 1997. |

| − | [14] Bea | + | [14] Bea J.A., Doblaré M., Gracia L. Evaluation of the probability distribution of crack propagation life in metal fatigue by means of probabilistic finite element method and B-models. Eng Fract Mech, 63:675–711, 1999. [https://doi.org/10.1016/S0013-7944 https://doi.org/10.1016/S0013-7944](99)00053-3. |

| − | [15] Bea | + | [15] Bea J.A., Doblaré M., Gracia L. Fiabilidad de elementos metálicos en crecimiento de grieta por fatiga aleatoria mediante elementos finitos probabilistas y modelos B. Rev Int Métod Numér para Cálculo Diseño en Ing, 15(1):85–112, 1999. [https://www.scipedia.com/public/Bea_et_al_1999a. https://www.scipedia.com/public/Bea_et_al_1999a.] |

| − | [16] Hillmansen S, Smith | + | [16] Hillmansen S., Smith R.A. The management of fatigue crack growth in railway axles. Proc Inst Mech Eng Part F J Rail Rapid Transit, 218:327–336, 2004. [https://doi.org/10.1243/0954409043125879. https://doi.org/10.1243/0954409043125879.] |

| − | [17] Hong | + | [17] Hong Y.J., Xing J., Wang J.B. A second-order third-moment method for calculating the reliability of fatigue. Int J Press Vessels Pip, 76:567–70, 1999. [https://doi.org/10.1016/S0308-0161 https://doi.org/10.1016/S0308-0161](99)00013-7. |

| − | [18] Náhlík L, Pokorný P, Ševčík M, Fajkoš R, Matušek P, Hutař P. Fatigue lifetime estimation of railway axles. Eng Fail Anal | + | [18] Náhlík L., Pokorný P., Ševčík M., Fajkoš R,, Matušek P,, Hutař P. Fatigue lifetime estimation of railway axles. Eng Fail Anal, 73:139–57, 2017. [https://doi.org/10.1016/j.engfailanal.2016.12.014. https://doi.org/10.1016/j.engfailanal.2016.12.014.] |

| − | [19] Wang L, Liang J, Yang Y, Zheng Y. Time-dependent reliability assessment of fatigue crack growth modeling based on perturbation series expansions and interval mathematics. Theor Appl Fract Mech | + | [19] Wang L., Liang J., Yang Y., Zheng Y. Time-dependent reliability assessment of fatigue crack growth modeling based on perturbation series expansions and interval mathematics. Theor Appl Fract Mech, 95:104–18, 2018. [https://doi.org/10.1016/j.tafmec.2018.02.010. https://doi.org/10.1016/j.tafmec.2018.02.010.] |

| − | [20] Yasniy O, Lapusta Y, Pyndus Y, Sorochak A, Yasniy V. Assessment of lifetime of railway axle. Int J Fatigue | + | [20] Yasniy O., Lapusta Y., Pyndus Y., Sorochak A., Yasniy V. Assessment of lifetime of railway axle. Int J Fatigue, 50:40–6, 2013. [https://doi.org/10.1016/j.ijfatigue.2012.04.008. https://doi.org/10.1016/j.ijfatigue.2012.04.008.] |

| − | [21] Zhu S-P, Liu Q, Huang H-Z. Probabilistic | + | [21] Zhu S.-P., Liu Q., Huang H.-Z. Probabilistic modeling of damage accumulation for fatigue reliability analysis. Procedia Struct Integr, 4:3–10, 2017. [https://doi.org/10.1016/j.prostr.2017.07.012. https://doi.org/10.1016/j.prostr.2017.07.012.] |

| − | [22] Forman | + | [22] Forman R.G., Mettu S.R. Behavior of surface and corner cracks subjected to tensile and bending loads in Ti-6Al-4V alloy. ASTM STP 1131 Am Soc Test Mater Phila PA, 519–46, 1990. |

| − | [23] Beretta S, Carboni M. Experiments and stochastic model for propagation lifetime of railway axles. Eng Fract Mech | + | [23] Beretta S., Carboni M. Experiments and stochastic model for propagation lifetime of railway axles. Eng Fract Mech, 73:2627–2641, 2006. [https://doi.org/10.1016/j.engfracmech.2006.04.024. https://doi.org/10.1016/j.engfracmech.2006.04.024.] |

| − | [24] Beretta S, Villa A. A RV approach for the analysis of fatigue crack growth with NASGRO equation. 4th | + | [24] Beretta S., Villa A. A RV approach for the analysis of fatigue crack growth with NASGRO equation. Proceedings of the 4th International ASRANet Colloquium, 1–7, 2008. |

| − | [25] Mallor C, Calvo S, Núñez | + | [25] Mallor C., Calvo S., Núñez J.L., Rodríguez-Barrachina R., Landaberea A. Full second-order approach for expected value and variance prediction of probabilistic fatigue crack growth life. Int J Fatigue, 133:105454, 2020. [https://doi.org/10.1016/j.ijfatigue.2019.105454. https://doi.org/10.1016/j.ijfatigue.2019.105454.] |

| − | [26] Mayer M. Die Sicherheit der Bauwerke und ihre Berechnung nach Grenzkräften anstatt nach zulässigen Spannungen. Berlin | + | [26] Mayer M. Die Sicherheit der Bauwerke und ihre Berechnung nach Grenzkräften anstatt nach zulässigen Spannungen. Berlin, Springer Verlag, 1926. |

| − | [27] Mayer M. La seguridad en las construcciones y su cálculo aplicando los esfuerzos límite en lugar de las tensiones admisibles = Safety in constructional works and its design according to limit states instead of permissible stresses. Madrid | + | [27] Mayer M. La seguridad en las construcciones y su cálculo aplicando los esfuerzos límite en lugar de las tensiones admisibles = Safety in constructional works and its design according to limit states instead of permissible stresses. Madrid, INTEMAC, 1975. |

| − | [28] Cornell | + | [28] Cornell C.A. A Probability-based structural code. ACI J Proc, 66:974–85, 1969. [https://doi.org/10.14359/7446. https://doi.org/10.14359/7446.] |

| − | [29] Cornell | + | [29] Cornell C.A. Structural safety specifications based on second-moment reliability analysis. IABSE Symposium on Concepts of Safety of Structures and Methods of Design, 1969. [https://doi.org/10.5169/seals-5948. https://doi.org/10.5169/seals-5948.] |

| − | [30] Núñez | + | [30] Núñez J.L. Análisis del fenómeno de la fatiga en metales en etapa de nucleación mediante la utilización de modelos estadísticos de daño acumulado y elementos finitos probabilistas. PhD Thesis, Universidad de Zaragoza, 2003. |

| − | [31] Calvo S. Determinación de la probabilidad de fallo en componentes métalicos sometidos a estados multiaxiales de tensión mediante la utilización de elementos finitos probabilistas y modelos estadísticos de daño acumulado. PhD | + | [31] Calvo S. Determinación de la probabilidad de fallo en componentes métalicos sometidos a estados multiaxiales de tensión mediante la utilización de elementos finitos probabilistas y modelos estadísticos de daño acumulado. PhD Thesis, Universidad de Zaragoza, 2008. |

| − | [32] Calvo S, Canales M, Gómez C, Valdés | + | [32] Calvo S., Canales M., Gómez C., Valdés J.R., Núñez J.L. Probabilistic formulation of the multiaxial fatigue damage of Liu. Int J Fatigue, 33:460–5, 2011. [https://doi.org/10.1016/j.ijfatigue.2010.10.003. https://doi.org/10.1016/j.ijfatigue.2010.10.003.] |

| − | [33] Pearson K. X. Contributions to the mathematical theory of evolution.—II. Skew variation in homogeneous material. Philos Trans R Soc Lond A | + | [33] Pearson K. X. Contributions to the mathematical theory of evolution.—II. Skew variation in homogeneous material. Philos Trans R Soc Lond A, 186:343–414, 1895. [https://doi.org/10.1098/rsta.1895.0010. https://doi.org/10.1098/rsta.1895.0010.] |

| − | [34] Johnson | + | [34] Johnson N.L., Kotz S., Balakrishnan N. Continuous univariate distributions. Wiley-Interscience, Vol. 1, 2nd edition, 784 pages, 1994. |

| − | [35] EN 13261:2009+A1:2010: Railway applications – Wheelsets and bogies – Axles – Product requirements. European Committee for Standardization | + | [35] EN 13261:2009+A1:2010: Railway applications – Wheelsets and bogies – Axles – Product requirements. European Committee for Standardization, 2010. |

| − | [36] Haldar A, Mahadevan S. Probability, reliability, and statistical methods in engineering design. John Wiley | + | [36] Haldar A., Mahadevan S. Probability, reliability, and statistical methods in engineering design. John Wiley, 320 pages, 1999. |

| + | </div> | ||

Latest revision as of 13:51, 16 July 2020

Abstract

Uncertainty propagation of fatigue crack growth life commonly aims to provide the probability distribution of the lifespan needed for probabilistic damage tolerance analysis and for structural integrity assessment. This paper presents a novel methodology for efficiently estimating the parameters of the probability distribution of fatigue lifespan considering the Pearson distribution family. First, the full second-order approach for expected value and variance prediction of probabilistic fatigue crack growth life is extended to predict higher order statistical moments of the underlying distribution. That is, the expected value (first raw moment) and the variance (second central moment) equations are complemented with the probabilistic formulations for the skewness and for the kurtosis (third and fourth central standardized moments, respectively). Then, from these moments, the Pearson distribution type is automatically determined. Finally, the parameters of the particular Pearson distribution type are estimated making the statistical moments of the constructed lifespan distribution match the first four prescribed moments predicted by the probabilistic equations. The validity of the proposed method is verified by a numerical example regarding the fatigue crack growth in a railway axle under random bending loading. It is proven that the probability density function of the lifespan is properly derived by the methodology, without knowing or assuming the output probability distribution beforehand. The methodology presented enables an efficient and an accurate quantification of the lifespan uncertainties via its probabilistic distribution. This probabilistic description of fatigue crack growth life can be subsequently used in reliability studies or in damage tolerance assessment.

Keywords: Probabilistic fatigue crack growth, uncertainty propagation, lifespan probability distribution, pearson distribution family, NASGRO

Nomenclature

: crack depth / normal semiaxis

: final crack depth

: initial crack depth

: real roots of the quadratic equation in the denominator of the integral of the Pearson solution

: superscript above referring to the bending loading case

: superscript above referring to the bending plus interference loading case

: parameter of the crack growth equation in the Paris region

: random variables number

: crack growth rate

: scale parameter of the log-normal distribution

: Newman’s crack opening function

: probability density function for the standardized beta distribution

: probability density function for the standardized log-normal distribution

: probability density function of the random variable fatigue life

: first partial derivative of with respect to

: second partial derivative of with respect to and

: evaluation of at the mean value vector of

: step increment

: superscript above referring to the interference loading case

: index from 1 to random variables

: stress intensity factor (general)

: critical stress intensity factor for static unstable crack growth

, : maximum and minimum

: bending moment

: exponent of the crack growth equation in the Paris region

: steps number

: number of applied cycles

: parameter describing the sigmoidal shape of the crack growth equation in the threshold region

: Pearson probability density function

: parameter describing the sigmoidal shape of the crack growth equation in the toughness region

: stress ratio

: radial coordinate direction at the axle surface

: set of random variables

: general multivariate function

: shape parameters of the beta distribution

: square of skewness of

: kurtosis of

: skewness of

: gamma function

: stress intensity factor range

: threshold stress intensity factor range

: location parameter of the log-normal and the beta distributions.

: expected value of or first raw moment simply denoted

: third central moment of

: fourth central moment of

: stress (general)

: shape parameter of the log-normal distribution

: standard deviation of

: variance of also simply denoted

: probability density function for the standard normal distribution

Abbreviations

FOSM: first order second moment

FEM: finite element method

SIF: stress intensity factor

MC: Monte Carlo

Pr. Eq.: probabilistic equation

PDF: probability density function

1. Introduction

The fatigue crack growth mechanism is affected by many sources of variability such as the statistical variations of the mechanical properties of solid materials [1–4], random loading conditions [5–7] and uncertainties inherent to geometrical parameters [8]. Therefore, the stochastic nature of the fatigue crack growth phenomenon requires a proper uncertainty processing for reliability assessment and durability prediction. Uncertainty propagation methods in the fatigue life prediction commonly characterize the lifespan after a certain crack growth through a probability distribution. In consequence, probabilistic fatigue crack growth analyses aim to determine the probability distribution of the random response, lifespan, as a result of the randomness of the input variables. In areas such as damage tolerance analysis in the railway sector, predicting the probability distribution of fatigue crack growth life is becoming an important aspect. However, there is still a lack of harmonization of probabilistic procedures to define in-service inspection intervals in train axles for crack detection [9,10]. This particular application still deserves some developments via the extension of the current numerical methodologies.

Probabilistic fatigue crack growth is an extensive area of research. Numerous studies develop probabilistic models based on deterministic crack growth equations such as the Paris’ law [11]. For instance, some probabilistic approaches founded on the Paris law are presented in [12–21], being the model most frequently used. Over recent years, the first advances considering the complete crack growth curve have been made because of the increasing importance of taking into account the early stages of crack growth for an adequate estimation of the lifespan. The state of the art equation in the field of the fatigue crack propagation problem is a modified version of the Paris’ law referred to as NASGRO equation [22]. The NASGRO equation is commonly applied in the evaluation of components as in the case of railway axles [18,23–25]. Additionally, the use of the first-order second-moment (FOSM) probabilistic method [26–29] has enabled some new perspectives in the fatigue crack growth analysis of components. Some examples are the fatigue life estimation according to the Paris' law [13,14], the crack nucleation stage analysis based on the Coffin-Manson model [30], the multiaxial fatigue assessment based on the virtual strain energy damage model of Liu [31,32] and especially the fatigue crack propagation based on the NASGRO equation in [25] where an extended version of the FOSM to full second-order approach is developed for predicting statistical moments of the fatigue lifetime in a railway axle under random loading.

The probabilistic fatigue crack growth strategies above provide certain statistics that describe the response distribution, for instance, mathematical moments like the expected value and the variance. Then, the problem under investigation is further analyzed according to these statistics. One such interesting analysis is to construct the whole probability density function (PDF) of fatigue crack growth life, namely, the uncertainty propagation in fatigue crack growth life. The PDF can be used to describe the relative likelihood that the value of the lifespan would be equal to a particular value. Generally, the random output variable is assumed to follow a common probability distribution, such as the normal or the log-normal distribution, and subsequently the parameters of the distribution are estimated considering the statistics of the response as constraints. An illustrative example of the previous strategy is presented in [25] where the full second-order approach provides the expected value and the variance of the random output variable lifespan and then the normal and the log-normal PDFs are constructed according to these two statistics of the lifespan. The discussion in the example mentioned above highlights some drawbacks regarding the need to assume in advance a probability distribution of two parameters, since only the expected value and the variance of the underlying lifespan probability distribution are calculated, and also that the accuracy or similarity between the constructed PDFs and the results of the Monte Carlo method (MC) can be improved. A general methodology that considers the statistics of the response and automatically provides an appropriate PDF of the response distribution will be more useful than a predefined one. It would thus be of interest to explore some alternatives to overcome the limitations aforementioned to contribute to a better knowledge of the distribution of fatigue life.

As shown in the previous literature, the scientific community has studied the uncertainty propagation in fatigue crack growth life for many years. These investigations are usually intended to provide the probability distribution of the lifespan which, as is the case of train axles, is a fundamental aspect for the maintenance planning definition to keep the probability of failure as small as possible, as far as it is economically viable. Addressing the problem in an efficient and precise manner is, therefore, a challenge. The construction of a PDF under moment constraints has historically been of great interest. In some cases, the underlying probability distribution manifests asymmetry or presents a characteristic heaviness of the tails relative to the rest of the distribution or a combination of both. Therefore the need to manage the shape of the constructed PDF arises. The shape of the constructed distribution can be handled by means of controlling its skewness and kurtosis moments. Early contributions considered this topic, devising a system of distributions, the Pearson distribution family [33], which has the appeal of encompassing several well-known distributions as members. This distribution has a rich flexibility in shape, covering a wide skewness-kurtosis region. Furthermore, the location, scale and shape parameters of a particular Pearson distribution can be estimated in terms of the first four prescribed moments, that is, the expected value, first raw moment; the variance, second central moment; the skewness, third central standardized moment, and the kurtosis, fourth central standardized moment. As a consequence, the Pearson family of distributions has been used for modelling purposes by those engaged in the probabilistic analysis of structures. However, an overall treatment of the uncertainty propagation in fatigue crack growth life based on the NASGRO equation combined with the versatile Pearson distribution family is missing. To the best of the authors’ knowledge, the work presented in this paper is the first attempt to develop an effective, efficient and practical uncertainty propagation approach that is capable of predicting the first four moments of the lifespan distribution according to the NASGRO equation and using them to construct a probability density function based on the Pearson distribution family.

The objective of this work is to providea novel uncertainty propagation methodology for efficiently estimating the parameters of the probability distribution of fatigue lifespan considering the Pearson distribution family. For this purpose, the pertinent Pearson distribution type is automatically determined depending on the stochastic moments of the underlying lifespan distribution according to the NASGRO equation. Subsequently, the parameters of the distribution are calculated making the statistical moments of the constructed lifespan distribution match the first four prescribed moments. To estimate these first four required moments in advance, the full second-order approach for expected value and variance prediction presented in [25] is extended to predict the skewness and the kurtosis of the underlying lifetime distribution. As a result, the methodology developed enables an efficient estimation of the parameters of the particular Pearson distribution type and, in the meantime, provides the first four moments of the underlying lifetime distribution. The combination of both, contributes to overcome the drawbacks previously highlighted, avoiding the need to assume a probability distribution of two parameters and also increasing the accuracy of the PDF constructed. The proposed uncertainty propagation methodology is illustrated and discussed in detail through an application example specifically oriented on the fatigue crack growth in a metallic railway axle.

The paper is organized as follows. Section 2 presents the methods used for the uncertainty propagation methodology. Firstly, the full second-order approach for the skewness and kurtosis moments of functions of random variables is described in detail. It also includes the probabilistic expressions regarding its integration with the NASGRO model. Secondly, an overview of the Pearson distribution family is given and the estimation of the distribution parameters from prescribed moments is summarized. Section 3 illustrates and discusses the proposed uncertainty propagation procedure by means of an application example in a metallic railway axle. The results of the full second-order approach are compared with those obtained by the Monte Carlo method in terms of skewness and kurtosis. Furthermore, the quality of PDF constructed with the Pearson distribution in comparison with the histogram from the Monte Carlo method is discussed. Finally, Section 6 concludes the main findings in this paper.

2. Uncertainty propagation methodology

The objective of the uncertainty propagation methodology is to efficiently estimate the parameters of the probability distribution of a random variable of interest. To establish a general methodology, a key point is to consider the Pearson distribution family because of the following two reasons combined. Firstly, it is a rich family that is able to adjust a broad range of distribution shapes and therefore it can closely represent a portion of the reality. Secondly, the Pearson distribution family is easy to use in practice because it has mathematical characteristics that make the different distribution parameters be expressed as function of the first four moments.

To obtain the first four required moments of the underlying distribution, the full second-order approach for expected value and variance prediction of probabilistic fatigue crack growth life is extended to predict higher order statistical moments of the underlying distribution. That is, the expected value (first raw moment) and the variance (second central moment) probabilistic equations (Pr. Eq.) are complemented with the Pr. Eq. for the skewness and for the kurtosis (third and fourth central standardized moments, respectively). The reasoning followed for the expected value and the variance estimation is used to derive the Pr. Eq. for the skewness and the kurtosis prediction.

2.1. Full second-order approach for skewness and kurtosis prediction of probabilistic fatigue crack growth life

The full second-order approach for the moments of functions of random variables presented in [25] enables the prediction of the expected value and the variance of the lifespan of interest. Here, the approach is extended to predict the skewness and the kurtosis of the probabilistic fatigue crack growth life. This section recalls the definition of skewness and kurtosis, then derives the full second-order approximation for the third and fourth central moments of a general function and finally provides the probabilistic formulations for propagating the third and fourth central moments through the fatigue crack growth NASGRO model.

The third central moment is a measure of the distribution symmetry or lack of symmetry. Any symmetric distribution will have a third central moment of zero. The third central moment divided by the standard deviation to the power of three is referred to as normalized or standardized third central moment and commonly known as skewness. The skewness is denoted by as it is shown in Eq. (1)

|

|

(1) |

As the third central moment has units of the random variable to the power of three, after normalization, skewness is dimensionless. Usually, the square of the skewness is denoted by as it is expressed in Eq. (2)

|

|

(2) |

The fourth central moment is a measure of the combined weight or heaviness of the tails relative to the rest of the distribution. As the variance, it measures the spread of the data but is more dependent on the behavior of outliers in the tails. The fourth central moment divided by the standard deviation to the power of four is known as normalized or standardized fourth central moment and generally referred to as kurtosis. The kurtosis is frequently denoted by as it is presented in Eq. (3), being dimensionless for the same reason mentioned above

|

|

(3) |

The skewness and the kurtosis are calculated from the third and fourth central moments as indicated in the previous definitions. Following the reasoning presented in [25] to predict the expected value and the variance, the third central moment approximation is derived and as a result the skewness can be calculated. The full second-order approximation for the third central moment of a general function is given by Eq. (4)

|

|

(4) |

Note that indicates second central moment , indicates the third central moment , indicates the fourth central moment and so on. In other words the central multivariate moments of continuous random variables are denoted with consecutive indexes, two for the second central moment, three indexes for the third central moment, four indexes for the fourth central moment etc.

Likewise, following the reasoning presented in [25] the fourth central moment approximation is derived and as a result the kurtosis can be calculated. The full second-order approximation for fourth central moment of a general function is given by Eq. (5)

|

|

(5) |