| Line 422: | Line 422: | ||

|- | |- | ||

| <math>A</math> | | <math>A</math> | ||

| − | | | + | | variable that depends on <math display="inline">Re</math> and <math display="inline">\epsilon</math> (dimensionless); <math display="inline">A=</math><math>\frac{Re}{z}\cdot \frac{\epsilon }{3.71}</math> |

|- | |- | ||

| <math>B</math> | | <math>B</math> | ||

| − | | | + | | variable that depends on <math display="inline">Re</math> and <math display="inline">z</math> (dimensionless); <math display="inline">B=</math><math>\mathrm{ln}\,(Re)-ln(z)\approx \mathrm{ln}\,\left( Re\right) -0.7794</math> |

|- | |- | ||

| <math>C</math> | | <math>C</math> | ||

| − | | | + | | variable that depends on <math display="inline">x</math> (dimensionless); <math display="inline">C=</math><math>\mathrm{ln}\,\left( x\right)</math> |

|- | |- | ||

| <math>f</math> | | <math>f</math> | ||

| − | | | + | | Darcy (Moody) flow friction factor (dimensionless) – main output parameter |

|- | |- | ||

| <math>s</math> | | <math>s</math> | ||

| − | | | + | | approximation of <math display="inline">y</math> by a truncated series about infinity; <math display="inline">{y}_{i}=</math><math>\sum _{i=1}^{+\infty }{s}_{i}</math> |

|- | |- | ||

| <math>Re</math> | | <math>Re</math> | ||

| − | | | + | | Reynolds number (dimensionless) – main input parameter |

|- | |- | ||

| <math>x</math> | | <math>x</math> | ||

| − | | | + | | variable that depends on <math display="inline">A</math> and <math display="inline">B</math> (dimensionless); <math display="inline">x=A+</math><math>B</math> |

|- | |- | ||

| <math>y</math> | | <math>y</math> | ||

| − | | | + | | approximation of <math display="inline">\omega (x)-</math><math>x</math>, i.e. of <math display="inline">W\left( {e}^{x}\right) -</math><math>x</math> |

|- | |- | ||

| <math>{y}_{sr}</math> | | <math>{y}_{sr}</math> | ||

| − | | | + | | approximation of <math display="inline">\omega (x)-</math><math>x</math>, i.e. of <math display="inline">W\left( {e}^{x}\right) -</math><math>x</math> found by symbolic regression |

|- | |- | ||

| <math>Y</math> | | <math>Y</math> | ||

| − | | <math display="inline">y</math | + | | <math display="inline">y</math> suitable for error minimization using function <math display="inline">{\xi }_{1}</math> |

|- | |- | ||

| <math>z</math> | | <math>z</math> | ||

| − | | | + | | constant (dimensionless); <math display="inline">z=</math><math>\frac{2\cdot 2.51}{\mathrm{ln}\,\left( 10\right) }</math> |

|- | |- | ||

| <math>\alpha</math> | | <math>\alpha</math> | ||

| − | | | + | | constant (dimensionless); half of the smallest term in the asymptotic series |

|- | |- | ||

| <math>\epsilon</math> | | <math>\epsilon</math> | ||

| − | | | + | | Relative roughness of inner pipe surface (dimensionless) – main input parameter |

|- | |- | ||

| <math>{\delta }_{\%}</math> | | <math>{\delta }_{\%}</math> | ||

| − | | | + | | Relative error (%); <math display="inline">{\delta }_{\%}=</math><math>\frac{f-{f}_{i}}{f}\cdot 100\%</math> |

|- | |- | ||

| − | | <math display="inline">\xi</math> | + | | <math display="inline">\xi</math> and <math display="inline">{\xi }_{1}</math> |

| − | | | + | | error-functions developed using symbolic regression |

|- | |- | ||

| <math>e</math> | | <math>e</math> | ||

| − | | | + | | exponential function |

|- | |- | ||

| <math>{log}_{10}</math> | | <math>{log}_{10}</math> | ||

| − | | | + | | logarithm with base 10 |

|- | |- | ||

| <math>ln</math> | | <math>ln</math> | ||

| − | | | + | | natural logarithm |

|- | |- | ||

| <math>W</math> | | <math>W</math> | ||

| − | | | + | | Lambert <math display="inline">W</math>-function |

|- | |- | ||

| <math>\omega</math> | | <math>\omega</math> | ||

| − | | | + | | Wright <math display="inline">\omega</math> -function |

|- | |- | ||

| <math>i</math> | | <math>i</math> | ||

| − | | | + | | counter |

|- | |- | ||

| − | | | + | | ''wrightOmega'' |

| − | | | + | | Matlab’s built-in function |

|- | |- | ||

| − | | | + | | ''Globalsearch'' |

| − | | | + | | Matlab’s built-in solver |

|} | |} | ||

| − | |||

==References== | ==References== | ||

Revision as of 09:34, 23 March 2020

Abstract: Using only a limited number of computationally expensive functions, we show a way how to construct accurate and computationally efficient approximations of the Colebrook equation for flow friction based on the asymptotic series expansion of the Wright ω-function and on symbolic regression. The results are verified with 8 million of Quasi-Monte Carlo points covering the domain of interest for engineers. In comparison with the built-in “wrightOmega” feature of Matlab R2016a, the herein introduced related approximations of the Wright ω-function significantly accelerate the explicit solution of the Colebrook equation. Such balance between speed and accuracy could be achieved only using symbolic regression, a computational intelligence approach that can find optimal coefficients and the best structure of the equation. The presented numerical experiments show that the novel symbolic regression approximation reduced the maximal relative error from 0.045% to 0.00337%, i.e. more than 13 times, even the complexity remains almost unchanged. Moreover, we also provide a novel highly precise symbolic regression approximation (max. relative error 0.000024%), which, for the same speed as asymptotic expansion, reduces the relative error by factor 219. This research is motivated by estimation of flow rate using electrical parameters of pumps where direct measurement is not always possible such as in offshore underwater pipelines.

Keywords: Colebrook equation; Hydraulic flow friction; Wright ω-function; explicit approximations; symbolic regression; computational intelligence

1. Introduction

The empirical Colebrook equation [1]; Eq. (1)., widely used in hydraulics, implicitly relates in an entangled logarithmic form the known Reynolds number and the relative roughness of inner pipe surface with the unknown Darcy flow friction factor . The equation is based on the experiment by Colebrook and White from 1937 [2].

|

(1) |

To date, the Colebrook equation can be explicitly expressed only in terms of the Lambert W-function, the function introduced by Corless et al. in 1996 [3]. Based on series expansion of its cognate, the Wright ω-function, introduced by Wright [4], explicit approximations of the Colebrook equation of any degree of accuracy can be constructed. With only two computationally expensive logarithmic functions and without exponential nor non-integer power functions, the herein presented approximations are also computationally efficient.

Such balance between speed and accuracy could be achieved only using symbolic regression, a computational intelligence approach that can find optimal coefficients and the best structure of equation. This analysis is needed as an introduction for our method for estimation of flow rate using electrical parameters of pumps where direct measurement is not always possible such as in offshore underwater pipelines.

The paper has the following structure. After this Introducion, Section 2 brings transformation of the Colebrook equation through the Wright ω-function. As the the Wright ω-function is computationally demanding, Section 3 introdudes series expansion of ω(x)-x using assymptotic expansion and symbolic regression. Then, Section 4 presents approximations suitable for engineering use. The novelty of this paper includes introducing of optimal constants and simple rational functions, which reduce the relative error of the assymptotic expansion for the Colebrook equation by global optimization and symbolic regression (Sections 3.1 and Section 4.1). Moreover, the novel symbolic regression approximation of the Colebrook equation based on minimization of the relative error is introduces in Section 4.2. In comparison with asymptotic expansion of the same complexity, the novel symbolic-based rational approximation reduces the maximal relative error from 0.045% to 0.00337%, i.e. more than 13 times. Finally, Section 5 includes conclusions and future work.

2. Transformation through the Wright ω-function

In 1998, Keady [5] was the first to found that the Colebrook equation can be rearranged in explicit form in terms of the Lambert W-function (however Keady’s solution has some undesired computational side effects related to a fast-growing term which can cause overflow error [6,7]). As explained by Hayes [8], the Lambert W-function, named after the mathematician Johann Heinrich Lambert, who lived in XVIII century, is defined as the inverse of F(x)=x·ex where is an exponential function. The Lambert W-function has provided to date the unique available closed-form explicit solution of the Colebrook equation in respect to the unknown Darcy’s flow friction factor . According to Brkić and Praks [9,10], Biberg [11], Rollmann and Spindler [12], among others, the Colebrook equation can be exactly explicitly solved by Eq. (2).

|

(2) |

In Eq. (2), the symbol W denotes the Lambert W-function and represents the Wright ω-function, where . Further, for the real engineering implementation denotes an approximation of , where ; ; ; and .

In this review, we will test approximations given by the asymptotic expansion of , as we confirmed that the accuracy and especially the speed of the algorithm very depends on the used implementation of the Wright ω-function. We will start with approximations based on the asymptotic expansion of the Wright ω-function, and then we will introduce novel approximations of based on the symbolic regression tool Eureqa [13,14].

3. Methods and discussion

In addition to the already showed Eq. (3) [9] which represents only the first term of series expansion from Table 1, in Section 3.1.1., we show additional terms. Using them, the accuracy of explicit approximations which is put in the form suitable for engineering use in Section 3.2.1. is increased significantly (In addition at the end of Section 3.1.1., we show an efficient strategy to reduce error using symbolic regression). Also additional strategy how to use symbolic regression to construct approximations of is given in Section 3.1.2., where their form suitable for engineering use is given in 3.2.2.. Only one example of this really promising strategy how to construct accurate explicit approximations based on symbolic regression is given in [9], while here we give additional expressions which are to date the most accurate, but also very simple. These extreme accurate approximations are offered in the form suitable for human eyes, but also in forms suitable for coding.

3.1. Series expansion of 3.1. Series expansion of

ω

(

x

)

−

x

{\textstyle \omega (x)-x}

3.1.1. Assymptotic expansion of about infinity3.1.1. Assymptotic expansion of

ω

(

x

)

−

x

{\textstyle \omega (x)-x}

about infinity

Table 1 presents terms (i=1, 2, …, 5); Eqs. (3-7) used for approximating by a truncated series about infinity [15], where generally as given in Table 2.

| 1 | Eq. (3) | |

| 2 | Eq. (4) | |

| 3 | Eq. (5) | |

| 4 | Eq. (6) | |

| 5 | Eq. (7) |

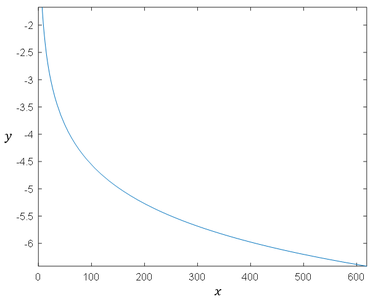

As can be seen in Figure 1, the function needs to be accurate only in the domain 7.51<x<619, which is the one relevant for the Colebrook equation; Eq. (1). On the other hand, the Reynolds number should be between 4000 and 108, while roughness of inner pipe surface should be from 0 to 0.05.

|

Figure 1. Strictly monotonic decreasing of for the Colebrook equation.

Winning and Coole [16,17] found that logarithmic, exponential, non-integer power terms and similar functions require extensive additional execution of floating-point operations in the Central Processor Units (CPUs) of modern computers compared with the simple arithmetic operations (+,-,*,/). The logarithmic function is needed only once in Eq. (2); to evaluate and as can be seen from Table 1, one additional logarithmic function is needed for evaluation of in order to approximate the .

Table 2 brings the first five approximations of ; Eqs. (8-12) based on the series expansion of about infinity by Corless et al. [3, 15]. These approximations are expressed in terms of functions from Table 1. The coefficients of series expansion about infinity are unsigned Stirling numbers of the first kind [18] as pointed out by Rollmann and Spindler [12].

The last line of Table 2 represents the “exact” explicit accurate solution of the Colebrook equation given by Eq. (2), in which is calculated by the Matlab’s built-in command wrightOmega (e.g. similar function does not yet exist in MS Excel [19,20] and user-defined Visual Basic for Applications (VBA) script should be provided instead [21]). However, this wrightOmega solution is extremely slow; it requires more than 189 minutes(!) to evaluate the benchmark, even the here presented approximations requires only seconds. The column “Time” represents time in seconds to evaluate the proposed explicit approximations of the Colebrook equation using 8 million of Quasi Monte-Carlo samples (a benchmark study). For this sampling, the LPTAU51 algorithm was used [22]. We can clearly see from Table 2 that it makes sense to introduce fast, but accurate approximations of the wrightOmega function.

| Structure of approximations | 1 | Time (sec) | ||

| 1 | 0.153% | 0.4 | Eq. (8) | |

| 2 | 0.118% | 0.4 | Eq. (9) | |

| 3 | 0.008% | 1.1 | Eq. (10) | |

| 4 | 0.00249% | 2.4 | Eq. (11) | |

| 5 | 0.00247% | 4.4 | Eq. (12) | |

| 2 | 0% | 11394 |

As can be seen in Table 2, the function approximates the function by various quality and complexity. The larger i of the function implies a more precise approximation of , but the computation time increases.

Further, to increase the accuracy of expansions in Table 1, approximations can be written in a form , where the constant represents a constant, which minimizes the relative error of the flow friction factor. The constant was obtained in Matlab by global optimization solver Globalsearch. This optimal constant is 0.00056 for Eq. (8) gives Eq. (13), -0.0014 for Eq. (9) gives Eq. (14), and -0.000093 for Eq. (10) gives Eq. (15); as given in Table 3. This strategy makes also the distribution of the error more uniform, and the methodology for the relative error and time mesurment is in correlation with Table 2.

| Time (sec) | |||

| 0.129% | 0.4 | Eq. (13) | |

| 0.0691% | 0.4 | Eq. (14) | |

| 0.00527% | 1.1 | Eq. (15) |

By extending the approach for error minimization by adding a constant as in Table 3, a more accurate approximation can be constructed using a function for error minimization (instead of the constant ) which is found through symbolic regression [27]. Eq. (16) is based on Eq. (8) where function reduce the relative error significantly.

|

(16) |

The error function of Eq. (16) is developed using symbolic regression, while in Section 3.2. will be approximated using the same approach.

3.1.2. Symbolic regression-based expansions of for Colebrook equation3.1.2. Symbolic regression-based expansions of

y

=

ω

(

x

)

−

{\textstyle y=\omega \left(x\right)-}

x

{\displaystyle x}

for Colebrook equation

An additional strategy for increasing the accuracy of for the Collebrook equation is given in Table 4; Eqs. (17-20). These approximations were found by symbolic regression [9]. Software Eureqa is used to perform regression analyses [13,14]. These approximations are optimized for the domain 7.51<x<619, which is of the interest for the Colebrook equation.

With the strategy used for Eq. (16), the accuracy of Eq. (19) is significantly improved using a newly constructed error function as shown in Eq. (20).

| Time (sec) | |||

| 0.0497% | 0.42 | Eq. (17) | |

| 0.0105% | 0.42 | Eq. (18) | |

| 0.00229% | 0.42 | Eq. (19) | |

| 0.000024% | 1.1 | Eq. (20) |

3.2. Approximations suitable for engineering use

3.2.1. Approximations and procedures based on series expansions of about infinity3.2.1. Approximations and procedures based on series expansions of

ω

(

x

)

−

{\textstyle \omega (x)-}

x

{\displaystyle x}

about infinity

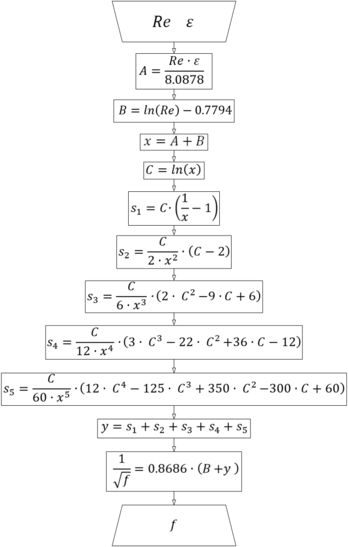

To use the procedure for solving Eq. (2) based on series expansions from Table 1 and Table 2, one should follow the algorithm illustrated in Figure 2. It can be modified so can be given as , , etc. Also, Table 2 can be extended to construct etc. (more details in [28]).

From Table 2; Eq. (12), it can be seen that the algorithm from Figure 2 introduces a relative error of no more than 0.00247% and that it needs around 4.4 seconds to execute 8 million of Quasi Monte-Carlo tested samples carefully selected from the domain of the Colebrook equation which is of interest for engineering practice.

|

Figure 2. Algorithm for the procedure for solving Eq. (2) based on series expansions from Table 1 and Table 2.

In addition, if , Table 2, Eq. (8), the relative error is up to 0.153% with around 0.2 seconds for the execution of 8 million of Quasi Monte-Carlo tested samples. Based on the algorithm from Figure 2, Eq. (21) can be constructed (this equation is already presented in [9]).

|

(21) |

Further accurate approximations based on expansions from Table 3 are given in Table 5; Eqs. (22-25). Based on the expansions from Table 3, the appropriate explicit approximations to the Colebrook equation can be constructed; Eq. (13) → Eq. (22), Eq. (14) → Eq. (23), and Eq. (15) → Eq. (24).

To construct the approximations from Table 5 based on Table 3, the notation should be used in order to avoid multiple repetitions of the logarithmic function, as C is computed only once.

Comparing Eq. (22) from Table 5 with the maximal relative error of 0.1266% and Eq. (21) with 0.153%, it is confirmed that adding the carefully chosen constant , gives more accurate results for the Colebrook equation.

| Approximation | ||

| 0.129% | Eq. (22) | |

| 0.0691% | Eq. (23) | |

| 0.00527% | Eq. (24) | |

| , , , |

Eq. (25), which is based on Eq. (22), brings the relative error of up to 0.000391% thanks to the novel function which reduce the error. Let us compare Eq. (22) and Eq. (25) by terms of accuracy and speed. The relative error of Eq.(25) is reduced significanty by the factor 0.129%/0.000391% ~ 330. Of course, the computational time of novel Eq. (25) is 1.1 seconds, as it is slower than Eq. (17) by the factor 1.1/0.42~ 2.616, as Eq. (25) is more complex. However, Eq. (25) can be implemented easily in software codes, as is a simple rational function. Here, only the error function is developed using symbolic regression, whereas this technique is used in a more thorough way also in Section 4.2.

|

(25) |

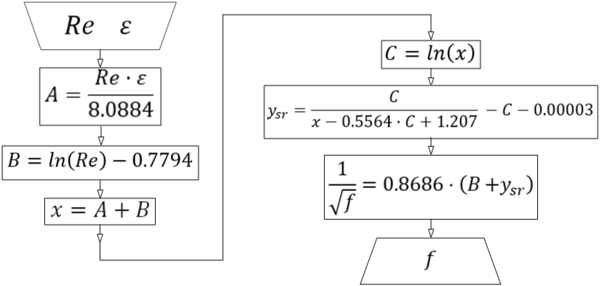

3.2.2. Approximations based on symbolic regression

Four simple but very accurate approximations based on symbolic regression are presented in Eqs. (26-29) of Table 6 where Eqs. (26) and (27) are already given in [9], whereas Eqs. (28) and (29) are novel simple, but very accurate approximations found by symbolic regression. Although Eureqa allows only minimization of the absolute error [13], we can use it also for minimizing the relative error; Gholamy and Kreinovich [29] showed how to use existing absolute-error-minimizing software to minimize relative errors. Consequently, Eureqa was used for the minimization of the maximal error (worst-case) of , where denotes a symbolic regression-based approximation of . Table 6 shows that this formulation significantly reduces the approximation error. Comparing Eq. (26) which is already available in [9] with the here introduced Eq. (28), it can be seen that both approximations have similar complexity, but thanks to the minimizing of the relative error [29] through symbolic regression, the maximal relative error of the friction factor was reduced from 0.0497% of Eq. (26) to 0.00229% of Eq. (28), i.e. more than 21 times. Moreover, Eqs. (26-28) are based on Table 4 while Eq. (29) is improved Eq. (28) by adding the carefully chosen constant, in order to minimize the relative error of the friction factor of the Colebrook equation.

To date, the most accurate approximation of the Colebrook equation is by Vatankhah [30] with the relative error of no more than 0.0028% with three logarithmic and one noninteger power functions used (Clamond [31] reported that in a modern computer, evaluation of noniteger power goes also through logarithmic function). However, our novel Eq. (29) with the relative error of no more than 0.00224% is not only more accurate, but with two logarithmic function, it is also simpler (approaches with the only one logarithmic function [32], and even without [33], exist, but they are less accurate).

| Approximation | ||

| 0.0497% | Eq. (26) | |

| 0.0105 % | Eq. (27) | |

| 0.00229% | Eq. (28) | |

| 0.00224% | Eq. (29) | |

| , , , |

Coefficients of Eq. (28) can be further optimized, where the following vector should be used [0.8685972, 0.779626, 8.0897, 0.5588, 1.2079] instead of [0.8686, 0.7794, 8.0884, 0.5564, 1.207] in order to decrease the relative error to 0.0012%. The worst case for the updated coefficients is for = 92957 and for =3.1769·10-7 while computation of the benchmark sample tooks 0.388 seconds.

Eq.(26) - Eq.(29) require only 0.42 seconds. Algorithm for solving Eq. (29) from Table 6 is given in Figure 3.

|

Figure 3. Algorithm for solving Eq. (29) of Table 6.

Based on Eq. (20), thanks to the function for error minimization , a novel very accurate approximation given with Eq. (30) can be constructed.

|

(30) |

The computation speed of Eq.(30) is the same as Eq. (15), i.e. 1.1 seconds. However, let us compare the precision of the approximation given by the improved series expansion (see Eq. 15) with the precision of the novel symbolic regression-based approximation given by Eq. (30). The maximal relative error of Eq. (15) is , while the maximal relative error of Eq. 30 is only 0.000024%. Thus, the novel symbolic regression approximation of Eq. (30) reduces the relative error by factor 219, which confirms advantages of using symbolic regression for flow friction estimations.

Before, Praks and Brkić [34] already developed approximations of the Colebrook equation based on symbolic regression analyses, which was recognized as a benchmark for feeding the automatic programming methods [35-38]. The study of Praks and Brkić [34] deals with symbolic regression with raw data based on the Colebrook equation by iterations and not through . Belkić [39] provided a detailed review of applications of transcendental Lambert and Euler functions, which includes mathematics, physics, chemistry, biomedicine, ecologogy and sociology. Recently, approximations of the Colebrook equation based on symbolic regression of [9] received a high ranking in large accuracy/speed benchmarks [40-43].

4. Conclusions and future work

In this review, we showed very accurate and fast explicit approximations for the implicitly given Colebrook equation for flow friction. They are based on the Lambert W-function and its cognate the Wright ω-function. These explicit approximations are constructed on series expansion and symbolic regression analysis of the Wright ω-function which are much faster compared with the related Matlab built-in function. Using methods presented in this paper, an explicit approximation of any desired accuracy can be constructed.

The proposed approximations should be compared with very recent comparative studies of the available approximations of the Colebrook equation [40-46]. Such comparisons will confirm that the approximations proposed in this review are both accurate and computationally efficient.

In terms of the balance among simplicity for human eyes, accuracy and computational simplicity, the novel Eq. (29) with an relative error of up to 0.00234% is highly recommended (a simple algorithm shown in Figure 3 should be followed for engineering use). For very accurate software implementation, its more complex version given in Eq. (30) should be followed, as the maximal relative error is only 0.000024%. These formulas can be also used for indirect estimation of the flow friction rate using electrical parameters of pumps, when direct measurement is not possible, for example in offshore installations. For remote sensing control, the needed indirect electrical parameters of pump such as electrical pressure drop, must be measured accurately. Consequently, flow friction can be estimated indirectly from electrical parameters of the pump using the here proposed simple, but accurate flow friction equation.

Author Contributions: P.P. worked mostly on the mathematical background of the proposed methods and procedures, while D.B. put it in a form suitable for engineering use. P.P. made also tests with symbolic regression tool and global optimization. D.B. made the draft of this paper.

Funding: This work has been partially supported by the Technology Agency of the Czech Republic under the project “National Centre for Energy” TN01000007,“Energy System for Grids” TK02030039 and by the Ministry of Education, Youth and Sports of the Czech Republic through the National Programme of Sustainability (NPS II) project “IT4Innovations excellence in science-LQ1602”.

Acknowledgments: We especially thank Marcelo Masera for his careful scientific supervision and kind approvals. We acknowledge support from the European Commission, Joint Research Centre (JRC), Directorate C: Energy, Transport, and Climate, Unit C3: Energy Security, Distribution, and Markets.

Conflicts of Interest: The authors declare no conflict of interest. Neither the European Commission, the VŠB - Technical University of Ostrava, nor any person acting on their behalf is responsible for any use of this publication.

Notations

The following symbols are used in this review:

| variable that depends on and (dimensionless); | |

| variable that depends on and (dimensionless); | |

| variable that depends on (dimensionless); | |

| Darcy (Moody) flow friction factor (dimensionless) – main output parameter | |

| approximation of by a truncated series about infinity; | |

| Reynolds number (dimensionless) – main input parameter | |

| variable that depends on and (dimensionless); | |

| approximation of , i.e. of | |

| approximation of , i.e. of found by symbolic regression | |

| suitable for error minimization using function | |

| constant (dimensionless); | |

| constant (dimensionless); half of the smallest term in the asymptotic series | |

| Relative roughness of inner pipe surface (dimensionless) – main input parameter | |

| Relative error (%); | |

| and | error-functions developed using symbolic regression |

| exponential function | |

| logarithm with base 10 | |

| natural logarithm | |

| Lambert -function | |

| Wright -function | |

| counter | |

| wrightOmega | Matlab’s built-in function |

| Globalsearch | Matlab’s built-in solver |

References

1. Colebrook, C.F. Turbulent flow in pipes with particular reference to the transition region between the smooth and rough pipe laws. J. Inst. Civ. Eng. 1939, 11, 133–156, doi:10.1680/ijoti.1939.13150.

2. Colebrook, C.; White, C. Experiments with fluid friction in roughened pipes. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1937, 161, 367–381, doi:10.1098/rspa.1937.0150.

3. Corless, R.M.; Gonnet, G.H.; Hare, D.E.; Jeffrey, D.J.; Knuth, D.E. On the Lambert W function. Adv. Comput. Math. 1996, 5, 329–359, doi:10.1007/BF02124750.

1. Wright, E.M. Solution of the equation . Bull. Am. Math Soc. 1959, 65, 89–93, doi:10.1090/S0002-9904-1959-10290-1.

2. Keady, G. Colebrook-White formula for pipe flows. J. Hydraul. Eng. 1998, 124, 96–97, doi:10.1061/(ASCE)0733-9429(1998)124:1(96).

3. Sonnad, J.R.; Goudar, C.T. Constraints for using Lambert W function-based explicit Colebrook–White equation. Journal of Hydraulic Engineering 2004, 130, 929-931, doi:10.1061/(ASCE)0733-9429(2004)130:9(929)

4. Brkić, D. Comparison of the Lambert W‐function based solutions to the Colebrook equation. Engineering Computations 2012, 29, 617-630, doi:10.1108/02644401211246337

5. Hayes, B. Why W? Am. Sci. 2005, 93, 104–108.

6. Brkić, D.; Praks, P. Accurate and efficient explicit approximations of the Colebrook flow friction equation based on the Wright ω-function. Mathematics 2019, 7, 34, doi:10.3390/math7010034.

7. Brkić, D.; Praks, P. Accurate and efficient explicit approximations of the Colebrook flow friction equation based on the Wright ω-function: Reply to Discussion. Mathematics 2019, 7, 410, doi:10.3390/math7050410.

8. Biberg, D. Fast and accurate approximations for the Colebrook equation. J. Fluids Eng. 2017, 139, 031401, doi:10.1115/1.4034950.

9. Rollmann, P.; Spindler, K. Explicit representation of the implicit Colebrook–White equation. Case Stud. Therm. Eng. 2015, 5, 41–47, doi:10.1016/j.csite.2014.12.001.

10. Schmidt, M.; Lipson, H. Distilling free-form natural laws from experimental data. Science 2009, 324, 81–85, doi:10.1126/science.1165893.

11. Dubčáková, R. Eureqa: Software review. Genet. Program. Evolvable Mach. 2011, 12, 173–178, doi:10.1007/s10710-010-9124-z.

12. Horchler, A.D. Complex Double-Precision Evaluation of the Wright Omega Function. 2017. Available online: https://github.com/horchler/wrightOmegaq (accessed on 10 December 2019).

13. Winning, H.K.; Coole, T. Explicit friction factor accuracy and computational efficiency for turbulent flow in pipes. Flow Turbul. Combust. 2013, 90, 1–27, doi:10.1007/s10494-012-9419-7.

14. Winning, H.K.; Coole, T. Improved method of determining friction factor in pipes. Int. J. Numer. Methods Heat Fluid Flow 2015, 25, 941–949, doi:10.1108/HFF-06-2014-0173.

15. On-Line Encyclopedia of Integer Sequences; Sequence A008275 for Stirling numbers of first kind, Available from: http://oeis.org/A008275 (accessed on 25 February 2020)

16. Niazkar, M. Afzali, S.H. Analysis of water distribution networks using MATLAB and Excel spreadsheet: h‐based methods. Computer Applications in Engineering Education 2017, 25, 129-141, doi:10.1002/cae.21786

17. Niazkar, M. Afzali, S.H. Analysis of water distribution networks using MATLAB and Excel spreadsheet: Q‐based methods. Computer Applications in Engineering Education 2017, 25, 277-289, doi:10.1002/cae.21796

18. Demir, S., Karadeniz, A., Demir, N.M., Duman, S. Excel VBA-based solution to pipe flow measurement problem. Spreadsheets Educ. (EJSiE) 2018, 10, 1, Available online: https://sie.scholasticahq.com/article/4671.pdf (accessed on 13 February 2020).

19. Sobol, I.M.; Turchaninov, V.I.; Levitan, Y.L.; Shukhman, B.V. Quasi-Random Sequence Generators; Distributed by OECD/NEA Data Bank; Keldysh Institute of Applied Mathematics; Russian Academy of Sciences: Moscow, Russia. 1992. Available online: https://ec.europa.eu/jrc/sites/jrcsh/files/LPTAU51.rar (accessed on 19 November 2019).

20. Brkić, D. Review of explicit approximations to the Colebrook relation for flow friction. J. Pet. Sci. Eng. 2011, 77, 34–48, doi:10.1016/j.petrol.2011.02.006.

21. Brkić, D. Solution of the implicit Colebrook equation for flow friction using Excel. Spreadsheets Educ. (EJSiE) 2017, 10, 2. Available online: https://sie.scholasticahq.com/article/4663 (accessed on 07 February 2020).

22. Praks, P.; Brkić, D. Choosing the optimal multi-point iterative method for the Colebrook flow friction equation. Processes 2018, 6, 130. doi:10.3390/pr6080130

23. Praks, P.; Brkić, D. Advanced iterative procedures for solving the implicit Colebrook equation for fluid flow friction. Advances in Civil Engineering 2018, 2018, 5451034. doi:10.1155/2018/5451034

24. Sun, S.; Ouyang, R.; Zhang, B.; Zhang, T.Y. Data-driven discovery of formulas by symbolic regression. MRS Bulletin 2019, 44, 559-564, doi:10.1557/mrs.2019.156

25. Corless R.M., Jeffrey D.J. (2002) The Wright ω Function. In: Calmet J., Benhamou B., Caprotti O., Henocque L., Sorge V. (eds) Artificial Intelligence, Automated Reasoning, and Symbolic Computation. AISC 2002, Calculemus 2002. Lecture Notes in Computer Science, vol 2385. Springer, Berlin, Heidelberg, https://doi.org/10.1007/3-540-45470-5_10

26. Gholamy, A.; Kreinovich, V. How to use absolute-error-minimizing software to minimize relative error: Practitioner’s guide. Int. Math. Forum 2017, 12, 763-770, doi:10.12988/imf.2017.7761

27. Vatankhah, A.R. Approximate analytical solutions for the Colebrook equation. J. Hydraul. Eng. 2018, 144, 06018007, doi:10.1061/(ASCE)HY.1943-7900.0001454

28. Clamond, D. Efficient resolution of the Colebrook equation. Industrial & Engineering Chemistry Research 2009, 48, 3665-3671, doi:10.1021/ie801626g

29. Brkić, D.; Praks, P. Colebrook’s flow friction explicit approximations based on fixed-point iterative cycles and symbolic regression. Computation 2019, 7, 48. doi:10.3390/computation7030048

30. Praks, P.; Brkić, D. Rational Approximation for solving an implicitly given Colebrook flow friction equation. Mathematics 2020, 8, 26. doi:10.3390/math8010026

31. Praks, P.; Brkić, D. Symbolic regression-based genetic approximations of the Colebrook equation for flow friction. Water 2018, 10, 1175, doi:10.3390/w10091175.

32. Gorkemli, B.; Karaboga, D. A quick semantic artificial bee colony programming (qsABCP) for symbolic regression. Information Sciences 2019, 502, 346–362. doi:10.1016/j.ins.2019.06.052

33. Niazkar, M.; Talebbeydokhti, N.; Afzali, S. -H. Bridge backwater estimation: A Comparison between artificial intelligence models and explicit equations. Scientia Iranica (in press), doi:10.24200/SCI.2020.51432.2175

34. Filippov, A.E.; Gorb, S.N. Methods of the pattern formation in numerical modeling of biological problems. Facta Universitatis, Series: Mechanical Engineering 2019, 17, 217-242. doi:10.22190/FUME190227027F

35. Diyaley, S. and Chakraborty, S. Optimization of multi-pass face milling parameters using metaheuristic algorithms. Facta Universitatis, Series: Mechanical Engineering 2019, 17, 365-383. doi:10.22190/FUME190605043D

36. Belkić, Dž. All the trinomial roots, their powers and logarithms from the Lambert series, Bell polynomials and Fox–Wright function: illustration for genome multiplicity in survival of irradiated cells. J. Math. Chem. 2019, 57, 59–106, doi:10.1007/s10910-018-0985-3

37. Niazkar, M.; Talebbeydokhti, N. Comparison of explicit relations for calculating Colebrook friction factor in pipe network analysis using h-based methods. Iranian Journal of Science and Technology, Transactions of Civil Engineering 2020, 44, 231–249, doi:10.1007/s40996-019-00343-2

38. Niazkar, M. Revisiting the estimation of Colebrook friction factor: A comparison between artificial intelligence models and CW based explicit equations. KSCE J. Civ. Eng. 2019, 23, 4311–4326, doi:10.1007/s12205-019-2217-1.

39. Muzzo, L.E.; Pinho, D.; Lima, L.E.; Ribeiro, L.F. Accuracy/Speed analysis of pipe friction factor correlations. In International Congress on Engineering and Sustainability in the XXI Century—INCREaSE 2019, Section: Water for Ecosystem and Society, Faro, Portugal, 9–11 October 2019; Monteiro, J., Silva, A.J., Mortal, A., Aníbal, J., da Silva, M.M., Oliveira, M., Eds.; Springer Nature Switzerland AG 2020: Cham, Switzerland, 2019; pp. 664–679, doi:10.1007/978-3-030-30938-1_51.

40. Brkić, D.; Ćojbašić, Ž. Evolutionary optimization of Colebrook’s turbulent flow friction approximations. Fluids 2017, 2, 15. doi:10.3390/fluids2020015

41. Pimenta, B.D.; Robaina, A.D.; Peiter, M.X.; Mezzomo, W.; Kirchner, J.H.; Ben, L.H. Performance of explicit approximations of the coefficient of head loss for pressurized conduits. Revista Brasileira de Engenharia Agrícola e Ambiental 2018, 22, 301-307. doi:10.1590/1807-1929/agriambi.v22n5p301-307

42. Olivares, A.; Guerra, R.; Alfaro, M.; Notte-Cuello, E.; Puentes, L. Evaluación experimental de correlaciones para el cálculo del factor de fricción para flujo turbulento en tuberías cilíndricas (Experimental evaluation of correlations used to calculate friction factor for turbulent flow in cylindrical pipes) /in Spanish/. Revista Internacional de Métodos Numéricos para Cálculo y Diseño en Ingeniería 2019, 35, 15. doi:10.23967/j.rimni.2019.01.001

43. Zeghadnia, L.; Robert, J.L.; Achour, B. Explicit solutions for turbulent flow friction factor: A review, assessment and approaches classification. Ain Shams Engineering Journal 2019, 10, 243-252. doi:10.1016/j.asej.2018.10.007

Document information

Published on 03/09/20

Accepted on 02/09/20

Submitted on 22/03/20

Volume 36, Issue 3, 2020

DOI: 10.23967/j.rimni.2020.09.001

Licence: CC BY-NC-SA license

Share this document

Keywords

claim authorship

Are you one of the authors of this document?