Abstract

Roller-compacted concrete (RCC) is a dry, zero-slump concrete prepared from the same ingredients as conventional cement but with a lower cement percentage. It is frequently compacted in the same way as dirt is. RCC is utilized chiefly to build massive structures such as dams and vast horizontal surfaces like highway foundations. Because of the low cement concentration, it slows the rise of temperature in mass concrete and decreases thermal strains. However, this paper analyzes the possibility of a chemical link forming between functionalized Multi-Wall Carbon Nanotubes and Nano-alpha Alumina in Roller-Compacted Concrete (RCC) structure using spectroscopic analysis. Various characterization methods, including X-ray diffraction patterns, Fourier-transform infrared (FT-IR) spectrometry, and scanning electron microscopy (SEM), were employed to analyze the nanocomposite's interaction. Based on X-ray diffraction pattern results, Multi-Wall Carbon Nanotubes (MWCNT) peaks show that the powder is amorphous, but it becomes crystalline when combined at high temperatures. The X-Ray diffraction (XRD) profile of the carbon nanotube-doped alumina sample reflects the leading share of Al2O3, with angles and diffraction plates of Al2O3 being the same as α- Al2O3 orthorhombic crystalline phase owing to the low carbon concentration. Besides, scanning electron microscope analysis revealed that α-Al2O3 powder samples without MWCNT and containing MWCNT have a shell state that the doped sample tends to be spherical.

Keywords: Multi-Wall Carbon Nanotubes, Nanoparticles, Chemical Interaction, Nano-alpha Alumina, Roller-Compacted Concrete.

| Abbreviations | |||

| GHG | Greenhouse Gases | CR | Crumb Rubber |

| RCC | Roller-Compacted Concrete | RCCP | Roller Compacted Concrete Pavement |

| NVC | Normal Vibrated Concrete | HVFA | High-Volume Fly Ash |

| SEM | Scanning Electron Microscopy | FTCs | freezing and thawing cycles |

| RCR | Roller-Compacted Rubbercrete | OPC | Ordinary Portland cement |

| NMK | Nano-Metakaolin | MWCNTS | Multi-Wall Carbon Nanotubes |

| α-Al2O3 | Nano-alpha Alumina | FT-IR | Fourier-transform infrared |

| FESEM | Field Emission Scanning Electron Microscope | SEM | Scanning Electron Microscope |

| CNTs | Carbon Nanotubes |

1. Introduction

The construction industry is one of the significant consumers of energy resources globally, and among all materials used in construction, concrete is the most widely used. In other words, Buildings are assigned as the highest sectors for wasting energy. As a result, greenhouse gases (GHG) have been emitted worldwide; by attending to this issue, they are at the first level of using the initial energy with 40%. Nanotechnology, however, is one of the most effective technologies in the present century and has significantly impacted the construction sector. Nanoscale cementitious materials are more durable and resistant than traditional materials [3].

Nanotechnology has gained a lot of popularity among researchers during the previous years. Due to the unique potential of nano-particles, interest in their effect, notably in concrete and cement mortar, has developed. Nano concrete is a kind of concrete that comprises nanomaterials or nano-particles with a particle size smaller than 500 (nm) to ameliorate its strength. Nano-particles enhance the bulk properties of concrete, which are also referred to as packing model structures [4]. As Richard Feynman proposed nanotechnology in his best-known speech in 1959 called "Plenty of Room at the Bottom," a plethora of significant advances in physics, chemistry, and biology have been made [5]. The prefix nano in nanotechnology refers to a billionth. Nanotechnology is concerned with studying matter structures with dimensions on a billionth of a meter. Novel though nanotechnology is, the reality of functioning nanometer-scale devices and structures is not, and such structures have existed on Earth for an extended period. Nanotechnology is divided into two categories: (i) bottom-up approach; in which both organic and inorganic structures are manufactured atom by atom or molecule by molecule; (ii) top-down approach; in which mechanical attrition and etching procedures are used to reduce bulk materials to nano-particles via a process of assembly or self-assembly (Fig. 1) [6]. In the C–S–H phase, well-dispersed nano-particles help to speed up cement slurry hydration and contribute to the creation of tiny crystals and homogenous clusters. Furthermore, nano-particles participate in accelerating pozzolanic processes, causing wear in the hardening cement of chemically unstable Ca(OH)2 portlandite and creating an extra quantity of C–A–S–H phase [7]. Nano-particles can ameliorate mechanical qualities such as freeze-thaw durability, vibration damping capacity, abrasion resistance, binding strength with steel rebars, chemical attack resistance, and steel rebar corrosion resistance [8].

Roller-compacted concrete (RCC) is a kind of concrete with zero slump compacted by vibration by rollers, growing technology throughout the world. There are two types of RCCP used in construction: bulk concrete with a low cement content, which is used to build dams and large structures such as retaining walls, heavy foundations, and dams where high strength is not required; and RCC with a relatively high cement content, which is used to quickly implement highway pavement layers and similar coatings that require high mechanical and abrasion resistance. The main advantage of this type of concrete is its low cost. RCC is a more abrasion-resistant and stiffer concrete than traditional concrete. It has the same fundamental materials (water, cement, and aggregate) as ordinary concrete but uses less water and cement [9]. Furthermore, because of its low heat generating properties at early ages and longer set time, type II portland cement is more widely utilized with RCC. Utilizing a pozzolan or ground slag as a mineral filler and its cementitious properties and providing some lubrication during compaction could be advantageous in RCC; which Class F fly ash is the most frequently used pozzolan or mineral filler for RCC rather than Class C [10]. Nonetheless, contractors and designers should avoid using too much cement in their mixtures. A more significant cement percentage does not always imply a longer service life and, in most cases, raises manufacturing costs and building requirements [11]. Due to the relatively dry and stiff nature of RCC, an abnormal test for concrete workability (slump test) could not be used. Alternatively, the vibrating table or Vebe test is often used to determine the RCC mixture's workability [9]. When compared to regular vibrated concrete (NVC) specimens, images of the microstructure of the RCCP demonstrate that it has a high back density. The largest void size of NVCs is roughly 858 µm, according to scanning electron microscopy (SEM) photographs of concretes. For RCCs, however, this number is about 192 µm [12].

However, during the past years, a plethora of studies have been carried out to evaluate the applicability of nanomaterials in concrete, especially RCCs. ADDIN EN.CITE <EndNote><Author>Shekari</Author><Year>2011</Year><RecNum>802</RecNum><DisplayText>Shekari and Razzaghi [13]</DisplayText><record><rec-number>802</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639611318">802</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Shekari, A. H.</author><author>Razzaghi, M. S.</author></authors></contributors><titles><title>Influence of Nano Particles on Durability and Mechanical Properties of High Performance Concrete</title><secondary-title>Procedia Engineering</secondary-title></titles><periodical><full-title>Procedia Engineering</full-title></periodical><pages>3036-3041</pages><volume>14</volume><keywords><keyword>Nano particles</keyword><keyword>concrete</keyword><keyword>durability</keyword><keyword>mechanical [properties</keyword></keywords><dates><year>2011</year><pub-dates><date>2011/01/01/</date></pub-dates></dates><isbn>1877-7058</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S1877705811014597</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.proeng.2011.07.382</electronic-resource-num></record></EndNote> properties</keyword></keywords><dates><year>2011</year><pub-dates><date>2011/01/01/</date></pub-dates></dates><isbn>1877-7058</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S1877705811014597</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.proeng.2011.07.382</electronic-resource-num></record></Cite></EndNote>]Shekari and Razzaghi [13] analyzed nano-particles' effects, such as Nano-ZrO2, Nano-Fe3O4, Nano TiO2, and Nano-Al2O3, on the mechanical characteristics and durability of concrete. ADDIN EN.CITE <EndNote><Author>Liu</Author><Year>2019</Year><RecNum>803</RecNum><DisplayText>Liu, et al. [14]</DisplayText><record><rec-number>803</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639611616">803</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Liu, Fang</author><author>Zhang, Tonghuan</author><author>Luo, Tao</author><author>Zhou, Mengzhen</author><author>Ma, Weiwei</author><author>Zhang, Kunkun</author></authors></contributors><titles><title>The Effects of Nano-SiO(2) and Nano-TiO(2) Addition on the Durability and Deterioration of Concrete Subject to Freezing and Thawing Cycles</title><secondary-title>Materials (Basel, Switzerland)</secondary-title><alt-title>Materials (Basel)</alt-title></titles><periodical><full-title>Materials (Basel, Switzerland)</full-title><abbr-1>Materials (Basel)</abbr-1></periodical><alt-periodical><full-title>Materials (Basel, Switzerland)</full-title><abbr-1>Materials (Basel)</abbr-1></alt-periodical><pages>3608</pages><volume>12</volume><number>21</number><keywords><keyword>concrete</keyword><keyword>freezing and thawing cycles</keyword><keyword>industrial CT scanning technology</keyword><keyword>internal damage [analysis</keyword><keyword>nano-particles</keyword></keywords><dates><year>2019</year></dates><publisher>MDPI</publisher><isbn>1996-1944</isbn><accession-num>31684149</accession-num><urls><related-urls><url>https://pubmed.ncbi.nlm.nih.gov/31684149</url><url>https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6862060/</url></related-urls></urls><electronic-resource-num>10.3390/ma12213608</electronic-resource-num><remote-database-name>PubMed</remote-database-name><language>eng</language></record></EndNote> analysis</keyword><keyword>nano-particles</keyword></keywords><dates><year>2019</year></dates><publisher>MDPI</publisher><isbn>1996-1944</isbn><accession-num>31684149</accession-num><urls><related-urls><url>https://pubmed.ncbi.nlm.nih.gov/31684149</url><url>https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6862060/</url></related-urls></urls><electronic-resource-num>10.3390/ma12213608</electronic-resource-num><remote-database-name>PubMed</remote-database-name><language>eng</language></record></Cite></EndNote>]Liu, et al. [14] looked at how adding nano-particles to concrete affected its durability and internal deterioration throughout freezing and thawing cycles (FTCs). For this purpose, 15 nm of SiO2, 30 nm of SiO2, and 30 nm of TiO2 were added to concrete to create specimens with varying contents. ADDIN EN.CITE <EndNote><Author>Hosseini</Author><Year>2014</Year><RecNum>804</RecNum><DisplayText>Hosseini, et al. [15]</DisplayText><record><rec-number>804</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639611810">804</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Hosseini, Payam</author><author>Hosseinpourpia, Reza</author><author>Pajum, Arash</author><author>Khodavirdi, Mohammad Mahdi</author><author>Izadi, Hamed</author><author>Vaezi, Ali</author></authors></contributors><titles><title>Effect of nano-particles and aminosilane interaction on the performances of cement-based composites: An experimental study</title><secondary-title>Construction and Building Materials</secondary-title></titles><periodical><full-title>Construction and Building Materials</full-title></periodical><pages>113-124</pages><volume>66</volume><keywords><keyword>Cement mortar</keyword><keyword>Nano-particles</keyword><keyword>Aminosilane</keyword><keyword>Interaction</keyword><keyword>Low replacement [ratio</keyword></keywords><dates><year>2014</year><pub-dates><date>2014/09/15/</date></pub-dates></dates><isbn>0950-0618</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0950061814005315</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2014.05.047</electronic-resource-num></record></EndNote> ratio</keyword></keywords><dates><year>2014</year><pub-dates><date>2014/09/15/</date></pub-dates></dates><isbn>0950-0618</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0950061814005315</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2014.05.047</electronic-resource-num></record></Cite></EndNote>]Hosseini, et al. [15] explored the interaction of various nano-particles (SiO2, Al2O3, clay, and CaCO3) with aminosilane in cement paste and mortar matrices. The authors asserted that 0.75 percent aminosilane was the optimal concentration for increasing the compressive strength of cement mortar after 28 days. ADDIN EN.CITE <EndNote><Author>M.S. Morsy</Author><Year>2012</Year><RecNum>805</RecNum><DisplayText>M.S. Morsy [16]</DisplayText><record><rec-number>805</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639612167">805</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author> M.S. Morsy, Y.A. Al-Salloum, H. Abbas, S.H. Alsayed </author></authors></contributors><titles><title>Behavior of blended cement mortars containing nano-metakaolin at elevated temperatures</title><secondary-title>Construction and Building Materials</secondary-title></titles><periodical><full-title>Construction and Building [Materials</full-title></periodical><pages>900-905</pages><volume>35</volume><number>Complete</number><dates><year>2012</year></dates><urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2012.04.099</electronic-resource-num></record></EndNote> Materials</full-title></periodical><pages>900-905</pages><volume>35</volume><number>Complete</number><dates><year>2012</year></dates><urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2012.04.099</electronic-resource-num></record></Cite></EndNote>]M.S. Morsy [16] evaluated the influence of elevated temperatures up to 800 degrees Celsius on the mechanical characteristics and microstructure of nano-metakaolin cement mortars, in which the blended cement employed Ordinary Portland cement (OPC) with nano-metakaolin (NMK). ADDIN EN.CITE <EndNote><Author>Morsy</Author><Year>2011</Year><RecNum>806</RecNum><DisplayText>Morsy, et al. [17]</DisplayText><record><rec-number>806</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639612424">806</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Morsy, M. S.</author><author>Alsayed, S. H.</author><author>Aqel, M.</author></authors></contributors><titles><title>Hybrid effect of carbon nanotube and nano-clay on physico-mechanical properties of cement mortar</title><secondary-title>Construction and Building Materials</secondary-title></titles><periodical><full-title>Construction and Building Materials</full-title></periodical><pages>145-149</pages><volume>25</volume><number>1</number><keywords><keyword>Carbon nanotube</keyword><keyword>Nano-clay</keyword><keyword>Cement mortar</keyword><keyword>Thermal analysis</keyword><keyword>Compressive [strength</keyword><keyword>Microstructure</keyword></keywords><dates><year>2011</year><pub-dates><date>2011/01/01/</date></pub-dates></dates><isbn>0950-0618</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0950061810002953</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2010.06.046</electronic-resource-num></record></EndNote> strength</keyword><keyword>Microstructure</keyword></keywords><dates><year>2011</year><pub-dates><date>2011/01/01/</date></pub-dates></dates><isbn>0950-0618</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0950061810002953</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2010.06.046</electronic-resource-num></record></Cite></EndNote>]Morsy, et al. [17] used diverse nanomaterials in cementitious matrices, including multi wall carbon nanotubes (MWCNTs) and nano-clays in order to evaluate the physico-mechanical behavior of these nanomaterials and OPC. ADDIN EN.CITE <EndNote><Author>Mohammed</Author><Year>2018</Year><RecNum>798</RecNum><DisplayText>Mohammed and Adamu [18]</DisplayText><record><rec-number>798</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639610177">798</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Mohammed, Bashar S.</author><author>Adamu, Musa</author></authors></contributors><titles><title>Mechanical performance of roller compacted concrete pavement containing crumb rubber and nano silica</title><secondary-title>Construction and Building Materials</secondary-title></titles><periodical><full-title>Construction and Building Materials</full-title></periodical><pages>234-251</pages><volume>159</volume><keywords><keyword>Crumb rubber</keyword><keyword>Nano silica</keyword><keyword>Roller compacted rubbercrete</keyword><keyword>Response surface methodology</keyword><keyword>Compressive strength</keyword><keyword>Flexural [strength</keyword></keywords><dates><year>2018</year><pub-dates><date>2018/01/20/</date></pub-dates></dates><isbn>0950-0618</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0950061817321529</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2017.10.098</electronic-resource-num></record></EndNote> strength</keyword></keywords><dates><year>2018</year><pub-dates><date>2018/01/20/</date></pub-dates></dates><isbn>0950-0618</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0950061817321529</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2017.10.098</electronic-resource-num></record></Cite></EndNote>]Mohammed and Adamu [18] produced roller-compacted rubbercrete (RCR) by partly substituting fine aggregate in roller compacted concrete pavement (RCCP) with crumb rubber (CR) to increase flexural resistance, ductility, and lessen the environmental impact of waste tires. ADDIN EN.CITE <EndNote><Author>Tavakoli</Author><Year>2020</Year><RecNum>799</RecNum><DisplayText>Tavakoli, et al. [19]</DisplayText><record><rec-number>799</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639610460">799</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Tavakoli, Davoud</author><author>Sakenian Dehkordi, Rahbar</author><author>Divandari, Hassan</author><author>de Brito, Jorge</author></authors></contributors><titles><title>Properties of roller-compacted concrete pavement containing waste aggregates and nano SiO2</title><secondary-title>Construction and Building Materials</secondary-title></titles><periodical><full-title>Construction and Building Materials</full-title></periodical><pages>118747</pages><volume>249</volume><keywords><keyword>Roller-compacted concrete pavement</keyword><keyword>Nano SiO</keyword><keyword>Waste [materials</keyword><keyword>Strength</keyword></keywords><dates><year>2020</year><pub-dates><date>2020/07/20/</date></pub-dates></dates><isbn>0950-0618</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0950061820307522</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2020.118747</electronic-resource-num></record></EndNote> materials</keyword><keyword>Strength</keyword></keywords><dates><year>2020</year><pub-dates><date>2020/07/20/</date></pub-dates></dates><isbn>0950-0618</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0950061820307522</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.conbuildmat.2020.118747</electronic-resource-num></record></Cite></EndNote>]Tavakoli, et al. [19] used nano SiO2 in the mix design of RCCP to improve the mechanical properties of cement paste. ADDIN EN.CITE <EndNote><Author>Mohammed</Author><Year>2018</Year><RecNum>800</RecNum><DisplayText>Mohammed, et al. [20]</DisplayText><record><rec-number>800</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639610857">800</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Mohammed, Bashar S.</author><author>Adamu, Musa</author><author>Liew, Mohd Shahir</author></authors></contributors><titles><title>Evaluating the effect of crumb rubber and nano silica on the properties of high volume fly ash roller compacted concrete pavement using non-destructive techniques</title><secondary-title>Case Studies in Construction Materials</secondary-title></titles><periodical><full-title>Case Studies in Construction Materials</full-title></periodical><pages>380-391</pages><volume>8</volume><keywords><keyword>Crumb rubber</keyword><keyword>High volume fly ash</keyword><keyword>Nano silica</keyword><keyword>Roller compacted concrete pavement</keyword><keyword>Ultrasonic pulse velocity</keyword><keyword>Rebound [number</keyword></keywords><dates><year>2018</year><pub-dates><date>2018/06/01/</date></pub-dates></dates><isbn>2214-5095</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S2214509517302619</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.cscm.2018.03.004</electronic-resource-num></record></EndNote> number</keyword></keywords><dates><year>2018</year><pub-dates><date>2018/06/01/</date></pub-dates></dates><isbn>2214-5095</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S2214509517302619</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.cscm.2018.03.004</electronic-resource-num></record></Cite></EndNote>]Mohammed, et al. [20] created high-volume fly ash (HVFA) RCC pavement by replacing 50% of the cement with fly ash by volume, in which crumb rubber was utilized as a replacement material for fine aggregate nano-silica was added to help with early strength development. ADDIN EN.CITE <EndNote><Author>Adamu</Author><Year>2020</Year><RecNum>801</RecNum><DisplayText>Adamu, et al. [21]</DisplayText><record><rec-number>801</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639611133">801</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Adamu, Musa</author><author>Mohammed, Bashar S.</author><author>Shafiq, Nasir</author><author>Liew, Mohd Shahir</author></authors></contributors><titles><title>Durability performance of high volume fly ash roller compacted concrete pavement containing crumb rubber and nano silica</title><secondary-title>International Journal of Pavement Engineering</secondary-title></titles><periodical><full-title>International Journal of Pavement Engineering</full-title></periodical><pages>1437-1444</pages><volume>21</volume><number>12</number><dates><year>2020</year><pub-dates><date>2020/10/14</date></pub-dates></dates><publisher>Taylor & [Francis</publisher><isbn>1029-8436</isbn><urls><related-urls><url>https://doi.org/10.1080/10298436.2018.1547825</url></related-urls></urls><electronic-resource-num>10.1080/10298436.2018.1547825</electronic-resource-num></record></EndNote> Francis</publisher><isbn>1029-8436</isbn><urls><related-urls><url>https://doi.org/10.1080/10298436.2018.1547825</url></related-urls></urls><electronic-resource-num>10.1080/10298436.2018.1547825</electronic-resource-num></record></Cite></EndNote>]Adamu, et al. [21] examined the impact of a crumb rubber-nano silica hybrid on the durability and skid resistance of an HVFA roller compacted concrete pavement. ADDIN EN.CITE <EndNote><Author>Roelofs</Author><Year>2006</Year><RecNum>819</RecNum><DisplayText>Roelofs and Vogelsberger [22]</DisplayText><record><rec-number>819</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1640213942">819</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Roelofs, Frank</author><author>Vogelsberger, Wolfram</author></authors></contributors><titles><title>Dissolution kinetics of nanodispersed γ-alumina in aqueous solution at different pH: Unusual kinetic size effect and formation of a new phase</title><secondary-title>Journal of Colloid and Interface Science</secondary-title></titles><periodical><full-title>Journal of Colloid and Interface Science</full-title></periodical><pages>450-459</pages><volume>303</volume><number>2</number><keywords><keyword>-Alumina</keyword><keyword>Dissolution behavior</keyword><keyword>Gibbs free energy of cluster formation</keyword><keyword>Aluminum hydroxide</keyword><keyword>Bayerite</keyword><keyword>X-ray powder diffraction</keyword><keyword>Nitrogen adsorption</keyword><keyword>IR/UV-Raman [spectroscopy</keyword></keywords><dates><year>2006</year><pub-dates><date>2006/11/15/</date></pub-dates></dates><isbn>0021-9797</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0021979706007302</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.jcis.2006.08.016</electronic-resource-num></record></EndNote> spectroscopy</keyword></keywords><dates><year>2006</year><pub-dates><date>2006/11/15/</date></pub-dates></dates><isbn>0021-9797</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0021979706007302</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.jcis.2006.08.016</electronic-resource-num></record></Cite></EndNote>]Roelofs and Vogelsberger [22] discovered that when nano-Al2O3 (γ phase) comes into contact with an aqueous solution at pH = 11, it dissolves swiftly, and the real aluminum content rises rapidly until it reaches its maximum value (2.5 mmol/L at 25°C). One of the most important aspects of this research is the use of nanomaterials for the first time in RCC injection grout and its effect on mechanical properties by various tests such as compressive strength, tensile strength and freezing and thawing. Besides, another novelty is the introduction of a stable air system in the slurry-enriched RCC. The core purposes of this paper were to synthesis MWCNT/ nano-alpha Alumina nanocomposites and analyze them using various spectroscopic methods in order to get novel insight into the interaction between alumina and Multi-Wall Carbon Nanotubes. More emphasis will be placed on characterizing the interaction between nano-alpha Alumina and carbon nanotubes.

The remainder of this paper is organized as follows. In the next section, experimental work, including materials and methods, will be explained. In Section 3, the results of the different analyses are discussed. Finally, some conclusions are drawn in Section 4.

2. Experimental work

This paper performed mechanical tests on RCC samples with a specific mix design. Also, different ratios of nano alumina and multi-wall carbon nanotubes in concrete mixes were used for testing. Changes that could be applied to concrete were investigated using related tests.

2.1 Materials

2.1.1 Cement

The type II Portland cement was employed in this work. Cement tested following ASTM C109, C187, C191, and C204, and the findings were approved by ASTM C150 specifications (ASTM 2003). Table 1 summarizes the cement's physical and mechanical qualities following ASTM C150 standard criteria.

| Test | ASTM specification | Typical Feature | Findings |

| Setting time (min) | C191 | Initilal | 105 |

| final | 315 | ||

| Water demand (%) | C187 | - | 27.5 |

| Blain fineness (cm2/g) | C204 | - | 3035 |

| Mortar compressive strength (Mpa) | C109 | 3,7, and 28 days | 13.5, 29.6, 47.3 |

2.1.2 Aggregates

The experimental study utilized natural coarse material from Eynali Mountain located in Tabriz city. There were two miscellaneous sizes of coarse aggregates employed. The Iranian National Standard No. 302 entitled "Concrete Aggregates – Features" was used to test the coarse aggregate. The physical parameters of the coarse aggregates utilized are shown in table 4. Furthermore, siliceous sand was used as fine aggregate, which its physical characteristics are illustrated in table 2.

| Absorption | Specification | Apparent specific gravity | Bulk specific gravity | Bulk specific gravity in SSD | Normal Average Flakiness (%) | Specification | Void Ratio (%) | Water Absorption (%) | Fineness modulus | |

| Coarse Aggregate (10-19) mm | 1.60 | Max. 2% | 2.8370 | 2.7140 | 2.7560 | 16 | 0- 20% | 39.45 | 1.950 | - |

| Coarse Aggregate (5-10) mm | 1.90 | Max. 2% | 2.2830 | 2.6620 | 2.7200 | 10 | 0- 20% | 39.16 | 0.32 | - |

| Fine Aggregate (0-5) mm | 1.70 | Max. 2% | 2.831 | 2.70 | 2.7460 | - | - | 35.85 | - | 2.70 |

2.1.3 Superplasticizer

The superplasticizer used in this research is Sika 5110 B based on polycarboxylate ether, as shown in fig.2. Besides, typical Properties of the superplasticizer are shown in Table 3.

| Form | Sika 5110 B |

| Appearance | Yellowish translucent liquid |

| Density (20 ℃) | 1.10 kg/litter |

| pH value (20 ℃) | 3-5 |

2.1.4 Nano Materials

2.1.4.1 Nano alfa-Al2O3 Powder

As catalysts, catalyst supports, absorbents, and wear-resistant coatings, alumina is one of the most commonly utilized ceramic materials. Sol-gel, hydrothermal, coprecipitation, mechanical milling, vapor-phase reaction, and combustion processes may all be used to synthesize it. On the other hand, nanoscale alpha-alumina (Al2O3) powder is pretty hard to come by. It is due to the following factors: initially, after calcining at high temperatures, α-Al2O3 is in a stable phase, which easily prompts powder grain growth and makes it difficult to obtain nanoscale particles; and second, α-Al2O3 particles tend to aggregate during the dehydration process in the wet chemistry method [23]. Before converting to α-Al2O3, the following sequence of phase transformations may be used to create a stable α-Al2O3 phase during thermal treatment by Eq.1. Nonetheless, The used nano-alpha alumina (α-Al2O3) powder with white color, an average grain size of 60 nanometers, purity of 99%, and rhombohedral structure with spherical shapes was purchased from Nanopoyeshyekta company, which table 4 indicates its synthesis analysis.

| Al2O3 | Ca | V | Cl | Na | Mn | Co |

| ≥ 99% | ≤ 200 ppm | ≤ 5 ppm | ≤ 280 ppm | ≤ 30 ppm | ≤ 5 ppm | ≤ 5 ppm |

2.1.4.2 Multi-Wall Carbon Nanotubes

Carbon nanotubes, commonly known as fullerenes, are gigantic buckyball molecules. The basic buckyball is a soccer ball with 60 carbon atoms. To make a rugby ball, split the atom into two half and add a ring of ten atoms. You'll have cylindrical molecules with half-buckyball caps on both ends if you keep doing this. This is also true for well-ordered MWNTs, with all their shells capped. Carbon onions are another name for multishell fullerenes. Therefore, a multiwall nanotube is a carbon leek or a cylindrical onion. Aside from these varied forms, the physics of carbon nanotubes is determined by the orientation of the tube axis concerning the graphite sheet's lattice [24]. Furthermore, MWNTs are inert materials with a well-known propensity to clump together owing to van der Waals forces, making them challenging to distribute and align in a concrete matrix. This stumbling block prevents them from being used as concrete reinforcing additives. The functionalization of MWCNTs prevents nanotube aggregation and aids in the dispersion and stabilization of carbon nanotubes inside the matrix [25]. However, MWCNT powder used with black color, an average diameter of 10-20 nm, carbon tube length of 30 μm, and purity of 98% was purchased from Yeta Company. Table 5 shows its main characteristics.

| Density | Specific surface area | Inner diameter |

External diameter |

The length | Electrical conductivity | Production method |

| 2.1 gr/cm3 | 110 ≤ m2/g | 5-10 nm | 15-20 nm | 30 μm | 100 S/cm | CVD |

In this study, the XRD X-ray diffraction device belonging to Tabriz Geological Center, model D-5000 Siemens with Cu-Kα beam (with wavelength A˚ = 1.5404 λ) was used to investigate the structure and type of phases formed. Fuzzy analyzes were performed for Al2O3, CNT, and Al2O3 / MWCNT samples from angles of 20 to 80 degrees with an angular step of 0.02 degrees for 0.3 seconds. Additionally, To observe the surface changes and morphology of alumina powder (Al2O3) and alumina powder doped with multi-walled carbon nanotube (α-Al2O3 / MWCNT) in different magnifications, field emission scanning electron microscope (FESEM) belonging to the Central Laboratory of Tabriz University ( model MIRA3 TESCAN FESEM with a voltage of 30 Kv) was used by the secondary electron SE method. And, to identify organic compounds and functional groups, and metal-ligand bonds, the FTIR Tensor27 device (manufactured by Broker, Germany) at the University of Tabriz was used.

2.2 Concrete mix design

Once concrete ingredient tests are completed and ensure that all materials such as water, aggregate, sand, and cement meet ASTM specifications, concrete with a strength of 35 MPA at 28 days is created. Standard Practice for Selecting Proportions for No-Slump Concrete used to develop the project mix (ACI 211.3R-02). The following are the design criteria that were employed in this study:

- At 28 days, the cylindrical mold had a compressive strength of 35 MPa.

- Slump: RCC slump ranges from 0 to 25 mm.

- Nominal maximum aggregate size: 19 mm in the work mix is the nominal maximum aggregate size.

- Water cement ratio: the task mix had a water-cement ratio of 0.47.

- The final average job mix weight: table 6 shows the final average weight for the job mix.

| Materials | Weight (Kg) |

| Water | 189.8 |

| Cement | 331 |

| Coarse aggregate | 1440 |

| Fine aggregate | 491.4 |

| Total | 2452.2 |

After completing the RCC mixture design, Nanomaterials were added to the RCC mix by substituting cement with varying percentages. The RCC specimens were mixed and prepared according to ASTM C 192 and a routine technique for creating roller-compacted concrete in cylinder molds using a vibrating table, as described in ASTM C 1176. First, the mixing water containing nanomaterials is added to the coarse aggregate. The mixer then began to rotate. Consequently, fine aggregate, cement, and water were added. Following the addition of all concrete constituents to the mixer, the RCC mixed for 3 minutes, followed by a 3-minute pause, and then a 2-minute final mixing. The hardened concrete is carefully removed from the molds one day after the specimens have been molded to avoid any defects or breaks in the samples. All specimens were cured regarding the C192 specification, where they were placed in a curing water tank at a temperature of 21-25°C for the duration of the testing period.

In the following steps, nitric acid and sulfuric acid were mixed in a ratio of 1 to 3, respectively; and poured on carbon nanotube powder and placed at 70 ° C for 2 hours. After the solution had cooled, about twice as much water was added to it, and it remained stationary for 1 hour, settling to some extent. The solution was separated using a funnel and filter paper. Finally, the whole solution was washed with ethanol to lower the pH. Next, the carbon nanotube filters were placed in an oven at 100 °C for approximately 24 hours to dry, separating the carbon from the filter paper. An aqueous solution containing modified carbon and 2 d decal sodium surfactant (about 3 (gr) per 5 (gr) of carbon was used) was then prepared and subjected to ultrasonic for half an hour. This solution was incubated in the laboratory for two weeks. Subsequently, a solution containing α-Al2O3 with 2 wt% MWCNT was prepared and ultrasonicated for 1 hour. A filter was used again to separate the materials from the solution, and finally, it was placed in an oven at 100 °C for 24 hours to obtain a powder mixture. The mixture was poured into plants and placed in a rotary kiln at 1100 °C for 2 hours.

3. Results and discussion

3.1 X-ray diffraction pattern

The results of EDS of two samples of α-Al2O3 and carbon-doped alumina are given in Fig.3. A spectral study of the first sample (α-Al2O3 powder), 1-a, shows the presence of aluminum and oxygen elements with 35.23 and 64.77% atomic weight without impurities. According to ADDIN EN.CITE <EndNote><Author>Zoladz</Author><Year>2020</Year><RecNum>810</RecNum><DisplayText>Zoladz, et al. [26]</DisplayText><record><rec-number>810</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639952652">810</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Zoladz, Frank</author><author>Rhodes, Steven</author><author>Patterson, Dwight</author><author>Cribb, Warner</author><author>Chapagain, Puskar</author><author>Seifu, Dereje</author><author>Taufour, Valentin</author><author>Kamali, Saeed</author><author>Neupane, Suman</author></authors></contributors><titles><title>Enhanced magnetic properties of aluminum oxide nanopowder reinforced with carbon nanotubes</title><secondary-title>Journal of Nanoparticle Research</secondary-title></titles><periodical><full-title>Journal of Nanoparticle [Research</full-title></periodical><pages>157</pages><volume>22</volume><number>6</number><dates><year>2020</year><pub-dates><date>2020/06/08</date></pub-dates></dates><isbn>1572-896X</isbn><urls><related-urls><url>https://doi.org/10.1007/s11051-020-04896-6</url></related-urls></urls><electronic-resource-num>10.1007/s11051-020-04896-6</electronic-resource-num></record></EndNote> Research</full-title></periodical><pages>157</pages><volume>22</volume><number>6</number><dates><year>2020</year><pub-dates><date>2020/06/08</date></pub-dates></dates><isbn>1572-896X</isbn><urls><related-urls><url>https://doi.org/10.1007/s11051-020-04896-6</url></related-urls></urls><electronic-resource-num>10.1007/s11051-020-04896-6</electronic-resource-num></record></Cite></EndNote>]Zoladz, et al. [26] studies, a similar chemical composition has been reported on α-Al2O3 powder sintered at 1300 °C. Spectral study of the second sample (alumina powder/carbon nanotubes) 1-b shows the presence of aluminum, oxygen, and carbon with 30.69, 61.65, and 7.66% atomic weight, respectively. ADDIN EN.CITE <EndNote><Author>Barthwal</Author><Year>2019</Year><RecNum>811</RecNum><DisplayText>Barthwal, et al. [27]</DisplayText><record><rec-number>811</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1639953000">811</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Barthwal, Subodh</author><author>Singh, Nakshatra</author><author>Singh, Bhim</author></authors></contributors><titles><title>Electrical Conductivity and Mechanical Hardness of Al2O3-1wt% MWCNT Nanocomposite Synthesized by Ball Milling Method</title><secondary-title>Journal of scientific and industrial research</secondary-title></titles><periodical><full-title>Journal of scientific and industrial research</full-title></periodical><pages>532-534</pages><volume>78</volume><dates><year>2019</year><pub-dates><date>08/01</date></pub-dates></dates><urls></urls></record></EndNote>Barthwal, et al. [27] studies on alumina powder doped with 1% by weight of MWCNT by ball milling method also show that the weight percentage of elements was 1.8.

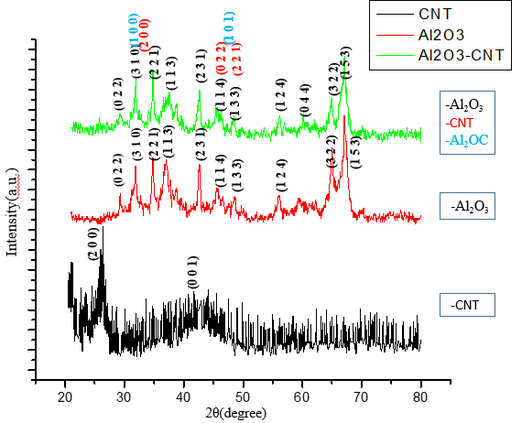

Fig.4 shows the X-ray diffraction pattern of α-Al2O3, MWCNT, and MWCNT / Al2O3. The XRD MWCNT pattern (JCPDs file number 0415-008-00) had broad peaks at angles of 26.42 and 42.36, which belonged to the page categories (2 0 0) and (0 0 1). MWCNT peaks indicate that the powder is amorphous, which is more crystalline when mixed at high temperatures. In the α-Al2O3 sample diffraction pattern without impurities, sharp peaks at angles of 29.23°, 32.80°, 34.80°, 36.93°, 42.67°, 45.65°, 48.56°, 56.05°, 59.31°, 60.74°, 65.01°, 67.07°, 70.01°, and 73.08° are seen. All resulting peaks correspond to the orthorhombic crystalline phase of α-Al2O3 (JCPDs file No. 0107-088-01). The crystal size of α-Al2O3 nano-particles is calculated from the Scherrer equation by determining the full width at half the maximum corresponding to the most intense diffraction of the plate (3 5 1). Based on the results, the estimated value of crystal size for α-Al2O3 nano-particles is 80 nm. Scherrer obtained his equation for the ideal condition of an X-ray beam incident on a monodisperse powder of cube-shaped crystallites that is perfectly parallel, infinitely thin, and monochromatic. The equation is Dhkl = Kλ/(Bhklcosθ), where Dhkl is the crystallite size in the direction perpendicular to the lattice planes; K is a numerical factor frequently referred to as the crystallite-shape factor5; λ is the wavelength of the X-rays, Bhkl is the width (full-width at half-maximum) of the X-ray diffraction peak in radians and θ is the Bragg angle.

In the spectrum of the carbon nanotube-doped alumina sample, due to the low carbon content, the XRD profile represents the predominant share of Al2O3, with angles and diffraction plates of Al2O3 being the same as the α-Al2O3 orthorhombic crystalline phase (JCPDs file No. 0107-088 -01) is. In stark contrast, the peak of carbon phase plates with slightly oxide phase appears at angles of 31.91°, 45.55°, 48.47°, 73.19° and 77.66°, which has a cubic crystal shape (JCPDs file number 0306-101-96) and finally the α- combined phase. Al2O3 and MWCNT overlap with some Al2O3 plates at three angles of 32.47°, 37.53°, and 70.18° with a hexagonal crystal shape (JCPDs case number 0148-036-00), and these peaks are difficult to detect. However, the sharp properties of diffraction peaks confirm the high crystallization of nanocomposite materials as synthesized. Homogeneous dispersion and strong interaction between MWCNTs and α-Al2O3 can improve composite strength [28]. According to the calculation, the estimated value of crystal size with the Debye Scherrer equation for Al2O3 / MWCNT composite nano-particles is 50 nm, which is reduced compared to the pure sample. As can be seen, the spectral lines have not changed much with the addition of MWCNT. ADDIN EN.CITE <EndNote><Author>Guo</Author><Year>2020</Year><RecNum>813</RecNum><DisplayText>Guo, et al. [29]</DisplayText><record><rec-number>813</rec-number><foreign-keys><key app="EN" db-id="zerwvdp2o9z5axexvpnvxzxcat9etwtfz0td" timestamp="1640042829">813</key></foreign-keys><ref-type name="Journal Article">17</ref-type><contributors><authors><author>Guo, C.</author><author>Luo, X.</author><author>Shah, W. A.</author><author>Li, J. K.</author><author>Huang, B.</author><author>Umer, M. A.</author><author>Yang, Y. Q.</author></authors></contributors><titles><title>Mechanical and thermal properties of multiwalled carbon-nanotube-reinforced Al2O3 nanocomposites</title><secondary-title>Ceramics International</secondary-title></titles><periodical><full-title>Ceramics International</full-title></periodical><pages>17449-17460</pages><volume>46</volume><number>11, Part A</number><keywords><keyword>Carbon nanotubes</keyword><keyword>AlO</keyword><keyword>Nanocomposite</keyword><keyword>Mechanical properties</keyword><keyword>Thermal [properties</keyword></keywords><dates><year>2020</year><pub-dates><date>2020/08/01/</date></pub-dates></dates><isbn>0272-8842</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0272884220309834</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.ceramint.2020.04.039</electronic-resource-num></record></EndNote> properties</keyword></keywords><dates><year>2020</year><pub-dates><date>2020/08/01/</date></pub-dates></dates><isbn>0272-8842</isbn><urls><related-urls><url>https://www.sciencedirect.com/science/article/pii/S0272884220309834</url></related-urls></urls><electronic-resource-num>https://doi.org/10.1016/j.ceramint.2020.04.039</electronic-resource-num></record></Cite></EndNote>]Guo, et al. [29] added various MWCNT additives to the α-Al2O3 nanopowder and subjected it to the ball milling operation; It was observed that the resulting graphs did not change with the addition of different MWCNT values, indicating that MWCNTs do not affect the overall fuzzy structure of the composite. Next, the XRD pattern showed no significant reversal, indicating almost no residual stress in the sintering and doping samples. However, the peak intensity increased slightly after adding a low percentage of MWCNTs to alumina. According to the Scherrer equation, the expansion of diffraction peaks may be due to germination. According to studies, increasing MWCNT content up to 1.5% by weight of alumina can increase the intensity of peak diffraction. Furthermore, a significant drop occurs when the MWCNT content reaches 2% by weight. Many factors affect peak diffraction intensity, including the percentage of MWCNT content, grain size, and MWCNT dispersion. In general, the higher the CNT content, the higher the peak diffraction intensity, and the more evenly distributed the CNTs, the higher the diffraction peak intensity. However, when MWCNTs are not evenly distributed in the matrix, aggregated MWCNTs cause more defects, which reduce the intensity of peak diffraction [29].

3.2 Fourier-transform infrared (FT-IR) spectrometry

Fourier-transform infrared spectroscopy was used to study the functional groups and molecular structure of nano α-Al2O3 and the doped mixture of alumina with carbon nanotubes. Fig.5 indicates the spectrum of FTIR absorption bands for α-Al2O3, MWCNT / α-Al2O3 powder and in the MWCNT range 450–4000 cm− 1. In the MWCNT spectrum, the 1113 and 1256 cm-1 peaks can be assigned to the C-O traction of phenol or lactone groups. The broad peak of about 3433-3852 cm-1 and 1437-1378 cm-1 are related to OH tensile vibrations. This peak can also be assigned to the hydroxyl group of moisture, alcohol, or carboxylic. C = C cyclic alkene elongation is observed in the MWCNT spectrum at 1630 and 901 cm-1. However, the presence of bands near 1733 cm-1 is related to the C = O tensile vibration of the atoms of the -COOH and N carboxylic groups, which are covalently attached to the carbon lattice C = N. Besides, the sharp peak of 2857 cm-1 is related to the C-H stretching of alkane-alkene. There is also a strong alkyl halide tensile at the peak of 604 cm-1 [1, 28].

In the diagram related to nano-α-Al2O3 powder adsorption due to the vibration peak of O-H hydroxide tensile strength in the range of 2856-3453 cm-1 can be assigned to the hydroxyl group of moisture, alcohol, or carboxylic. There is also a strong alkyl halide tensile at peaks of 422.31, 563.59, and 595.63 cm-1. Furthermore, the Al-O vibration absorption band appears, ranging from 400 to 1000 cm-1. The absorption peak is observed at about 422.31 cm-1, indicating the presence of α-Al2O3 after confirmation from the database [30, 31]. The adsorption peak at 1744 cm-1 is related to the carboxylic groups' C = O tensile vibration (-COOH). The characteristic carbonyl peak is observed with a tensile vibration of about 1641 cm-1 and can be assigned to the quinine structure or ring of the carbonyl group. In the α-Al2O3 / MWCNT diagram, the broad absorption peaks in the range of 2925-3844 cm-1 are related to OH, which illustrates the presence of hydroxyl groups on the surface nanocomposites (doped mixtures) or can be due to moisture absorption during Measure FTIR. Peaks around 1649 cm-1 show the functional groups' C = O tensile state at the MWCNT level. There is also a tensile strength of the strong alkyl halide 568 cm-1. The difference between the two diagrams is related to the disappearance of the characteristic peak of α-Al2O3 in the doped sample, which increases the bonds related to the carboxylic group and the probability of bonding between the carbon group of MWCNT and the oxygen group of α-Al2O3. This is done in two steps; initially, a hydrogen bond is formed between the surface hydroxyl functions of alumina and the carboxylic acid groups, ie Al_OH… O = C (OH) _ CNT, and then H2O is removed. As shown in Fig.6, the three fundamental configurations that may form between a carboxylate ion and metal atoms are (a) monodentate, (b) bidentate bridging, and (c) bidentate chelating [1].

3.3 Scanning Electron Microscope (SEM)

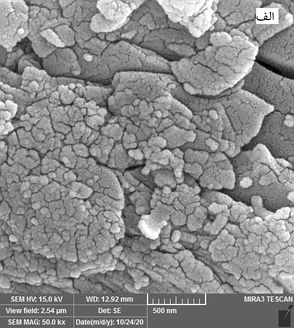

Fig.7 shows the electron microscope images of the doped α-Al2O3 and α-Al2O3 powder samples with 2% by weight MWCNT at two different magnifications, indicating the presence of carbon in the second sample. Image analysis at different magnifications indicates that α-Al2O3 powder samples without MWCNT and containing MWCNT have a shell state that the doped sample tends to be spherical. Also, the particle size of the powder decreased after preparing the doped sample of α-Al2O3 with MWCNT. The reason for the very small change in sample size is the conversion of the shell to a spherical state under heat treatment and re-crushing, which was performed on them after drying in the oven. MWCNTs, on the other hand, have been shortened, and their walls have been demolished and de-clustered. According to SEM and XRD grain size calculations, another possible factor in grain size reduction due to duplication is that grain size is reported as average and samples with different grain sizes but the same overall average under operation and test. Finally, MWCNTs are placed on α-Al2O3 in the form of thaw-like particles, and a bond and interaction have occurred between them, which has not been ineffective in heat treatment up to 1100 °C and the use of ultrasonic waves. More research has been done to eliminate the crustal state and create more spherical particles, which used a ball mill before heat treatment and increasing the processing time has been effective in further homogenization and creating a spherical shape. Figs. 7.a and 7.c show the nanometer size of the samples, the grain size of which was calculated using Image J software. The grain size obtained for the α-Al2O3 sample doped with MWCNT was about 80 nm and for the initial α-Al2O3 sample was about 100 nm. The mean particle size calculated by SEM is larger than the crystal size calculated by XRD, indicating that the particles have multiple crystallites.

4. Conclusion

In this study, Spectroscopic analysis was used to investigate the possibilities of a chemical connection emerging between functionalized Multi-Wall Carbon Nanotubes and Nano-alpha Alumina in Roller-Compacted Concrete (RCC) structure. The interaction of the nanocomposite was studied using a variety of characterization techniques, including X-ray diffraction patterns, Fourier-transform infrared (FT-IR) spectroscopy, and scanning electron microscopy (SEM). Based on X-ray diffraction pattern results, MWCNT peaks show that the powder is amorphous, but it becomes crystalline when combined at high temperatures. Sharp peaks at angles of 29.23°, 32.80°, 34.80°, 36.93°, 42.67°, 45.65°, 48.56°, 56.05°, 59.31°, 60.74°, 65.01°, 67.07°, 70.01°, and 73.08° can be detected in the -Al2O3 sample diffraction pattern without impurities. The XRD profile of the carbon nanotube-doped alumina sample reflects the leading share of Al2O3, with angles and diffraction plates of Al2O3 being the same as α-Al2O3 orthorhombic crystalline phase owing to the low carbon concentration. Furthermore, C = C cyclic alkene elongation is observed in the MWCNT spectrum at 1630 and 901 cm-1, and the sharp peak of 2857 cm-1 is related to the C-H stretching of alkane-alkene. Furthermore, the Al-O vibration absorption band appears, ranging from 400 to 1000 cm-1. The absorption peak is observed at about 422.31 cm-1, indicating the presence of α-Al2O3 after confirmation from the database. Scanning Electron Microscope analysis revealed that α-Al2O3 powder samples without MWCNT and containing MWCNT have a shell state that the doped sample tends to be spherical. Also, the particle size of the powder decreased after preparing the doped sample of α-Al2O3 with MWCNT. Finally, further studies should be focused on analyzing the mechanical properties of RCC concretes with miscellaneous nano-particles such as nano-silica (nano-SiO2), nano-ferric oxide (nano-Fe2O3), nano-titanium oxide (nano-TiO2), carbon nanotubes (CNTs), graphene, and graphene oxide.

Conflict of Interests

The authors have declared no conflict of interests.

References

[1] T. Saleh, V. Gupta, Characterization of the Chemical Bonding between Al2O3 and Nanotube in MWCNT/ Al2O3 Nanocomposite, Current Nanoscience, 8 (2012) 739-743. https://doi.org/10.2174/157341312802884418

[2] F. Sanchez, K. Sobolev, Nanotechnology in concrete – A review, Construction and Building Materials, 24(11) (2010) 2060-2071. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2010.03.014

[3] A.H. Daqiqnia, S. Fard Moradinia, M. Baghalzadeh Shishehgarkhaneh, Toward Nearly Zero Energy Building Designs: A Comparative Study of Various Techniques, AUT Journal of Civil Engineering, 5(2) (2021) 12-12. https://doi.org/https://doi.org/10.22060/ajce.2021.20458.5771

[4] M.S.M. Norhasri, M.S. Hamidah, A.M. Fadzil, Applications of using nano material in concrete: A review, Construction and Building Materials, 133 (2017) 91-97. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2016.12.005

[5] R.P. Feynman, Plenty of Room at the Bottom, in: APS annual meeting, 1959.

[6] K. Sobolev, M. Ferrada Gutierrez, How Nanotechnology Can Change the Concrete World, in, 2014, pp. 113-116.

[7] W. Iskra-Kozak, J. Konkol, The Impact of Nano-Al2O3 on the Physical and Strength Properties as Well as on the Morphology of Cement Composite Crack Surfaces in the Early and Later Maturation Age, Materials, 14(16) (2021) 4441.

[8] Z. Li, H. Wang, S. He, Y. Lu, M. Wang, Investigations on the preparation and mechanical properties of the nano-alumina reinforced cement composite, Materials Letters, 60(3) (2006) 356-359. https://doi.org/https://doi.org/10.1016/j.matlet.2005.08.061

[9] T. Sok, Y.K. Kim, J.Y. Park, S.W. Lee, Evaluation of early-age strains and stresses in roller-compacted concrete pavement, Journal of Traffic and Transportation Engineering (English Edition), (2021). https://doi.org/https://doi.org/10.1016/j.jtte.2020.04.007

[10] R.L. FUHRMAN, Engineering and Design ROLLER-COMPACTED CONCRETE, Department of the army US Army Corps of Engineers., Washington DC, USA, U.S. Department of the Army, Corps of Engineers, 2000.

[11] P.C. Association, Frost durability of roller compacted concrete pavements, RD, 135 (2004) 150.

[12] S. Moradi, S. Shahnoori, Eco-friendly mix for Roller-Compacted Concrete: Effects of Persian-Gulf-Dredged marine sand on durability and resistance parameters of concrete, Construction and Building Materials, 281 (2021) 122555. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2021.122555

[13] A.H. Shekari, M.S. Razzaghi, Influence of Nano Particles on Durability and Mechanical Properties of High Performance Concrete, Procedia Engineering, 14 (2011) 3036-3041. https://doi.org/https://doi.org/10.1016/j.proeng.2011.07.382

[14] F. Liu, T. Zhang, T. Luo, M. Zhou, W. Ma, K. Zhang, The Effects of Nano-SiO(2) and Nano-TiO(2) Addition on the Durability and Deterioration of Concrete Subject to Freezing and Thawing Cycles, Materials (Basel, Switzerland), 12(21) (2019) 3608. https://doi.org/10.3390/ma12213608

[15] P. Hosseini, R. Hosseinpourpia, A. Pajum, M.M. Khodavirdi, H. Izadi, A. Vaezi, Effect of nano-particles and aminosilane interaction on the performances of cement-based composites: An experimental study, Construction and Building Materials, 66 (2014) 113-124. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2014.05.047

[16] Y.A.A.-S. M.S. Morsy, H. Abbas, S.H. Alsayed Behavior of blended cement mortars containing nano-metakaolin at elevated temperatures, Construction and Building Materials, 35(Complete) (2012) 900-905. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2012.04.099

[17] M.S. Morsy, S.H. Alsayed, M. Aqel, Hybrid effect of carbon nanotube and nano-clay on physico-mechanical properties of cement mortar, Construction and Building Materials, 25(1) (2011) 145-149. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2010.06.046

[18] B.S. Mohammed, M. Adamu, Mechanical performance of roller compacted concrete pavement containing crumb rubber and nano silica, Construction and Building Materials, 159 (2018) 234-251. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2017.10.098

[19] D. Tavakoli, R. Sakenian Dehkordi, H. Divandari, J. de Brito, Properties of roller-compacted concrete pavement containing waste aggregates and nano SiO2, Construction and Building Materials, 249 (2020) 118747. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2020.118747

[20] B.S. Mohammed, M. Adamu, M.S. Liew, Evaluating the effect of crumb rubber and nano silica on the properties of high volume fly ash roller compacted concrete pavement using non-destructive techniques, Case Studies in Construction Materials, 8 (2018) 380-391. https://doi.org/https://doi.org/10.1016/j.cscm.2018.03.004

[21] M. Adamu, B.S. Mohammed, N. Shafiq, M.S. Liew, Durability performance of high volume fly ash roller compacted concrete pavement containing crumb rubber and nano silica, International Journal of Pavement Engineering, 21(12) (2020) 1437-1444. https://doi.org/10.1080/10298436.2018.1547825

[22] F. Roelofs, W. Vogelsberger, Dissolution kinetics of nanodispersed γ-alumina in aqueous solution at different pH: Unusual kinetic size effect and formation of a new phase, Journal of Colloid and Interface Science, 303(2) (2006) 450-459. https://doi.org/https://doi.org/10.1016/j.jcis.2006.08.016

[23] F. Mirjalili, L.C. Abdullah, H. Mohamad, A. Fakhr• l-Razi, A.B.D. Radiah, R. Aghababazadeh, Process for Producing Nano-Alpha-Alumina Powder, International Scholarly Research Notices, 2011 (2011) 1-5.

[24] C. Schönenberger, L. Forro, PHYSICS OF MULTIWALLED CARBON NANOTUBES, in: Physics, Chemistry And Application Of Nanostructures, World Scientific, 2001, pp. 86-93.

[25] E.Y. Malikov, The effect of polyvinyl alcohol functionalized multiwall carbon nanotubes on the improvement of the compressive strength of concrete, Fullerenes, Nanotubes and Carbon Nanostructures, 28(10) (2020) 781-785.

[26] F. Zoladz, S. Rhodes, D. Patterson, W. Cribb, P. Chapagain, D. Seifu, V. Taufour, S. Kamali, S. Neupane, Enhanced magnetic properties of aluminum oxide nanopowder reinforced with carbon nanotubes, Journal of Nanoparticle Research, 22(6) (2020) 157. https://doi.org/10.1007/s11051-020-04896-6

[27] S. Barthwal, N. Singh, B. Singh, Electrical Conductivity and Mechanical Hardness of Al2O3-1wt% MWCNT Nanocomposite Synthesized by Ball Milling Method, Journal of scientific and industrial research, 78 (2019) 532-534.

[28] H. Liu, J. Wang, J. Wang, S. Cui, Sulfonitric Treatment of Multiwalled Carbon Nanotubes and Their Dispersibility in Water, Materials (Basel, Switzerland), 11(12) (2018) 2442. https://doi.org/10.3390/ma11122442

[29] C. Guo, X. Luo, W.A. Shah, J.K. Li, B. Huang, M.A. Umer, Y.Q. Yang, Mechanical and thermal properties of multiwalled carbon-nanotube-reinforced Al2O3 nanocomposites, Ceramics International, 46(11, Part A) (2020) 17449-17460. https://doi.org/https://doi.org/10.1016/j.ceramint.2020.04.039

[30] J. Chandradass, K.H. Kim, Synthesis of Nanocrystalline α-Al2O3 Powder Using Acetylacetone, Materials and Manufacturing Processes, 24(5) (2009) 541-545. https://doi.org/10.1080/10426910902746697

[31] R. Bharthasaradhi, L.C. Nehru, Structural and phase transition of α-Al2O3 powders obtained by co-precipitation method, Phase Transitions, 89(1) (2016) 77-83. https://doi.org/10.1080/01411594.2015.1072628

(1) Corresponding Author Email: zandi@iaut.ac.ir

Document information

Published on 12/02/22

Licence: CC BY-NC-SA license

Share this document

claim authorship

Are you one of the authors of this document?