m (Randall moved page Draft SONG 946531540 to Review 427877953602) |

|||

| Line 4: | Line 4: | ||

<span id='OLE_LINK11'></span><span id='OLE_LINK16'></span><span id='OLE_LINK17'></span> | <span id='OLE_LINK11'></span><span id='OLE_LINK16'></span><span id='OLE_LINK17'></span> | ||

| − | == | + | == CMM-PWD:a feature extraction method of subway fan under piston wind effect== |

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 11: | Line 11: | ||

1 School of Thermal Engineering, Shandong Jianzhu University, Jinan 250101, Shandong, China | 1 School of Thermal Engineering, Shandong Jianzhu University, Jinan 250101, Shandong, China | ||

| − | + | 2 Key Laboratory of High-efficiency and Clean Mechanical Manufacture, National Demonstration Center for Experimental Mechanical Engineering Education, School of Mechanical Engineering, Shandong University, Jinan 250061, Shandong, China | |

--> | --> | ||

| Line 22: | Line 22: | ||

===1. INTRODUCTION=== | ===1. INTRODUCTION=== | ||

| − | <span id='OLE_LINK7'></span><span id='OLE_LINK8'></span>With the rapid development of the public transport systems, the subway is one of the most important section of large cities’ transport system. Subway fan is widely used in ventilation system which plays a significant role in ventilation, eliminating smoke and cooling. Thus, subway fan condition monitoring and fault diagnosis are essential to guarantee safe operation[1,2]. However, train passing causes unsteady airflows in subway stations and tunnels. This phenomenon is called piston effect, which is a challenge for fan condition monitoring and fault diagnosis. Since decades, many researchers have focused on the issue of piston effect in subways stations and tunnels. Peng et al. uses in situ experimental data and computational fluid dynamics (CFD) method to analyze the unsteady air flow in subway station and tunnel[3]. The effects of different kinds of jet fans in the ventilation airflow field were analyzed by fluent simulation | + | <span id='OLE_LINK7'></span><span id='OLE_LINK8'></span><span id='_GoBack'></span>With the rapid development of the public transport systems, the subway is one of the most important section of large cities’ transport system. Subway fan is widely used in ventilation system which plays a significant role in ventilation, eliminating smoke and cooling. Thus, subway fan condition monitoring and fault diagnosis are essential to guarantee safe operation[1,2]. However, train passing causes unsteady airflows in subway stations and tunnels. This phenomenon is called piston effect, which is a challenge for fan condition monitoring and fault diagnosis. Since decades, many researchers have focused on the issue of piston effect in subways stations and tunnels. Peng et al. uses in situ experimental data and computational fluid dynamics (CFD) method to analyze the unsteady air flow in subway station and tunnel[3]. The effects of different kinds of jet fans in the ventilation airflow field were analyzed by fluent simulation [4]. González and team members present a numerical methodology based on a dynamic mesh technique to properly simulate the influence of piston effect in the ventilation system of subway tunnels[5]. Huang et al. investigate numerically the characteristics of train-induced unsteady airflow in a subway tunnel with natural ventilation ducts by using the dynamic layering method for the moving boundary method[6]. Kim et al. analyze the unsteady three-dimensional flow in the subway tunnel caused by train, both experimental and computational studies have been conducted[7]. Monitoring, modeling, and characterizing single-speed ventilation fans was proposed by Qin et al[8]. Wang et al. create and validate the theoretical model of the platform piston wind wall jet through three methods: mathematical theory modeling, field measurements and a scale model test[9]. But, there are few studies on the fault diagnosis of fan condition by taking the piston wind effect into account. And piston wind effect will cause many unnecessary false alarm and deteriorate the fault detection performance. |

<span id='OLE_LINK9'></span><span id='OLE_LINK10'></span>Subway fan is typical rotating machinery, for which, fault diagnosis methods have been studied by many researchers[10,11]. Feature extraction is the most important part of fault diagnosis. In order to extract the feature of the vibration[12] or acoustic signal, many methods have been proposed in the literature, such as short time Fourier transform (STFT), wavelet transform, empirical mode decomposition (EMD), Kurtogram, Infogram and Cyclostationarity, etc. STFT decomposes a time domain signal into a 2D time-frequency representation, but it’s restricted by a trade-off between time resolution and frequency resolution. The wavelet transform introduces a scaling factor which can change the time and frequency resolution, but its performance relies on the selection of mother wavelet. Wang et al. use wavelet approach to evaluate quantitatively gear fault adventure under varying load conditions [13]. EMD is an adaptive decomposition method which has been developed and widely applied in machine fault diagnosis. Recent applications of EMD to fault diagnosis of rotating machinery are summarized in terms of the key components by Lei et al., such as rolling element bearings, gears and rotors[14]. Keegan et al. present a new approached based on EMD, designated as wavelet-bounded empirical mode decomposition (WBEMD)[15]. But the EMD easy gets the problem of model-mixing. The kurtogram is a fourth-order spectral analysis tool recently introduced for detecting and characterizing signal nonstationarities[16,17]. Infogram significantly extends the domain of applicability of the kurtogram, in particular to situations corrupted with impulsive noise or when the relaxation time of the transients is low as compared to their rate of repetition[18]. Cyclostationarity is one of the key characteristics rotating machinery signals, which involves in many statistical typology signals. Antoni presents the detail cyclostationary analysis and applications in various rotating machinery[19,20]. In this study cyclostationarity method is applied in feature extraction by combining with the piston wind detection. | <span id='OLE_LINK9'></span><span id='OLE_LINK10'></span>Subway fan is typical rotating machinery, for which, fault diagnosis methods have been studied by many researchers[10,11]. Feature extraction is the most important part of fault diagnosis. In order to extract the feature of the vibration[12] or acoustic signal, many methods have been proposed in the literature, such as short time Fourier transform (STFT), wavelet transform, empirical mode decomposition (EMD), Kurtogram, Infogram and Cyclostationarity, etc. STFT decomposes a time domain signal into a 2D time-frequency representation, but it’s restricted by a trade-off between time resolution and frequency resolution. The wavelet transform introduces a scaling factor which can change the time and frequency resolution, but its performance relies on the selection of mother wavelet. Wang et al. use wavelet approach to evaluate quantitatively gear fault adventure under varying load conditions [13]. EMD is an adaptive decomposition method which has been developed and widely applied in machine fault diagnosis. Recent applications of EMD to fault diagnosis of rotating machinery are summarized in terms of the key components by Lei et al., such as rolling element bearings, gears and rotors[14]. Keegan et al. present a new approached based on EMD, designated as wavelet-bounded empirical mode decomposition (WBEMD)[15]. But the EMD easy gets the problem of model-mixing. The kurtogram is a fourth-order spectral analysis tool recently introduced for detecting and characterizing signal nonstationarities[16,17]. Infogram significantly extends the domain of applicability of the kurtogram, in particular to situations corrupted with impulsive noise or when the relaxation time of the transients is low as compared to their rate of repetition[18]. Cyclostationarity is one of the key characteristics rotating machinery signals, which involves in many statistical typology signals. Antoni presents the detail cyclostationary analysis and applications in various rotating machinery[19,20]. In this study cyclostationarity method is applied in feature extraction by combining with the piston wind detection. | ||

| Line 37: | Line 37: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image1.png|342px]] </div> |

<div id="_Ref510560737" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510560737" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 76: | Line 76: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image18.png|342px]] </div> |

<div id="_Ref510802425" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510802425" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 115: | Line 115: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image25.png|342px]] </div> |

<div id="_Ref511225153" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref511225153" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 136: | Line 136: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image28.png|342px]] </div> |

<div id="_Ref511312063" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref511312063" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 309: | Line 309: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image60.png|342px]] </div> |

<div id="_Ref510560844" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510560844" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 369: | Line 369: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image61.png|342px]] </div> |

<div id="_Ref510560894" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510560894" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 409: | Line 409: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image65.png|342px]] </div> |

<div id="_Ref510560940" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510560940" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 419: | Line 419: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image69.png|342px]] </div> |

<div id="_Ref510560981" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510560981" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 427: | Line 427: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image72.png|342px]] </div> |

<div id="_Ref510561075" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510561075" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 435: | Line 435: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image76.png|342px]] </div> |

<div id="_Ref510561096" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510561096" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 449: | Line 449: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image78.png|342px]] </div> |

<div id="_Ref510561026" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510561026" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 459: | Line 459: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image80.png|342px]] </div> |

<div id="_Ref510561050" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510561050" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 467: | Line 467: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image84.png|324px]] </div> |

<div id="_Ref510561127" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510561127" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 475: | Line 475: | ||

<div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| − | [[Image: | + | [[Image:Review_427877953602-image91.png|342px]] </div> |

<div id="_Ref510561137" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | <div id="_Ref510561137" class="center" style="width: auto; margin-left: auto; margin-right: auto;"> | ||

| Line 490: | Line 490: | ||

===REFERENCES=== | ===REFERENCES=== | ||

| − | [1] A.H. Ã | + | [1] A.H. Ã, S. Zhang, A.C.C. Tan, J. Mathew, Rotating machinery prognostics : State of the art , challenges and opportunities, Mech. Syst. Signal Process. 23 (2009) 724–739. [https://doi.org/10.1016/j.ymssp.2008.06.009. https://doi.org/10.1016/j.ymssp.2008.06.009.] |

| − | [2] Z. Du | + | [2] Z. Du, B. Fan, X. Jin, J. Chi, Fault detection and diagnosis for buildings and HVAC systems using combined neural networks and subtractive clustering analysis, Build. Environ. 73 (2014) 1–11. [https://doi.org/10.1016/j.buildenv.2013.11.021. https://doi.org/10.1016/j.buildenv.2013.11.021.] |

| − | [3] P. Xue | + | [3] P. Xue, S. You, J. Chao, T. Ye, Numerical investigation of unsteady airflow in subway influenced by piston effect based on dynamic mesh, Tunn. Undergr. Sp. Technol. 40 (2014) 174–181. [https://doi.org/10.1016/j.tust.2013.10.004. https://doi.org/10.1016/j.tust.2013.10.004.] |

| − | [4] E. Eftekharian | + | [4] E. Eftekharian, A. Dastan, O. Abouali, J. Meigolinedjad, G. Ahmadi, A numerical investigation into the performance of two types of jet fans in ventilation of an urban tunnel under traffic jam condition, Tunn. Undergr. Sp. Technol. 44 (2014) 56–67. [https://doi.org/10.1016/j.tust.2014.07.005. https://doi.org/10.1016/j.tust.2014.07.005.] |

| − | [5] M. López González | + | [5] M. López González, M. Galdo Vega, J.M. Fernández Oro, E. Blanco Marigorta, Numerical modeling of the piston effect in longitudinal ventilation systems for subway tunnels, Tunn. Undergr. Sp. Technol. 40 (2014) 22–37. [https://doi.org/10.1016/j.tust.2013.09.008. https://doi.org/10.1016/j.tust.2013.09.008.] |

| − | [6] Y.D. Huang, W. Gao, | + | [6] Y.D. Huang, W. Gao, C.N. Kim, A numerical study of the train-induced unsteady airflow in a subway tunnel with natural ventilation ducts using the dynamic layering method, J. Hydrodyn. 22 (2010) 164–172. [https://doi.org/10.1016/S1001-6058 https://doi.org/10.1016/S1001-6058](09)60042-1. |

| − | [7] J.Y. Kim | + | [7] J.Y. Kim, K.Y. Kim, Experimental and numerical analyses of train-induced unsteady tunnel flow in subway, Tunn. Undergr. Sp. Technol. 22 (2007) 166–172. [https://doi.org/10.1016/j.tust.2006.06.001. https://doi.org/10.1016/j.tust.2006.06.001.] |

| − | [8] J.Q. Ni | + | [8] J.Q. Ni, S. Liu, I.M. Lopes, Q. Xie, P. Zheng, C.A. Diehl, Monitoring, modeling, and characterizing single-speed ventilation fans for an animal building, Build. Environ. 118 (2017) 225–233. [https://doi.org/10.1016/j.buildenv.2017.03.036. https://doi.org/10.1016/j.buildenv.2017.03.036.] |

| − | [9] L. Wang | + | [9] L. Wang, H. Tao, X. Du, R. Dai, C. Huang, Theoretical modeling of the platform piston wind wall jet using field measurements and model testing, Tunn. Undergr. Sp. Technol. 45 (2015) 1–9. [https://doi.org/10.1016/j.tust.2014.08.002. https://doi.org/10.1016/j.tust.2014.08.002.] |

| − | [10] J. Zarei, M.A. Tajeddini, | + | [10] J. Zarei, M.A. Tajeddini, H.R. Karimi, Vibration analysis for bearing fault detection and classification using an intelligent filter, Mechatronics. 24 (2014) 151–157. [https://doi.org/10.1016/j.mechatronics.2014.01.003. https://doi.org/10.1016/j.mechatronics.2014.01.003.] |

| − | [11] C. Pezzani, G. Bossio, | + | [11] C. Pezzani, G. Bossio, C. De Angelo, Winding distribution effects on induction motor rotor fault diagnosis, Mechatronics. 24 (2014) 1050–1058. [https://doi.org/10.1016/j.mechatronics.2013.09.008. https://doi.org/10.1016/j.mechatronics.2013.09.008.] |

| − | [12] C.F. Chang | + | [12] C.F. Chang, J.J. Chen, Vibration monitoring of motorized spindles using spectral analysis techniques, Mechatronics. 19 (2009) 726–734. [https://doi.org/10.1016/j.mechatronics.2009.02.009. https://doi.org/10.1016/j.mechatronics.2009.02.009.] |

| − | [13] X. Wang, V. Makis, | + | [13] X. Wang, V. Makis, M. Yang, A wavelet approach to fault diagnosis of a gearbox under varying load conditions, J. Sound Vib. 329 (2010) 1570–1585. [https://doi.org/10.1016/j.jsv.2009.11.010. https://doi.org/10.1016/j.jsv.2009.11.010.] |

| − | [14] Y. Lei | + | [14] Y. Lei, J. Lin, Z. He, M.J. Zuo, A review on empirical mode decomposition in fault diagnosis of rotating machinery, Mech. Syst. Signal Process. 35 (2013) 108–126. [https://doi.org/10.1016/j.ymssp.2012.09.015. https://doi.org/10.1016/j.ymssp.2012.09.015.] |

| − | [15] Keegan J.MooreaMehmetKurtbMelihEritencD. MichaelMcFarlanddLawrence A.BergmandAlexander F.Vakakisa, Wavelet-bounded empirical mode decomposition for measured time series analysis.pdf, | + | [15] Keegan J.MooreaMehmetKurtbMelihEritencD. MichaelMcFarlanddLawrence A.BergmandAlexander F.Vakakisa, Wavelet-bounded empirical mode decomposition for measured time series analysis.pdf, Mech. Syst. Signal Process. 99 (2018) 14–29. [https://doi.org/10.1016/j.ymssp.2017.06.005. https://doi.org/10.1016/j.ymssp.2017.06.005.] |

| − | [16] J. Antoni, Fast computation of the kurtogram for the detection of transient faults, | + | [16] J. Antoni, Fast computation of the kurtogram for the detection of transient faults, Mech. Syst. Signal Process. 21 (2007) 108–124. [https://doi.org/10.1016/j.ymssp.2005.12.002. https://doi.org/10.1016/j.ymssp.2005.12.002.] |

| − | [17] Y. Wang | + | [17] Y. Wang, J. Xiang, R. Markert, M. Liang, Spectral kurtosis for fault detection , diagnosis and prognostics of rotating machines : A review with applications, Mech. Syst. Signal Process. 66–67 (2016) 679–698. [https://doi.org/10.1016/j.ymssp.2015.04.039. https://doi.org/10.1016/j.ymssp.2015.04.039.] |

| − | [18] J. Antoni, The | + | [18] J. Antoni, The infogram : Entropic evidence of the signature of repetitive transients, Mech. Syst. Signal Process. 74 (2016) 73–94. [https://doi.org/10.1016/j.ymssp.2015.04.034. https://doi.org/10.1016/j.ymssp.2015.04.034.] |

| − | [19] J. Antoni, Cyclostationarity by examples, | + | [19] J. Antoni, Cyclostationarity by examples, Mech. Syst. Signal Process. 23 (2009) 987–1036. [https://doi.org/10.1016/j.ymssp.2008.10.010. https://doi.org/10.1016/j.ymssp.2008.10.010.] |

| − | [20] J. Antoni, G. Xin, | + | [20] J. Antoni, G. Xin, N. Hamzaoui, Fast computation of the spectral correlation, Mech. Syst. Signal Process. 92 (2017) 248–277. [https://doi.org/10.1016/j.ymssp.2017.01.011. https://doi.org/10.1016/j.ymssp.2017.01.011.] |

| − | [21] J. Serrà | + | [21] J. Serrà, J.L. Arcos, An empirical evaluation of similarity measures for time series classification, Knowledge-Based Syst. 67 (2014) 305–314. [https://doi.org/10.1016/j.knosys.2014.04.035. https://doi.org/10.1016/j.knosys.2014.04.035.] |

| − | [22] K. Shin | + | [22] K. Shin, S.-H. Lee, Machinery Fault Diagnosis Using Two-Channel Analysis Method Based on Fictitious System Frequency Response Function, Shock Vib. 2015 (2015) 1–7. [https://doi.org/10.1155/2015/561238. https://doi.org/10.1155/2015/561238.] |

| − | [23] K. Shin, An alternative approach to measure similarity between two deterministic transient signals, | + | [23] K. Shin, An alternative approach to measure similarity between two deterministic transient signals, J. Sound Vib. 371 (2015) 434–445. [https://doi.org/10.1016/j.jsv.2016.02.037. https://doi.org/10.1016/j.jsv.2016.02.037.] |

Revision as of 15:30, 27 May 2020

ABSTRACT

Subway fans play significant roles in subway system such as ventilation, smoke discharging and cooling. Nowadays, fast and effective condition monitoring of subway fan is highly important for the safety and comfort in subway system. However, as one of the most important monitoring tool, fan vibration signals are strongly interfered by frequent piston winds during train arrival-depart, such effect will cause many unnecessary false alarm and deteriorate the fault detection performance. To overcome this problem, this study proposes a condition monitoring method of subway fan under piston wind effect. Piston wind detection method and feature extraction method two key techniques for CMM-PWD method. The piston wind detection method is based on similarity estimation and a new similarity criterion is proposed in this paper. For feature extraction, cyclostationary analysis is exploited for the cyclic feature extraction. And the proposed approach is verified by the piston wind experiments and bolt looseness experiments of axial flow fan and jet fan, which are widely used in subway ventilation system. The results show that the piston wind is accurately detected by proposed method, and fan fault feature is effectively extracted. More importantly, this approach could have great potential to extend to deal with other background interference in fault diagnosis of rotating machinery.

Keywords: Condition monitoring; Subway fan; Piston wind effect; Similarity estimation; Feature extraction

1. INTRODUCTION

With the rapid development of the public transport systems, the subway is one of the most important section of large cities’ transport system. Subway fan is widely used in ventilation system which plays a significant role in ventilation, eliminating smoke and cooling. Thus, subway fan condition monitoring and fault diagnosis are essential to guarantee safe operation[1,2]. However, train passing causes unsteady airflows in subway stations and tunnels. This phenomenon is called piston effect, which is a challenge for fan condition monitoring and fault diagnosis. Since decades, many researchers have focused on the issue of piston effect in subways stations and tunnels. Peng et al. uses in situ experimental data and computational fluid dynamics (CFD) method to analyze the unsteady air flow in subway station and tunnel[3]. The effects of different kinds of jet fans in the ventilation airflow field were analyzed by fluent simulation [4]. González and team members present a numerical methodology based on a dynamic mesh technique to properly simulate the influence of piston effect in the ventilation system of subway tunnels[5]. Huang et al. investigate numerically the characteristics of train-induced unsteady airflow in a subway tunnel with natural ventilation ducts by using the dynamic layering method for the moving boundary method[6]. Kim et al. analyze the unsteady three-dimensional flow in the subway tunnel caused by train, both experimental and computational studies have been conducted[7]. Monitoring, modeling, and characterizing single-speed ventilation fans was proposed by Qin et al[8]. Wang et al. create and validate the theoretical model of the platform piston wind wall jet through three methods: mathematical theory modeling, field measurements and a scale model test[9]. But, there are few studies on the fault diagnosis of fan condition by taking the piston wind effect into account. And piston wind effect will cause many unnecessary false alarm and deteriorate the fault detection performance.

Subway fan is typical rotating machinery, for which, fault diagnosis methods have been studied by many researchers[10,11]. Feature extraction is the most important part of fault diagnosis. In order to extract the feature of the vibration[12] or acoustic signal, many methods have been proposed in the literature, such as short time Fourier transform (STFT), wavelet transform, empirical mode decomposition (EMD), Kurtogram, Infogram and Cyclostationarity, etc. STFT decomposes a time domain signal into a 2D time-frequency representation, but it’s restricted by a trade-off between time resolution and frequency resolution. The wavelet transform introduces a scaling factor which can change the time and frequency resolution, but its performance relies on the selection of mother wavelet. Wang et al. use wavelet approach to evaluate quantitatively gear fault adventure under varying load conditions [13]. EMD is an adaptive decomposition method which has been developed and widely applied in machine fault diagnosis. Recent applications of EMD to fault diagnosis of rotating machinery are summarized in terms of the key components by Lei et al., such as rolling element bearings, gears and rotors[14]. Keegan et al. present a new approached based on EMD, designated as wavelet-bounded empirical mode decomposition (WBEMD)[15]. But the EMD easy gets the problem of model-mixing. The kurtogram is a fourth-order spectral analysis tool recently introduced for detecting and characterizing signal nonstationarities[16,17]. Infogram significantly extends the domain of applicability of the kurtogram, in particular to situations corrupted with impulsive noise or when the relaxation time of the transients is low as compared to their rate of repetition[18]. Cyclostationarity is one of the key characteristics rotating machinery signals, which involves in many statistical typology signals. Antoni presents the detail cyclostationary analysis and applications in various rotating machinery[19,20]. In this study cyclostationarity method is applied in feature extraction by combining with the piston wind detection.

In the present study, the condition monitoring method under piston wind effect (called CMM-PWE) is proposed. The innovation of the proposed method not only realizes the detection of piston effect and feature extraction, but also can be implemented for real-time condition monitoring. This paper is structured as follows: in section 2, a description of the proposed method is given. The piston wind detection method is based on similarity estimation, and the detail background of similarity method is presented. The second-order cyclostationary method is utilized in feature extraction, and a brief introduction is also presented in this section. Section 3 introduces experiment setup for the validation of the proposed method. Section 4 presents experiment results and illustrates how to detect the piston wind effect and how to extract fault feature. Finally, section 5 concludes the paper.

2. Method

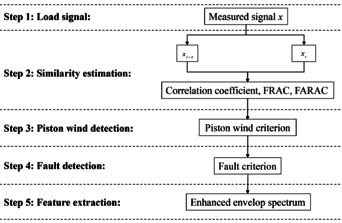

The proposed CMM-PWE method will be illustrated in the following three parts. The first part discusses the proposed procedure. The proposed similarity estimation method is introduced in the second. The third part explains the cyclostationarity theory and how the method could be applied for feature extraction.

2.1 Condition monitoring method under piston wind effect (CMM-PWE)

In this proposed CMM-PWE method, the piston wind will be detected before fault detection and feature extraction. Due to the piston wind just affect the measured vibration signal for a short time, so the piston wind can be seen as interference rather than any fault. For this reason, the measured signal can be free of fault detection and feature extraction when piston wind occurs. The Fig. 1 summarizes the proposed procedure for condition monitoring method under piston wind effect.

The technical route of proposed condition monitoring method under piston wind effect is illustrated in Fig. 1, where the detail algorithm of the technical route is expressed as follows.

Step 1: The subway fan vibration signal is sampled using data acquired system and accelerator sensors placed on the fan.

Step 2: Two time series and segments are extracted from the acquired vibration signal in time. and are expressed as Eq.(1-2).

|

(1) |

|

(2) |

Where is the time delay of each time series segment, which is set by similarity estimation method. is instant time of signal .

The similarity is calculated between and . And three kind of similarity estimation method are introduced in next subsection2.2. If the two segments are not similar to each other, it seems that the signal itself is accidentally changed and can be seen as sudden signal, which may be caused by piston wind, other interference or faults.

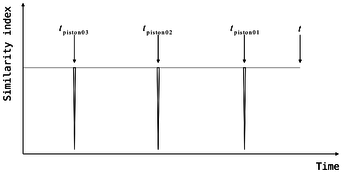

Step 3: In this step, one criterion is put forward to determine whether piston wind occurs. is the maximum piston wind lasting time, which is set based on subway station actual condition. , and are the piston wind occurring, disappearing or fault moments respectively. is the most recent time of low similarity index. is the second last time of low similarity index. is the third last time of low similarity index. These relationship can be shown in Fig. 2.

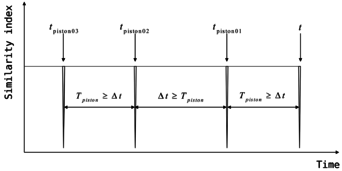

The piston wind detection criterion is expressed as Eq.(3-5), and this working condition is shown in Fig. 3.

|

(3) |

|

(4) |

|

(5) |

According to Eq.(5) and Fig. 3, it shows that piston wind sudden signal has been occurred. The Eq.(3) shows that the sudden signal last time is longer than standard length . And the Eq.(4) shows that the new sudden signal last time is shorter than standard length , so the sudden signal can be seen as caused by piston wind.

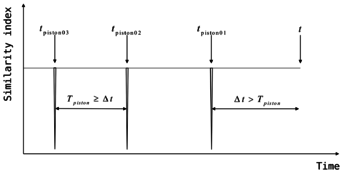

Step 4: In this step, one standard criterion is put forward as Eq.(5) and Eq.(6), to determine whether subway fan fault occurs.

|

(6) |

According to Eq.(5) and Fig. 4, it shows that piston wind sudden signal has been occurred. And the Eq.(6) shows that the sudden signal last time is longer than standard length , so the sudden signal can be seen as caused by faults.

Step 5: If subway fan fault occurs, cyclostationary analysis is applied for feature extraction.

For transient signal with piston wind, this proposed method could reduce false alarm and guarantee fault diagnosis to some extent. The proposed method includes two key techniques: similarity estimation and feature extraction.

2.2 Similarity estimate

Similarity is one of the best ways to measure the difference between the vibration signals before and during piston wind. Various types of similarity methods can be used in this application[21]. These similarity methods include distance-based measures, dynamic time warping, correlation-based measures, etc. In addition, there are many other specific similarity measures for specific applications. For the similarity measures mentioned above, the correlation coefficient is the most frequently used for time series signals in sound and vibration applications, which is defined as

|

(7) |

Where is the covariance between signals and , and , are the standard deviations of the corresponding signals. The correlation coefficient can quantify the linear relationship between two signals.

Beside in time domain, the frequency response assurance criterion (FRAC) is extensively used in frequency domain[22], which is defined as.

|

(8) |

Where and are the power spectrum density (PSD) of signal and , and are the lower and upper frequency limits of power spectrum density and usually take the full frequency band of spectrum, and the symbol ‘*’ denotes the complex conjugate. This method is used as a measure of the linear relationship between two spectrum data.

Correlation coefficient and FRAC were developed as probabilistic and statistical measures and have been successfully applied in numerous applications. However, researchers have found that correlation-based measures do not always provide sensible results in some cases with deterministic transient signals. This may be due to the correlation-based similarity measures taking into account both the magnitude and shape of signals simultaneously. So that some researcher proposed the M–S similarity measure which separately consider the magnitude similarity and the shape similarity[23].

Compared with the above signal similarity estimations, this study proposes the spectral amplitude similarity which only considers the magnitude similarity. The frequency amplitude response assurance criterion (FARAC) is defined as follows.

|

(9) |

Where and are the PSD amplitudes of signal and , and are the lower and upper frequency limits of PSD.

In this paper, the performance of the correlation coefficient, FRAC and FARAC are compared in section 4.

2.3 Feature extraction

Nowadays it is widely accepted that vibration signals during fans operation are perfectly fitted to the theory of cyclostationary processes. In general, a cyclostationary processes is a signal having statistical properties that vary cyclically with time. For rotating machine, its second–order statistics is usually periodic, which can be used as an index for fault diagnosis.

As stated earlier, whether stationary or cyclostationary, a signal can be identified from the state of its autocorrelation. From a mathematical point of view, it is expressed as follows:

|

(10) |

Where is the delay between two observations, is mean operation symbol. By the property of , stationary and cyclostationary second order can be shown as follows.

|

(11) |

where is the cyclic period, and the basic cyclic frequency is expressed as follows:

|

(12) |

The autocorrelation function is periodic and it can be expressed as a Fourier series:

|

(13) |

The Fourier transforms, with respect to , gives the function of the spectral correlation density (SCD) as follows.

|

(14) |

To reveal the coherence coefficients in details, thus cyclic spectral coherence (CSC) function is employed by normalizing the CSD image as follows:

|

(15) |

where represents the CSC image. To extract the cyclic frequency components, the enhanced envelop spectrum (EES) is the results of CSC values summed up along the continuous frequency axis, and normalized by the signal energy as:

|

(16) |

where represents the EES function which is a figure display directly the cyclic components distribution.

Subway fan is typical rotating machinery, and its vibration signal is belonging to cyclotationarity signal. In this study, cyclostationary analysis method is used to feature extract for subway fan vibration signals.

3. Experiments

To verify the effectiveness of proposed piston wind detection and feature extraction method, two experiments are carried out as follows.

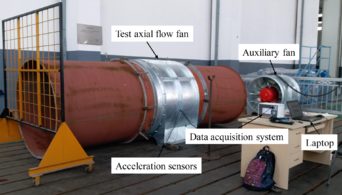

3.1 Axial flow fan experiment description

In this section, the proposed method is verified via axial flow fan under piston wind and fault experiment rig. The picture of the test rig is shown in Fig. 5, which mainly includes three parts: (1) test axial flow fan, (2) auxiliary fan, (3) data acquisition (DAQ) system. The auxiliary fan is used to supply wind for axial flow fan to simulate the piston wind, which has the same working condition as the test axial flow fan does. The DAQ system includes a data acquisition system (USB-4432, NI Inc.), two accelerators (LW186548, LW186548, PCB Inc.). The sampling frequency (Fs) is set as 5120Hz in all the experiments. The detail information of accelerators is provided in Table 1, and axial flow fan detail information is provided in Table 2.

For axial flow fan experiment, it includes the piston wind experiment and bolt looseness experiment. The piston wind experimental procedure includes four steps as follows:

(1) Start up the test axial flow fan; (2) Start up the auxiliary fan; (3) Power off the auxiliary fan; (4) Power off the test axial flow fan.

The bolt looseness experiment procedure includes four steps as follows:

(1) Start up the test axial flow fan; (2) Loosen one of four bolts on the test axial flow fan; (3) Power off the test axial flow fan; (4) Fixed fan bolt.

Table 1

The detail information of accelerators.

| Sensor numbers | Accelerator 1 | Accelerator 2 | |

| Sensitivity | 50.18(mV/g) | 51.55(mV/g) |

Table 2

The axial flow fan detail information.

| Parameters | Air flow rate | Total pressure | Speed | Power | Voltage | |

| Values | 108000m3/h | 900Pa | 3000r/min | 45kW | 380V |

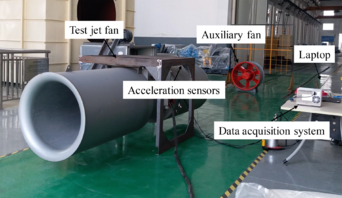

3.2 Jet fan experiment description

In this section, the proposed method is validated using vibration signals of jet fan and an experiment rig has been set up. The picture of the test rig is shown in Fig. 6, which also includes three parts: (1) test jet fan, (2) auxiliary fan, (3) data acquisition (DAQ) system. The information of jet fan is shown in Table 3. And the DAQ system is the same as that in axial flow fan experiment. In addition, this experiment rig has one difference from the former one. The test jet fan has different fixing method from the axial flow fan. One suspension device is designed, which can simulate the suspending condition. For jet fan experiment, it also includes two sections that the piston wind experiment and bolt looseness experiment. And the detail procedures are the same as that in axial flow fan experiment.

Table 3

The information of jet fan.

| Parameters | Air flow rate | Total pressure | Speed | Power | Voltage | |

| Values | 30500m3/h | 540Pa | 3000r/min | 7.5kW | 380V |

4. RESULTS AND DISCUSSION

4.1 Experiments for axial flow fan

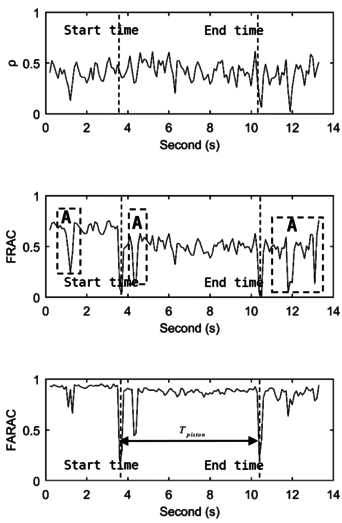

The performance of the piston wind detection method described in previous section is investigated using measured data. For similarity estimate methods, correlation coefficient ( ), frequency response assurance criterion (FRAC) and proposed frequency amplitude response assurance criterion (FARAC) are calculated. Through axial flow fan and jet fan experiments, the best method among them will be obtained.

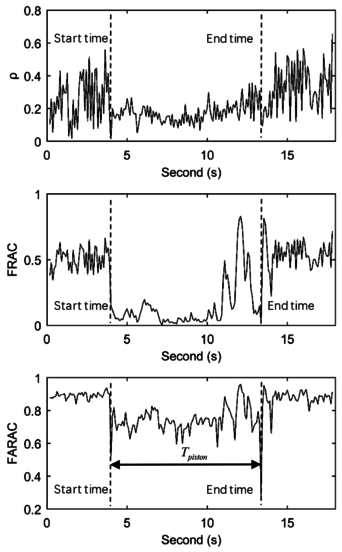

4.1.1 Case 1: Axial flow fan with piston wind

For axial flow fan with piston wind, the correlation coefficient ( ), FRAC, and FARAC are calculated and shown in Fig. 7. The correlation coefficient ( ) performance is very poor and can’t detect the start time and end time of piston wind. FRAC has a better performance than , but it is usually fault detection that there are some confused low similarity index time as shown region A. The proposed FARAC exactly detects the start time and end time of piston wind effect, and the piston wind last time is shown in the figure. In addition, the FARAC are tested to show the stable and effective performance.

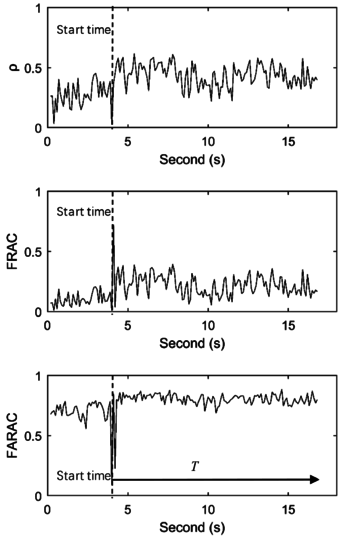

4.1.2 Case 2: Axial flow fan with bolt looseness

Besides the piston wind, fault detection is another key issue. In axial flow fan fault experiment, the bolt looseness is set up. Based on the similarity estimate method, the fault is detected. The vibration data is acquired from accelerators in axial flow fan fault experiment, and correlation coefficient ( ), FRAC and proposed FARAC are calculated and shown in Fig. 8. Correlation coefficient ( ) and FRAC show very poor performance that both method can’t detect the start time exactly. From the FARAC detection and the sudden signal last time and , the axial flow fan can be detected with fault by proposed method. From the figure, similarity indexes have some fluctuation in start and end time, which caused by the instability of the flow.

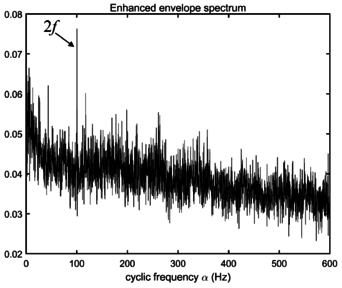

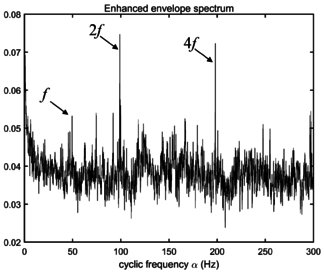

The bolt looseness fault can be detected by proposed FARAC method. However, for fault diagnosis, fault feature can be used as criterion for detail fault diagnosis. The axial flow fan normal working condition enhanced envelop spectrum (EES) is shown in Fig. 9, which can be calculated by Eq.(16). In EES, labeled cyclic frequency is the characteristic frequency axial flow fan in normal working condition, in which is the shaft frequency.

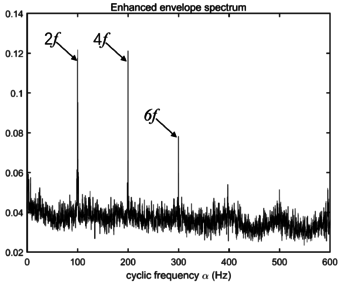

The EES of bolt looseness is shown in Fig. 10. It shows that the labeled cyclic frequencies alpha= , , are the characteristic frequencies of axial flow fan in bolt looseness fault. Compared with the EES of normal condition in Fig. 9, the bolt looseness fault with axial flow fan can be effectively diagnosed by cyclic feature extraction.

4.2 Experiments for jet fan

Feature extraction method is important part of proposed method, which can be used for fault diagnosis. The performance of the feature extraction method described in previous section is investigated using measured data in this section.

4.2.1 Case 1: Jet fan with piston wind effect

In addition to the axial flow fan, jet fan is another important equipment in ventilation system. Due to the suspending installation, piston wind has more serious effect than axial flow fan. Correlation coefficient ( ), FRAC and proposed FARAC are calculated and shown in Fig. 11. From the Fig. 11, correlation coefficient and FRAC show poor performance. And both method can’t detect start time and end time exactly. During the piston wind condition, correlation coefficient and FRAC also have worse performance than the proposed FARAC. Whereas, by the proposed FARAC, the piston wind can be detected exactly and also can be got.

4.2.2 Case 2: Jet fan with bolt looseness

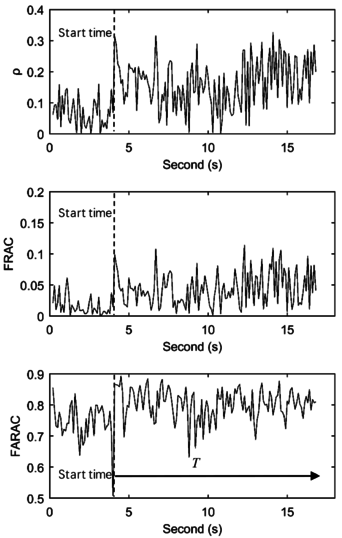

For jet fan fault detection, correlation coefficient ( ),FRAC and proposed FARAC are calculated and shown in Fig. 12. Both correlation coefficient ( ) and FRAC can’t detect the bolt looseness start time. But proposed FARAC can detect it exactly. From the start time, duration time satisfies , so the bolt looseness is detected by proposed method.

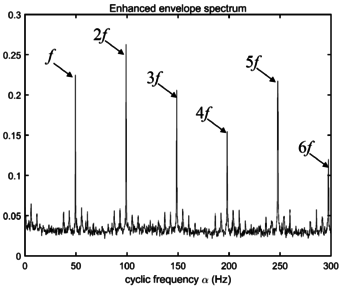

For jet fan, the EES of normal working condition is calculated by Eq.(16) and shown in Fig. 13. It shows that the labeled cyclic frequencies alpha= , and can represent the characteristic frequencies of jet fan in normal working condition.

For the jet fan in bolt looseness fault, the EES is calculated and shown in Fig. 14. The labeled cyclic frequencies alpha= , , , , and are charactristic frequencies for jet fan in bolt looseness fault. Compared with the EES of normal condition in Fig. 13, the bolt looseness fault with jet fan can be effectively diagnosed by cyclic feature extraction. In addition, the cyclic frequencies of bolt looseness fault for jet and axial flow fans are different to each other. Moreover, cyclic feature extraction can be extended for fault diagnosis.

5. CONCLUSIONS

In this paper, a new method for condition monitoring under piston wind effect of subway fan is presented. Similarity estimate method and cyclostationary analysis are two key techniques for CMM-PWD method. The presented method is validated through in lab-scale experiments of axial flow fan and jet fan. For piston wind detection, the proposed frequency amplitude response assurance criterion (FARAC) has better performance than the conventional methods such as the correlation coefficient and frequency response assurance criterion (FRAC). For fan feature extraction, the cyclostationary analysis was employed to inspect the railway fan fault. Moreover, two typical experiments of fan bolt looseness are set up to verify the proposed CMM-PWD method. Results show that the magnitudes of the cyclic frequency components are able to reveal the spectral characteristics of subway fans, and such magnitudes keep the similar trends with potential faults. The proposed method provides an alternative way to realize the fast and effective condition monitoring of railway fans under piston wind effect, and it can be extended to detect other background interference and typical faults.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the financial supports of the National Key R&D Plan of China (No. 2016YFF0203300), the National Natural Science Foundation of China (No. 51706199) and the Fundamental Research Funds for the Central Universities (No. 2017QNA4015). Authors appreciate valuable helps for the experiment support from the Zhejiang Shang Feng Gao Ke Co.Ltd.

REFERENCES

[1] A.H. Ã, S. Zhang, A.C.C. Tan, J. Mathew, Rotating machinery prognostics : State of the art , challenges and opportunities, Mech. Syst. Signal Process. 23 (2009) 724–739. https://doi.org/10.1016/j.ymssp.2008.06.009.

[2] Z. Du, B. Fan, X. Jin, J. Chi, Fault detection and diagnosis for buildings and HVAC systems using combined neural networks and subtractive clustering analysis, Build. Environ. 73 (2014) 1–11. https://doi.org/10.1016/j.buildenv.2013.11.021.

[3] P. Xue, S. You, J. Chao, T. Ye, Numerical investigation of unsteady airflow in subway influenced by piston effect based on dynamic mesh, Tunn. Undergr. Sp. Technol. 40 (2014) 174–181. https://doi.org/10.1016/j.tust.2013.10.004.

[4] E. Eftekharian, A. Dastan, O. Abouali, J. Meigolinedjad, G. Ahmadi, A numerical investigation into the performance of two types of jet fans in ventilation of an urban tunnel under traffic jam condition, Tunn. Undergr. Sp. Technol. 44 (2014) 56–67. https://doi.org/10.1016/j.tust.2014.07.005.

[5] M. López González, M. Galdo Vega, J.M. Fernández Oro, E. Blanco Marigorta, Numerical modeling of the piston effect in longitudinal ventilation systems for subway tunnels, Tunn. Undergr. Sp. Technol. 40 (2014) 22–37. https://doi.org/10.1016/j.tust.2013.09.008.

[6] Y.D. Huang, W. Gao, C.N. Kim, A numerical study of the train-induced unsteady airflow in a subway tunnel with natural ventilation ducts using the dynamic layering method, J. Hydrodyn. 22 (2010) 164–172. https://doi.org/10.1016/S1001-6058(09)60042-1.

[7] J.Y. Kim, K.Y. Kim, Experimental and numerical analyses of train-induced unsteady tunnel flow in subway, Tunn. Undergr. Sp. Technol. 22 (2007) 166–172. https://doi.org/10.1016/j.tust.2006.06.001.

[8] J.Q. Ni, S. Liu, I.M. Lopes, Q. Xie, P. Zheng, C.A. Diehl, Monitoring, modeling, and characterizing single-speed ventilation fans for an animal building, Build. Environ. 118 (2017) 225–233. https://doi.org/10.1016/j.buildenv.2017.03.036.

[9] L. Wang, H. Tao, X. Du, R. Dai, C. Huang, Theoretical modeling of the platform piston wind wall jet using field measurements and model testing, Tunn. Undergr. Sp. Technol. 45 (2015) 1–9. https://doi.org/10.1016/j.tust.2014.08.002.

[10] J. Zarei, M.A. Tajeddini, H.R. Karimi, Vibration analysis for bearing fault detection and classification using an intelligent filter, Mechatronics. 24 (2014) 151–157. https://doi.org/10.1016/j.mechatronics.2014.01.003.

[11] C. Pezzani, G. Bossio, C. De Angelo, Winding distribution effects on induction motor rotor fault diagnosis, Mechatronics. 24 (2014) 1050–1058. https://doi.org/10.1016/j.mechatronics.2013.09.008.

[12] C.F. Chang, J.J. Chen, Vibration monitoring of motorized spindles using spectral analysis techniques, Mechatronics. 19 (2009) 726–734. https://doi.org/10.1016/j.mechatronics.2009.02.009.

[13] X. Wang, V. Makis, M. Yang, A wavelet approach to fault diagnosis of a gearbox under varying load conditions, J. Sound Vib. 329 (2010) 1570–1585. https://doi.org/10.1016/j.jsv.2009.11.010.

[14] Y. Lei, J. Lin, Z. He, M.J. Zuo, A review on empirical mode decomposition in fault diagnosis of rotating machinery, Mech. Syst. Signal Process. 35 (2013) 108–126. https://doi.org/10.1016/j.ymssp.2012.09.015.

[15] Keegan J.MooreaMehmetKurtbMelihEritencD. MichaelMcFarlanddLawrence A.BergmandAlexander F.Vakakisa, Wavelet-bounded empirical mode decomposition for measured time series analysis.pdf, Mech. Syst. Signal Process. 99 (2018) 14–29. https://doi.org/10.1016/j.ymssp.2017.06.005.

[16] J. Antoni, Fast computation of the kurtogram for the detection of transient faults, Mech. Syst. Signal Process. 21 (2007) 108–124. https://doi.org/10.1016/j.ymssp.2005.12.002.

[17] Y. Wang, J. Xiang, R. Markert, M. Liang, Spectral kurtosis for fault detection , diagnosis and prognostics of rotating machines : A review with applications, Mech. Syst. Signal Process. 66–67 (2016) 679–698. https://doi.org/10.1016/j.ymssp.2015.04.039.

[18] J. Antoni, The infogram : Entropic evidence of the signature of repetitive transients, Mech. Syst. Signal Process. 74 (2016) 73–94. https://doi.org/10.1016/j.ymssp.2015.04.034.

[19] J. Antoni, Cyclostationarity by examples, Mech. Syst. Signal Process. 23 (2009) 987–1036. https://doi.org/10.1016/j.ymssp.2008.10.010.

[20] J. Antoni, G. Xin, N. Hamzaoui, Fast computation of the spectral correlation, Mech. Syst. Signal Process. 92 (2017) 248–277. https://doi.org/10.1016/j.ymssp.2017.01.011.

[21] J. Serrà, J.L. Arcos, An empirical evaluation of similarity measures for time series classification, Knowledge-Based Syst. 67 (2014) 305–314. https://doi.org/10.1016/j.knosys.2014.04.035.

[22] K. Shin, S.-H. Lee, Machinery Fault Diagnosis Using Two-Channel Analysis Method Based on Fictitious System Frequency Response Function, Shock Vib. 2015 (2015) 1–7. https://doi.org/10.1155/2015/561238.

[23] K. Shin, An alternative approach to measure similarity between two deterministic transient signals, J. Sound Vib. 371 (2015) 434–445. https://doi.org/10.1016/j.jsv.2016.02.037.

Document information

Published on 03/07/20

Accepted on 24/06/20

Submitted on 25/05/20

Volume 36, Issue 3, 2020

DOI: 10.23967/j.rimni.2020.06.004

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?