m (Move page script moved page Draft Samper 876641692 to Onate et al 2004h) |

|||

| (130 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | Published in ''Encyclopedia of Computational Mechanics'', Encyclopedia of Computational Mechanics, E. Stein, R. de Borst and T.J.R. Hughes (Eds.), John Wiley & Sons Ltd, Vol. 3, Chapter 18, pp. 579 - 607, 2004<br /> | |

| − | + | DOI: 10.1002/9781119176817 | |

| − | + | ||

| − | ''' | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

==Abstract== | ==Abstract== | ||

| Line 34: | Line 18: | ||

Wave resistance in practical cases amounts to <math display="inline">10</math> to <math display="inline">60%</math> of the total resistance of a ship in still water (Raven, 1996 <span id="citeF-84"></span>[[#cite-84|[84]]]). It increases very rapidly at high speeds dominating the viscous component for high speed ships. Furthermore, wave resistance is very sensitive to the hull form design and easily affected by small shape modifications. For all these reasons, the possibility to predict and reduce the wave resistance is an important target. | Wave resistance in practical cases amounts to <math display="inline">10</math> to <math display="inline">60%</math> of the total resistance of a ship in still water (Raven, 1996 <span id="citeF-84"></span>[[#cite-84|[84]]]). It increases very rapidly at high speeds dominating the viscous component for high speed ships. Furthermore, wave resistance is very sensitive to the hull form design and easily affected by small shape modifications. For all these reasons, the possibility to predict and reduce the wave resistance is an important target. | ||

| − | The prediction of the wave pattern and the wave resistance of a ship has challenged mathematicians and hydrodynamicists for over a century. The Boundary Element Method (BEM) is the basis of many computational algorithms developed in past years. Here the flow problem is solved using a simple potential model. BEM methods, termed by hydrodynamicists as Panel Methods may be classified into two categories. The first one uses the Kelvin wave source as the elementary singularity. The main advantage of such scheme is the automatic satisfaction of the radiation condition. The theoretical background of this method was reviewed by Wehausen (1970) <span id="citeF-103"></span>[[#cite-103|[103]]], while computational aspects can be found in Soding (1996) <span id="citeF-87"></span>[[#cite-87|[87]]] and Jenson and Soding (1989) <span id="citeF-58"></span>[[#cite-58|[58]]]. The second class of BEM schemes uses the Rankine source as the elementary singularity. This procedure, first presented by Dawson (1977) <span id="citeF-29"></span>[[#cite-29|[29]]], has been widely applied in practice and many improvements have been addressed to account for the nonlinear wave effects. Among these, a succesful example is the Rankine Panel Method (Xia, 1986 <span id="citeF-106"></span>[[#cite-106|[106]]]; Jenson and Soding, 1989 <span id="citeF-58"></span>[[#cite-58|[58]]]; Nakos and Sclavounos, 1990 <span id="citeF- | + | The prediction of the wave pattern and the wave resistance of a ship has challenged mathematicians and hydrodynamicists for over a century. The Boundary Element Method (BEM) is the basis of many computational algorithms developed in past years. Here the flow problem is solved using a simple potential model. BEM methods, termed by hydrodynamicists as Panel Methods may be classified into two categories. The first one uses the Kelvin wave source as the elementary singularity. The main advantage of such scheme is the automatic satisfaction of the radiation condition. The theoretical background of this method was reviewed by Wehausen (1970) <span id="citeF-103"></span>[[#cite-103|[103]]], while computational aspects can be found in Soding (1996) <span id="citeF-87"></span>[[#cite-87|[87]]] and Jenson and Soding (1989) <span id="citeF-58"></span>[[#cite-58|[58]]]. The second class of BEM schemes uses the Rankine source as the elementary singularity. This procedure, first presented by Dawson (1977) <span id="citeF-29"></span>[[#cite-29|[29]]], has been widely applied in practice and many improvements have been addressed to account for the nonlinear wave effects. Among these, a succesful example is the Rankine Panel Method (Xia, 1986 <span id="citeF-106"></span>[[#cite-106|[106]]]; Jenson and Soding, 1989 <span id="citeF-58"></span>[[#cite-58|[58]]]; Nakos and Sclavounos, 1990 <span id="citeF-109"></span>[[#cite-109|[109]]]). |

In addition to the important developments in potential flow panel methods for practical ship hydrodynamics analysis during the period 1960-1980, much research in the second half of the twentieth century was oriented towards the introduction of viscosity in the CFD analysis. In the 1960's the viscous flow research was mainly focused in 2D boundary layer theory and by the end of the decade several methods for arbitrary pressure gradients were available. This research continued to solve the 3D case during the following decade and an evaluation of the capability of the new methods to predict ship wave resistance was carried out at different workshops (Bai and McCarthy, 1979 <span id="citeF-7"></span>[[#cite-7|[7]]]; Larsson, 1981 <span id="citeF-61"></span>[[#cite-61|[61]]]; Noblesse and McCarthy, 1983 <span id="citeF-69"></span>[[#cite-69|[69]]]). Here application to some well specified test cases were reported and numerical and experimental results compared acceptable well for most part of the boundary layer along the hull, while wrong results were obtained near the stern. This prompted additional research and by the end of the 1980's a number of numerical procedures for solving the full viscous flow equation accounting for simple turbulence modes based on Reynolds averaged Navier-Stokes (RANS) equations were available. Considerable improvements for predicting the stern flow were reported in subsequent workshops organized in the 1990's (Kim and Lucas, 1990 <span id="citeF-59"></span>[[#cite-59|[59]]]; Reed ''et al.'' , 1990<span id="citeF-85"></span>[[#cite-85|[85]]]; Beck ''et al.'', 1993 <span id="citeF-8"></span>[[#cite-8|[8]]]; Raven, 1996 <span id="citeF-84"></span>[[#cite-84|[84]]]; Soding, 1996 <span id="citeF-87"></span>[[#cite-87|[87]]]; Janson and Larsson, 1996 <span id="citeF-57"></span>[[#cite-57|[57]]]; Alessandrini and Delhommeau, 1996 <span id="citeF-1"></span>[[#cite-1|[1]]]; Miyata, 1996 <span id="citeF-67"></span>[[#cite-67|[67]]], Löhner ''et al.'', 1998 <span id="citeF-64"></span>[[#cite-64|[64]]]). A good review of the status of CFD in ship hydrodynamics in the last part of the 20th century can be found in Larsson ''et al.'' (1998) <span id="citeF-62"></span>[[#cite-62|[62]]]. | In addition to the important developments in potential flow panel methods for practical ship hydrodynamics analysis during the period 1960-1980, much research in the second half of the twentieth century was oriented towards the introduction of viscosity in the CFD analysis. In the 1960's the viscous flow research was mainly focused in 2D boundary layer theory and by the end of the decade several methods for arbitrary pressure gradients were available. This research continued to solve the 3D case during the following decade and an evaluation of the capability of the new methods to predict ship wave resistance was carried out at different workshops (Bai and McCarthy, 1979 <span id="citeF-7"></span>[[#cite-7|[7]]]; Larsson, 1981 <span id="citeF-61"></span>[[#cite-61|[61]]]; Noblesse and McCarthy, 1983 <span id="citeF-69"></span>[[#cite-69|[69]]]). Here application to some well specified test cases were reported and numerical and experimental results compared acceptable well for most part of the boundary layer along the hull, while wrong results were obtained near the stern. This prompted additional research and by the end of the 1980's a number of numerical procedures for solving the full viscous flow equation accounting for simple turbulence modes based on Reynolds averaged Navier-Stokes (RANS) equations were available. Considerable improvements for predicting the stern flow were reported in subsequent workshops organized in the 1990's (Kim and Lucas, 1990 <span id="citeF-59"></span>[[#cite-59|[59]]]; Reed ''et al.'' , 1990<span id="citeF-85"></span>[[#cite-85|[85]]]; Beck ''et al.'', 1993 <span id="citeF-8"></span>[[#cite-8|[8]]]; Raven, 1996 <span id="citeF-84"></span>[[#cite-84|[84]]]; Soding, 1996 <span id="citeF-87"></span>[[#cite-87|[87]]]; Janson and Larsson, 1996 <span id="citeF-57"></span>[[#cite-57|[57]]]; Alessandrini and Delhommeau, 1996 <span id="citeF-1"></span>[[#cite-1|[1]]]; Miyata, 1996 <span id="citeF-67"></span>[[#cite-67|[67]]], Löhner ''et al.'', 1998 <span id="citeF-64"></span>[[#cite-64|[64]]]). A good review of the status of CFD in ship hydrodynamics in the last part of the 20th century can be found in Larsson ''et al.'' (1998) <span id="citeF-62"></span>[[#cite-62|[62]]]. | ||

| Line 232: | Line 216: | ||

The solution of above problems in the context of the finite element method (FEM) has been attempted in a number of ways. The underdiffusive character of the Galerkin FEM for high convection flows (which incidentaly also occurs for centred FD and FV methods) has been corrected by adding some kind of artificial viscosity terms to the standard Galerkin equations. A good review of such approach can be found in Zienkiewicz and Taylor, Vol. 3 2000 <span id="citeF-107"></span>[[#cite-107|[107]]] and Donea and Huerta, 2003 <span id="citeF-31"></span>[[#cite-31|[31]]]. | The solution of above problems in the context of the finite element method (FEM) has been attempted in a number of ways. The underdiffusive character of the Galerkin FEM for high convection flows (which incidentaly also occurs for centred FD and FV methods) has been corrected by adding some kind of artificial viscosity terms to the standard Galerkin equations. A good review of such approach can be found in Zienkiewicz and Taylor, Vol. 3 2000 <span id="citeF-107"></span>[[#cite-107|[107]]] and Donea and Huerta, 2003 <span id="citeF-31"></span>[[#cite-31|[31]]]. | ||

| − | A popular way to overcome the problems with the incompressibility constraint is by introducing a pseudo-compressibility in the flow and using implicit and explicit algorithms developed for this kind of problems, such as artificial compressibility schemes (Chorin, 1967A <span id="citeF-14"></span>[[#cite-14|[14]]] popular way to overcome the problems with the incompressibility constraint is by introducing a pseudo-compressibility in the flow and using implicit and explicit algorithms developed for this kind of problems, such as artificial compressibility schemes (Chorin, 1967 <span id="citeF-14"></span>[[#cite-14|[14]]]; Farmer ''et al.'', 1993 <span id="citeF-35"></span>[[#cite-35|[35]]]; Peraire ''et al.'', 1994 <span id="citeF-82"></span>[[#cite-82|[82]]]; Briley ''et al.'', 1995 <span id="citeF-10"></span>[[#cite-10|[10]]]; Sheng ''et al.'', 1996 <span id="citeF-86"></span>[[#cite-86|[86]]]) and preconditioning techniques (Idelsohn ''et al.'', 1995 <span id="citeF-51"></span>[[#cite-51|[51]]]). Other FEM schemes with good stabilization properties for the convective and incompressibility terms are based in Petrov-Galerkin (PG) techniques. The background of PG methods are the non-centred (upwind) schemes for computing the first derivatives of the convective operator in FD and FV methods. More recently a general class of Galerkin FEM has been developed where the standard Galerkin variational form is extended with adequate residual-based terms in order to achieve a stabilized numerical scheme (Codina, 1998 <span id="citeF-16"></span>[[#cite-16|[16]]], 2000 <span id="citeF-17"></span>[[#cite-17|[17]]]). Among the many FEM of this kind we can name the Streamline Upwind Petrov Galerkin (SUPG) method (Hughes and Brooks, 1979 <span id="citeF-45"></span>[[#cite-45|[45]]]; Brooks and Hughes, 1982 <span id="citeF-11"></span>[[#cite-11|[11]]]; Tezduyar and Hughes, 1983 <span id="citeF-97"></span>[[#cite-97|[97]]]; Hughes and Tezduyar, 1984 <span id="citeF-46"></span>[[#cite-46|[46]]]; Hughes and Mallet, 1986 <span id="citeF-48"></span>[[#cite-48|[48]]]; Idelsohn ''et al.'', 1995 <span id="citeF-51"></span>[[#cite-51|[51]]]; Storti ''et al.'', 1995 <span id="citeF-88"></span>[[#cite-88|[88]]], 1997 <span id="citeF-89"></span>[[#cite-89|[89]]]; Cruchaga and Oñate, 1997 <span id="citeF-27"></span>[[#cite-27|[27]]], 1999 <span id="citeF-28"></span>[[#cite-28|[28]]]), the Galerkin Least Square (GLS) method (Hughes ''et al.'', 1989 <span id="citeF-50"></span>[[#cite-50|[50]]]; Tezduyar, 1991 <span id="citeF-94"></span>[[#cite-94|[94]]]; Tezduyar ''et al.'', 1992a <span id="citeF-99"></span>[[#cite-99|[99]]]), the Taylor-Galerkin method (Donea, 1984 <span id="citeF-30"></span>[[#cite-30|[30]]]), the Characteristic Galerkin method (Douglas and Russell, 1982 <span id="citeF-32"></span>[[#cite-32|[32]]]; Pironneau, 1982 <span id="citeF-83"></span>[[#cite-83|[83]]]; Löhner ''et al.'', 1984 <span id="citeF-63"></span>[[#cite-63|[63]]]) and its variant the characteristic Based Split (CBS) method (Zienkiewicz and Codina, 1995 <span id="citeF-108"></span>[[#cite-108|[108]]]; Codina ''et al.'', 1998 <span id="citeF-23"></span>[[#cite-23|[23]]]; Codina and Zienkiewicz, 2002 <span id="citeF-25"></span>[[#cite-25|[25]]]), pressure gradient operator methods (Codina and Blasco, 1997 <span id="citeF-22"></span>[[#cite-22|[22]]], 2000 <span id="citeF-24"></span>[[#cite-24|[24]]]) and the Subgrid Scale (SGS) method (Hughes, 1995 <span id="citeF-44"></span>[[#cite-44|[44]]]; Brezzi ''et al.'', 1997 <span id="citeF-9"></span>[[#cite-9|[9]]]; Codina, 2000 <span id="citeF-17"></span>[[#cite-17|[17]]], 2002 <span id="citeF-21"></span>[[#cite-21|[21]]]). | + | A popular way to overcome the problems with the incompressibility constraint is by introducing a pseudo-compressibility in the flow and using implicit and explicit algorithms developed for this kind of problems, such as artificial compressibility schemes (Chorin, 1967A <span id="citeF-14"></span>[[#cite-14|[14]]]) popular way to overcome the problems with the incompressibility constraint is by introducing a pseudo-compressibility in the flow and using implicit and explicit algorithms developed for this kind of problems, such as artificial compressibility schemes (Chorin, 1967 <span id="citeF-14"></span>[[#cite-14|[14]]]; Farmer ''et al.'', 1993 <span id="citeF-35"></span>[[#cite-35|[35]]]; Peraire ''et al.'', 1994 <span id="citeF-82"></span>[[#cite-82|[82]]]; Briley ''et al.'', 1995 <span id="citeF-10"></span>[[#cite-10|[10]]]; Sheng ''et al.'', 1996 <span id="citeF-86"></span>[[#cite-86|[86]]]) and preconditioning techniques (Idelsohn ''et al.'', 1995 <span id="citeF-51"></span>[[#cite-51|[51]]]). Other FEM schemes with good stabilization properties for the convective and incompressibility terms are based in Petrov-Galerkin (PG) techniques. The background of PG methods are the non-centred (upwind) schemes for computing the first derivatives of the convective operator in FD and FV methods. More recently a general class of Galerkin FEM has been developed where the standard Galerkin variational form is extended with adequate residual-based terms in order to achieve a stabilized numerical scheme (Codina, 1998 <span id="citeF-16"></span>[[#cite-16|[16]]], 2000 <span id="citeF-17"></span>[[#cite-17|[17]]]). Among the many FEM of this kind we can name the Streamline Upwind Petrov Galerkin (SUPG) method (Hughes and Brooks, 1979 <span id="citeF-45"></span>[[#cite-45|[45]]]; Brooks and Hughes, 1982 <span id="citeF-11"></span>[[#cite-11|[11]]]; Tezduyar and Hughes, 1983 <span id="citeF-97"></span>[[#cite-97|[97]]]; Hughes and Tezduyar, 1984 <span id="citeF-46"></span>[[#cite-46|[46]]]; Hughes and Mallet, 1986 <span id="citeF-48"></span>[[#cite-48|[48]]]; Idelsohn ''et al.'', 1995 <span id="citeF-51"></span>[[#cite-51|[51]]]; Storti ''et al.'', 1995 <span id="citeF-88"></span>[[#cite-88|[88]]], 1997 <span id="citeF-89"></span>[[#cite-89|[89]]]; Cruchaga and Oñate, 1997 <span id="citeF-27"></span>[[#cite-27|[27]]], 1999 <span id="citeF-28"></span>[[#cite-28|[28]]]), the Galerkin Least Square (GLS) method (Hughes ''et al.'', 1989 <span id="citeF-50"></span>[[#cite-50|[50]]]; Tezduyar, 1991 <span id="citeF-94"></span>[[#cite-94|[94]]]; Tezduyar ''et al.'', 1992a <span id="citeF-99"></span>[[#cite-99|[99]]]), the Taylor-Galerkin method (Donea, 1984 <span id="citeF-30"></span>[[#cite-30|[30]]]), the Characteristic Galerkin method (Douglas and Russell, 1982 <span id="citeF-32"></span>[[#cite-32|[32]]]; Pironneau, 1982 <span id="citeF-83"></span>[[#cite-83|[83]]]; Löhner ''et al.'', 1984 <span id="citeF-63"></span>[[#cite-63|[63]]]) and its variant the characteristic Based Split (CBS) method (Zienkiewicz and Codina, 1995 <span id="citeF-108"></span>[[#cite-108|[108]]]; Codina ''et al.'', 1998 <span id="citeF-23"></span>[[#cite-23|[23]]]; Codina and Zienkiewicz, 2002 <span id="citeF-25"></span>[[#cite-25|[25]]]), pressure gradient operator methods (Codina and Blasco, 1997 <span id="citeF-22"></span>[[#cite-22|[22]]], 2000 <span id="citeF-24"></span>[[#cite-24|[24]]]) and the Subgrid Scale (SGS) method (Hughes, 1995 <span id="citeF-44"></span>[[#cite-44|[44]]]; Brezzi ''et al.'', 1997 <span id="citeF-9"></span>[[#cite-9|[9]]]; Codina, 2000 <span id="citeF-17"></span>[[#cite-17|[17]]], 2002 <span id="citeF-21"></span>[[#cite-21|[21]]]). |

In this work a stabilized FEM for incompressible flows is derived taking as the starting point the modified governing equations of the flow problem formulated via a finite calculus (FIC) approach. The FIC method is based in invoking the balance of fluxes in a domain of finite size. This introduces naturally additional terms in the classical differential equations of infinitessimal fluid mechanics which are a function of the balance domain dimensions. The new terms in the modified governing equations provide naturally the necessary stabilization to the standard Galerkin finite element method. | In this work a stabilized FEM for incompressible flows is derived taking as the starting point the modified governing equations of the flow problem formulated via a finite calculus (FIC) approach. The FIC method is based in invoking the balance of fluxes in a domain of finite size. This introduces naturally additional terms in the classical differential equations of infinitessimal fluid mechanics which are a function of the balance domain dimensions. The new terms in the modified governing equations provide naturally the necessary stabilization to the standard Galerkin finite element method. | ||

| Line 296: | Line 280: | ||

|} | |} | ||

| − | We see that the FIC procedure introduces ''naturally'' an additional diffusion term into the standard convection-diffusion equation. This is the basis of the popular “artificial diffusion” method (Hirsch | + | We see that the FIC procedure introduces ''naturally'' an additional diffusion term into the standard convection-diffusion equation. This is the basis of the popular “artificial diffusion” method (Hirsch, 1990 <span id="citeF-42"></span>[[#cite-42|[42]]]). The characteristic length <math display="inline">h</math> is typically expressed as a function of the cell or element dimensions. The optimal or critical value of <math display="inline">h</math> can be computed from numerical stability conditions such as obtaining a physically meaningful solution, or even obtaining “exact” nodal values (Zienkiewicz and Taylor, 2000 <span id="citeF-107"></span>[[#cite-107|[107]]]; Oñate and Manzan, 1999 <span id="citeF-76"></span>[[#cite-76|[76]]], 2000 <span id="citeF-77"></span>[[#cite-77|[77]]]; Oñate, 2004 <span id="citeF-72"></span>[[#cite-72|[72]]]). |

Equation ([[#eq-13|13]]) can be extended to account for source and time effects. The full FIC equation for the transient convection-diffusion problem can be written in compact form as | Equation ([[#eq-13|13]]) can be extended to account for source and time effects. The full FIC equation for the transient convection-diffusion problem can be written in compact form as | ||

| Line 770: | Line 754: | ||

Note that the stabilization matrix <math display="inline">\hat{\boldsymbol K}</math> brings in an additional orthotropic diffusivity of value <math display="inline">\rho \displaystyle{h_k v_l\over 2}</math>. Matrices <math display="inline">{\boldsymbol A}, \hat {\boldsymbol K}</math> and <math display="inline">\hat{\boldsymbol C}</math> are dependent on the velocity field. The solution process can be advanced in time in a (quasi-nearly) implicit iterative manner using the following scheme. | Note that the stabilization matrix <math display="inline">\hat{\boldsymbol K}</math> brings in an additional orthotropic diffusivity of value <math display="inline">\rho \displaystyle{h_k v_l\over 2}</math>. Matrices <math display="inline">{\boldsymbol A}, \hat {\boldsymbol K}</math> and <math display="inline">\hat{\boldsymbol C}</math> are dependent on the velocity field. The solution process can be advanced in time in a (quasi-nearly) implicit iterative manner using the following scheme. | ||

| + | <span id="step-1"></span> | ||

''Step 1'' | ''Step 1'' | ||

| − | + | <span id="eq-44"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 778: | Line 763: | ||

|- | |- | ||

| style="text-align: center;" | <math>\bar{\boldsymbol u}^{n+1,i} = \bar{\boldsymbol u}^n - \Delta t {\boldsymbol M}^{-1} [({\boldsymbol A}^{n+\theta _1,i-1}+ {\boldsymbol K} + \hat {\boldsymbol K}^{n+\theta _1,i-1})\bar{\boldsymbol u}^{n+\theta _1,i-1}-{\boldsymbol G}{\boldsymbol p}^{n+\theta _2,i-1} + {\boldsymbol C} \bar {\boldsymbol c}^{n+\theta _3,i-1}-{\boldsymbol f}^{n+1}] </math> | | style="text-align: center;" | <math>\bar{\boldsymbol u}^{n+1,i} = \bar{\boldsymbol u}^n - \Delta t {\boldsymbol M}^{-1} [({\boldsymbol A}^{n+\theta _1,i-1}+ {\boldsymbol K} + \hat {\boldsymbol K}^{n+\theta _1,i-1})\bar{\boldsymbol u}^{n+\theta _1,i-1}-{\boldsymbol G}{\boldsymbol p}^{n+\theta _2,i-1} + {\boldsymbol C} \bar {\boldsymbol c}^{n+\theta _3,i-1}-{\boldsymbol f}^{n+1}] </math> | ||

| + | |- | ||

|} | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (44) | | style="width: 5px;text-align: right;white-space: nowrap;" | (44) | ||

|} | |} | ||

| − | + | <span id="step-2"></span> | |

| − | + | ''Step 2'' | |

| − | + | <span id="eq-45"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 793: | Line 779: | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (45) | | style="width: 5px;text-align: right;white-space: nowrap;" | (45) | ||

|} | |} | ||

| − | + | <span id="step-3"></span> | |

| − | + | ''Step 3'' | |

| − | + | <span id="eq-46"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 805: | Line 791: | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (46) | | style="width: 5px;text-align: right;white-space: nowrap;" | (46) | ||

|} | |} | ||

| − | + | <span id="step-4"></span> | |

| − | + | ''Step 4'' | |

| − | + | <span id="eq-47"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 820: | Line 806: | ||

In above <math display="inline">\theta _i</math> are time integration parameters with <math display="inline">0\le \theta _i\le 1</math> and <math display="inline">\bar{(\cdot )}^{n,i}</math> denotes nodal values at the <math display="inline">n</math>th time step and the ith iteration. <math display="inline">{\boldsymbol A}^{n+\theta _1,i-1}\equiv {\boldsymbol A}(\bar {\boldsymbol u}^{n+\theta _1,i-1})</math> etc. Also <math display="inline">(\cdot )^{n+\theta _i,0}\equiv (\cdot )^n</math> for the computations in step 1 at the onset of the iterations. | In above <math display="inline">\theta _i</math> are time integration parameters with <math display="inline">0\le \theta _i\le 1</math> and <math display="inline">\bar{(\cdot )}^{n,i}</math> denotes nodal values at the <math display="inline">n</math>th time step and the ith iteration. <math display="inline">{\boldsymbol A}^{n+\theta _1,i-1}\equiv {\boldsymbol A}(\bar {\boldsymbol u}^{n+\theta _1,i-1})</math> etc. Also <math display="inline">(\cdot )^{n+\theta _i,0}\equiv (\cdot )^n</math> for the computations in step 1 at the onset of the iterations. | ||

| − | Steps 1, 3 and 4 can be solved explicitely by choosing a ''lumped (diagonal) form'' of matrices | + | Steps [[#step-1|1]], [[#step-3|3]] and [[#step-4|4]] can be solved explicitely by choosing a ''lumped (diagonal) form'' of matrices <math display="inline">M</math> and <math display="inline">\hat {\boldsymbol M}</math>. In this manner the main computational cost is the solution of step [[#step-2|2]] involving the inverse of a Laplacian matrix. This can be solved very effectively using an iterative method. |

For <math display="inline">\theta _i\not =0</math> the iterative proces is unavoidable. The iterations follow until convergence is reached. This can be measured using an adequate error norm in terms of the velocity and pressure variables, or the residuals. Indeed some ot the <math display="inline">\theta _i</math>'s can be made equal to zero. Note that for <math display="inline">\theta _2=0</math> the algorithm is inconditionable unstable. A simple form is obtained making <math display="inline">\theta _1 = \theta _3=\theta _4=0</math>. This elliminates the non linear dependence with the velocity of matrices <math display="inline">{\boldsymbol A}</math> and <math display="inline">\hat{\boldsymbol K}</math> during the iterative scheme. | For <math display="inline">\theta _i\not =0</math> the iterative proces is unavoidable. The iterations follow until convergence is reached. This can be measured using an adequate error norm in terms of the velocity and pressure variables, or the residuals. Indeed some ot the <math display="inline">\theta _i</math>'s can be made equal to zero. Note that for <math display="inline">\theta _2=0</math> the algorithm is inconditionable unstable. A simple form is obtained making <math display="inline">\theta _1 = \theta _3=\theta _4=0</math>. This elliminates the non linear dependence with the velocity of matrices <math display="inline">{\boldsymbol A}</math> and <math display="inline">\hat{\boldsymbol K}</math> during the iterative scheme. | ||

Convergence of above solution scheme is however difficult for some problems. An enhanced version of the algorithm can be obtained by adding the term <math display="inline">\hat {\boldsymbol L} (\bar {\boldsymbol p}^{n+1,i} - \bar {\boldsymbol p}^{n+1,i-1})</math> where <math display="inline">\hat L_{ij} =\Delta t \int _{\Omega ^e} {\boldsymbol \nabla }^T N_i {\boldsymbol \nabla } N_j d\Omega </math> to the equation for the computation of the pressure in the second step. The new term acts as a preconditioner of the pressure equation given now by | Convergence of above solution scheme is however difficult for some problems. An enhanced version of the algorithm can be obtained by adding the term <math display="inline">\hat {\boldsymbol L} (\bar {\boldsymbol p}^{n+1,i} - \bar {\boldsymbol p}^{n+1,i-1})</math> where <math display="inline">\hat L_{ij} =\Delta t \int _{\Omega ^e} {\boldsymbol \nabla }^T N_i {\boldsymbol \nabla } N_j d\Omega </math> to the equation for the computation of the pressure in the second step. The new term acts as a preconditioner of the pressure equation given now by | ||

| − | + | <span id="eq-48"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 842: | Line 828: | ||

===6.2 Fractional step method=== | ===6.2 Fractional step method=== | ||

| − | The pressure can be split from the discretized momentum equations (see Eq.(44)) as | + | The pressure can be split from the discretized momentum equations (see Eq.([[#eq-44|44]])) as |

| − | + | <span id="eq-49"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 853: | Line 839: | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (49) | | style="width: 5px;text-align: right;white-space: nowrap;" | (49) | ||

|} | |} | ||

| − | + | <span id="eq-50"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 864: | Line 850: | ||

|} | |} | ||

| − | In above equations <math display="inline">\alpha </math> is a variable taking values equal to zero or one. For <math display="inline">\alpha =0</math>, <math display="inline">\delta p \equiv p^{n+1}</math> (first order scheme) and for <math display="inline">\alpha =1</math>, <math display="inline">\delta p =\Delta p</math> (second order scheme) (Codina, 2001). Note that in both cases the sum of Eqs.(49) and (50) gives the time discretization of the momentum equations with the pressures computed at <math display="inline">t^{n+1}</math>. The value of <math display="inline">\bar {\boldsymbol u}^{n+1}</math> from Eq.(50) is substituted now into (41b) to give | + | In above equations <math display="inline">\alpha </math> is a variable taking values equal to zero or one. For <math display="inline">\alpha =0</math>, <math display="inline">\delta p \equiv p^{n+1}</math> (first order scheme) and for <math display="inline">\alpha =1</math>, <math display="inline">\delta p =\Delta p</math> (second order scheme) (Codina, 2001 <span id="citeF-19"></span>[[#cite-19|[19]]]). Note that in both cases the sum of Eqs.([[#eq-49|49]]) and ([[#eq-50|50]]) gives the time discretization of the momentum equations with the pressures computed at <math display="inline">t^{n+1}</math>. The value of <math display="inline">\bar {\boldsymbol u}^{n+1}</math> from Eq.([[#eq-50|50]]) is substituted now into ([[#eq-41b|41b]]) to give |

| − | + | <span id="eq-51a"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 877: | Line 863: | ||

The product <math display="inline">{\boldsymbol G}^T {\boldsymbol M}^{-1}{\boldsymbol G}</math> can be approximated by a laplacian matrix, i.e. | The product <math display="inline">{\boldsymbol G}^T {\boldsymbol M}^{-1}{\boldsymbol G}</math> can be approximated by a laplacian matrix, i.e. | ||

| − | + | <span id="eq-51b"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 890: | Line 876: | ||

A semi-implicit algorithm can be derived as follows.<br/> | A semi-implicit algorithm can be derived as follows.<br/> | ||

| − | + | <span id="s1"></span> | |

| + | ''Step 1'' Compute the nodal fractional velocities <math display="inline">{\boldsymbol u}^*</math> explicitely from Eq.([[#eq-49|49]]) with <math display="inline">{\boldsymbol M}={\boldsymbol M}_d</math> where subscript <math display="inline">d</math> denotes a diagonal matrix. | ||

<br/> | <br/> | ||

| − | + | <span id="s2"></span> | |

| − | + | ''Step 2'' Compute <math display="inline">\delta \bar {\boldsymbol p}</math> from Eq.([[#eq-51a|51a]]) (using Eq.([[#eq-51b|51b]])) as | |

| − | + | <span id="eq-52"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 905: | Line 892: | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (52) | | style="width: 5px;text-align: right;white-space: nowrap;" | (52) | ||

|} | |} | ||

| − | + | <span id="s3"></span> | |

| − | + | ''Step 3'' Compute the nodal velocities <math display="inline"> \bar{\boldsymbol u}^{n+1}</math> explicitely from Eq.([[#eq-50|50]]) with <math display="inline">{\boldsymbol M}={\boldsymbol M}_d</math> | |

<br/> | <br/> | ||

| + | <span id="s4"></span> | ||

| + | ''Step 4'' Compute <math display="inline"> \bar{\boldsymbol c}^{n+1}</math> explicitely from Eq.([[#eq-46|46]]) using <math display="inline">{\boldsymbol M}_d</math>. | ||

| − | + | <span id="s5"></span> | |

| − | + | ''Step 5'' Compute <math display="inline"> \bar{\boldsymbol \pi }^{n+1}</math> explicitely from Eq.([[#eq-47|47]]) with <math display="inline">\hat {\boldsymbol M} = \bar{\boldsymbol M}_d</math>. | |

| − | + | ||

| − | This algorithm has an additional step than the iterative algorithm of Section 6.1. The advantage is that now Steps 1 and 2 can be fully linearized by choosing <math display="inline">\theta _1 = \theta _3=\theta _4=0</math>. Also the equation for the pressure variables in Step 2 has improved stabilization properties due to the additional laplacian matrix <math display="inline">\hat{\boldsymbol L}</math>. | + | This algorithm has an additional step than the iterative algorithm of Section [[#6.1 Discretization of the fluid flow equations|6.1.]] The advantage is that now Steps [[#s1|1]] and [[#s2|2]] can be fully linearized by choosing <math display="inline">\theta _1 = \theta _3=\theta _4=0</math>. Also the equation for the pressure variables in Step [[#s2|2]] has improved stabilization properties due to the additional laplacian matrix <math display="inline">\hat{\boldsymbol L}</math>. |

| − | Details on the stability properties of the FIC formulation for incompressible fluid flow problems can be found in Oñate ''et al.'' (2002). | + | Details on the stability properties of the FIC formulation for incompressible fluid flow problems can be found in Oñate ''et al.'' (2002) <span id="citeF-79"></span>[[#cite-79|[79]]]. |

===6.3 Discretization of free-surface wave equation=== | ===6.3 Discretization of free-surface wave equation=== | ||

| − | The solution in time of Eq.(39) can be written in terms of the nodal velocities computed from the flow solution, as | + | The solution in time of Eq.([[#eq-39|39]]) can be written in terms of the nodal velocities computed from the flow solution, as |

| − | + | <span id="eq-53"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 932: | Line 920: | ||

|} | |} | ||

| − | Eq.(53) can now be discretized in space using the standard Galerkin method and solved ''explicitely'' for the nodal wave heights at <math display="inline">t^{n+1}</math>. Typically the general algorithm will be as follows: | + | Eq.([[#eq-53|53]]) can now be discretized in space using the standard Galerkin method and solved ''explicitely'' for the nodal wave heights at <math display="inline">t^{n+1}</math>. Typically the general algorithm will be as follows: |

<ol> | <ol> | ||

| − | <li>Solve for the nodal velocities <math display="inline">\bar{\boldsymbol u}^{n+1}</math> and the pressures <math display="inline">\bar{\boldsymbol p}^{n+1}</math> in the fluid domain using any of the algorithms of Sections 6.1 and 6.2. When solving for the pressure equation impose <math display="inline">p^{n+1}= p_a</math> at the free-surface <math display="inline">\Gamma _\beta </math>. </li> | + | <li>Solve for the nodal velocities <math display="inline">\bar{\boldsymbol u}^{n+1}</math> and the pressures <math display="inline">\bar{\boldsymbol p}^{n+1}</math> in the fluid domain using any of the algorithms of Sections [[#6.1 Discretization of the fluid flow equations|6.1]] and [[#6.2 Fractional step method|6.2.]] When solving for the pressure equation impose <math display="inline">p^{n+1}= p_a</math> at the free-surface <math display="inline">\Gamma _\beta </math>. </li> |

| − | <li>Solve for the free-surface elevation <math display="inline">\beta ^{n+1}</math> (viz. Eq.(53)). </li> | + | <li>Solve for the free-surface elevation <math display="inline">\beta ^{n+1}</math> (viz. Eq.([[#eq-53|53]])). </li> |

<li>Compute the new position of the mesh nodes in the fluid domain at time <math display="inline">t^{n+1}</math>. Alternatively, regenerate a new mesh. </li> | <li>Compute the new position of the mesh nodes in the fluid domain at time <math display="inline">t^{n+1}</math>. Alternatively, regenerate a new mesh. </li> | ||

| Line 945: | Line 933: | ||

The mesh updating process can also include the free-surface nodes, although this is not strictly necessary. An ''hydrostatic adjustement'' can be implemented once the new free-surface elevation is computed simply by imposing the pressure at the nodes on the reference surface as | The mesh updating process can also include the free-surface nodes, although this is not strictly necessary. An ''hydrostatic adjustement'' can be implemented once the new free-surface elevation is computed simply by imposing the pressure at the nodes on the reference surface as | ||

| − | + | <span id="eq-54"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 958: | Line 946: | ||

where <math display="inline">g</math> is the gravity constant. | where <math display="inline">g</math> is the gravity constant. | ||

| − | Eq.(54) takes into account the changes in the free-surface without the need of updating the reference surface nodes. A higher accuracy in the flow solution can be obtained by updating these nodes after a number of time steps. | + | Eq.([[#eq-54|54]]) takes into account the changes in the free-surface without the need of updating the reference surface nodes. A higher accuracy in the flow solution can be obtained by updating these nodes after a number of time steps. |

==7 FLUID-SHIP INTERACTION== | ==7 FLUID-SHIP INTERACTION== | ||

| Line 965: | Line 953: | ||

In both cases the computation of the ship motion involves solving the dynamic equations of the ship structure written as | In both cases the computation of the ship motion involves solving the dynamic equations of the ship structure written as | ||

| − | + | <span id="eq-55"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 976: | Line 964: | ||

|} | |} | ||

| − | where <math display="inline">{\boldsymbol d}</math> and <math display="inline">\ddot {\boldsymbol d}</math> are the displacement and acceleration vectors of the nodes discretizing the ship structure, respectively, <math display="inline">{\boldsymbol M}_s</math> and <math display="inline">{\boldsymbol K}_s</math> are the mass and stiffness matrices of the structure and <math display="inline">{\boldsymbol f}_{ext}</math> is the vector of external nodal forces accounting for the fluid flow loads induced by the pressure and the viscous stresses. Clearly the main driving forces for the motion of the ship is the fluid pressure which acts in the form of a surface traction. Indeed Eq.(55) can be augmented with an appropriate damping term. The form of all the relevant matrices and vectors can be found in standard books on FEM for structural analysis (Zienkiewicz and Taylor, Vol 2 2000). | + | where <math display="inline">{\boldsymbol d}</math> and <math display="inline">\ddot {\boldsymbol d}</math> are the displacement and acceleration vectors of the nodes discretizing the ship structure, respectively, <math display="inline">{\boldsymbol M}_s</math> and <math display="inline">{\boldsymbol K}_s</math> are the mass and stiffness matrices of the structure and <math display="inline">{\boldsymbol f}_{ext}</math> is the vector of external nodal forces accounting for the fluid flow loads induced by the pressure and the viscous stresses. Clearly the main driving forces for the motion of the ship is the fluid pressure which acts in the form of a surface traction. Indeed Eq.([[#eq-55|55]]) can be augmented with an appropriate damping term. The form of all the relevant matrices and vectors can be found in standard books on FEM for structural analysis (Zienkiewicz and Taylor, Vol 2 2000 <span id="citeF-107"></span>[[#cite-107|[107]]]). |

| − | Solution of Eq.(55) in time can be performed using implicit or fully explicit time integration algorithms. In both cases the values of the nodal displacements, the velocities and the accelerations at time <math display="inline">t^{n+1}</math> are found. | + | Solution of Eq.([[#eq-55|55]]) in time can be performed using implicit or fully explicit time integration algorithms. In both cases the values of the nodal displacements, the velocities and the accelerations at time <math display="inline">t^{n+1}</math> are found. |

| − | A simple coupled fluid-ship-structure solution in time using, for instance, the fractional step method of Section 6.2 (for <math display="inline">\theta _1=\theta _2=\theta _3=\theta _4=0</math>) involves the following steps. | + | A simple coupled fluid-ship-structure solution in time using, for instance, the fractional step method of Section [[#6.2 Fractional step method|6.2]] (for <math display="inline">\theta _1=\theta _2=\theta _3=\theta _4=0</math>) involves the following steps. |

<br/> | <br/> | ||

| + | <span id="step1"></span> | ||

| + | '''Step 1''' Solve for the fractional velocities <math display="inline">\bar{\boldsymbol u}^*</math> using Eq.([[#eq-49|49]]). Here use of <math display="inline">\alpha =1</math> is recommended. | ||

| − | '''Step | + | <br/> |

| + | <span id="step2"></span> | ||

| + | '''Step 2''' Compute <math display="inline">\delta \bar {\boldsymbol p}</math> from Eq.([[#eq-51a|51a]]) solving a simultaneous system of equations. | ||

<br/> | <br/> | ||

| − | + | <span id="step3"></span> | |

| − | + | '''Step 3''' Compute explicitely the nodal velocities <math display="inline"> \bar{\boldsymbol u}^{n+1}</math> from Eq.([[#eq-50|50]]) with a diagonal mass matrix. | |

| − | + | ||

| − | '''Step 3''' Compute explicitely the nodal velocities <math display="inline"> \bar{\boldsymbol u}^{n+1}</math> from Eq.(50) with a diagonal mass matrix. | + | |

<br/> | <br/> | ||

| − | + | <span id="step4"></span> | |

| − | '''Step 4''' Compute explicitely the projected convective variables <math display="inline">\bar{\boldsymbol c}^{n+1}</math> from Eq.(46) using <math display="inline">{\boldsymbol M}_d</math>. | + | '''Step 4''' Compute explicitely the projected convective variables <math display="inline">\bar{\boldsymbol c}^{n+1}</math> from Eq.([[#eq-46|46]]) using <math display="inline">{\boldsymbol M}_d</math>. |

<br/> | <br/> | ||

| − | + | <span id="step5"></span> | |

| − | '''Step 5''' Compute explicitely the projected pressure gradients <math display="inline">\bar {\boldsymbol \pi }^{n+1}</math> from Eq.(47) using <math display="inline">\hat{\boldsymbol M}_d</math>. | + | '''Step 5''' Compute explicitely the projected pressure gradients <math display="inline">\bar {\boldsymbol \pi }^{n+1}</math> from Eq.([[#eq-47|47]]) using <math display="inline">\hat{\boldsymbol M}_d</math>. |

<br/> | <br/> | ||

| − | + | <span id="step6"></span> | |

| − | '''Step 6''' Compute explicitely the new position of the free-surface elevation <math display="inline">\bar{\boldsymbol \beta }^{n+1}</math> from Eq.(53). | + | '''Step 6''' Compute explicitely the new position of the free-surface elevation <math display="inline">\bar{\boldsymbol \beta }^{n+1}</math> from Eq.([[#eq-53|53]]). |

<br/> | <br/> | ||

| − | + | <span id="step7"></span> | |

'''Step 7''' Compute the movement of the ship by solving the dynamic equations of motion for the ship structure under the hydrodynamic forces induced by the pressures <math display="inline">\bar {\boldsymbol p}^{n+1}</math> and the viscous stresses <math display="inline">{\boldsymbol s}^{n+1}</math>. | '''Step 7''' Compute the movement of the ship by solving the dynamic equations of motion for the ship structure under the hydrodynamic forces induced by the pressures <math display="inline">\bar {\boldsymbol p}^{n+1}</math> and the viscous stresses <math display="inline">{\boldsymbol s}^{n+1}</math>. | ||

<br/> | <br/> | ||

| + | <span id="step8"></span> | ||

| + | '''Step 8''' Update the position of the mesh nodes in the fluid domain at <math display="inline">t^{n+1}</math> by using the mesh update algorithm described in the next section. The updating process can also include the free-surface nodes although this is not strictly necessary to be done at every time step and the hydrostatic adjustment of the pressure acting on the free-surface (Section [[#6.3 Discretization of free-surface wave equation|6.3]]) can be used as an alternative.<br/> | ||

| − | + | Obviously, the use of a value different from zero for the <math display="inline">\theta _1,\theta _2,\theta _3</math> or <math display="inline">\theta _4</math> parameters will require an iterative process between steps [[#step1|1]] and [[#step8|8]] until a converged solution for the variables describing the fluid and ship motions is found. | |

| − | + | ||

| − | Obviously, the use of a value different from zero for the <math display="inline">\theta _1,\theta _2,\theta _3</math> or <math display="inline">\theta _4</math> parameters will require an iterative process between steps 1 and 8 until a converged solution for the variables describing the fluid and ship motions is found. | + | |

A common option is to update the position of the mesh nodes only when the iterative process for computing the fluid and ship variables has converged. Clearly the regeneration of the mesh is unavoidable when the distorsion of the elements exceed a certain limit. | A common option is to update the position of the mesh nodes only when the iterative process for computing the fluid and ship variables has converged. Clearly the regeneration of the mesh is unavoidable when the distorsion of the elements exceed a certain limit. | ||

| Line 1,018: | Line 1,008: | ||

==8 A SIMPLE ALGORITHM FOR UPDATING THE MESH NODES== | ==8 A SIMPLE ALGORITHM FOR UPDATING THE MESH NODES== | ||

| − | Different techniques have been proposed for dealing with mesh updating in fluid-structure interaction problems. The general aim of all methods is to prevent element distortion during mesh deformation (Tezduyar, 2001a; Tezduyar ''et al.'', | + | Different techniques have been proposed for dealing with mesh updating in fluid-structure interaction problems. The general aim of all methods is to prevent element distortion during mesh deformation (Tezduyar, 2001a <span id="citeF-95"></span>[[#cite-95|[95]]]; Tezduyar ''et al.'', 1992bc <span id="citeF-100"></span>[[#cite-100|[100]]-<span id="citeF-101"></span>[[#cite-101|101]]]). |

| − | + | ||

| − | + | ||

| + | Tezduyar ''et al.'' (1992c) <span id="citeF-101"></span>[[#cite-101|[101]]] and Chiandussi ''et al.'' (2000) <span id="citeF-13"></span>[[#cite-13|[13]]] have proposed simple method for moving the mesh nodes based on the iterative solution of a fictious linear elastic problem on the mesh domain. In the method introduced in Tezduyar ''et al.'' (1992c) <span id="citeF-101"></span>[[#cite-101|[101]]], the mesh deformation is handled selectively based on the element sizes and deformation modes, with the objective to increase stiffening of the smaller elements, which are typically located near solid surfaces. In Chiandusi ''et al.'' (2000) <span id="citeF-13"></span>[[#cite-13|[13]]] in order to minimize the mesh deformation the “elastic” properties of each mesh element are appropiately selected so that elements suffering greater movements are stiffer. A simple and effective procedure is to select the Poisson's ratio <math display="inline">\nu =0</math> and compute the “equivalent” Young modulus for each element by | ||

| + | <span id="eq-56"></span> | ||

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 1,034: | Line 1,024: | ||

where <math display="inline">\varepsilon _i</math> are the principal strains, <math display="inline">\bar E</math> is an arbitrary value of the Young modulus and <math display="inline">\bar \varepsilon </math> is a prescribed uniform strain field. <math display="inline">\bar E</math> and <math display="inline">\bar \varepsilon </math> are constant for all the elements in the mesh. | where <math display="inline">\varepsilon _i</math> are the principal strains, <math display="inline">\bar E</math> is an arbitrary value of the Young modulus and <math display="inline">\bar \varepsilon </math> is a prescribed uniform strain field. <math display="inline">\bar E</math> and <math display="inline">\bar \varepsilon </math> are constant for all the elements in the mesh. | ||

| − | In summary, the solution scheme proposed by Chiandusi ''et al.'' (2000) includes the following two steps. | + | In summary, the solution scheme proposed by Chiandusi ''et al.'' (2000) <span id="citeF-13"></span>[[#cite-13|[13]]] includes the following two steps. |

''Step 1''. Consider the FE mesh as a linear elastic solid with homogeneous material properties characterized by a prescribed uniform strain field <math display="inline">\bar \varepsilon </math>, an arbitrary Young modulus <math display="inline">\bar E</math> and <math display="inline">\nu =0</math>. Solve a linear elastic problem with imposed displacements at the mesh boundary defined by the actual movement of the boundary nodes. An approximate solution to this linear elastic problem, such as that given by the first iterations of a conjugate gradient solution scheme, suffices for practical purposes. | ''Step 1''. Consider the FE mesh as a linear elastic solid with homogeneous material properties characterized by a prescribed uniform strain field <math display="inline">\bar \varepsilon </math>, an arbitrary Young modulus <math display="inline">\bar E</math> and <math display="inline">\nu =0</math>. Solve a linear elastic problem with imposed displacements at the mesh boundary defined by the actual movement of the boundary nodes. An approximate solution to this linear elastic problem, such as that given by the first iterations of a conjugate gradient solution scheme, suffices for practical purposes. | ||

| − | ''Step 2''. Compute the principal strains in each element. Repeat the (approximate) FE solution of the linear elastic problem with prescribed boundary displacements using the values of <math display="inline">E</math> of Eq.(56). | + | ''Step 2''. Compute the principal strains in each element. Repeat the (approximate) FE solution of the linear elastic problem with prescribed boundary displacements using the values of <math display="inline">E</math> of Eq.([[#eq-56|56]]). |

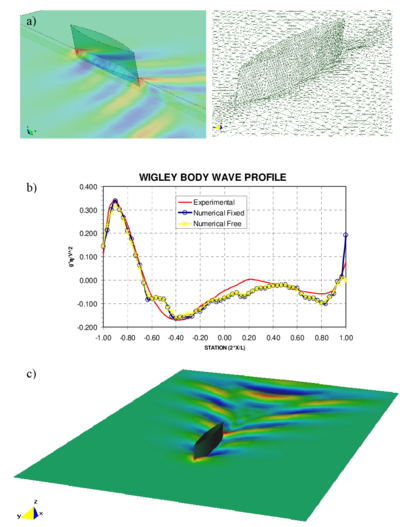

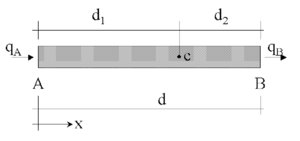

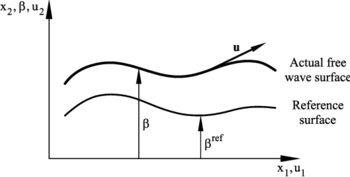

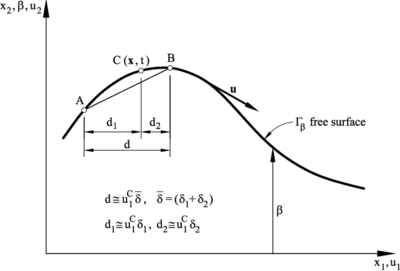

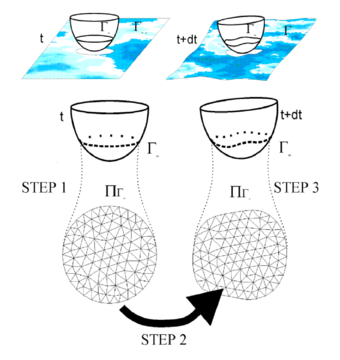

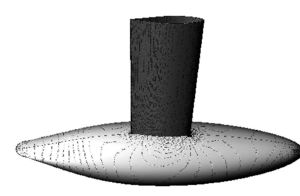

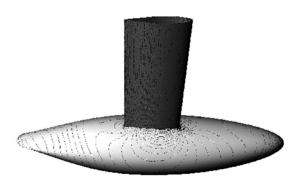

| − | The previous algorithm is able to treat the movement of the mesh due to changes in position of fully submerged and semi-submerged bodies such as ships. However if the floating body intersects the free-surface, the changes in the analysis domain can be very important as emersion or inmersion of significant parts of the body can occur within a time step. A possible solution to this problem is to remesh the analysis domain. However, for most problems a mapping of the moving surfaces linked to mesh updating algorithm described above can avoid remeshing. The surface mapping technique used by the authors is based on transforming the 3D curved surfaces into reference planes (Figure 4). This makes it possible to compute within each plane the local (in-plane) coordinates of the nodes for the final surface mesh accordingly to the changes in the floating line. The final step is to transform back the local coordinates of the surface mesh in the reference plane to the final curved configuration which incorporates the new floating line (García, 1999; Oñate and García, 2001). | + | The previous algorithm is able to treat the movement of the mesh due to changes in position of fully submerged and semi-submerged bodies such as ships. However if the floating body intersects the free-surface, the changes in the analysis domain can be very important as emersion or inmersion of significant parts of the body can occur within a time step. A possible solution to this problem is to remesh the analysis domain. However, for most problems a mapping of the moving surfaces linked to mesh updating algorithm described above can avoid remeshing. The surface mapping technique used by the authors is based on transforming the 3D curved surfaces into reference planes (Figure [[#img-4|4]]). This makes it possible to compute within each plane the local (in-plane) coordinates of the nodes for the final surface mesh accordingly to the changes in the floating line. The final step is to transform back the local coordinates of the surface mesh in the reference plane to the final curved configuration which incorporates the new floating line (García, 1999 <span id="citeF-37"></span>[[#cite-37|[37]]]; Oñate and García, 2001 <span id="citeF-78"></span>[[#cite-78|[78]]]). |

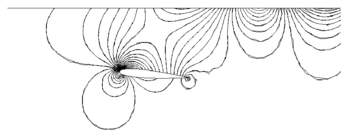

==9 MODELLING OF THE TRANSOM STERN FLOW== | ==9 MODELLING OF THE TRANSOM STERN FLOW== | ||

| − | The transom stern causes a discontinuity in the domain and the solution of the free-surface equation close to this region is inconsistent with the convective nature of the equation. This leads to instability of the wave height close to the transom region. This instability is found experimentally for low speeds. The flow at a sufficient high speed is physically more stable although it still can not be reproduced by standard numerical techniques (Reed ''et al.'', 1990). | + | The transom stern causes a discontinuity in the domain and the solution of the free-surface equation close to this region is inconsistent with the convective nature of the equation. This leads to instability of the wave height close to the transom region. This instability is found experimentally for low speeds. The flow at a sufficient high speed is physically more stable although it still can not be reproduced by standard numerical techniques (Reed ''et al.'', 1990) <span id="citeF-85"></span>[[#cite-85|[85]]]. |

A solution to this problem is to apply adequate free-surface boundary conditions at the transom boundary. The obvious condition is to fix both the free surface elevation <math display="inline">\beta </math> and its derivative along the corresponding streamline to values given by the transom position and the surface gradient. However, prescribing those values can influence the transition between the transom flux and the lateral flux, resulting in unaccurate wave maps. | A solution to this problem is to apply adequate free-surface boundary conditions at the transom boundary. The obvious condition is to fix both the free surface elevation <math display="inline">\beta </math> and its derivative along the corresponding streamline to values given by the transom position and the surface gradient. However, prescribing those values can influence the transition between the transom flux and the lateral flux, resulting in unaccurate wave maps. | ||

| − | The method proposed in García and Oñate (2003) is to extend the free-surface below the ship. In this way the necessary Dirichlet boundary conditions imposed at the inflow domain are enough to define a well posed problem. This method is valid both for the wetted and dry transom cases and it is also applicable to ships with regular stern. | + | The method proposed in García and Oñate (2003) <span id="citeF-38"></span>[[#cite-38|[38]]] is to extend the free-surface below the ship. In this way the necessary Dirichlet boundary conditions imposed at the inflow domain are enough to define a well posed problem. This method is valid both for the wetted and dry transom cases and it is also applicable to ships with regular stern. |

This scheme does not work for partially wetted transoms. This situation can occur for highly unsteady flows where wake vortex induces the free-surface deformation and the flow remains adhered to the transom. To favour the computation of the free-surface, an artificial viscosity term is added to the free-surface equation in the vicinity of the transom in these cases. | This scheme does not work for partially wetted transoms. This situation can occur for highly unsteady flows where wake vortex induces the free-surface deformation and the flow remains adhered to the transom. To favour the computation of the free-surface, an artificial viscosity term is added to the free-surface equation in the vicinity of the transom in these cases. | ||

| Line 1,056: | Line 1,046: | ||

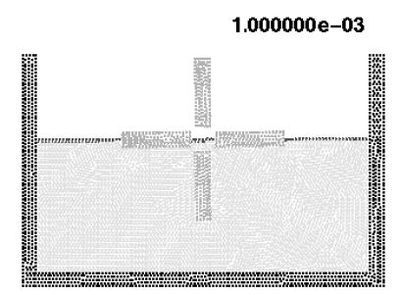

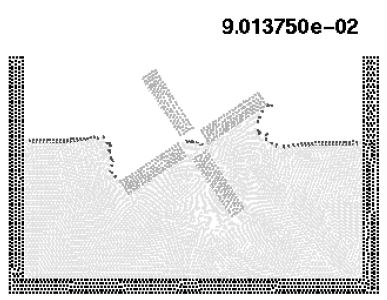

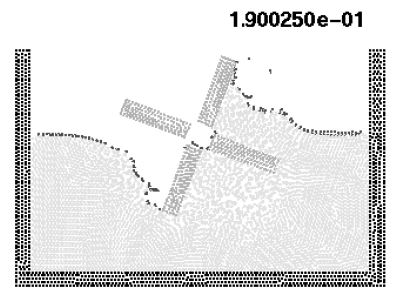

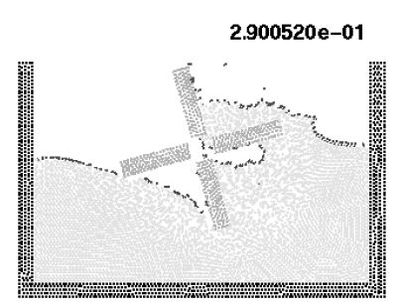

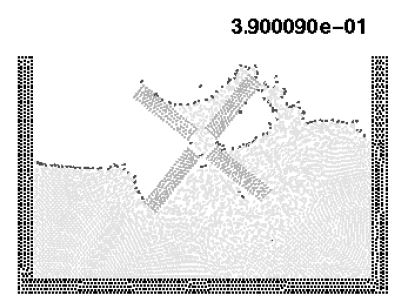

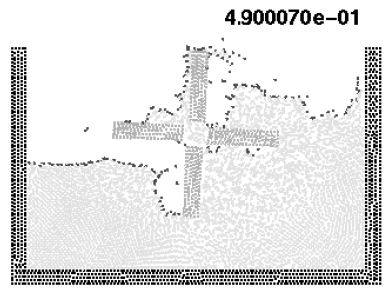

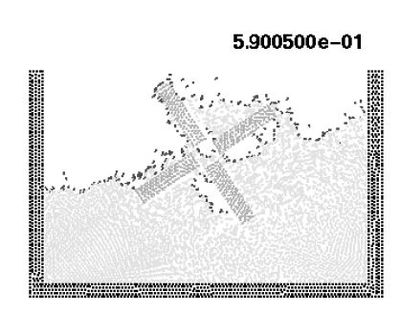

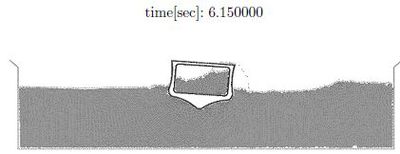

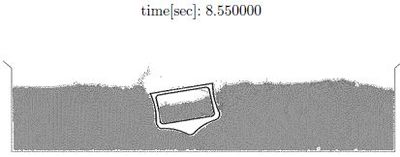

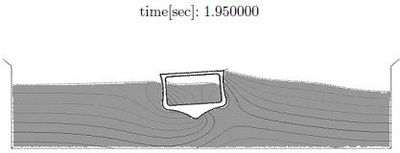

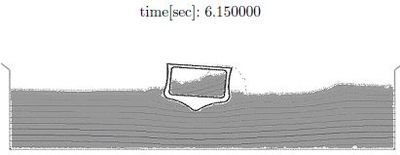

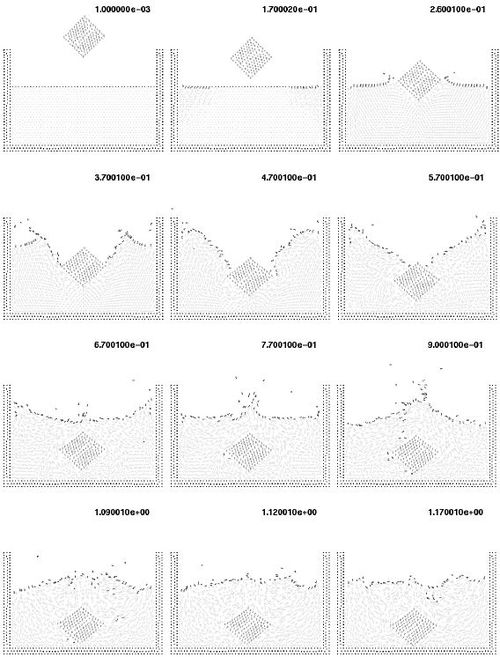

The Lagrangian formulation is an effective (and relatively simple) procedure for modelling the flow of fluid particles undergoing severe distorsions such as water jets, high amplitude waves, braking waves, water splashing, filling of cavities, etc. Indeed the Lagrangian formulation is very suitable for treating ship hydrodynamic problems where the ship undergoes large motions. An obvious “a priori” advantage of the Lagrangian formulation is that both the ship and the fluid motion are defined in the same frame of reference. | The Lagrangian formulation is an effective (and relatively simple) procedure for modelling the flow of fluid particles undergoing severe distorsions such as water jets, high amplitude waves, braking waves, water splashing, filling of cavities, etc. Indeed the Lagrangian formulation is very suitable for treating ship hydrodynamic problems where the ship undergoes large motions. An obvious “a priori” advantage of the Lagrangian formulation is that both the ship and the fluid motion are defined in the same frame of reference. | ||

| − | The Lagrangian fluid flow equations are obtained by noting that the velocity of the mesh nodes and that of the fluid particles are the same. Hence the relative velocities <math display="inline">v_i</math> are zero in Eq.(21) and the convective terms vanish in the momentum equations, while the rest of the fluid flow equations remain unchanged. Also, the solution of the free surface equation is not needed in the Lagrangian formulation, as the free surface motion is modelled naturally by computing the displacement of (all) the fluid particles at each time step. In any case, the new position of the free surface nodes must be properly identified as described below. | + | The Lagrangian fluid flow equations are obtained by noting that the velocity of the mesh nodes and that of the fluid particles are the same. Hence the relative velocities <math display="inline">v_i</math> are zero in Eq.([[#eq-21|21]]) and the convective terms vanish in the momentum equations, while the rest of the fluid flow equations remain unchanged. Also, the solution of the free surface equation is not needed in the Lagrangian formulation, as the free surface motion is modelled naturally by computing the displacement of (all) the fluid particles at each time step. In any case, the new position of the free surface nodes must be properly identified as described below. |

| − | The FEM algorithms for solving the Lagrangian flow equations are very similar to those for the ALE description presented earlier. We will focus in the second order fractional step algorithm of Section 6.2 (for <math display="inline">\theta _1 = \theta _4=0</math> and <math display="inline">\alpha =1</math>) accounting also for fluid-ship interaction effects. | + | The FEM algorithms for solving the Lagrangian flow equations are very similar to those for the ALE description presented earlier. We will focus in the second order fractional step algorithm of Section [[#6.2 Fractional step method|6.2]] (for <math display="inline">\theta _1 = \theta _4=0</math> and <math display="inline">\alpha =1</math>) accounting also for fluid-ship interaction effects. |

'''Step 1''' Compute explicitely a predicted value of the velocities <math display="inline">{\boldsymbol u}^*</math> as | '''Step 1''' Compute explicitely a predicted value of the velocities <math display="inline">{\boldsymbol u}^*</math> as | ||

| − | + | <span id="eq-57"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 1,072: | Line 1,062: | ||

|} | |} | ||

| − | Note that matrices | + | Note that matrices <math display="inlne">A</math> and <math display="inline">\bar{\boldsymbol K}</math> of Eq.([[#eq-48|48]]) emanating from the convective terms have been elliminated. |

| − | '''Step 2''' Compute <math display="inline">\delta \bar {\boldsymbol p}</math> from Eq.(52). | + | '''Step 2''' Compute <math display="inline">\delta \bar {\boldsymbol p}</math> from Eq.([[#eq-52|52]]). |

| − | '''Step 3''' Compute explicitely <math display="inline"> \bar{\boldsymbol u}^{n+1}</math> from Eq.(50) with <math display="inline">{\boldsymbol M}={\boldsymbol M}_d</math>. | + | '''Step 3''' Compute explicitely <math display="inline"> \bar{\boldsymbol u}^{n+1}</math> from Eq.([[#eq-50|50]]) with <math display="inline">{\boldsymbol M}={\boldsymbol M}_d</math>. |

| − | '''Step 4''' Compute <math display="inline">\bar {\boldsymbol \pi }^{n+1}</math> explicitely from Eq.(46). | + | '''Step 4''' Compute <math display="inline">\bar {\boldsymbol \pi }^{n+1}</math> explicitely from Eq.([[#eq-46|46]]). |

| − | '''Step 5''' Solve for the motion of the ship structure by integrating Eq.(55). | + | <span id="se-5"></span> |

| + | '''Step 5''' Solve for the motion of the ship structure by integrating Eq.([[#eq-55|55]]). | ||

'''Step 6''' Update the mesh nodes in a Lagrangian manner as | '''Step 6''' Update the mesh nodes in a Lagrangian manner as | ||

| − | + | <span id="eq-58"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 1,096: | Line 1,087: | ||

'''Step 7''' Generate a new mesh and identify the new free surface nodes. | '''Step 7''' Generate a new mesh and identify the new free surface nodes. | ||

| − | Further details of above algorithm can be found in Idelsohn ''et al.'' (2002, 2003a) and Oñate ''et al.'' (2003,2004). | + | Further details of above algorithm can be found in Idelsohn ''et al.'' (2002 <span id="citeF-53"></span>[[#cite-53|[53]]], 2003a <span id="citeF-54"></span>[[#cite-54|[54]]]) and Oñate ''et al.'' (2003 <span id="citeF-80"></span>[[#cite-80|[80]]], 2004 <span id="citeF-81"></span>[[#cite-81|[81]]]). |

| − | The mesh regeneration process can be effectively performed using the extended Delaunay Tesselation described in Idelsohn ''et al.'' (2003b,c). This method allows the fast generation of good quality meshes combining four node tetrahedra (or three node triangles in 2D) with hexahedra and non standard polyhedra such as pentahedra (or quadrilaterals and pentagons in 2D) where linear shape functions are derived using non-Sibsonian interpolation rules. The mesh regeneration can take place at each time step (this has been the case for the examples presented in the paper), after a prescribed number of time steps, or when the nodal displacements induce significant element distorsions. | + | The mesh regeneration process can be effectively performed using the extended Delaunay Tesselation described in Idelsohn ''et al.'' (2003b,c <span id="citeF-55"></span>[[#cite-55|[55]]-<span id="citeF-56"></span>[[#cite-56|56]]])). This method allows the fast generation of good quality meshes combining four node tetrahedra (or three node triangles in 2D) with hexahedra and non standard polyhedra such as pentahedra (or quadrilaterals and pentagons in 2D) where linear shape functions are derived using non-Sibsonian interpolation rules. The mesh regeneration can take place at each time step (this has been the case for the examples presented in the paper), after a prescribed number of time steps, or when the nodal displacements induce significant element distorsions. |

| − | The identification of the free-surface nodes in the Lagrangian analysis can be made using the Alpha Shape method. This is based on the search of all nodes which are on an empty Voronoi sphere with a radius greater than a specified distance defined in terms of the mesh size. For details see Edelsbrunner and Mucke (1994) and Idelsohn ''et al.'' (2002, 2003a,b,c). A known value of the pressure (typically zero pressure or the atmospheric pressure) is prescribed at the free surface nodes. | + | The identification of the free-surface nodes in the Lagrangian analysis can be made using the Alpha Shape method. This is based on the search of all nodes which are on an empty Voronoi sphere with a radius greater than a specified distance defined in terms of the mesh size. For details see Edelsbrunner and Mucke (1994) <span id="citeF-34"></span>[[#cite-34|[34]]] and Idelsohn ''et al.'' (2002 <span id="citeF-53"></span>[[#cite-53|[53]]], 2003a,b,c <span id="citeF-54"></span>[[#cite-54|[54]]-<span id="citeF-56"></span>[[#cite-56|56]]]). A known value of the pressure (typically zero pressure or the atmospheric pressure) is prescribed at the free surface nodes. |

| − | The conditions of prescribed velocities or pressures at the solid boundaries in the Lagrangian formulation are usually applied on a layer of nodes adjacent to the boundary. These nodes typically remain fixed during the solution process. Contact between water particles and the solid boundaries is accounted for by the incompressibility condition which naturally prevents the water nodes to penetrate into the solid boundaries. This simple way to treat the water-wall contact is another attractive feature of the Lagrangian flow formulation. For details see Idelsohn ''et al.'' (2002, 2003a) and Oñate ''et al.'' (2003,2004). | + | The conditions of prescribed velocities or pressures at the solid boundaries in the Lagrangian formulation are usually applied on a layer of nodes adjacent to the boundary. These nodes typically remain fixed during the solution process. Contact between water particles and the solid boundaries is accounted for by the incompressibility condition which naturally prevents the water nodes to penetrate into the solid boundaries. This simple way to treat the water-wall contact is another attractive feature of the Lagrangian flow formulation. For details see Idelsohn ''et al.'' (2002 <span id="citeF-53"></span>[[#cite-53|[53]]], 2003a <span id="citeF-54"></span>[[#cite-54|[54]]]) and Oñate ''et al.'' (2003 <span id="citeF-80"></span>[[#cite-80|[80]]], 2004 <span id="citeF-81"></span>[[#cite-81|[81]]]). |

==11 MODELLING THE STRUCTURE AS A VISCOUS FLUID== | ==11 MODELLING THE STRUCTURE AS A VISCOUS FLUID== | ||

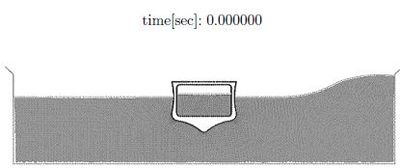

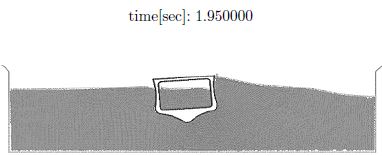

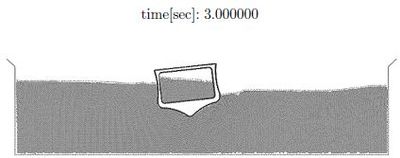

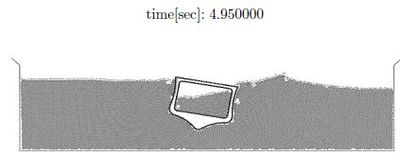

| − | A simple and yet effective way to analyze the rigid motion of solid bodies in fluids with the Lagrangian flow description is to model the solid as a fluid with a viscosity much higher than that of the surrounding fluid. The fractional step scheme of Section 10 can be readily applied skipping now step 5 to solve for the motion of both fluid domains (the actual fluid and the fictitious fluid modelling the rigid body displacements of the solid). An example of this type is presented in Sections 14.6.4 and 14.6. | + | A simple and yet effective way to analyze the rigid motion of solid bodies in fluids with the Lagrangian flow description is to model the solid as a fluid with a viscosity much higher than that of the surrounding fluid. The fractional step scheme of Section [[#10 LAGRANGIAN FLOW FORMULATION|10]] can be readily applied skipping now step [[#se-5|5]] to solve for the motion of both fluid domains (the actual fluid and the fictitious fluid modelling the rigid body displacements of the solid). An example of this type is presented in Sections [[#14.6.4 Floating wood piece|14.6.4]] and [[#14.6.7 Rigid cube falling in a recipient with water|14.6.7.]] |

Indeed this approach can be further extended to account for the elastic deformation of the solid treated now as a visco-elastic fluid. This will however introduce some complexity in the formulation and the full coupled fluid-structure interaction scheme previously described is preferable. | Indeed this approach can be further extended to account for the elastic deformation of the solid treated now as a visco-elastic fluid. This will however introduce some complexity in the formulation and the full coupled fluid-structure interaction scheme previously described is preferable. | ||

| Line 1,112: | Line 1,103: | ||

==12 COMPUTATION OF THE CHARACTERISTIC LENGTHS== | ==12 COMPUTATION OF THE CHARACTERISTIC LENGTHS== | ||

| − | The evaluation of the stabilization parameters is a crucial issue in stabilized methods. Most existing methods use expressions which are direct extensions of the values obtained for the simplest 1D case. It is also usual to accept the so called SUPG assumption, i.e. to admit that vector <math display="inline">{\boldsymbol h}</math> has the direction of the velocity field. This restriction leads to instabilities when sharp layers transversal to the velocity direction are present. This deficiency is usually corrected by adding a shock capturing or crosswind stabilization term (Hughes and Mallet, 1986; Tezduyar and Partk, 1986; Codina, 1993). Indeed, in the FIC formulation the components of <math display="inline">{\boldsymbol h}</math> introduce the necessary stabilization along both the streamline and transversal directions to the flow. | + | The evaluation of the stabilization parameters is a crucial issue in stabilized methods. Most existing methods use expressions which are direct extensions of the values obtained for the simplest 1D case. It is also usual to accept the so called SUPG assumption, i.e. to admit that vector <math display="inline">{\boldsymbol h}</math> has the direction of the velocity field. This restriction leads to instabilities when sharp layers transversal to the velocity direction are present. This deficiency is usually corrected by adding a shock capturing or crosswind stabilization term (Hughes and Mallet, 1986 <span id="citeF-48"></span>[[#cite-48|[48]]]; Tezduyar and Partk, 1986 <span id="citeF-98"></span>[[#cite-98|[98]]]; Codina, 1993 <span id="citeF-15"></span>[[#cite-15|[15]]]). Indeed, in the FIC formulation the components of <math display="inline">{\boldsymbol h}</math> introduce the necessary stabilization along both the streamline and transversal directions to the flow. |

Excellent results have been obtained in all problems solved with the ALE formulation using linear tetrahedra with the value of the characteristic length vector defined by | Excellent results have been obtained in all problems solved with the ALE formulation using linear tetrahedra with the value of the characteristic length vector defined by | ||

| − | + | <span id="eq-59"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 1,127: | Line 1,118: | ||

where <math display="inline">u=\vert {\boldsymbol u}\vert </math> and <math display="inline">h_s</math> and <math display="inline">h_{c}</math> are the “streamline” and “cross wind” contributions given by | where <math display="inline">u=\vert {\boldsymbol u}\vert </math> and <math display="inline">h_s</math> and <math display="inline">h_{c}</math> are the “streamline” and “cross wind” contributions given by | ||

| − | + | <span id="eq-60"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 1,133: | Line 1,124: | ||

{| style="text-align: left; margin:auto;width: 100%;" | {| style="text-align: left; margin:auto;width: 100%;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math> | + | | style="text-align: center;" | <math>{\boldsymbol h}_s=\max ({\boldsymbol l}^T_j {\boldsymbol u})/{u} </math> |

| + | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (60) | | style="width: 5px;text-align: right;white-space: nowrap;" | (60) | ||

| + | |} | ||

| + | <span id="eq-61"></span> | ||

| + | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| − | | style="text-align: center;" | <math> | + | | |

| + | {| style="text-align: left; margin:auto;width: 100%;" | ||

| + | |- | ||

| + | | style="text-align: center;" | <math> {\boldsymbol h}_{c}=\max ({\boldsymbol l}^T_j {\boldsymbol \nabla }u)/ \vert {\boldsymbol \nabla }u\vert \quad , \quad j=1,n_s </math> | ||

| + | |} | ||

| style="width: 5px;text-align: right;white-space: nowrap;" | (61) | | style="width: 5px;text-align: right;white-space: nowrap;" | (61) | ||

|} | |} | ||

| − | + | ||

where <math display="inline">{\boldsymbol l}_j</math> are the vectors defining the element sides (<math display="inline">n_s=6</math> for tetrahedra). | where <math display="inline">{\boldsymbol l}_j</math> are the vectors defining the element sides (<math display="inline">n_s=6</math> for tetrahedra). | ||

| − | The form chosen for the characteristic length parameters is similar to that proposed by other authors (see references of previous paragraph and also Donea and Huerta, 2003 and Tezduyar, 2001b). | + | The form chosen for the characteristic length parameters is similar to that proposed by other authors (see references of previous paragraph and also Donea and Huerta, 2003 <span id="citeF-31"></span>[[#cite-31|[31]]] and Tezduyar, 2001b <span id="citeF-96"></span>[[#cite-96|[96]]]). |

As for the free-surface equation the following value of the characteristic length vector <math display="inline">{\boldsymbol h}_\beta </math> has been taken | As for the free-surface equation the following value of the characteristic length vector <math display="inline">{\boldsymbol h}_\beta </math> has been taken | ||

| − | + | <span id="eq-62"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 1,157: | Line 1,156: | ||

|} | |} | ||

| − | The streamline parameter <math display="inline">\bar | + | The streamline parameter <math display="inline">\bar {\boldsymbol h}_s</math> has been obtained by Eq.([[#eq-60|60]]) using the value of the velocity vector <math display="inline">\boldsymbol u</math> over the 3 node triangles discretizing the free-surface and <math display="inline">n_s=3</math>. |

The cross wind parameter <math display="inline">\bar h_c</math> has been computed by | The cross wind parameter <math display="inline">\bar h_c</math> has been computed by | ||

| − | + | <span id="eq-63"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 1,171: | Line 1,170: | ||

|} | |} | ||

| − | The cross-wind terms in eqs.(59) and (62) take into account the gradient of the solution in the stabilization parameters. This is a standard assumption in shock-capturing stabilization procedures. | + | The cross-wind terms in eqs.([[#eq-59|59]]) and ([[#eq-62|62]]) take into account the gradient of the solution in the stabilization parameters. This is a standard assumption in shock-capturing stabilization procedures. |

| − | A more consistent evaluation of | + | A more consistent evaluation of <math display="inline">{\boldsymbol h}</math> based on a diminishing residual technique can be found in Oñate and García (2001) <span id="citeF-78"></span>[[#cite-78|[78]]]. |

==13 TURBULENCE MODELLING== | ==13 TURBULENCE MODELLING== | ||

| Line 1,182: | Line 1,181: | ||

One of the simplest and more effective choices for <math display="inline">\mu _T</math> is the Smagorinski LES model giving | One of the simplest and more effective choices for <math display="inline">\mu _T</math> is the Smagorinski LES model giving | ||

| − | + | <span id="eq-64"></span> | |

{| class="formulaSCP" style="width: 100%; text-align: left;" | {| class="formulaSCP" style="width: 100%; text-align: left;" | ||

|- | |- | ||

| Line 1,195: | Line 1,194: | ||

where <math display="inline">h^e</math> is the element size and <math display="inline">C</math> is a constant (<math display="inline">C\simeq 0.01</math>). In the examples analyzed <math display="inline">h^e</math> has been taken equal to <math display="inline">(\Omega ^e)^{1/2} </math> and <math display="inline">(V^e)^{1/3} </math> for 2D and 3D situations, respectively. | where <math display="inline">h^e</math> is the element size and <math display="inline">C</math> is a constant (<math display="inline">C\simeq 0.01</math>). In the examples analyzed <math display="inline">h^e</math> has been taken equal to <math display="inline">(\Omega ^e)^{1/2} </math> and <math display="inline">(V^e)^{1/3} </math> for 2D and 3D situations, respectively. | ||

| − | Many other options are possible such as the one and two equations turbulence models (i.e. the <math display="inline">k</math> model and the <math display="inline">k - \varepsilon </math> and <math display="inline">k - w</math> models) and the algebraic stress models. For further details the reader is refered to specialized publications (Celik ''el al.'', 1982; Wilcox, 1994). | + | Many other options are possible such as the one and two equations turbulence models (i.e. the <math display="inline">k</math> model and the <math display="inline">k - \varepsilon </math> and <math display="inline">k - w</math> models) and the algebraic stress models. For further details the reader is refered to specialized publications (Celik ''el al.'', 1982 <span id="citeF-12"></span>[[#cite-12|[12]]]; Wilcox, 1994 <span id="citeF-105"></span>[[#cite-105|[105]]]). |

==14 EXAMPLES== | ==14 EXAMPLES== | ||